Beruflich Dokumente

Kultur Dokumente

Peri Scope 2012

Hochgeladen von

William ChuiCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Peri Scope 2012

Hochgeladen von

William ChuiCopyright:

Verfügbare Formate

Cover Photo: (Left-to-right) Asia Square Tower 2,

Asia Square Tower 1 and Marina Bay Suites. All three

buildings are constructed using PERI formwork systems.

Dear Customers and Readers,

Welcome to the latest issue of our

PERI Scope. This issue is very special

as it features a number of Singapores

new landmarks such as Asia Square

Tower 2, dLeedon and Skysuites @

Anson. It also showcases impressions

of PERI Asias participation at the first

construction equipment exhibition in

Singapore, the BuildTechAsia 2011,

where we were delighted to welcome

more than 400 interested construction

professionals at our stand. The impressive display of exhibits which represent

the latest in formwork and scaffolding

technology has drawn the attention of

fair visitors to our stand.

Todays architectural designs pose a

challenge to both structural engineers

and construction execution.

Successful construction has never

been as difficult to achieve as it is now,

demands in regards to Quality, Safety

and Productivity have never been so

high.

To satisfy the above requirements from

vibrant cities, construction industries

demand contractors to rely on competent partners and suppliers. Modern

suppliers are expected to deliver in

many aspects:

- innovative products

- quality assurance

- product documentation

- the supply of the requested quantity

at the right time

- holistic project engineering solutions

and drawings

- project administration

- site support

- training

Successful presentation of products and services

at first BuildTechAsia 2011 exhibition

PERI Asia is constantly striving to excel

in every one of these duties to be your

competent partner in order to give you

the edge in this highly competitive

market. Our staff is our biggest assets

and undergoes frequent training to

ensure top performance.

The outlook for the coming years is

positive. BCA has projected construction demand for this year to be $21b to

$27b and the average annual demand

to be $19b to $27b for 2013 to 2014.

We are looking forward to working

with you on your next project and to a

successful result.

Sincerely,

Bernd Kieslich

Managing Director Asia

During BuildTechAsia 2011, PERI presented more than 10 different formwork and scaffolding systems among its product range.

Fast and safe construction of large slab areas

with PERI systems

Workshop for HG Metal Manufacturing, Singapore

Construction of a 4-storey workshop

for HG Metal Manufacturing Ltd. is currently being built at Jurong Port Road

and is expected to be completed by

May 2012.

The project uses the PD 8 Table System and ST 100 Stacking Towers for

casting of the slabs with a total formwork area of more than 1,900 m2.

For columns, the VARIO GT 24 Column

Formwork System has been designed

for standard columns and columns

with single and double-sided corbels

with more than 8 metres high.

PERIs CB 240 Climbing System and

VARIO GT 24 Wall Formwork System

were used for casting of the core walls

of the building.

Contractor

Erecon Construction

Co. Pte. Ltd.

Field Service

PERI ASIA Pte. Ltd.,

Singapore

Lim Beng Huat, Project Manager:

We have used PERI formwork systems for several of our projects and

find them to be fast and non labour

intensive. The technical support provided at the job site and off site is

also good.

PERI participated in the inaugural

BuildTechAsia 2011 exhibition that was

held from 27 to 29 April 2011 at the

Singapore Expo, Hall 3. The event was

held in conjunction with the Singapore

Construction and Productivity Week

and was jointly organised by Sphere

Exhibits Pte Ltd and the Building &

Construction Authority (BCA).

The three day event saw the involvement of 120 exhibiting companies and

other key industry associations. More

than 4,200 trade visitors and delegates

had also visited the show.

At the PERI stand, visitors were able to

see more than 10 types of PERI products. Some of the latest products that

were showcased include the PERIUP

Rosett Flex, MAXIMO Panel Wall

Formwork, UNO Monolithic Housing

Formwork, LIWA Panel Formwork and

VARIO QUATTRO Column.

PERI sales engineers were on hand to

explain and demonstrate the various

products on displayed. Goodie bags

were given to all visitors at the booth

and some even had the opportunity

to taste Bavarian beer and sausages

to experience the warmth of German

hospitality.

The booth was very well visited during the three exhibition days and considerable interest was shown

in PERI products.

The flexible PERI UP Rosett Flex Scaffolding offers

various application possibilities. Demonstrations

were conducted at the PERI booth.

VIPs visited the PERI booth (left-to-right):

Mr Tan Tee How, Permanent Secretary (National

Development), Mr Lee Chuan Seng, Deputy

Chairman, BCA Board of Directors,

Mr Tan Tian Chong, Director, Technology Development Division and Construction Productivity

Centre, BCA, Dr John Keung, CEO BCA and

Mr Bernd Kieslich, MD of PERI Asia Pte. Ltd.

The GRIDFLEX Aluminium Grid Slab Formwork

attracted the interests of many visitors.

Workers preparing to move a PD 8 Table System

with the lifting trolley.

A future prestigious iconic landmark designed

by Zaha Hadid is climbing with PERI systems

dLeedon Condominium, Singapore

The new development comprises 7 towers of

1,703 apartments and 12 villas on a large land site

of 838,488 square feet.

Fast and cost-effective formwork and scaffolding products

combined with best technical solutions

Contractor

Woh Hup (Private) Ltd.

