Beruflich Dokumente

Kultur Dokumente

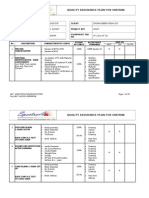

ITP For Storage Tank

Hochgeladen von

Ahmed Ben HmidaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ITP For Storage Tank

Hochgeladen von

Ahmed Ben HmidaCopyright:

Verfügbare Formate

Prepared By :

Tank No.

: T-30A1

Legend :

ITP

NO.

INSPECTION AND TEST ITEMS

QUALITY CONTROL PLAN

Date :

17-Aug-11

INSPECTION AND TEST PLAN FOR STORAGE TANK

REV :

(ALUMINUM DOME ROOF / INTERNAL FLOATING COVER (FULL FACE CONTACT))

I = Inspection by visual, II = Inspection by Surveillance, III = Inspection by Measurement, IV = Inspection by Testing, P = Prepare, R = Review Record, A = Approve Record, W = Witness, ( ) = Spot,

ACCEPTANCE CRITERIA

APPLICABLE

CODE/STANDARD

ITP

METHOD

SAMPLE SIZE /

FREQUENCY

ITP METHOD / BY

3rd-Party

Signature

Date

RECORD

FORM No.

[ ] = Random, H = Hold Point

REMARKS

Shop Fabrication

1.0

Material

1.1 Incoming Inspection

(a) Material Spec. and Grade

(b) Yield and Tensile Strength

(c) Chemical Composition

(d) Plate Size & Physical Condition

1.2 Identification and Traceability

1.3 Storage and Handling :

(a) Materials

(b) Welding Consumables

2.0

WPS / PQR / WQT Certs

3.0

Pre-fabrication

3.1 Dimensional Inspection :

Shell, Roof, Bottom , Annular Bottom,

Roof Annular, Reinforcing Plate, etc.

(a) Layout, Marking and Cutting

(b) Edge Preparation

(c) Curvature and Surface

Compliance with para.5 of project spec. No.

DEP 34.51.01.31 GEN. and & EN 14015

- Check purchase requisition

against D/O and order spec.

- Compliance with the Code

requirement.

- Thk.tolerance

specified thk., PO / code

- No flattening, thining, flaw, and

injurious defects on the surfaces

and cut edges.

- Check plate ID such as heat no.,

plate no., and thickness against

Mill Certificate.

- Timber piece req'd, never direct

on ground and proper handle to

avoid mechanical damage.

- Shall be kept in a clean/dry area

& proper handle to avoid physical

damage and contamination.

Compliance with ENTS-QWI-09(Issue no.04)

and Sex.IX of the ASME Code and PO/ Spec.

requirments

Compliance with project spec. No.

DEP 34.51.01.31 GEN.

-DEP 34.51.01.31-GEN.

-EN 14015 : 2004

-EN 10029 : 1991

-Para 6.1.8 EN 14015 :

2004 & Table 1 EN 10029

: 1991

To be accomplished

on each surveillance

Visual

100% of incoming goods

(below 5 pcs per one item)

I, II

[I]

Mill Cert. of

Materials

Vernier Caliper

or UTM Gauge

Visual

6 points of each steel plate

I, III

(R)

QA-F06B

Throughout fabrication

-Para 15.4 EN 14015:2004 Visual

All pressure retaining parts

QA-T-33

-Para 15.3 EN 14015:2004 Visual

Throughout fabrication

II

None

II

[ II ]

As per TREL11402-WP-005

IV, P

IV, P

R, A

R

QA-W-00,

QA-W-02

I, II, III,

IV, P

[W]

QA-T-01, QA-T-02,

QA-T-03

QA-T-20

TREL-11402-WP-005

-ENTS-QWI-09

-ASME SECTION IX

Visual

Before and after removal from

manufacturer's package

All applicable welding

process(es)

TOP

approved NDE companies

-DEP 34.51.01.31-GEN

-DEP 64.51.01.31-GEN.

- Dimension shall be within the

following tolerance:- Max.allow. tolerance for difference

in diagonal of shell plate : 3 mm.

- Tolerance within 2 mm. in length.

-Tolerance within 2 mm. in width.

- O.D., width & length tolerance for

reinforcing plate : 3 mm.

- Tolerance within 2.5 in single bevel.

- Plate thickness up to 12.5 mm.Max.16mm

differences between design and the as built

profile

-EN 14015 : 2004

-Final thickness of the plate shall not be less

than 95% of the plate thickness

-Para 15.7 EN 14015:2004

Measuring Tape

-Para 15.5 EN 14015 : 2004

-Para 15.5 EN 14015 :

2004

-Para 15.5 EN 14015 :

2004

Full inspection

Template,

Measuring Tape

QA-T-05

-Para 7.4e(3) TREL11402-MP-001

Weld Gauge

-Table 25 EN 14015 : 2004 Sweep Board 1

m long

Page 1 of 6

visit for which the

activity is applicable

Prepared By :

Tank No.

: T-30A1

Legend :

ITP

NO.

INSPECTION AND TEST ITEMS

3.2 Marking Inspection

(a) Third Point Punch Marking

(b) Pre-fabricated Material

Identification (piece mark)

3.3 Manhole & Nozzle pre-assembly

with Flange & Cover

3.4 Other Components(Internal pipe w/c supp't,

sump, vortex breaker, spiral stair-way, roof

handrail, roof walkway,roof way, water spray

system,

topangle,

earth piece,

cable conduit,support, settling

level mark, gussets,name plate bracket,

anchor chair,jacking up bracket, riser

pipe,internals and other structural etc.

