Beruflich Dokumente

Kultur Dokumente

Pages From SCDF Fire Safety Guidelines For Open Plant Structures in Oil, Chemical and Process Industries

Hochgeladen von

potatoteddyOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Pages From SCDF Fire Safety Guidelines For Open Plant Structures in Oil, Chemical and Process Industries

Hochgeladen von

potatoteddyCopyright:

Verfügbare Formate

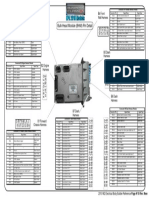

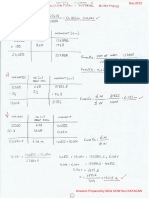

NOTES

Legend

11. For pumps operating above 316 degree C should be separately

considered - refer to Fire Code or relevant Documents.

12. High flash product tanks may be closer to facilities and equipment.

Crude oil stored in cone roof tanks require special consideration.

Refer to NFPA 30 for Tank Manual.

SS = Refer to Singapore Standard on tank separation & spacing.

MS = Minimum spacing of 61 metres or other consideration (see Note 5).

- = Meaning not relevant or not related directly.

ACC = Minimum access for personnel & maintenance are 0.8 metres & 1.2 metres respectively.

BC = Refer to Singapore Building Code & relevant documents.

11

Table 3.1: Separation and Spacing Table (distance in metre)

15

15

91

41

15

42

30

30

43

30

44

LPG = Refer to API Standards for LPG spacing to property line & NFPA 58.

FC = Fire Code & relevant documents.

Vapour recovery units

152

30

30

91

40

Other entrances

30

30

30

30

30

39

Motor highways

30

15

38

Entrance of the Main

Plant

8

91

30

15

37

Vehicle parking lots

15

30

91

30

30

15

36

Construction

site/area and material

Fire fighting training

area

Company residence

area

15

30

152

61

15

35

Fire house/brigade

LPG

34

Non-chemical/petroleum

warehouses

LPG spheres & drums

3

8

2

3

3

ACC

ACC ACC ACC ACC

3

3

ACC ACC 2

3

3

ACC ACC ACC 3

3

3

ACC ACC ACC ACC 3

15

15

15

15

15

15

15

27

28

29

30

31

32

33

Auxiliary - building,

shops, etc

Process reactors

Process drums

5

12

12

12

8

8

8

8

61

26

Process columns

(Towers)

MS

30 ACC

MS 15 ACC

MS 8

15

8

MS 15

15

15

MS 15

15

15

MS 8

15

15

MS 8

15

8

MS 8

15

8

MS 8

15

8

MS 8

15

15

MS 8

15

23

MS LPG 15

15

MS 15

30

91

61

46

91

61

30

MS 15

8

15

MS 8

15

91

91

91

91

91

61 ACC 46

MS 15

8

15

MS 15

3

15

MS 8

3

15

MS 15

15

8

22

23

24

25

Air-fan coolers

MS

8

8

15

15

15

8

8

15

15

15

15

21

Process heat

exchangers

15

MS

30

15

15

30

15

ACC

30

ACC

30

30

30

30

61

30

61

30

30

91

61

30

15

15

8

20

Process pumps

ACC

30

15

MS

30

15

15

30

30

8

30

15

30

30

30

30

30

30

30

30

30

91

61

30

30

15

19

Gas compressors

ACC

15

30

ACC

MS

30

ACC

23

30

30

30

30

30

30

30

30

61

30

30

30

15

91

15

8

15

15

15

18

14. For spacing of control building, refer to other Building Control

Code or relevant documents.

Furnaces

BC

15

30

30

ACC

91

61

ACC

46

61

30

30

61

61

61

61

61

61

BC

FC

BC

BC

152

BC

BC

BC

8

30

17

8. Tank trucks traffic to tank truck loading bays should not interfere

with process plant traffic.

16. For vehicle motor control centre, refer to electrical area classification

API document.

Process flares

BC

61

30

30

30

ACC

MS

30

ACC

15

30

30

30

30

30

30

30

30

30

30

30

61

15

BC

91

61

8

8

8

30

16

13. For the consideration of spacing from property lines that can be

built on:

- Residential commercial = as given.

- Industrial zoned properties = 1/2 distance given.

Flareline knock-out

drums

Motor vehicle control

centers

Plot limit manifolds

(piperack)

FC

3

30

30

ACC

MS

61

8

46

61

61

61

61

61

61

61

61

LPG

BC

FC

BC

BC

91

BC

BC

BC

BC

15

15

7. For wharves and piers, distance from hydrocarbon pumps,

manifolds, loading arms to process control rooms is greater.