Field Service

PERI ASIA Pte. Ltd.,

Singapore

Warehouse for Yang Kee Logistics, Singapore

A 10-storey warehouse and an ancillary

eight-storey office block are currently

being built at Jurong Pier Road. The

development is owned by Yang Kee

Logistics Pte. Ltd. and is the second

phase of its plan to build a chemicals

logistics hub.

Yang Kee Logistics provides a wide

range of logistics services, including

warehousing and inventory management, distribution and freight.

For slabs of the warehouse, the costeffective PD 8 Table System was used

to cover large slab areas.

For columns, VARIO GT 24 Column

Formwork System was used. PERIs

design engineer was able to incorporate the SKS Single Sided Climbing

System with the VARIO GT 24 Column

to cast 3-sided columns that were

located next to an existing building.

Contractor

HPC Builders Pte. Ltd.

Field Service

PERI ASIA Pte. Ltd.,

Singapore

Zhu Jianxin,

Site Manager:

I will recommend the use of PERI

formwork systems as they are fast and

cost-effective. They have also provided

good technical solutions and on site

support to us to resolve any problems

we may encounter.

For the large-scale columns, very good concrete

surface results have been achieved.

Alex Chua,

Site Agent:

PERI have provided us with good

products and custom-tailored solutions to meet the requirements of

this project. Their professional services have also helped us to resolve

problems encountered at the job site.

Consequently, we were able to achieve

the desired productivity with much

less resources.

PERI RCS Rail Climbing System and ACS Self

Climbing System minimise the use of cranes for

formworking operations.

The dLeedon is a residential development comprising of seven blocks of

36-storey apartments (1,703 units) and

12 units of double storey semi-detached

houses located at the Farrer Road area.

It is designed by world renowned architect, Zaha Hadid Architects.

For core walls of the residential blocks,

the VARIO GT 24 Girder Wall Formwork

System is used together with the RCS

Rail Climbing System and ACS Self

Climbing System to achieve maximum

efficiency. Through the use of hydraulics, the crane-independent RCS and

ACS systems allow the wall formwork

and platform to climb together in one

single operation. The RCS Rail Climbing Safety Screen is also being installed

With the PERI RCS Rail Climbing Safety Screen,

site personnel are secure against falling at all times

and protected against strong winds when working

at great heights.

to allow for safe working at the slab

edge at height. The screen can provide

protection up to two and a half floors

or more if required. In order to suit the

design of the buildings, a single rail RCS

Rail Climbing System has been specially

fabricated for the casting of slanting

columns and to provide safe working

access at the corners of the apartment

buildings.

With the VARIO GT 24 Column Formwork

System, square or rectangular cross-sections up to

80 x 120 cm can be concreted the formwork is

continually adjustable.

Fast and safe climbing solutions

help to realise fast building progress

Skysuites @ Anson, Singapore

At 71-storey high, Skysuites @ Anson is

set to be one of the tallest residential

building in Singapore. The development

will have 360 units and is situated in

Singapores CBD at 8 Enggor Street.

Skysuites @ Anson will share the same

building height of 250 m as Altez condominium, which was featured in the

2011 issue of PERI Scope, another project by the same contractor using similar PERI formwork systems which is

located just next to it. To achieve their

target of 6 to 7 day cycle per floor for

typical floors, the contractor adopted

The mobile self-climbing equipment can be retrofitted at any time.

The RCS Rail Climbing Safety Screen provides

perimeter safety.

PERI GRIDFLEX is the flexible slab formwork system complete with accessible girder grids and very

short shuttering times. The panel grid system allows

safe access for laying the free choice of formlining.

With the ACS Self Climbing System and the RCS

Rail Climbing System for both the internal and

external core walls, a 6 to 7 day cycle per floor can

be reached for the typical floors.

PERIs proposal by using the ACS Self

Climbing System and RCS Rail Climbing System for core walls. In addition,

the RCS Rail Climbing Safety Screen is

being used to provide perimeter safety.

A special transfer truss was designed

for it at the sky terraces and loft units

area to allow for anchor installation in

the absence of slabs.

For slabs, the GRIDFLEX Aluminium

Grid Slab Formwork is being used with

the PERI UP Rosett Flex for fast and

safe casting of concrete slabs.

The building is expected to be completed in Nov 2015.

Skysuites @ Anson will offer modern

high-rise living with 71 floors of exquisite apartments.

The cross-section shows the formwork solution

for core walls which climbs together with the

concrete placing boom.

Contractor

Woh Hup (Private) Limited

Field Service

PERI ASIA Pte. Ltd., Singapore

3,15

3,15

3,15

3,15

Skysuites @ Anson (left) apartment building rising

gradually next to the nearly completed Altez con

dominium which is also being constructed with

PERI formwork systems.

1,05

0,20

0,40

2,90

2,90

0,30

2,08

0,30

2,37

0,30

0,40

Cao Baochun, Site Manager:

PERI have provided us with very safe and highly efficient

formwork systems. In particular, they have given us a good

solution for the high void area with the ACS. With the

professional support from PERI, I believe we are able to

achieve our target.

Ahead of the schedule thanks to PERI products

and competent technical support

Asia Square Tower 2, Singapore

Contractor

Hyundai Engineering &

Construction Co., Ltd.