3.5 Heating coils-Shop welding if any

4.0

Shop Post Weld Heat Treatment (PWHT)

(Shell with nozzles, t 25 MM or D > 300 MM)

QUALITY CONTROL PLAN

Date :

17-Aug-11

INSPECTION AND TEST PLAN FOR STORAGE TANK

REV :

(ALUMINUM DOME ROOF / INTERNAL FLOATING COVER (FULL FACE CONTACT))

I = Inspection by visual, II = Inspection by Surveillance, III = Inspection by Measurement, IV = Inspection by Testing, P = Prepare, R = Review Record, A = Approve Record, W = Witness, ( ) = Spot,

ACCEPTANCE CRITERIA

- As per AFC. drawing and EN 14015 : 2004

(a) Shall be punched on the inside top

edge in every 1/3 plate length.

(b) Markings, such as number of tank,

piece, die-stamping

heat, and thickness.

(ccourse,

) Low stress

min.radius of

0.25mm. ,not suitable for plates less than

6mm.thick

- Manhole tolerance: ID.min.600mm.

- 3 mm for O.D. of flange and neck.

- +3 mm / -0 mm for flange Thk.

- 1 for inclination of flg. face to neck.

Nozzle tolerance :

- 0.5 for inclination of flg. face to neck.

- As per AFC drawing and EN 14015 : 2004

APPLICABLE

CODE/STANDARD

-Para 15.4 & 15.11 EN

14015 : 2004

ITP

METHOD

Visual

Shell plates section

Visual

All primary components

Square,

Measuring Tape

After welding

Square, Weld

Gauge,

Measuring Tape

Full inspection

- Dimension check & Tolerance as per drawings - EN14015 : 2004

Measuring Tape

- Visual & 100% RT

Per approved drawing

Visual

- Para 18.10 EN 14015 : 2004

Visual

a) No. of thermocouple & location

Thermocouple

b) Temperature / recorder

Full Inspection

Full Inspection

-Para 7.4e(3) TREL11402-MP-001

c) Holding time

d) Calibration / certification

5.0

Shop Examination of Welds

(a) Visual Inspection of Weldment, final

visual, dimension checks.

(b) PT or MT

- Temporary & Permanent attachment

6.0

Painting Inspection (External)

( Under Bottom, shell, roof and structure steel)

(a) Surface Preparation

(b) Primer Coat

SAMPLE SIZE /

FREQUENCY

- As per AFC. drawing and EN 14015 : 2004

- Accordance with Table 32-Imperfection

acceptance criteria

- Shall accordance with Table 29, EN14015 :

2004

- Accordance with Table 32-Imperfection

acceptance criteria

- As per para. 3 of project spec. no.

DEP 30.48.00.31-GEN. & TOSS-48-001

- As per appendix 1 & 2 of project spec. no.

DEP 30.48.00.31-GEN. and TOSS-48-001

ITP METHOD / BY

Signature

Date

RECORD

FORM No.

I, II

P

[I]

R

3rd-Party

-

III, P

[ III ], R

QA-T-04

I, II, III, IV, P (W), R

QA-G-01,QA-S-01

PWHT Chart

[ ] = Random, H = Hold Point

REMARKS

QA-T-33

I, III, P

R

I, II, III,

[W]

R

I, W, R

I, III, P

(W)

IV, P

(W), R, A

PT or MT report

I, III, P

[W]

QA-F-11B

Min. TC of 3 pcs

Heating <Max. 120 oC /hr /

Cooling < Max. 140 oC/hr

Min. 60 mins

Certificates

-Para 19.11 EN 14015 :

2004

-Para 19.6, 19.7 EN

14015 : 2004

-DEP 30.48.00.31-GEN.

-TOSS-48-001

Visual

MT/PT methods

Visual

Profile Gauge

DFT Gauge

Page 2 of 6

100% of welds

100% for steel yield strength

355N/mm2

Full inspection of blasted

area

10 points of the plate surface

and spot for other tank

components.

QA-T-04,QA-T-10

Painting report shall be

attached surveillance

reports from representative

paint manufacturer

Prepared By :

Tank No.

: T-30A1

Legend :

ITP

NO.

7.0

INSPECTION AND TEST ITEMS

Field Site Erection

(Handover from Civils Contractor to Tank Contractor.)

7.1 Foundation Survey ( field )

(a) Concrete

7.2 Diamensional check of CS tank ( field )

a Fit - Up of Tank Floor

( Prior To Welding )

( a ) Roundness of annular plate

( b ) Overlap of Plates

17-Aug-11

REV :

I = Inspection by visual, II = Inspection by Surveillance, III = Inspection by Measurement, IV = Inspection by Testing, P = Prepare, R = Review Record, A = Approve Record, W = Witness, ( ) = Spot,

ACCEPTANCE CRITERIA

APPLICABLE

CODE/STANDARD

ITP

METHOD

SAMPLE SIZE /

FREQUENCY

ITP METHOD / BY

3rd-Party

Signature

Date

RECORD

FORM No.

I, W, A

- Elevation differences of foundation shall not

exceed 3 mm. In 3 m. From the main level and shall

- Note 5 Tank foundation

Detail Drawing D-3001315-12X Rev.0

Level Transit

- Top of Foundation shall be level within 3

mm. within any 10000mm. Arc, and 6mm.

Around the entire periphery

DEP 34.51.01.31-GEN. and AFC. Drawing.

- Overlap of sketch plate to annular plate

- 0.1% of radius

I, P

QA-T-30

Any two point between around

the periphery

" D " Diameter

Around the circumference.

- As per AFC. drawing and project spec. no.

DEP 64.51.01.31-GEN. and DEP 34.51.01.31-GEN.

-DEP 34.51.01.31-GEN.

-DEP 64.51.01.31-GEN.