15. For incineration-type vapour recovery units, the spacing requirement

should meet the furnace spacing requirement.

Wharves & piers

30

BC

8

3

30

BC BC

8

30

BC 8

23

15

3

8

30

8

8

15

8

8 ACC ACC

MS MS 30

8

15

8

15 ACC ACC

15

15

8

15

30

8

15

15

8

3

15

8

15

15

8

15

8

15

15

8

15

15

8

15

15

8

15

15

15

15

30

30

15

15

15

30

91 152

30

BC 8

15

15

30

15

15

30

15

15

3

12

13

14

Power & instrument

cables / Pole lines

ACC

15

15

8

61

15

30

ACC

30

30

8

MS

8

ACC

15

15

15

3

15

15

23

23

23

23

15

30

30

15

15

91

30

15

8

15

15

11

Process control room

ACC

8

15

15

8

61

30

61

ACC

30

30

MS

15

ACC

23

23

23

23

23

23

23

23

23

15

30

61

15

15

91

61

46

15

8

15

10

10. Tank pumps should be outside tankfield (tankfarm) dikes and

impounding basin. Pumps for tanks without dikes should be a

minimum of 15 metres horizontally from the tank.

4. For plot limit valves, they should be accessible from grade or from a

raised platform. Platform should be accessible by stairway and not

located over pipeway (piperack) drainage channel.

6. For main pipeways (piperack), triple spacing for pipe trenched.

Unrestricted plant

roads

Property lines of

others can be built on

Chemical

Warehouses

Office buildings for

process personnel

Primary fire water

pumps

Tank truck loading

bays

SS

15

8

15

8

8

8

61

30

15

15 ACC

61

30

15

8

61

30

15

8

3

15

8

15

30

15

15

8

15

8

5

3

15

3

61

15

15

61

30

30

8

15

61

30

61

15

15

61

61

23

8 ACC

30

15

30

8

30

61

15

30

8

30

8

8

23

2

MS 30

MS

MS

15

2

15

2

15

15 ACC 15

8 ACC

15

8 ACC 15

30

30

30

8

23

8

8

15

8

15

3

3

15

3

15

30

30

15

8

15

15

15

8

15

15

15

23

8

15

30

30

23

8

15

30

30

23

8

15

15

3

23

8

15

30

15

15

8

15

61

30

61

15

30

61

61

15

8

15

30

8

23

8

15

30

8

23

8

15

91

91

91

30

91

61

30

61

15

15

61

8

8

30

30

30

8

8

15

15

30

5

8

3

3

15

8

15

5

6

7

8

9

9. Spacing of office building for process personnel is based on the

potential explosions that can shatter glass, wood and other

construction materials susceptible to explosion and fire damage.

Single offices for field supervisors can be located in shops or control

buildings.

5. In fire water distribution, primary fire water pumps and their spares

should be 61 metres from process equipment when spaced together.

Individual pumps 61 metres apart may be within 30 metres of the

process units.

Oily water separator

Main electrical substation

Utility boilers & power

generators

Plant instrument air

compressor & dryer

Process cooling towers

SS

15

2

61

8

30

30

30

15

23

30

61

61

30

30

8

MS

8

15

15

46

8

3

30

15

15

30

30

LPG

23

61

61

30

30

91

61

30

15

15

4

Main piperack

SS

SS

15

2

61

8

30

30

30

15

23

SS

30

61

61

30

30

8

MS

8

15

15

46

8

3

30

15

15

30

30

LPG

23

61

61

30

30

91

61

30

15

15

3

3. For spacing of flares, the minimum distance from flares is

determined by calculations for tolerable radiant heat at the point

closest to the flame where frequent occupancy by personnel is

required. However, the minimum distance to equipment of handling

flammable fluids should not be less than 61 metres (except equipment

directly related to the system and normally located near base of the

stack).

2. Need to provide a 6 metres minimum vertical space between

overhead air coolers and the top of pumps handling flammable or

combustible liquids.

