Beruflich Dokumente

Kultur Dokumente

Techlibrary Adjusting Your Carburetor

Hochgeladen von

Adrian Chippendale0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

109 Ansichten1 SeiteThere are two methods for adjusting floats on Holley performance carburetors - an internal dry setting and an external wet setting. The document provides guidelines for adjusting brass, nitrophyl, and Duracon plastic floats including dry and wet setting measurements and procedures. Safety warnings are also provided to exercise caution when performing wet adjustments due to fuel pressure.

Originalbeschreibung:

HOLLEY CARBURETOR ADJUSTMENT

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThere are two methods for adjusting floats on Holley performance carburetors - an internal dry setting and an external wet setting. The document provides guidelines for adjusting brass, nitrophyl, and Duracon plastic floats including dry and wet setting measurements and procedures. Safety warnings are also provided to exercise caution when performing wet adjustments due to fuel pressure.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

109 Ansichten1 SeiteTechlibrary Adjusting Your Carburetor

Hochgeladen von

Adrian ChippendaleThere are two methods for adjusting floats on Holley performance carburetors - an internal dry setting and an external wet setting. The document provides guidelines for adjusting brass, nitrophyl, and Duracon plastic floats including dry and wet setting measurements and procedures. Safety warnings are also provided to exercise caution when performing wet adjustments due to fuel pressure.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

GENERAL GUIDELINES FOR

ADJUSTING BRASS AND

NITROPHYL FLOATS

GENERAL GUIDELINES FOR

ADJUSTING DURACON (PLASTIC)

FLOATS

Two methods of float adjustment are provided for with Holley

performance carburetors depending on the style of float bowl

and needle and seat assembly employed. They are the internal (dry) setting and the external (wet) setting. The internal

float adjustment is accomplished with the fuel bowl off the

carburetor. With internally adjustable needle and seats, the

fuel bowl is inverted and the float tang, or tab, is adjusted to

the point where the float surface is parallel to the fuel bowl

surface, just underneath. An initial dry setting can also be

accomplished with externally adjustable needle and seats.

To achieve this, invert the fuel bowl and turn the adjusting nut

until the float surface lies parallel to the fuel bowl casting

surface underneath.

The Duracon float rides higher on the fuel than either the

brass or nitrophyl float and, therefore, a higher setting is in

order. A Duracon float, set at the same level as either a brass

or nitrophyl float, would make the carburetor run leaner,

everything else being equal. This is because there would be

less fuel available in the fuel bowl. The Duracon float setting

must be higher to compensate for this condition.

Another, more accurate adjustment can be made with the

side hung style float if measuring gauges, such as drill bits,

are available. Here, with the fuel bowl inverted, the primary

float can be adjusted to the point where there is a 7/64" gap

between the toe of the float and the bottom of the fuel bowl

surface underneath. The float toe is the part of the float furthest from where the arm is attached. The secondary float

can be adjusted to the point where there is a 13/64" gap

between the heel of the float and the bottom of the fuel

bowl surface underneath. The float heel is the part of the

float closest to the point where the arm is attached.

Dry Setting for Duracon Side Hung Float:

The primary side setting is .2188" (7/32"), measured with

the fuel bowl inverted, at the toe of the float. The secondary

side setting is .3125" (5/16"), measured with the fuel bowl

inverted, at the toe of the float.

A wet level float adjustment can be performed on either the

side or center hung floats, if the fuel bowls have provision for

the externally adjustable needle and seats. This adjustment is

made as follows. Start the vehicle up and move it out of the

garage and into an open area where plenty of fresh ventilation is available. Allow the idle to stabilize. Turn the engine

off and remove the sight plug from the primary fuel bowl to

inspect the fuel level. If its been determined that adjustment is

required use a large screw driver to crack loose the lock

screw. With a 5/8" open-end wrench turn the adjusting nut

clockwise to lower the float level.

WARNING: Caution should be exercised when doing the wet

level float adjustment. Fuel at the needle and seat is under

pressure from the fuel pump. Some may leak out when the

adjustment is made and shop rags should be available to

immediately wipe up any fuel spillage. Gasoline is flammable

and proper precaution should be taken.

Dry Setting for Duracon Center Hung Float:

The primary side setting is .3125" (5/16"), measured with

the fuel bowl inverted, at the middle of the float. The secondary side setting is .3750" (3/8"), measured with the fuel

bowl inverted, at the middle of the float (back side).