- 50 100 from rim annular plate to Outsied of shell

-Figure 3d EN 14015 : 2004 Visual &

- Minimum 300mm. With 3 plate lap ot other 3

plate lap

- Minimum 65 mm

Visual

Measurement minimum 8 point

Each Overlap plate

III, P

QA-T-06

I, P

QA-T-10

I, P

QA-T-10

III, P

W, A

QA-T-08

III, P

W, A

QA-T-32

I, III,

[W]

QA-T-10

- Para 8.4.1/Figuer 3c EN

14015 : 2004

- Para 16.6 EN 14015

:103:1032004

Each Overlap plate

Visual

- Para 4.1.2 DEP

34.51.01.31-Gen

-Table 24 EN 14015 : 2004 Measurement

Insied radius mesuasured

minimum 8 point holizontally at a height 200 mm.

above the bottom of the shell

Measurement minimum 8 point

( b ) Level before welding

- not exceed 25% of Tank diameter Max.100 mm.- Para 16.6 EN 14015 : 2004Level Transit

( c ) Fit up

with Annular plate

- 3mm.Maximum gap

- Minimum width 600 mm.

-Para 16.7.1 EN 14015 : 2004

Taper bore gap

-Para 4.1.2 DEP

measuring tape

34.51.01.31-Gen

- Minimum 10 time of lowest shell course

- Para 8.3.4 EN 14015:2004measuring tape

- Accordance Imperfaction acceptance

- Table 32 EN 14015 : 2004 Visual

Both side

I, P

[W]

QA-T-10

- 18% for 8mm.thk and 1.5mm for more than

8mm to 15mm.of shell plate

- min.distance vertical joint in adjacent(Thk.

above 5mm.)

- Table 26 EN 14015 : 2004 Visual

Any vertical joint

I, P

[ W ], R

QA-T-10

Any shell course

@ 45o intervals starting at 0o

I, P

[ W ], R

QA-T-10

II, P

QA-T-09

( d ) After Welding

7.3 Shell course ( Fit up and visual )

a) Shell Fit-Up Inspection By Vertical

b) Shell Fit-Up Inspection By horizontal

7.4 Plumb Check ( Shell Verticality )

REMARKS

DEP 64.51.01.31-GEN.& EN 14015 : 2004

- Minimum 5 time of bottom thickness

Vertical joint with annular joint

[ ] = Random, H = Hold Point

- As per AFC. drawing and project spec. no.

- Overlap of bottom plate

b 1 st Shell Course to bottom plate Joint

( a ) Roundness lowest shell course

Date :

INSPECTION AND TEST PLAN FOR STORAGE TANK

(ALUMINUM DOME ROOF / INTERNAL FLOATING COVER (FULL FACE CONTACT))

not Exceed. 3 mm. Between any two point around the

periphery

(b) Surface

(c) Underside of Shell Plate

QUALITY CONTROL PLAN

Bottom course to annular plate

Any point mesured from inside

of the tank to Scetch plate

Any Vertical joint weld of shell

to Annular joint

- Para 5.3 DEP

34.51.01.31-Gen

- Para 16.7.4.2 EN 14015

: 2004

- not exceed 20% of thk. Of upper plate max.3mm.

Visual

- Not exceed 1/200 of tank height, or 50mm.

Plumb Block

- Para 16.7.3 EN 14015 :

2004

Measuring Tape

& Try Square

Page 3 of 6

for each shell course.

Plumbness Inspection

TREL QC to Check all

and Client to Witness

only the first & Final Shell

course after Welding.

Prepared By :

Tank No.

: T-30A1

Legend :

ITP

NO.

INSPECTION AND TEST ITEMS

7.5 Peaking and Banding

(Local Departure of Shell due to welding)

8.0

QUALITY CONTROL PLAN

Date :

17-Aug-11

INSPECTION AND TEST PLAN FOR STORAGE TANK

REV :

(ALUMINUM DOME ROOF / INTERNAL FLOATING COVER (FULL FACE CONTACT))

I = Inspection by visual, II = Inspection by Surveillance, III = Inspection by Measurement, IV = Inspection by Testing, P = Prepare, R = Review Record, A = Approve Record, W = Witness, ( ) = Spot,

ACCEPTANCE CRITERIA

APPLICABLE

CODE/STANDARD

- Table 27 EN 14015 :

- Maximun 10 mm. for plate thk. Up to 12.5 mm. 2004

ITP

METHOD

SAMPLE SIZE /

FREQUENCY

ITP METHOD / BY

3rd-Party

Horizontal &

3 points across the

III,

vertical sweep

vertical and

( a ) Peaking @ Vertical weld joint

Boards 1 m.

( b ) Banding @ Horizontal weld joint

long.

the plate joint

-DEP 64.51.01.31-GEN.

Visual

All

- EN 14015 : 2004

Inspection

-TREL-11402-QP-003

Measuring Tape

Signature

Date

RECORD

FORM No.

QA-T-07

W, R

QA-T-12

(W), R

[ ] = Random, H = Hold Point

REMARKS

horizontal side of

Tank Appurtanances ( field )

8.1 Orientation Mark Check for

- As per approved construction drawings

Manholes / Nozzles

8.2 Trial Fit - Up Inspection of

Manholes / Nozzles

(a) 5mm projection from outside

of tankshell to extreme face of flange

III,

P

All

& Try Square

III,

P

QA-T-11

(b) 6 mm for nozzles, 13 mm for Manholes

centreline Elevation or radial location

(c) 3mm plumbness

9.0

Stairway, landing platforms, ladders

and handrails

10.0 Field Examination of Welds

(a) Visual Inspection of Weldment, final

- Corner fillet welded , shell to bottom annular

plate

- Bottom fillet welded

-Shell butt weld

- Roof to shell

- Roof plate

11.0

- As per approved construction drawings

Visual,

measuring tape

- Vertical attachment welds shall not be located - Para 13.5.2 EN

within 150 mm. of any main vertical seam and 14015:2004

horizontal attachment welds shall not be made

on top of any main horizontal seam

- Temporary attachment the requirement same - Para 13.16 EN 14015:2004

as permanent attachment

- Tack weld shall be cleaned to remove all rust and paint

- As per AFC. drawing and EN 14015 : 2004

-Para 19.11 EN 14015 :