Field Service

PERI ASIA Pte. Ltd.,

Singapore

Tower 2 will feature 46 floors with the hotel occupying the 32nd to 46th floors.

With the PERI RCS Rail Climbing Safety Screen,

the slab edges on the upper floors are completely

enclosed.

ST 100 is a very efficient shoring system which can be

assembled quickly. All ST 100 system components

are simply slotted together without any bolts or pins.

Asia Square Tower 2 is the second

building to be built as part of the twintower Asia Square Towers development. It is located at the Marina Bay

area and will accommodate retail shops,

offices and a Westin hotel (Starwood

Hotel group) when completed. Similar

to Asia Square Tower 1, the project

uses a variety of PERI formwork

systems to ensure speed and safety

in the construction process.

For slabs, the ST 100 Stacking Tower is

being used for the transfer floors up to

a height of 21.6 m (from 1st to 6th floor)

and 8.3 m (from 32nd to 34th floors).

In addition, more than 5,000 m of formwork area of PERI MULTIPROP system,

Different PERI systems and solutions are used for

forming the slabs. Slab tables with steel walers supported by the MULTIPROP System

as well as shoring solutions based on the

PERI UP Rosett Flex scaffolding system.

Kim Ju-Han, Senior Construction Manager:

Even for such a big scale project, the use of the ACS and

RCS climbing systems has made a 4-day per floor cycle

possible. When combined with the other PERI formwork

systems and their impeccable technical support, we were

able to be ahead of our schedule by three to four months.

PD 8 Table System and PERI UP tables

are being used to cast the typical floor

slabs.

4,49

For construction of the hotel (from 32nd

to 46th floor), the GRIDFLEX Aluminium

Grid Slab Formwork will be used for the

slabs and TRIO Panel Wall Formwork

will be used for the shear walls.

4,49

4,49

To meet the target of 5 days per floor

cycle for the core walls, the crane-inde

pendent RCS Rail Climbing System

and the ACS Self Climbing System

were used for the internal and external

platforms respectively. For perimeter

safety, the RCS Rail Climbing Safety

Screen has been adopted to prevent

workers from falling off the edge of

the building. For greater efficiency, the

concrete placing boom has been incorporated into the core wall systems. As

a result, there is no need for additional

openings in the slab.

The building has been slated to open

on 1 July 2014.

0,25

Asia Square Tower, located along Marina View at

Marina Bay in Singapore, is a twin-tower mixed-use

development. Tower 1 was completed in late 2011,

Tower 2 is currently under construction.

2,80

0,25

The concrete placing boom has been incorporated

into the climbing solution for the core wall systems

and ensures maximum efficiency in the formworking process.

Safe and time-saving concreting

of slabs in great heights

8 Storey Factory, Singapore

A new 8-storey factory is currently being built in the western industrial area

of Singapore at Sunview Way.

Each floor of the factory is being divided

into three sections, with each section

covering an area of about 3,500 m2

(50 m x 70 m). For fast and cost-effective casting of slabs, the PD 8 Table

System was chosen for this application. The typical tables have a height

of 11 metres and were designed to provide optimal coverage with the largest

table measuring 3.6 m (W) x 5.5 m (L).

For columns, the VARIO GT 24 Column

Formwork System was used. The

column formwork come in two sizes,

1,100 mm x 1,100 mm x 10.5 m (H)

and 1,100 mm x 900 mm x 10.5 m (H).

PERIs CB 240 Climbing System was

used for casting the core walls of the

building with a height of 5.4 m.

(Left) A PD 8 Table System being crane-lifted onto

the next level. (Below) A few workers moving a

PD 8 Table System with the help of lifting trolleys.

Flexibility and easy handling of formwork

and shoring systems saves time and manpower

Contractor

MA Builders Pte. Ltd.

Field Service

PERI ASIA Pte. Ltd.,

Singapore

Woodlands 11 Factory, Singapore

Woodlands 11 is a 10-storey ramp-up

multi-user light industrial factory located

at Woodlands Close.

For fast and cost-effective construction

of large slab areas, the PD 8 Table System and the MULTIPROP System are

chosen for this task. The largest PD8

tables measure 6.0 m x 2.9 m and

4.47 m x 3.9 m with typical height at

3.8m. The total formwork area for the

PD 8 table is 6,400 m2.

10

could even go faster if the job site is not

located near to residential buildings.

For core walls, the CB 240 Climbing

System and VARIO GT 24 Wall Formwork System are used. As for columns,

the VARIO GT 24 Column Formwork

System is being used for casting various

column sizes of the buildings.

Contractor

Yee Hong Pte. Ltd.

Field Service

PERI ASIA Pte. Ltd.,

Singapore

The contractor was able to construct

an area of 1,700 m2 in a 15 to 17 days

cycle. They have advised that they

The expected date of completion of the

factory is 7 December 2012.

Wee Moong Eng, Project Director:

We have not encountered any shortcoming in PERIs formwork systems

for this project. The formwork systems

provided by PERI have been flexible and easy to handle. As a result,

we have been able to save time and

manpower.

View of the PD 8 Slab Tables during positioning

and after concreting the slabs.

MULTIPROP post shores are made of aluminium

which means they are of very light weight.

The safe and easy to assemble PERI UP

Stair Tower 75 offers full headroom and

provided quick access to workers at the

job site.