Tank field dikes

30

30

61

61

30

15

8

30

61

23

15

15

8

46

30

91

61

30

30

23

61

ACC

15

8

ACC

61

15

91

30

15

30

91

91

46

30

15

15

2

Product storage tanks

23

30

30

61

61

30

15

8

23

46

23

15

15

8

30

30

91

61

30

30

15

61

ACC

15

8

ACC

61

15

91

30

15

23

91

91

46

30

15

15

1

1. For the spacing between the near edge of a road to a high- or lowhazard plants ( the road bordering a main pipeway (piperack) and highor low-hazard plants) may be reduced to 1.5 metres. All roads closer

than 8 metres to high- or low- hazard plants are considered restricted

roads.

Floating roof/crude oil

storage tanks

Remote impounding

basin

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

Process unit equipment set

backline (Lo hazard <34 bar)

Process unit equipment set

backline (Hi hazard >34 bar)

Equipment set back lines are used to establish plant spacing. They should clearly defined on all plot plans. The plot limit lines, which delineate the near edge of adjacent roads are not used to establish plant spacing.

45

Das könnte Ihnen auch gefallen

- Method Statement For Solid Wastes DisposalDokument5 SeitenMethod Statement For Solid Wastes DisposalNkem Joseph-Palmer67% (3)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsVon Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsBewertung: 4 von 5 Sternen4/5 (1)

- 6.7L DieselDokument94 Seiten6.7L DieselBrendan Brodie100% (15)

- Carrier Commercial Systems 2008 List Prices: 30Rb Air Cooled ChillersDokument13 SeitenCarrier Commercial Systems 2008 List Prices: 30Rb Air Cooled ChillersvickersNoch keine Bewertungen

- User Manual Vaillant VCW 25 1 t3w eDokument10 SeitenUser Manual Vaillant VCW 25 1 t3w edusanNoch keine Bewertungen

- Energy-Saving Chillers With Screw Compressor Using Environmentally Friendly Refrigerant R134aDokument30 SeitenEnergy-Saving Chillers With Screw Compressor Using Environmentally Friendly Refrigerant R134atechnokakiNoch keine Bewertungen

- Reznor HandbookDokument72 SeitenReznor Handbookethen223100% (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsVon EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsBewertung: 3.5 von 5 Sternen3.5/5 (3)

- SCE ManagementDokument16 SeitenSCE Managementpotatoteddy100% (1)

- Notes: Table 3.1: Separation and Spacing Table (Distance in Metre)Dokument1 SeiteNotes: Table 3.1: Separation and Spacing Table (Distance in Metre)aahmed2001Noch keine Bewertungen

- LGB BControlDokument21 SeitenLGB BControlaalfaqiNoch keine Bewertungen

- VOL II - Technical-Co Boiler Dismantling PDFDokument538 SeitenVOL II - Technical-Co Boiler Dismantling PDFNassimNusNoch keine Bewertungen

- Buck 210 211 Users ManualDokument103 SeitenBuck 210 211 Users ManualjfmflNoch keine Bewertungen

- Deviation List-MechanicalDokument12 SeitenDeviation List-MechanicalRaji SuriNoch keine Bewertungen

- GodrejdDokument49 SeitenGodrejdsandeshlikesNoch keine Bewertungen

- Sime RX Range Installation ManualDokument12 SeitenSime RX Range Installation ManualToni ChirilaNoch keine Bewertungen

- 30HXC CNDokument12 Seiten30HXC CNtechnokakiNoch keine Bewertungen

- Piping Connection EquipmentDokument19 SeitenPiping Connection EquipmentOmar TocmoNoch keine Bewertungen

- E Valupak M Specs InstructionsDokument8 SeitenE Valupak M Specs Instructionsmgk80Noch keine Bewertungen

- Minimum DistanceDokument2 SeitenMinimum DistancehmdhojjatNoch keine Bewertungen

- Ap003 PDFDokument20 SeitenAp003 PDFjefferson_argotiNoch keine Bewertungen

- 7856-Me-Spc-198-025 Rev - ADokument17 Seiten7856-Me-Spc-198-025 Rev - Ashameer_febi100% (1)

- Gas Reticulation Project Group 8Dokument13 SeitenGas Reticulation Project Group 8Mohd Hafiz50% (2)

- Oil Burner Controls: Building TechnologiesDokument18 SeitenOil Burner Controls: Building TechnologiesThiago FernandesNoch keine Bewertungen

- Installers Manual ING 2010Dokument161 SeitenInstallers Manual ING 2010Aminu IbrahimNoch keine Bewertungen

- 30HXC-High COP China CatalogDokument12 Seiten30HXC-High COP China CatalogAnit SinghNoch keine Bewertungen