- Accordance Table 32-Imperfection acceptance criteria

2004

- min. 2 layers, throat thk.shell be equal 0.7

-Para 4.2, 4.3 DEP

time of annular thickness

34.51.01.31-Gen

- Minimum throat thk. Of each fillet shall be

- Para 8.4.5 EN 14015 :

equal to thk. Of plate , need not exceed 9.5 mm. 2004

All

I, III, P

(W), R

QA-G-01

Visual

weldment

I ,P

[W]

QA-T-10

measuring tape

Both side

H, A

QA-T-14

[ W ], A

PT Report

H,A

QA-T-18

weldment

- Surface of adjoining plate to a height of not

more than 1.5 mm.

- seal weld 3mm for OD.12.5m.& less / 5mm.

For over 12.5m.OD of tank

- Para 5.1 DEP

64.51.01.31-Gen.

- Para 5.4.1 / 6.1.3.4 DEP

34.51.01.31-Gen

weldment

- Continuously fillet welded on the outside with

a minimum lap of 25mm.

- Para 10.3.5 EN 14015 :

2004

- No leak indication with minimun pressure of 30 kPa gauge and soapy water

- Table 29 EN 14015 : 2004 Visual

Roof plate shall not be attached

to the roof-supporting structure.

They shall be continuously filletwelded to top curb angle

Roof plate lap joint

Vacuum Box Test ( after welding )

( a ) Annular Plate Weldments

( b ) Bottom Plate Weldments

( c ) Roof Plate Weldments

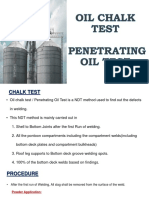

12.0 Dry penetrant Test

( a ) Bottom plate

- Accordance with table 32- Imperfection

( b ) Nozzle to shell , Nozzle to reinforcing plate acceptance criteria

( c ) Nozzle to roof fillet weld

- Substitute to Soab bubble test

( d ) Temporary bracket / Permanent bracket and pad plate

( e ) Stiffening rings (Wind girders)

- Para 19.5 EN 14015 : 2004Inspection

- Table 29 EN 14015 : 2004 Visual &

- Para 19.6 EN 14015 : 2004PT test

- Para 19.8 EN 14015 : 2004Soapy water

All weldments

IV,

with test overlapped

100% Fillet weld lap plate

100% Welded ment

100% Welded ment

IV,

P

IV,

100% for steel yield strength

355N/mm2

Page 4 of 6

Cover when Pneumatic Roof

Prepared By :

Tank No.

: T-30A1

Legend :

ITP

NO.

INSPECTION AND TEST ITEMS

QUALITY CONTROL PLAN

Date :

17-Aug-11

INSPECTION AND TEST PLAN FOR STORAGE TANK

REV :

(ALUMINUM DOME ROOF / INTERNAL FLOATING COVER (FULL FACE CONTACT))

I = Inspection by visual, II = Inspection by Surveillance, III = Inspection by Measurement, IV = Inspection by Testing, P = Prepare, R = Review Record, A = Approve Record, W = Witness, ( ) = Spot,

ACCEPTANCE CRITERIA

APPLICABLE

CODE/STANDARD

ITP

METHOD

SAMPLE SIZE /

FREQUENCY

ITP METHOD / BY

3rd-Party

Signature

Date

RECORD

FORM No.

[ ] = Random, H = Hold Point

REMARKS

13.0 Magnetic Particle Examination

( a ) Bottom plates, Bottom annular plate

( b ) Bottom to shell fillet weld

( c ) Roof , Roof to shell

- Accordance with table 32- Imperfection

acceptance criteria

- Substitute to Vacuum test or soap test

- Table 29 EN 14015 : 2004 MT Yoke

- Para 19.7 EN 14015 : 2004

IV,

100% On both side

[ W ], A

MT Report

100% Butt weld , fillet weld

( d ) Nozzle to shell , Nozzle to reinforcing plate - Substitute to Dry penetrant

Substitute

( e ) Temporary bracket / Permanent bracket and- pad

plate to Dry penetrant

( f ) Stiffening rings (Wind girders)

If vacuum box test impractical

100% weldment

100% for steel yield strength

355N/mm2

- Substitute to Dry penetrant

14.0 Soap bubble examination

( a ) Reinforcing plate to shell

15.0 Radiography examination

( a ) Vertical weld in the first shell course

- No leaks at pressure 30 kPa gauge, holding

time not less than 30 seconds

Accordance

with

table

Imperfection

acceptance criteria

-- Addition

there

shell

be 32at least

one

examination

- Table 30 EN 14015 : 2004 Visual &

1. For each welding process on first

( b ) Vertical weld in the remaining shell course vert.&Horiz.

( c ) T-joint

- Table 29 EN 14015 : 2004 Soapy water

- Para 19.10 EN 14015 : 2004

Radio-graphy

2.For each welder or welding operator

3. Vertical lowest course change from manual to automatic

- If one of these add. Film is reject, Total Exam. - Para 19.4.5 EN 14015 : 2004

Of the Day's product by welder / machine

( f ) Heating internal Pipe, if any

- table 32- Imperfection acceptance criteria

IV, P

[ W ], A

QA-T-15

5% of total length of 1st course

R, A

IV,P

RT Film & Report

1% of total remaining course

( Gamma Ray )

( d ) Horizontal seam

( e ) Additional if imperfections are found

100% weldment

25% of total T-joint

1% of total horizontal length

Each side of the original area

- Para 19.9 EN 14015 : 2004

Film length 400mm.