Tan Eng Hwee, Project Manager:

The use of the PD 8 Table System for

this project is at least 50 % faster as

compared to conventional formwork.

Furthermore, for tables of such height

(11 m) it will not be as safe to use

conventional and more materials will

be needed. PERI have provided us with

the right formwork systems fast and

reliable.

11

The crane-independent ACS Self Climbing System

and RCS Rail Climbing System are being used for

casting of the core walls.

Uniquely designed condominium development

formed with safe and reliable system equipment

Le Nouvel Ardmore, Singapore

Contractor

Thian Sung Construction Pte. Ltd.

Field Service

PERI ASIA Pte. Ltd.,

Singapore

Khoo Wang Yang, Site Manager:

The unique design of the Le Nouvel

Ardmore has posed many challenges

in the construction process. But PERI

have been able to support us with

solutions and formwork systems that

are fast, safe and efficient.

Le Nouvel Ardmore is a luxurious condominium development designed by

globally renowned architect and winner

of the Pritzker Architecture Prize, Jean

Nouvel. This 33-storey condominium

has only 43 exclusive residences and

is situated on 1A Ardmore Park.

Due to the unique and interesting

design of the building, PERIs design

engineers need to cater to the floor-byfloor changing layout through the use

of several formwork systems.

For core walls, the crane-independent

ACS Self Climbing Sytem and RCS Rail

Climbing System are being used. The

ACS has also been designed for use

with the spider placing boom. For flat

slabs, the GRIDFLEX Aluminium Grid

Slab Formwork provided much speed

and flexibility when concreting slabs

of the building. On the other hand,

the PERI UP Rosett Flex is being used

for the perimeter beam.

The building has a total of eight void

areas between the 7th and 32nd floor.

For these areas, the ST 100 Stacking

Tower is being used to complete the

job with height of the towers ranging

from 8 m to 25 m.

The building is expected to be completed by December 2014.

GRIDFLEX Aluminium Grid Slab Formwork is the

flexible slab formwork system complete with accessible girder grids. It fits best to PEP slab props

as well as to MULTIPROP props with higher loadbearing capacities for greater heights.

Safe

The girder grid design of the GRIDFLEX automatically forms an accessible working area which provides

a high level of safety when laying the plywood

sheets.

Flexible

The telescopic function provides a flexible twodimensional adaptability in both transverse and

longitudinal directions with the elements.

GRIDFLEX Aluminium Grid Slab Formwork

Fast Safe Flexible

The GRIDFLEX is an innovative

and award winning product that

can maximize cost-effectiveness

and increase the levels of working

safety concurrently. Applications

on job sites have shown that for

the same slab area, it is capable of

achieving a productivity of 26 m to

53 m/day with half the manpower

as compared to 5 m to 6 m/day

using conventional formwork.

07044

GRIDFLEX A type tested and award

winning product

Rated Band 2 by BCA Singapore under the

Constructability Points for System Formwork.

12

Only 2 system components

are required for placing the girder grid in a standard

field: the Prophead GFH (with prop) and the GRIDFLEX GFP Panel (Standard Element GFP 200 x 100).

Fast

The standard field is formed using only three system parts: elements, plywood and prop. The easy

to handle parts and an element weight of 10kg/m

simplify the forming process.

13

PERI sponsors BCAs Skilled Builders Competition

It was a privilege for PERI to be one of

the sponsors for the Skilled Builders

Competition System Formwork Installation category, jointly organized by the

Building & Construction Authority (BCA)

and the Singapore Contractors Association Limited (SCAL).

The Skilled Builders Competition for

System Formwork Installation was held

from 25 to 26 April 2011 at the BCA

Academy. It was part of the Singapore

Construction Productivity Week which

aimed to raise awareness of productivity improvement at the workers level

through the adoption of technology

and best practices.

Over the two days, a total of 10 teams

consisting of four men in each team

participated in the System Formwork

Installation category. They were tested

on their ability to comprehend drawings,

Short shuttering times due to lightweight components

and pre-determined assembly sequence

Multi Storey Car Park at Simei, Singapore

Contractor

Logistics Construction

Pte. Ltd.

Field Service

PERI ASIA Pte. Ltd.,

Singapore

Kenneth Paw, Project Manager:

The GRIDFLEX is an efficient and

flexible system that can reduce construction time significantly. It is light

weight and easy to handle and has

almost zero wastage.

A multi storey car park at Simei was

upgraded with the addition of two more

decks by using the PERI GRIDFLEX

Aluminium Grid Slab Formwork.

The contractor wanted a fast slab formwork system that could expedite their

construction sequence with minimal inconveniences. The GRIDFLEX was their

ideal choice as it is light weight and has

only three system components.

The standard element of the GRIDFLEX

is used jointly with the PERI UP Rosett

Flex at the perimeter area and with the

PEP Prop at the main deck area. The

required slab thickness was 300 mm

and the total formwork area used was

1,800 m2.

Besides the GRIDFLEX, PERI

MULTIPROP was used for back propping and GT 24 and VT 20K girders

were used with the PERI UP Rosett

Flex for casting of the ramp of the

new car park decks.

plan their time and to use the provided

tools to install the system formwork

allocated to them within a specific

timeframe.