Wet Setting for Duracon Float:

Refer to Wet Float Setting, discussed previously.

CAUTION: Once again, remember that these are general

guidelines for adjusting floats. Your particular application

may require additional fine tuning over and above these

listed procedures.

Conversely, turn the adjusting nut counter-clockwise to raise

the float level. Tighten the lock screw. Restart the vehicle and

let the engine idle stabilize. Shut the engine off. Remove the

sight plug to reinspect the fuel level. The fuel level should stabilize at just below the level of the fuel bowl sight plug hole.

This same adjustment procedure is performed on the secondary bowl.

NOTE: The float adjustment feature on Holley carburetors cannot cure

a poor running engine, a bad ignition system, a clogged fuel filter, an

improperly operating fuel pump or fuel pressure that is too high or

low. This adjustment is provided solely to ensure that the fuel in the

bowl can be adjusted to the correct level for the carburetor to perform

its function. There is no need to wrench excessively on the adjustment nut. A quarter of a turn one way or the other should be enough

to bring you into spec.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- VN VP Commodore Calais Workshop ManualDokument292 SeitenVN VP Commodore Calais Workshop ManualAdrian Chippendale100% (15)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- VK Commodore Workshop ManualDokument456 SeitenVK Commodore Workshop ManualAdrian Chippendale90% (10)

- Checking Fault Codes For VT and VX2Dokument3 SeitenChecking Fault Codes For VT and VX2Adrian ChippendaleNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Alfa Romeo 147 Workshop Manual Various GuidesDokument51 SeitenAlfa Romeo 147 Workshop Manual Various GuidesAdrian ChippendaleNoch keine Bewertungen

- Alfa Romeo 147 Workshop Manual Various GuidesDokument51 SeitenAlfa Romeo 147 Workshop Manual Various GuidesAdrian ChippendaleNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Mazda6 (GH) Wiring DiagramDokument693 SeitenMazda6 (GH) Wiring DiagramSergeusRod100% (2)

- Electronic Wiring Diagram Zafira MY 2001 PDFDokument315 SeitenElectronic Wiring Diagram Zafira MY 2001 PDFAdrian Chippendale100% (1)

- Special Tools: CatalogueDokument160 SeitenSpecial Tools: CatalogueKot8780% (1)

- Chemical Engg Basic IndiabixDokument123 SeitenChemical Engg Basic IndiabixRishikesh Awale100% (3)

- Your Rights Against PoliceDokument44 SeitenYour Rights Against PoliceAdrian ChippendaleNoch keine Bewertungen

- Ducati 1098S Parts Catalouge (Us Version)Dokument115 SeitenDucati 1098S Parts Catalouge (Us Version)Adrian ChippendaleNoch keine Bewertungen

- O2 Sensor WiringDokument1 SeiteO2 Sensor WiringAdrian ChippendaleNoch keine Bewertungen

- Doc20160124152535 PDFDokument3 SeitenDoc20160124152535 PDFAdrian ChippendaleNoch keine Bewertungen

- R34 GTT Tiptronic Self DiagnosticDokument1 SeiteR34 GTT Tiptronic Self DiagnosticAdrian ChippendaleNoch keine Bewertungen

- Interject Harry Tech Book EFISpares TipsDokument10 SeitenInterject Harry Tech Book EFISpares Tipsgolden68Noch keine Bewertungen

- 03 FloWatch HGVF Input and OutputDokument21 Seiten03 FloWatch HGVF Input and Outputedwin_triana_9Noch keine Bewertungen

- Standard Specification For Standard Specification For: Designation: A 1018/A 1018M - 01a Designation: A 1018/A 1018M - 01aDokument5 SeitenStandard Specification For Standard Specification For: Designation: A 1018/A 1018M - 01a Designation: A 1018/A 1018M - 01arahil shahNoch keine Bewertungen

- Cutting Edges & End Bits: Bolt-On & Weld-In Cutting Edges For Buckets & BladesDokument32 SeitenCutting Edges & End Bits: Bolt-On & Weld-In Cutting Edges For Buckets & Blades8897477809Noch keine Bewertungen

- Compressed Air MonitoringDokument4 SeitenCompressed Air MonitoringRonak JoshiNoch keine Bewertungen