T-Joint position with in

50% vertical and 50%

horizontal

100% Butt Welded

16.0 Final Inspection prior to hydrostatic test

(a) All attachment shell ,bottom internal & External

- Punch "A" shall be cleared

(b) Peripheral level check

- Empty checked and record

- Para 19.13 EN 14015 : 2004

Visual

- Para 19.13.5.1 EN 14015 Level Transit

(c ) Bottom surface level survey

- Record contour of the bottom tank

- Para 19.13.5.2 EN 14015 Level Transit

17.0 Examination during Hydrostatic Test

All welding has been completed

I, P

D 10m on 4 mark, <10m.on 8 mark

IV,P

[W]

D 10m.on 3 radii, D<10m.on 6 radii IV,P

QA-T-00

QA-T-30

QA-T-35

QA-T-00

- As per AFC. Drawing

(a) Peripheral level check

- After holding time

- Para 19.13.5.1 EN 14015 Level Transit

(b) Filling rate

- Water filling Stage 1 ot 4 checked and record

- Table 1 DEP 64.51.01.31-Gen

(c) Shell joint / Corner shell to bottom

- No laek , should a leak be discovered

- Para 19.13.6 EN 14015

- No leak under pressure 1.1 time of design

pressure greater than 10mbar gauge

- Para 19.8 EN 14015 : 2004Visual

Visual

QA-T-30

Settlement mark per AFC. drawing

IV,P

Monitoring stage 1 to 4

I, P

(W)

QA-T-25

lowered to app.300 mm.repair point

[W]

QA-G-01

Apply soapy water during the

pneumatic pressure test of the

roof

IV,

H,A

QA-T-18

18.0 Hydro-Pneumatic Test

( a ) Roof , Roof to shell

( b ) Roof nozzles / manholes

19.0 After Hydrostatic Test

(a) All accessories internal & External

(b) Peripheral level check

(c ) Bottom surface level survey

20.0 Heating internal pipe if any

(a) Butt weld

- Para 19.15 EN 14015 : 2004

Visual

Level Transit

- Empty checked and record after drainage

- Para 19.14 EN 14015

- to ensure bottom is in contact with foundation - Para 19.13.5.2 EN 14015 Level Transit

profile./ measured values shall be verified

against.

- No leak on Pressure test of 1.5 time of design - TREL-11402-QP-003

pressure

21.0 Painting Inspection

I, P

QA-T-00

Settlement mark per AFC. drawing

After tested, 25 cm of water

shoule be left inside

IV,P

I ,P

H

[W]

QA-T-30

QA-T-35

All weldment

IV, P

QA-G-01

Visual

- TOSS-48-001

(a) Surface Preparation

- As per para. 3 of project spec. no.

(b) Primer Coat

DEP 30.48.00.31-GEN. & TOSS-48-001

- As per appendix 1 & 2 of project spec. no.

DEP 30.48.00.31-GEN. and TOSS-48-001

(c) Intermediate coats

(d) Top coats

All accessories has been restate

- Punch "B" shall be cleared

-DEP 30.48.00.31-GEN

Profile Gauge

Visual

DFT Gauge

Page 5 of 6

Full inspection of blasted

Painting report shall be

area

10 points of the plate surface

and spot for other tank

components.

attached surveillance

reports from representative

I, III, P

[W]

QA-F-11B

paint manufacturer

Prepared By :

Tank No.

: T-30A1

Legend :

ITP

NO.

INSPECTION AND TEST ITEMS

22.0 Final Inspection Prior to Box-up

QUALITY CONTROL PLAN

Date :

17-Aug-11

INSPECTION AND TEST PLAN FOR STORAGE TANK

REV :

(ALUMINUM DOME ROOF / INTERNAL FLOATING COVER (FULL FACE CONTACT))

I = Inspection by visual, II = Inspection by Surveillance, III = Inspection by Measurement, IV = Inspection by Testing, P = Prepare, R = Review Record, A = Approve Record, W = Witness, ( ) = Spot,

ACCEPTANCE CRITERIA

- Perform visual inspection for tank

APPLICABLE

CODE/STANDARD

ITP

METHOD

- TOSS-48-001

Visual

completed installation without damaged

-DEP 30.48.00.31-GEN

Inspection

painting and cleanliness per

-DEP 64.51.01.31-GEN.

project requirements

-DEN 34.51.01.31-GEN.

SAMPLE SIZE /

FREQUENCY

Full

ITP METHOD / BY

3rd-Party

I

- Completeness

-Verify compliance with

dossier requirements.

Date

RECORD

FORM No.

Punch list closer

QA-T-00

- EN 14015 : 2004

23.0 Review of MDR

Signature

Review

Page 6 of 6

Full

P/

R

H, A

[ ] = Random, H = Hold Point

REMARKS

Das könnte Ihnen auch gefallen

- FIELD INSPECTION PROCEDURESDokument29 SeitenFIELD INSPECTION PROCEDURESsbmmla91% (22)

- Inspection and Test Plan For Storage TankDokument7 SeitenInspection and Test Plan For Storage TankAhmed100% (5)

- Contractor Quality Control Plan For Storage Tank ErectionDokument2 SeitenContractor Quality Control Plan For Storage Tank ErectionHamid Alilou100% (4)

- Mechanical Calculations for Air Receiver Pressure VesselDokument32 SeitenMechanical Calculations for Air Receiver Pressure VesselAndiWSutomoNoch keine Bewertungen

- Storage Tank (API 650)Dokument20 SeitenStorage Tank (API 650)sbmmla83% (6)

- Water Fill Up Testing Procedure-R3 07.07.2011sohar 2Dokument7 SeitenWater Fill Up Testing Procedure-R3 07.07.2011sohar 2AjeetKumarNoch keine Bewertungen

- Sample QAPDokument3 SeitenSample QAPsniperiNoch keine Bewertungen

- Scaffoldless Tank Erection MethodDokument20 SeitenScaffoldless Tank Erection MethodPlok Caca piiii100% (5)