The system formwork sponsored by

PERI at the competition included:

The GRIDFLEX elements are hooked in from below

and swivelled upwards means the erection of the

formwork is very safe. After this, the PEP prop can

be positioned.

14

With the GRIDFLEX, simple labour-saving filler areas

can be realized for any building shape. The telescopic function provides a flexible two-dimensional

adaptability.

Yellow powder-coated MULTIPROP props offer a

high load-bearing capacity. According to type calculations, the permissible load-bearing capacity is up

to 90 kN (DIN EN 12812).

GRIDFLEX Aluminium Grid

Slab Formwork

PERI UP Rosett Flex

PEP Ergo Prop

TRIO Panel Wall Formwork

GT 24 formwork girders

This year, PERI will once again sponsor

the competition which will be held at

the Marina Bay Sands from 15 to 16

May 2012. The organisers are targeting

to increase the total number of participating teams from 10 to 12 and the

competition area and standard will also

be increased.

All participants will be awarded with a

Certificate of Participation. The top two

teams will also be awarded with cash

prizes and a trophy.

15

PERI Product Range

Wall Formwork

Panel Formwork

Girder Formwork

Circular Formwork

Facade Formwork

Brace Frame

Climbing Systems

Climbing Scaffold

Self-Climbing System

Climbing Protection Panel

Platform Systems

Column Formwork

Square

Rectangular

Circular

Scaffold, Stairways,

Working Platforms

Facade Scaffold

Working Platform

Weather Protection Roof

Stairway Access

Slab Formwork

Panel Formwork

Beam Grid Formwork

Girder Formwork

Slab Table

Beam Formwork

Bridge and Tunnel

Formwork

Cantilevered Parapet Carriage

Cantilevered Parapet Platform

Engineers Construction Kit

Shoring Systems

Steel Slab Props

Aluminium Slab Props

Tower Systems

Heavy-Duty Props

Accessories

Plywood

Formwork Girders

Stopend Systems

Pallets

Transportation Containers

Engineering and Software

Efficient formwork planning

and design through use of

PERI CAD software.

Site Supervision

Provided to ensure efficient

use of systems.

Rental Service

Large rental fleet with cleaning

and repair services.

Training

Seminars and customised courses

to support our customers.

The illustration featured in

this brochure are photographs

taken at a particular time on

a construction site. This is why

the safety details shown cannot

be considered as final.

Copyright by PERI GmbH

PERI ASIA Pte. Ltd.

No. 1 Sims Lane #06-10

Singapore 387355

Phone +65 6744 2989

Fax +65 6744 3693

pha@periasia.com

www.periasia.com

Rep Ofce of PERI ASIA Pte. Ltd.

in HCMC

Room 1333, Floor 13,

No. 39 Le Duan

Ho Chi Minh City, Vietnam

Phone: +84 8 6288 8974

Fax: +84 8 6288 8701

SG en 05 | 2012 5xp XXXXXX PERI GmbH

PERI Services

Das könnte Ihnen auch gefallen

- Scope: Successful Construction With PERIDokument20 SeitenScope: Successful Construction With PERIfarshan296015Noch keine Bewertungen

- PERIDokument9 SeitenPERIkrmcharigdc100% (1)

- Peri Scope Uk 2007Dokument16 SeitenPeri Scope Uk 2007farshan296015Noch keine Bewertungen

- Peri Form WorksDokument20 SeitenPeri Form WorksSiva Prasad MamillapalliNoch keine Bewertungen

- Construction and Maintenance of AirportsDokument28 SeitenConstruction and Maintenance of AirportsCoccinella Septempunctata100% (1)

- SKYRISE - 12 - 01 - DPS-ilovepdf-compressed Ascenseurs Pour Bâtiments de Grande HauteurDokument13 SeitenSKYRISE - 12 - 01 - DPS-ilovepdf-compressed Ascenseurs Pour Bâtiments de Grande HauteurHaddad RedhamalekNoch keine Bewertungen

- A K Group's 40-Year Journey in Steel FabricationDokument28 SeitenA K Group's 40-Year Journey in Steel FabricationAziz ShaikhNoch keine Bewertungen

- PERI UP Rosett For The Use On The Constr Jobsite Brochure HQ enDokument28 SeitenPERI UP Rosett For The Use On The Constr Jobsite Brochure HQ endragan321Noch keine Bewertungen

- VSL, Partner of Choice Laayoune Wharf New Protection For AnchoragesDokument32 SeitenVSL, Partner of Choice Laayoune Wharf New Protection For AnchoragesDrPadipat ChaemmangkangNoch keine Bewertungen

- Aircraft Hangars and Doors: REIDsteel's Guide to Hangar Design and ConstructionDokument20 SeitenAircraft Hangars and Doors: REIDsteel's Guide to Hangar Design and ConstructionAnonymous ww55t9CNoch keine Bewertungen

- Combisafe Handbook UK-File024092Dokument164 SeitenCombisafe Handbook UK-File024092Leuri MoraesNoch keine Bewertungen

- Megawide Precast PlantDokument21 SeitenMegawide Precast PlantPaolo ManansalaNoch keine Bewertungen

- Heavy Lifting and Offshore Transportation SolutionsDokument32 SeitenHeavy Lifting and Offshore Transportation SolutionsKhoironSyamdatuNoch keine Bewertungen