- Bosch Greenstar ZWBR 7-25 A23 Gcno.46-311-44 Boiler Installation and Service ManualDokument36 SeitenBosch Greenstar ZWBR 7-25 A23 Gcno.46-311-44 Boiler Installation and Service ManualMerlin1950Noch keine Bewertungen

- Important PointsDokument9 SeitenImportant PointssaadwingNoch keine Bewertungen

- Airbus 29 A300 A310 HydraulicsDokument186 SeitenAirbus 29 A300 A310 HydraulicsElijah Paul Merto100% (6)

- Manual PROGRAMDOR Caldero AceiteDokument18 SeitenManual PROGRAMDOR Caldero AceiteMiguel Morales ChNoch keine Bewertungen

- Flare System Calculation NoteDokument9 SeitenFlare System Calculation NoteincaurcoNoch keine Bewertungen

- Comp Air Design GuideDokument23 SeitenComp Air Design GuideSaurabh Singh100% (1)

- GT Trips List (Generic)Dokument13 SeitenGT Trips List (Generic)Ovais Siddiqui100% (6)

- Design Basis Dtd.3.12.2013Dokument10 SeitenDesign Basis Dtd.3.12.2013Adil MominNoch keine Bewertungen

- Specification For Lube Oil and Dry Gas Seal SystemDokument17 SeitenSpecification For Lube Oil and Dry Gas Seal Systemjahosolaris5512Noch keine Bewertungen

- Ash KKSDokument56 SeitenAsh KKSAnonymous ahdhFMaNoch keine Bewertungen

- ES For Pipe Support 011123Dokument12 SeitenES For Pipe Support 011123dimdaliak_985662241Noch keine Bewertungen

- Installers Manual ING 2010Dokument161 SeitenInstallers Manual ING 2010aco1970Noch keine Bewertungen

- Itc Speciality Division & Paper Mills LTD - 400 TDS/D Recovery Boiler DOC NO.: 0913-40-90-29-3668 REV.0 SHEET NO.: Page 3 of 2Dokument2 SeitenItc Speciality Division & Paper Mills LTD - 400 TDS/D Recovery Boiler DOC NO.: 0913-40-90-29-3668 REV.0 SHEET NO.: Page 3 of 2Mohan RajNoch keine Bewertungen

- 30RW/30RWA: Water-Cooled/Condenserless Liquid Chillers With Integrated Hydronic ModuleDokument20 Seiten30RW/30RWA: Water-Cooled/Condenserless Liquid Chillers With Integrated Hydronic ModuleKossu69Noch keine Bewertungen

- Altronic Epc-150 Operating Manual Air-Fuel Controller FORM EPC-150 OM 12-04Dokument35 SeitenAltronic Epc-150 Operating Manual Air-Fuel Controller FORM EPC-150 OM 12-04Esau Jose PabloNoch keine Bewertungen

- 1.00.00 GENERAL Information: (For Vendor Registration Purpose)Dokument7 Seiten1.00.00 GENERAL Information: (For Vendor Registration Purpose)Rajendran SrnNoch keine Bewertungen

- Condenserless Liquid ChillersDokument12 SeitenCondenserless Liquid ChillersBader ShrbajiNoch keine Bewertungen

- Ioties Document No:-Mccpl-Pctl-Acc-Doc-M-0001 - Rev. P3Dokument23 SeitenIoties Document No:-Mccpl-Pctl-Acc-Doc-M-0001 - Rev. P3pramodtryNoch keine Bewertungen

- 22 1739 04 - 02012010XXDokument16 Seiten22 1739 04 - 02012010XXMartinez MarNoch keine Bewertungen

- 110 MW Steam Turbine Manual PDFDokument133 Seiten110 MW Steam Turbine Manual PDFvamsikl100% (1)

- 1016Dokument46 Seiten1016Jorge DovaleNoch keine Bewertungen

- Procedure For Commissioning of Auxiliary Prds SystemDokument14 SeitenProcedure For Commissioning of Auxiliary Prds SystemJackSparrow86100% (1)

- Automate Arzatoare Siemens LMG Landis Gyr Carte Tehnica Limba EnglezaDokument17 SeitenAutomate Arzatoare Siemens LMG Landis Gyr Carte Tehnica Limba EnglezaexperthvachomeNoch keine Bewertungen