- Tank Erection Itp & Org ChartDokument34 SeitenTank Erection Itp & Org Charthasan_676489616100% (2)

- Quality Assurance Plan For Unitank:: QAP/AAV/MFG/00107/UT Crown Beers India LTD: AAVI-GA-003, R0, 210507 00107Dokument10 SeitenQuality Assurance Plan For Unitank:: QAP/AAV/MFG/00107/UT Crown Beers India LTD: AAVI-GA-003, R0, 210507 00107Narayana Mugalur100% (1)

- Algeria Oman Fertilizer Project Inspection and Test PlanDokument22 SeitenAlgeria Oman Fertilizer Project Inspection and Test Planmister pogi100% (3)

- Pt. Bahana Karya Mandiri: Data SheetDokument8 SeitenPt. Bahana Karya Mandiri: Data SheetBowo Edhi WibowoNoch keine Bewertungen

- Itp TankDokument4 SeitenItp TankAmber Chavez100% (2)

- Prepration of ITP For Storage Tanks Fabrication & ErectionDokument27 SeitenPrepration of ITP For Storage Tanks Fabrication & ErectionRamuAlagappan93% (15)

- ITP Format For New PVDokument8 SeitenITP Format For New PVDavid LambertNoch keine Bewertungen

- Boq (110912)Dokument144 SeitenBoq (110912)Ali AlaliNoch keine Bewertungen

- ITP For Storage TankDokument6 SeitenITP For Storage Tankittiphon3194% (17)

- API 579-1 FFS AssessmentDokument16 SeitenAPI 579-1 FFS AssessmentMuhammad Omar100% (2)

- Itp Storage TankDokument10 SeitenItp Storage Tankmuhammad afrizalNoch keine Bewertungen

- Inspection of Storage Tank API - 650Dokument4 SeitenInspection of Storage Tank API - 650Michael Albuquerque0% (1)

- BCA - Design Guide On Use of Structural SteelDokument89 SeitenBCA - Design Guide On Use of Structural Steelsazkha2100% (1)

- M 111 Tank Weld Repair ProcedureDokument8 SeitenM 111 Tank Weld Repair ProcedureAAISATNoch keine Bewertungen

- Niigata - Replacing Bottom Plates of Oil Storage TanksDokument7 SeitenNiigata - Replacing Bottom Plates of Oil Storage TanksJohnson Olarewaju100% (2)

- DBR Structural Design Basis Report AvignaDokument8 SeitenDBR Structural Design Basis Report AvignaswapnilNoch keine Bewertungen

- GEE ElectrodeDokument17 SeitenGEE ElectrodeSatyamEngNoch keine Bewertungen

- Tank Erection ProcedureDokument15 SeitenTank Erection Procedurejohney294% (16)

- Itp For Storage TanksDokument7 SeitenItp For Storage TanksHamid MansouriNoch keine Bewertungen

- Reconstruction of Pakistan Refinery Tank T-53Dokument16 SeitenReconstruction of Pakistan Refinery Tank T-53javaidahmedshaikh100% (1)

- Report of Storage TankDokument44 SeitenReport of Storage TankAMALENDU PAUL100% (1)

- SOP Hydrotest Storage TankDokument3 SeitenSOP Hydrotest Storage TankRidwan Nursalam100% (1)

- API 579-1 FFS Assessment SummaryDokument28 SeitenAPI 579-1 FFS Assessment SummaryRobiansah Tri AchbarNoch keine Bewertungen

- IOCL Refinery Project Tank Settlement Survey ReportDokument1 SeiteIOCL Refinery Project Tank Settlement Survey Reportarkaprava ghosh100% (1)

- Method For Replacement The Bottom Plate With New OneDokument9 SeitenMethod For Replacement The Bottom Plate With New OneMian Aamir Saddiq100% (3)

- Tank-API-650-docx V-V-I-P PDFDokument20 SeitenTank-API-650-docx V-V-I-P PDFtomj9104100% (1)

- Cost Estimate of Hydro Plant 11MW and 16.5MWDokument33 SeitenCost Estimate of Hydro Plant 11MW and 16.5MWwalitedison100% (1)

- Storage Tank Foundation Settlement Quality Control and Inspection Report FormDokument1 SeiteStorage Tank Foundation Settlement Quality Control and Inspection Report FormKhepa BabaNoch keine Bewertungen

- Metallic Materials for FGD SystemsDokument21 SeitenMetallic Materials for FGD SystemsClaudia MmsNoch keine Bewertungen

- Fireproofing SpecificationDokument48 SeitenFireproofing SpecificationEsteban Castellano100% (12)

- Hydrotest ProcedureDokument6 SeitenHydrotest Procedurebagusu_6Noch keine Bewertungen

- Oil Chalk Test/Penetrating Oil TestDokument6 SeitenOil Chalk Test/Penetrating Oil TestWeld ManiacNoch keine Bewertungen

- Inspection Report: Vaccum Test RecordDokument21 SeitenInspection Report: Vaccum Test RecordWahyudi MetrizaNoch keine Bewertungen

- STS Co. storage tank fabrication methodologyDokument15 SeitenSTS Co. storage tank fabrication methodologypurshottam GHNoch keine Bewertungen

- Inspection & Test Plan TankDokument3 SeitenInspection & Test Plan TankJOSHUA SULLEGUE100% (1)

- Checklist Tank NewDokument11 SeitenChecklist Tank NewamevaluacionesNoch keine Bewertungen

- Description and Job SpecificationDokument10 SeitenDescription and Job SpecificationAhmed Ben HmidaNoch keine Bewertungen

- Storage Tank PresentationDokument62 SeitenStorage Tank PresentationpsychopassNoch keine Bewertungen