- Company Activities Mobile HomesDokument6 SeitenCompany Activities Mobile HomesEssam Al BakryNoch keine Bewertungen

- Scope: Bauma CONEXPO Held in Mumbai - 2013Dokument8 SeitenScope: Bauma CONEXPO Held in Mumbai - 2013Luna DachaNoch keine Bewertungen

- Layher Blitz Catalogue 2013enDokument36 SeitenLayher Blitz Catalogue 2013enArdamitNoch keine Bewertungen

- Peri Scope 2010Dokument18 SeitenPeri Scope 2010Nurali MamenNoch keine Bewertungen

- Multistory BuildingsDokument18 SeitenMultistory BuildingsShivamTomarNoch keine Bewertungen

- NFT BrochureDokument20 SeitenNFT BrochureSherif ZahranNoch keine Bewertungen

- Adjustable Pallet RackingDokument16 SeitenAdjustable Pallet RackingMnttoMecNoch keine Bewertungen

- Modular Silos and The Benefits of A Flat Pack' DesignDokument2 SeitenModular Silos and The Benefits of A Flat Pack' DesignMilling and Grain magazineNoch keine Bewertungen

- 8803 CS Systems Brochure - EN 1 PDFDokument20 Seiten8803 CS Systems Brochure - EN 1 PDFAnonymous jW9BkgbQmENoch keine Bewertungen

- Haitian Honeymoon For Hollowcore: Spiroll Precast Lecture Spans ContinentsDokument4 SeitenHaitian Honeymoon For Hollowcore: Spiroll Precast Lecture Spans ContinentsShreekanth NarayananNoch keine Bewertungen

- CeDokument5 SeitenCemarinette vasoNoch keine Bewertungen

- Tension Lift Frame AssemblyDokument2 SeitenTension Lift Frame AssemblyArgonauta_navegadorNoch keine Bewertungen

- Architectural Membranes: Case StudiesDokument48 SeitenArchitectural Membranes: Case Studiescvengr229Noch keine Bewertungen

- World Leader Steel Fabrication Delivers Complex Global ProjectsDokument19 SeitenWorld Leader Steel Fabrication Delivers Complex Global ProjectsKhaled AmmarNoch keine Bewertungen

- Saudi Cranes CatalogueDokument21 SeitenSaudi Cranes CatalogueNarayan PrasadNoch keine Bewertungen

- Pre-Engineered Steel BuildingsDokument40 SeitenPre-Engineered Steel BuildingsThilan SenarathneNoch keine Bewertungen

- AG&PDokument15 SeitenAG&PRachel Ann CabesuelaNoch keine Bewertungen

- Faq About PebDokument6 SeitenFaq About Pebsaravanan_c1Noch keine Bewertungen

- Construction of PEB Hangar ProjectDokument19 SeitenConstruction of PEB Hangar ProjectZuber AhmedNoch keine Bewertungen

- Catalog General PROFILITECDokument230 SeitenCatalog General PROFILITECEko Piff0% (1)

- Brochure Solutions For StadiumsDokument20 SeitenBrochure Solutions For StadiumsBambangShrNoch keine Bewertungen

- PPPi - Company Profile 2022Dokument82 SeitenPPPi - Company Profile 2022Jeff T.Noch keine Bewertungen

- Kingdom Tower DetailsDokument10 SeitenKingdom Tower DetailsZameer AhmedNoch keine Bewertungen

- Bridge TR BrochureDokument8 SeitenBridge TR BrochureSandra DevannyNoch keine Bewertungen

- 2014NOVIEMBREDokument132 Seiten2014NOVIEMBREEdwin GonzalezNoch keine Bewertungen

- Is Yapi As: Company PresentationDokument60 SeitenIs Yapi As: Company PresentationAnkita AgarwalNoch keine Bewertungen

- Internship ReportDokument18 SeitenInternship ReportAbigail Cosme100% (2)

- Hikvision Security Product GuideDokument111 SeitenHikvision Security Product GuideJonas PaulNoch keine Bewertungen

- WEB FORCE. Grating Etc PDFDokument39 SeitenWEB FORCE. Grating Etc PDFWidiyanto WidiyantiNoch keine Bewertungen

- Mivan ShutteringDokument80 SeitenMivan ShutteringAnish PatilNoch keine Bewertungen

- Company Profile SampleDokument62 SeitenCompany Profile SampleUnited Construction Est. TechnicalNoch keine Bewertungen

- Innovations+ +spring+2008Dokument35 SeitenInnovations+ +spring+2008Carla GaticaNoch keine Bewertungen

- EN - Accesos Temporales - 2015Dokument12 SeitenEN - Accesos Temporales - 2015Emmanuel CardosoNoch keine Bewertungen

- Gulf Precast BrochureDokument13 SeitenGulf Precast BrochureMohammad Abu-RadiNoch keine Bewertungen

- Long Paper Nicmar - Peb HangarDokument88 SeitenLong Paper Nicmar - Peb HangarZuber Ahmed100% (2)

- Sumit Final Project of Work Life BalanceDokument102 SeitenSumit Final Project of Work Life BalancetejasNoch keine Bewertungen

- Company Profile: India Tech Concrete Solutions Pvt LtdDokument1 SeiteCompany Profile: India Tech Concrete Solutions Pvt LtdMechatronics EngineeringNoch keine Bewertungen