- PRESSURISEDDokument17 SeitenPRESSURISEDrahigi8656Noch keine Bewertungen

- N 7808 eDokument4 SeitenN 7808 eEhab SaadNoch keine Bewertungen

- STP PDFDokument7 SeitenSTP PDFJames FernNoch keine Bewertungen

- Product Data: 40QNC / 38HDF 40QNQ / 38QRF High - Wall Duct Free Split System Sizes 018 To 036Dokument34 SeitenProduct Data: 40QNC / 38HDF 40QNQ / 38QRF High - Wall Duct Free Split System Sizes 018 To 036din_thorpe3248Noch keine Bewertungen

- ReticulationDokument118 SeitenReticulationIzzul Hazim100% (1)

- Aux Steam Ee 00100 Axs 002Dokument15 SeitenAux Steam Ee 00100 Axs 002anbarasusivaprakasam100% (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGVon EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNoch keine Bewertungen

- Bu32s01b10 01eDokument9 SeitenBu32s01b10 01epotatoteddyNoch keine Bewertungen

- Tncs Governing Mortgage LoansDokument15 SeitenTncs Governing Mortgage LoanspotatoteddyNoch keine Bewertungen

- A Case of Choice of Passive Fire Protection (PFP) in An Oil & Gas EPC Project - Part1Dokument1 SeiteA Case of Choice of Passive Fire Protection (PFP) in An Oil & Gas EPC Project - Part1potatoteddyNoch keine Bewertungen

- Mortgage of Residential Commercial Property TNCDokument20 SeitenMortgage of Residential Commercial Property TNCpotatoteddyNoch keine Bewertungen

- A Case of Choice of Passive Fire Protection (PFP) in An Oil & Gas EPC Project - Part2Dokument1 SeiteA Case of Choice of Passive Fire Protection (PFP) in An Oil & Gas EPC Project - Part2potatoteddyNoch keine Bewertungen

- Axa Wealth Accelerate Brochure (English)Dokument9 SeitenAxa Wealth Accelerate Brochure (English)potatoteddyNoch keine Bewertungen

- Pages From XV Paper 36Dokument1 SeitePages From XV Paper 36potatoteddyNoch keine Bewertungen

- Symposium Series No. 54 © 2008 IchemeDokument1 SeiteSymposium Series No. 54 © 2008 IchemepotatoteddyNoch keine Bewertungen

- Symposium Series No. 54 © 2008 Icheme: Design Capacity 100% 150,000 Bbls/DayDokument1 SeiteSymposium Series No. 54 © 2008 Icheme: Design Capacity 100% 150,000 Bbls/DaypotatoteddyNoch keine Bewertungen

- Symposium Series No. 54 © 2008 Icheme: Total Recordable Injuries and Illnesses 6 ApiDokument1 SeiteSymposium Series No. 54 © 2008 Icheme: Total Recordable Injuries and Illnesses 6 ApipotatoteddyNoch keine Bewertungen

- Pages From Duplication of Pressure and Level TransmittersDokument1 SeitePages From Duplication of Pressure and Level TransmitterspotatoteddyNoch keine Bewertungen

- Symposium Series No. 54 © 2008 Icheme: Raw Data 5-Year Average Linear (5-Year Average)Dokument1 SeiteSymposium Series No. 54 © 2008 Icheme: Raw Data 5-Year Average Linear (5-Year Average)potatoteddyNoch keine Bewertungen

- Pipe Stress Analysis Using CAESAR IIDokument1 SeitePipe Stress Analysis Using CAESAR IIpotatoteddyNoch keine Bewertungen

- Pages From FlowDokument1 SeitePages From FlowpotatoteddyNoch keine Bewertungen

- Pipe Stress Analysis Using CAESAR IIDokument1 SeitePipe Stress Analysis Using CAESAR IIpotatoteddyNoch keine Bewertungen

- Chapter 4Dokument28 SeitenChapter 4noddyjohnNoch keine Bewertungen

- 10 Bulk Head Module (BHM) Pin Detail-01-01Dokument1 Seite10 Bulk Head Module (BHM) Pin Detail-01-01memo velascoNoch keine Bewertungen

- MTS-Hard Landscaping & Road WorksDokument7 SeitenMTS-Hard Landscaping & Road WorksAshimolowo BabatundeNoch keine Bewertungen

- Lecture-5 Street Lighting: Md. Manik Mia Lecturer Sonargaon UniversityDokument14 SeitenLecture-5 Street Lighting: Md. Manik Mia Lecturer Sonargaon UniversityManik MiaNoch keine Bewertungen