- PQR 014 (Qualified Sa 106 GR BDokument5 SeitenPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- Shell Plate Dimension CheckDokument7 SeitenShell Plate Dimension Checksetak0% (1)

- 10) Itp - Tank Fabrication PDFDokument6 Seiten10) Itp - Tank Fabrication PDFAndy Chong100% (5)

- (732-Itp-40 (V-6905) 42000-SNG-69-42000P-MS-5733-504-0000-06Dokument10 Seiten(732-Itp-40 (V-6905) 42000-SNG-69-42000P-MS-5733-504-0000-06sathi11189Noch keine Bewertungen

- Storage Tank Hydrostatic Test Quality Control and Inspection Report FormDokument1 SeiteStorage Tank Hydrostatic Test Quality Control and Inspection Report FormsugiantobarusNoch keine Bewertungen

- 24.tank Oil Chalk TestDokument3 Seiten24.tank Oil Chalk TestShubham ShuklaNoch keine Bewertungen

- Tank Bottom Plate Replacement TechniquesDokument9 SeitenTank Bottom Plate Replacement TechniquesMS100% (1)

- WPS - Smaw - 2Dokument6 SeitenWPS - Smaw - 2Harkesh RajputNoch keine Bewertungen

- Hydrostatic and Settlement Tests ProcedureDokument12 SeitenHydrostatic and Settlement Tests Procedureツ ツ100% (1)

- QCP-0714-11, Rev. A, Field Welded API Std. 650 Tanks' Shop Pre-Fabrication QC Procedure.Dokument6 SeitenQCP-0714-11, Rev. A, Field Welded API Std. 650 Tanks' Shop Pre-Fabrication QC Procedure.abdul aziz100% (1)

- BS 07668-2016 PDFDokument26 SeitenBS 07668-2016 PDFAsheque IqbalNoch keine Bewertungen

- Vacuum Box Testing ProcedureDokument6 SeitenVacuum Box Testing ProcedureKandula Raju100% (1)

- Vessel Inspection ProcedureDokument17 SeitenVessel Inspection ProcedureVimal RajNoch keine Bewertungen

- Facture C3 ShineDokument1 SeiteFacture C3 ShineAhmed Ben HmidaNoch keine Bewertungen

- Volume3A MechDokument321 SeitenVolume3A MechAdeel JamilNoch keine Bewertungen

- Vaccum Box Test Procedure For All TanksDokument6 SeitenVaccum Box Test Procedure For All Tanksויליאם סן מרמיגיוסNoch keine Bewertungen

- TBE For UG Knock Out Drum - Draft For Rev.C1Dokument22 SeitenTBE For UG Knock Out Drum - Draft For Rev.C1pragatheeskNoch keine Bewertungen

- Tank Inspection NotesDokument5 SeitenTank Inspection Notesaneeshjose013Noch keine Bewertungen

- 21Dokument6 Seiten21Dannis AnantoNoch keine Bewertungen

- CNT230025 C3 HRSG - Air Tank TCV020&PCV068Dokument6 SeitenCNT230025 C3 HRSG - Air Tank TCV020&PCV068Dave CheungNoch keine Bewertungen

- Informe Inspección A-1150 Rev1Dokument8 SeitenInforme Inspección A-1150 Rev1bgonzalez1981Noch keine Bewertungen

- $1330PZT-9141C/I04-A : Construction Check SheetDokument3 Seiten$1330PZT-9141C/I04-A : Construction Check SheetAnonymous W939WdINoch keine Bewertungen

- 28 LaDokument3 Seiten28 Lagsinghal121Noch keine Bewertungen

- Pressure Vessel Inspection ReportDokument34 SeitenPressure Vessel Inspection ReportJinlong SuNoch keine Bewertungen

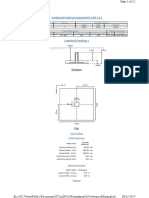

- Geometrical DescriptionDokument1 SeiteGeometrical DescriptionAhmed Ben HmidaNoch keine Bewertungen

- Geometrical DescriptionDokument1 SeiteGeometrical DescriptionAhmed Ben HmidaNoch keine Bewertungen

- Node Displacement Summary: Job No Sheet No RevDokument1 SeiteNode Displacement Summary: Job No Sheet No RevAhmed Ben HmidaNoch keine Bewertungen

- Fill in RulesDokument1 SeiteFill in RulesAhmed Ben HmidaNoch keine Bewertungen

- Cementatious Grout DASDokument3 SeitenCementatious Grout DASAhmed Ben HmidaNoch keine Bewertungen

- RESOLTECH Chemical Resistance GuideDokument45 SeitenRESOLTECH Chemical Resistance GuideAhmed Ben HmidaNoch keine Bewertungen

- 7357.what's New in STAAD Foundation Advanced 61Dokument27 Seiten7357.what's New in STAAD Foundation Advanced 61Panneer Selvam EaswaranNoch keine Bewertungen

- Structural steel shapes and propertiesDokument176 SeitenStructural steel shapes and propertiesAhmed Ben HmidaNoch keine Bewertungen

- SA Journal of Tech 2016Dokument90 SeitenSA Journal of Tech 2016mack_eausNoch keine Bewertungen

- Thrust BlockDokument3 SeitenThrust BlockAhmed Ben HmidaNoch keine Bewertungen

- AaaaaaaaaaaaaaaaaaaaaaDokument32 SeitenAaaaaaaaaaaaaaaaaaaaaaAhmed Ben HmidaNoch keine Bewertungen

- Geometrical Description: WATER TANK Geometry DEGASSER GeometryDokument1 SeiteGeometrical Description: WATER TANK Geometry DEGASSER GeometryAhmed Ben HmidaNoch keine Bewertungen

- Ferraillage plan de poteaux et dalles béton arméDokument1 SeiteFerraillage plan de poteaux et dalles béton arméAhmed Ben HmidaNoch keine Bewertungen