- Pre-Engineered Steel BuildingsDokument40 SeitenPre-Engineered Steel BuildingsHelen Kate SaccuanNoch keine Bewertungen

- Hilti Saudi Arabia Hiltinnovation Winter 2014Dokument16 SeitenHilti Saudi Arabia Hiltinnovation Winter 2014chadnileNoch keine Bewertungen

- DC Sept08 RackandPinionWEBDokument5 SeitenDC Sept08 RackandPinionWEBJosé TimanáNoch keine Bewertungen

- Glasgow's Riverside Museum of Transport and TravelDokument20 SeitenGlasgow's Riverside Museum of Transport and TravelAlvera SerapainNoch keine Bewertungen

- Case Study - Taipei 101 & TMDsDokument78 SeitenCase Study - Taipei 101 & TMDsBhushan RaisinghaniNoch keine Bewertungen

- Offshore SteelDokument42 SeitenOffshore SteelPuvas NandakwangNoch keine Bewertungen

- Modernisation, Mechanisation and Industrialisation of Concrete StructuresVon EverandModernisation, Mechanisation and Industrialisation of Concrete StructuresNoch keine Bewertungen

- Sustainability Management: New Approach in Project Management for Construction ProjectsVon EverandSustainability Management: New Approach in Project Management for Construction ProjectsNoch keine Bewertungen

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionVon EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNoch keine Bewertungen

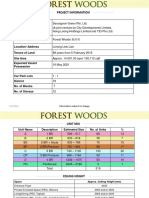

- Forest Woods FlyerDokument2 SeitenForest Woods FlyerWilliam ChuiNoch keine Bewertungen

- Forest WoodsDokument2 SeitenForest WoodsWilliam ChuiNoch keine Bewertungen

- CashFlow AnalysisDokument1 SeiteCashFlow AnalysisWilliam ChuiNoch keine Bewertungen

- Forest Woods Sales KitDokument23 SeitenForest Woods Sales KitWilliam ChuiNoch keine Bewertungen

- Documents To Submit (Executive Condominium)Dokument4 SeitenDocuments To Submit (Executive Condominium)William ChuiNoch keine Bewertungen

- Progressive Payment ScheduleDokument1 SeiteProgressive Payment ScheduleWilliam ChuiNoch keine Bewertungen

- Forest Woods Schematic DiagramDokument1 SeiteForest Woods Schematic DiagramWilliam ChuiNoch keine Bewertungen

- Forest Woods SummaryDokument11 SeitenForest Woods SummaryWilliam ChuiNoch keine Bewertungen

- Forest Woods Site PlanDokument1 SeiteForest Woods Site PlanWilliam ChuiNoch keine Bewertungen

- Forest Woods Draft Floor PlansDokument31 SeitenForest Woods Draft Floor Plansgladtan0511Noch keine Bewertungen

- Additional Buyer's Stamp Duties (ABSD)Dokument12 SeitenAdditional Buyer's Stamp Duties (ABSD)William ChuiNoch keine Bewertungen

- 25 Years Anniversary Brochure 2016Dokument28 Seiten25 Years Anniversary Brochure 2016William ChuiNoch keine Bewertungen

- Normal Progressive Payment SchemeDokument1 SeiteNormal Progressive Payment SchemeWilliam Chui0% (1)

- Cooling Measures For Executive Condominium DevelopmentsDokument8 SeitenCooling Measures For Executive Condominium DevelopmentsWilliam ChuiNoch keine Bewertungen

- Cooling Measures For Executive Condominium Developments Part 2Dokument8 SeitenCooling Measures For Executive Condominium Developments Part 2William ChuiNoch keine Bewertungen

- 2015 TOP Projects - Singapore ResidentialDokument1 Seite2015 TOP Projects - Singapore ResidentialWilliam ChuiNoch keine Bewertungen

- Loans (Residential)Dokument7 SeitenLoans (Residential)William ChuiNoch keine Bewertungen

- Cooling Measure For The Industrial Property MarketDokument12 SeitenCooling Measure For The Industrial Property MarketWilliam ChuiNoch keine Bewertungen

- Payment Schedule: Building Under Construction (BUC)Dokument1 SeitePayment Schedule: Building Under Construction (BUC)William ChuiNoch keine Bewertungen

- Procedures in New EC PurchaseDokument9 SeitenProcedures in New EC PurchaseWilliam ChuiNoch keine Bewertungen

- Loans (Residential)Dokument7 SeitenLoans (Residential)William ChuiNoch keine Bewertungen

- Fact Sheet For Ark at GambasDokument7 SeitenFact Sheet For Ark at GambasWilliam ChuiNoch keine Bewertungen

- Principal GardensDokument6 SeitenPrincipal GardensWilliam ChuiNoch keine Bewertungen

- 2014 TOP Projects - Singapore ResidentialDokument1 Seite2014 TOP Projects - Singapore ResidentialWilliam ChuiNoch keine Bewertungen

- Woods Square - Woodlands Commercial Mixed DevelopmentDokument64 SeitenWoods Square - Woodlands Commercial Mixed DevelopmentWilliam ChuiNoch keine Bewertungen

- 2016 TOP Projects - Singapore ResidentialDokument1 Seite2016 TOP Projects - Singapore ResidentialWilliam ChuiNoch keine Bewertungen