- Ilsucatiirwy10: Santa Cruz SCR Santa Cruz SCR 113.60Dokument1 SeiteIlsucatiirwy10: Santa Cruz SCR Santa Cruz SCR 113.60Gui VecchiioNoch keine Bewertungen

- Dokumen - Tips Ship Stability Tutorials Mca Oow Unlimited Written Exam Nuri KayacanDokument185 SeitenDokumen - Tips Ship Stability Tutorials Mca Oow Unlimited Written Exam Nuri KayacanMike MSBNoch keine Bewertungen

- E-Marking Notes On Biology SSC I May 2018 PDFDokument22 SeitenE-Marking Notes On Biology SSC I May 2018 PDFSobia ZeeshanNoch keine Bewertungen

- Teks Deskriptif Bhs InggrisDokument8 SeitenTeks Deskriptif Bhs Inggrisdidon pNoch keine Bewertungen

- 4th Smart Cities India 2018 Expo Post Show Report PDFDokument28 Seiten4th Smart Cities India 2018 Expo Post Show Report PDFbalajicaptainNoch keine Bewertungen

- Advantages and Disadvantages of Different Types of EngineDokument11 SeitenAdvantages and Disadvantages of Different Types of EngineJerome BalatbatNoch keine Bewertungen

- Boarding Pass Jakarta-SingaporeDokument7 SeitenBoarding Pass Jakarta-SingaporeNisa Dwi KumalasariNoch keine Bewertungen

- Supply Chain Management Practices in Printing Industry: University of Hyderabad, Hyderabad 500046, IndiaDokument7 SeitenSupply Chain Management Practices in Printing Industry: University of Hyderabad, Hyderabad 500046, IndiasaifrahmanNoch keine Bewertungen

- Road Safety Audit Report: Maitighar-Tinkune SectionDokument19 SeitenRoad Safety Audit Report: Maitighar-Tinkune SectionPadma Shahi0% (1)

- Gmail - RedBus Ticket - TQ5475122338Dokument3 SeitenGmail - RedBus Ticket - TQ5475122338mahesh atirasuNoch keine Bewertungen

- 2+1차로 도로 설계지침, 2015Dokument79 Seiten2+1차로 도로 설계지침, 2015김현준Noch keine Bewertungen

- GRF PPT05 - by ICAO, Abbas NiknejadDokument62 SeitenGRF PPT05 - by ICAO, Abbas NiknejadAliNoch keine Bewertungen

- Air Brakes SystemsDokument19 SeitenAir Brakes SystemsPrakhar AgarwalNoch keine Bewertungen

- Slewing Jib Cranes SI 18.3Dokument2 SeitenSlewing Jib Cranes SI 18.3reda mesbahNoch keine Bewertungen

- Redbus JavedDokument14 SeitenRedbus Javedakhtarjaved12Noch keine Bewertungen

- EMD 2015 - Zielenkiewicz - Maksimowicz - Lightning Protection Zones Created by TractionDokument5 SeitenEMD 2015 - Zielenkiewicz - Maksimowicz - Lightning Protection Zones Created by TractionDHARMENDRANoch keine Bewertungen

- Terex - Luffing TC.Dokument16 SeitenTerex - Luffing TC.guthaleNoch keine Bewertungen

- BGGGFDokument5 SeitenBGGGFjo_eboNoch keine Bewertungen

- UPSC Personality Test 2023Dokument20 SeitenUPSC Personality Test 2023abhijeet834uNoch keine Bewertungen

- NORTHERN ARIZONA UNIVERSITY - Technical Standards: Project XX - XXX.XXX - Project NameDokument69 SeitenNORTHERN ARIZONA UNIVERSITY - Technical Standards: Project XX - XXX.XXX - Project NameMEHDI FARROKHINoch keine Bewertungen

- Traffic Survey Manual and User GuideDokument37 SeitenTraffic Survey Manual and User Guidephanna0% (1)

- Hoval Compactgas (700-2800) : Technical Information Installation InstructionsDokument32 SeitenHoval Compactgas (700-2800) : Technical Information Installation InstructionsSegaran SickenNoch keine Bewertungen

- Resume - Sheetal Tantia Dec 2017Dokument4 SeitenResume - Sheetal Tantia Dec 2017Tantia AadityaNoch keine Bewertungen

- For More Visit WWW - Ktunotes.in: LI N E ARM O T O RSDokument23 SeitenFor More Visit WWW - Ktunotes.in: LI N E ARM O T O RSNANDHAKUMAR ANoch keine Bewertungen