- EPD Mineral Wool Panel PRMDokument7 SeitenEPD Mineral Wool Panel PRMAhmed Ben HmidaNoch keine Bewertungen

- Aciers Mottard 1 6 PDFDokument2 SeitenAciers Mottard 1 6 PDFAhmed Ben HmidaNoch keine Bewertungen

- Hand Calculations 2 Way Flat Plate SlabDokument18 SeitenHand Calculations 2 Way Flat Plate SlabAhmed Ben HmidaNoch keine Bewertungen

- Ferraillage plan de poteaux et dalles béton arméDokument1 SeiteFerraillage plan de poteaux et dalles béton arméAhmed Ben HmidaNoch keine Bewertungen

- Geometric Properties of The Cross-Section Parameter Value: Interval of The Stresses Values: (,) KN/CM 2 - 6,66e+2Dokument2 SeitenGeometric Properties of The Cross-Section Parameter Value: Interval of The Stresses Values: (,) KN/CM 2 - 6,66e+2Ahmed Ben HmidaNoch keine Bewertungen

- Sustainability at HDRDokument4 SeitenSustainability at HDRAhmed Ben HmidaNoch keine Bewertungen

- Structural Enterprise Infographic 0417Dokument1 SeiteStructural Enterprise Infographic 0417Ahmed Ben HmidaNoch keine Bewertungen

- TrnsLine PDFDokument495 SeitenTrnsLine PDFMomayKradookkradicNoch keine Bewertungen

- Isolated Footing Design (ACI 318-11) : ElevationDokument12 SeitenIsolated Footing Design (ACI 318-11) : ElevationAhmed Ben HmidaNoch keine Bewertungen

- Peyrot WindDokument25 SeitenPeyrot WindMuhannad AbdulRaoufNoch keine Bewertungen

- Pole LoadingDokument27 SeitenPole LoadingKho C AhlNoch keine Bewertungen

- Above Ground Pipe Installation With Non-Restrained JointsDokument36 SeitenAbove Ground Pipe Installation With Non-Restrained JointsWerner100% (1)

- Sika Casestudy HighstrengthDokument7 SeitenSika Casestudy HighstrengthAhmed Ben HmidaNoch keine Bewertungen

- FLOWTITE Install GuideDokument72 SeitenFLOWTITE Install GuideRanjit RjtNoch keine Bewertungen

- Price Bid 1513589779Dokument17 SeitenPrice Bid 1513589779Aashish kumarNoch keine Bewertungen

- 6280Dokument13 Seiten6280sanbarunNoch keine Bewertungen

- Spec 500 MT 020514 Godown 500mtDokument16 SeitenSpec 500 MT 020514 Godown 500mtdraqbhattiNoch keine Bewertungen

- AISC structural steel glossaryDokument1 SeiteAISC structural steel glossaryqc_531040655Noch keine Bewertungen

- 143 13 English Catalogue 2014Dokument319 Seiten143 13 English Catalogue 2014Ionut FloricaNoch keine Bewertungen

- A New Demountable Built-Up Steel Structural System: Optimization of Cross Sectional PropertiesDokument6 SeitenA New Demountable Built-Up Steel Structural System: Optimization of Cross Sectional PropertiesIoana KruckeNoch keine Bewertungen

- Steel Sheet, Aluminum-Coated, by The Hot-Dip Process: Standard Specification ForDokument6 SeitenSteel Sheet, Aluminum-Coated, by The Hot-Dip Process: Standard Specification ForYordan Vallentino PutraNoch keine Bewertungen

- RRSDokument21 SeitenRRSHardik ChaudhariNoch keine Bewertungen

- TC VerificationDokument33 SeitenTC VerificationmaheshNoch keine Bewertungen

- Double Bar Self-Closing Safety GateDokument4 SeitenDouble Bar Self-Closing Safety Gatechacha_yousraNoch keine Bewertungen

- Apf Cal Pipe Bridge Rev 2Dokument36 SeitenApf Cal Pipe Bridge Rev 2Edwin RachmanudinNoch keine Bewertungen

- Vvol II 2017 Rules For Hull2017 32 209Dokument178 SeitenVvol II 2017 Rules For Hull2017 32 209engineering jrNoch keine Bewertungen

- Firestone Air Spring W02-358-3004Dokument29 SeitenFirestone Air Spring W02-358-3004MROstop.com100% (1)

- Intro to TOS-I: Struct Engg History & FormsDokument54 SeitenIntro to TOS-I: Struct Engg History & FormsEdosa Efe BishopNoch keine Bewertungen

- Part II - 07 Steel ErectionDokument10 SeitenPart II - 07 Steel Erectionsalah abddayemNoch keine Bewertungen

- DormaDokument84 SeitenDormaJuraj JuravićNoch keine Bewertungen

- Session 1 Fundamental Concepts Part 1Dokument24 SeitenSession 1 Fundamental Concepts Part 1Ryan KuntzNoch keine Bewertungen

- Section 7 - Structural SteelDokument31 SeitenSection 7 - Structural SteeltunlajiNoch keine Bewertungen

- Presentation Explosive Welding (Ew)Dokument12 SeitenPresentation Explosive Welding (Ew)dnatarajanNoch keine Bewertungen

- Cantilever Racks SolutionDokument8 SeitenCantilever Racks SolutionDaniel SevillaNoch keine Bewertungen

- ASTMDokument6 SeitenASTMcarmin79100% (2)

- Ampp Nace Code Estructural CoatingDokument12 SeitenAmpp Nace Code Estructural CoatingJavier Enrique Diaz ChacinNoch keine Bewertungen

- Plates & Coils - Jindal Steel & Power LTDDokument12 SeitenPlates & Coils - Jindal Steel & Power LTDjindalsteelsNoch keine Bewertungen