- White Book C04 S05 Partitions GypWall QUIET SFDokument33 SeitenWhite Book C04 S05 Partitions GypWall QUIET SFPavaloaie Marian ConstantinNoch keine Bewertungen

- Syllabus Statics of Rigid BodiesDokument4 SeitenSyllabus Statics of Rigid Bodiesacurvz2005Noch keine Bewertungen

- AMAR POLYMERS: Manufacturer of Wind Turbine Parts Product BrochureDokument23 SeitenAMAR POLYMERS: Manufacturer of Wind Turbine Parts Product BrochurebalaNoch keine Bewertungen

- Maven Silicon VLSI RNDokument4 SeitenMaven Silicon VLSI RNPeter Gata AyubaNoch keine Bewertungen

- CV Yeshwanth Konduru HVAC ManagerDokument5 SeitenCV Yeshwanth Konduru HVAC ManagerShankker KumarNoch keine Bewertungen

- A Comparative Study of Soil Slope Stability Under Seismic Loading ConditionDokument7 SeitenA Comparative Study of Soil Slope Stability Under Seismic Loading ConditionG Kishore KumarNoch keine Bewertungen

- Soil Nailing For Stabilization of Steep Slopes NeaDokument216 SeitenSoil Nailing For Stabilization of Steep Slopes NeanidhisasidharanNoch keine Bewertungen

- Fundamentals of Engineering Economics by Pravin KumarDokument1 SeiteFundamentals of Engineering Economics by Pravin Kumarkumar372775% (4)

- Steel Design Calculation For Bridge False WorksDokument10 SeitenSteel Design Calculation For Bridge False Worksnelvar2005Noch keine Bewertungen

- Plain Mild Steel BarsDokument1 SeitePlain Mild Steel BarsPrabhakar KattulaNoch keine Bewertungen

- Dehumidifier - Munters MX2700Dokument2 SeitenDehumidifier - Munters MX2700Bozow SinclairNoch keine Bewertungen

- ANNEX B ElectricalDokument32 SeitenANNEX B ElectricalCharo AlmonteNoch keine Bewertungen

- Project: Helena Attached Location:: Item Detail Qty Total Qty L W H No. of ElementsDokument4 SeitenProject: Helena Attached Location:: Item Detail Qty Total Qty L W H No. of ElementsKevin Marc BabateNoch keine Bewertungen

- Control 3-Phase Motors with Digistart Soft StartersDokument15 SeitenControl 3-Phase Motors with Digistart Soft StartersriqkeNoch keine Bewertungen

- CE 1101 Lecture 1 PPT Summer SemesterDokument22 SeitenCE 1101 Lecture 1 PPT Summer Semesterniloy khanNoch keine Bewertungen

- General Standards in Physical Asset ManagementDokument54 SeitenGeneral Standards in Physical Asset ManagementMazin Al-Ghamdi100% (1)

- Woodworks Design Example - Four-Story Wood-Frame Structure Over Podium SlabDokument52 SeitenWoodworks Design Example - Four-Story Wood-Frame Structure Over Podium Slabcancery0707Noch keine Bewertungen

- Rio Tinto Alcan Gove G3 Experience On Pre-Assembled ModulesDokument5 SeitenRio Tinto Alcan Gove G3 Experience On Pre-Assembled ModulesRogerio CannoniNoch keine Bewertungen

- Etabs PT Slab DesignDokument649 SeitenEtabs PT Slab DesignEmanuelRodriguezElera100% (1)

- Guidelines PGElections 21-22Dokument5 SeitenGuidelines PGElections 21-22VLSISD23 KORRA NIKHILNoch keine Bewertungen

- GATE 2023 Official Site PapersDokument4 SeitenGATE 2023 Official Site PapersKushal SarkarNoch keine Bewertungen

- Hands On Education System Using Water RocketDokument5 SeitenHands On Education System Using Water Rocketazam.cheNoch keine Bewertungen

- Canam Steel Deck PDFDokument168 SeitenCanam Steel Deck PDFAnonymous 8hx6hKN3Noch keine Bewertungen

- Open PositionsDokument9 SeitenOpen PositionsAtheen GuptaNoch keine Bewertungen

- CS201 Introduction to Computing Course OverviewDokument66 SeitenCS201 Introduction to Computing Course OverviewSadi ÇelikNoch keine Bewertungen

- Instrument Engineer CVDokument5 SeitenInstrument Engineer CVJoseph Jinu AnsonNoch keine Bewertungen

- Ishrae Membership FormDokument3 SeitenIshrae Membership Formnkumaresh8195Noch keine Bewertungen

- Strut-and-Tie Modeling of Reinforced Concrete Deep PDFDokument41 SeitenStrut-and-Tie Modeling of Reinforced Concrete Deep PDFkellydelgado41Noch keine Bewertungen

- Doha Petroleum Construction Co. LTD Inspection & Test Plan: ElectricalDokument1 SeiteDoha Petroleum Construction Co. LTD Inspection & Test Plan: ElectricalmeeNoch keine Bewertungen

- Rajasthan Technical University, Kota Teaching & Scheme of Examination For B.Tech. (Computer Engineering)Dokument4 SeitenRajasthan Technical University, Kota Teaching & Scheme of Examination For B.Tech. (Computer Engineering)MUKESHNoch keine Bewertungen