- CHE 303 - Chemical Engineering Thermodynamics II / All Sections First Semester 2011 - 2012Dokument2 SeitenCHE 303 - Chemical Engineering Thermodynamics II / All Sections First Semester 2011 - 2012ArielNoch keine Bewertungen

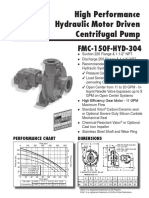

- FMC-150F-HYD-304 - 04-13 Bomba AceDokument2 SeitenFMC-150F-HYD-304 - 04-13 Bomba AceEmerson GomesNoch keine Bewertungen

- Estimation TCI Sanmar - EDC Vent Condenser Tag No E-102Dokument5 SeitenEstimation TCI Sanmar - EDC Vent Condenser Tag No E-102Raviraj Shashikant PatilNoch keine Bewertungen

- MINI Clubman Mobile Vehicle RepairDokument5 SeitenMINI Clubman Mobile Vehicle RepairJamal NoorNoch keine Bewertungen

- Augustin - A Contribution To The Design of Ribbed PlatesDokument10 SeitenAugustin - A Contribution To The Design of Ribbed Platesm2auNoch keine Bewertungen

- Flue Gas Analyzer O&M Manual ROENDokument2.353 SeitenFlue Gas Analyzer O&M Manual ROENAnonymous bSpP1m8j0nNoch keine Bewertungen

- WB140 2N PDFDokument12 SeitenWB140 2N PDFLuisAlbertoVerdejoTapiaNoch keine Bewertungen

- Extensive Applications of PM Gears: FocusDokument4 SeitenExtensive Applications of PM Gears: FocusAAAHNoch keine Bewertungen

- Common Rail System Diesel Engine Technology PDFDokument26 SeitenCommon Rail System Diesel Engine Technology PDFFedima100% (1)

- Thakur Institute of Aviation Technology: Module 17.4: Propeller SynchronisingDokument4 SeitenThakur Institute of Aviation Technology: Module 17.4: Propeller SynchronisingAshwini ChaurasiaNoch keine Bewertungen

- Trujillo PDFDokument12 SeitenTrujillo PDFVerdy A. KoehuanNoch keine Bewertungen

- D4B8046FF18-Suspension Wheels SteeringDokument469 SeitenD4B8046FF18-Suspension Wheels SteeringDaniel CharlesNoch keine Bewertungen

- Electrical Systems Console (S - N 512911001 - 512911999) - 331Dokument3 SeitenElectrical Systems Console (S - N 512911001 - 512911999) - 331Ronaldo Javier Vergara AnayaNoch keine Bewertungen

- Access - Catalog.805b.Color - DP&Casing Tools-51Dokument1 SeiteAccess - Catalog.805b.Color - DP&Casing Tools-51RICHARDNoch keine Bewertungen

- Manufacturing Processes Ch.4 (10 and 11) CastingDokument143 SeitenManufacturing Processes Ch.4 (10 and 11) Castingashoku24007Noch keine Bewertungen

- 下载Dokument4 Seiten下载Mars JackNoch keine Bewertungen

- Filtro Carbon ActivoDokument1 SeiteFiltro Carbon ActivoZzmangostazZNoch keine Bewertungen

- Hydraulic Quiz 8Dokument8 SeitenHydraulic Quiz 8Aireuxs AdjarainiNoch keine Bewertungen

- Line Sizing Spreadsheets-GeneralDokument8 SeitenLine Sizing Spreadsheets-GeneralFavoriteNoch keine Bewertungen

- TK-RC95 - Rev1 - 1211 SpecsDokument2 SeitenTK-RC95 - Rev1 - 1211 SpecsJames LoewenNoch keine Bewertungen

- CP2 2000 Installation, Operation and Maintenance of Electric Passenger and Goads LiftsDokument52 SeitenCP2 2000 Installation, Operation and Maintenance of Electric Passenger and Goads Liftskhant kyaw khaingNoch keine Bewertungen

- Unic Boom Trucks Spec 1b3c67Dokument3 SeitenUnic Boom Trucks Spec 1b3c67Zamaica Bandies DiazNoch keine Bewertungen

- Compressed Air System Gyanendra Sharma Npti DelhiDokument12 SeitenCompressed Air System Gyanendra Sharma Npti DelhiNPTINoch keine Bewertungen

- Steering Gear TestingDokument9 SeitenSteering Gear TestingArun GK100% (1)