Beruflich Dokumente

Kultur Dokumente

Labram Ii H: Innovative Mixing Solutions

Hochgeladen von

Sanjay GadeOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Labram Ii H: Innovative Mixing Solutions

Hochgeladen von

Sanjay GadeCopyright:

Verfügbare Formate

Innovative Mixing Solutions

LabRAM IIH

Second Generation Mixing

Technology of Choice for

Energetics Mixing

The industry standard in

hazardous and energetic

development and processing

Class I Div I Class II Div I

Vacuum System

FLARES

Jacketed

Vessel

Remote

Operation

Resodyn Acoustic Mixers hazardous location

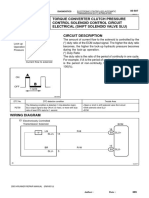

LabRAM II H is specifically designed for mixing

development mixer, the

energetic materials. The LabRAM

II H introduces significant benefits to government and defense customers who rely on ResonantAcoustic

Mixers technology for high quality and low-cost mixing of hazardous materials.

Mixing and Processing Technology of Choice

Since its introduction to the energetics marketplace in 2007, ResonantAcoustic Mixers have become the

processing technology of choice at many government and commercial facilities. The technology allows users

to employ intense, low-frequency acoustic mixing at up to 100gs of acceleration, without the several inherent

issues associated with the use of conventional mixing. The advanced design features incorporated into the

LabRAM II H reflect design and operational considerations provided to Resodyn by the energetics

community over the past several years.

Integrated Component Design

The fully integrated LabRAM II H system brings all electronic, power, and control hardware onboard,

eliminating the need for a separate cabinet. The LabRAM II H is fully functional with or without the

PROPELLANTS

optional acoustic housing depicted above, right. All enclosure and housing materials are 304L stainless steel.

Innovative New Features and Options

The LabRAM II H responds robustly to energetic users dynamic and demanding requirements:

MUNITIONS

2.2 Pounds/1,000 gram Capacity.

Rated Class I Division I and Class II Division I.

Jacketed Vessel provides mixing vessel temperature control from 302F heating to 34F cooling (optional).

Temperature sensor - 316L resistance temperature detectors (RTDs) with m12 connector (optional).

Automatic/programmable Mix Vacuum for application at any juncture of the processing/mixing cycle

(optional).

Remote control panel.

Remote operation up to 2.5 miles.

Onboard programmable control of mixing operations and

permanent recording of operations and measured results.

Sealed, hazardous rated, SS 304 mixing platform prevents

entry of mixing materials into the enclosure.

130 North Main Street, Suite 630

Laptop based human machine interface.

Butte, MT USA 59701 (406) 497-5333

Redundant ground paths mitigate static charge build-up.

info@ResodynMixers.com

www.ResodynMixers.com

Innovative Mixing Solutions

Introducing

LabRAM II H

Second Generation Mixing

Technology of Choice for

Energetics Mixing

Comparison between LabRAM and LabRAM II H Specifications

Item

1

2

FLARES

Description

Maximum Payload Capacity

Enclosure Material

3

4

5

6

7

8

9

Sealed Enclosure

Sound Emitted

Purged Enclosure

Enclosure Ground

Resonator Grounded

Payload Fixture Grounded

Vessel Temperature Monitoring

10

11

12

13

14

15

Automatic/Programmable Vacuum

Data Logging

Remote Operation

Class I Div 1 Ratable

Class II Div 1 Ratable

Recommended for use in Hazardous

environment

Onboard Programmable Control

and Recording

Weight

Dimensions (Resonator)

Dimensions (Electrical/Electronic

Control Cabinet)

16

17

18

19

LabRAM

LabRAM II H

1.1 lbs.

Stainless Steel, Powder

Coated steel, and Anodized

Aluminum

No

<80 dB at 3

No

Yes

No

No

2 thermocouples monitored external to LabRAM

No

Noi

Yesi

No

No

No

2.2 lbs.

304L Stainless Steel

No

Yes

170 lbs.iii

16" W, 23.5" D, 26.5" Hii

7.5" W, 23.5" D, 16" H

310 lbs.v

32" W, 30" D, 13" Hiv

Not Required unit

self-contained

Yes

<80 dB at 3

Yes

Yes

Yes

Yes

3 RTD's monitored

and recorded

Yes

Yes

Yes

Yes

Yes

Yes

Yes with RAMware2

With Acoustic Enclosure and Housing

iii

Resonator and Control Box

iv

32" High with Acoustic Housing

v

355 lbs with the Acoustic Housing

ii

PROPELLANTS

Processing Technology of Choice

for Energetics Developers

and Manufacturers

MUNITIONS

130 North Main Street, Suite 630

Butte, MT USA 59701

(406) 497-5333

info@ResodynMixers.com

www.ResodynMixers.com

LR2H 041816

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- HT Fluid SelectionDokument4 SeitenHT Fluid SelectionSanjay GadeNoch keine Bewertungen

- PWC Pharma Success StrategiesDokument56 SeitenPWC Pharma Success StrategiesSanjay Gade100% (1)

- CLEAN ROOM PresentationDokument54 SeitenCLEAN ROOM PresentationSanjay Gade100% (1)

- Role of Process Engineering Function In: Process Development & Scale-UpDokument8 SeitenRole of Process Engineering Function In: Process Development & Scale-UpSanjay GadeNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Tadano Aml m1 m2 TR Mkii Connection InstructionsDokument5 SeitenTadano Aml m1 m2 TR Mkii Connection Instructionsej ejaz0% (1)

- HEPHIS MZD MDD Series Frequency Conversion Mechanical Diaphragm Metering Pump DATA SHEETDokument14 SeitenHEPHIS MZD MDD Series Frequency Conversion Mechanical Diaphragm Metering Pump DATA SHEETDNoch keine Bewertungen

- DC Shunt Motors - Characteristics, Electric BrakingDokument5 SeitenDC Shunt Motors - Characteristics, Electric BrakingramonlinebooksNoch keine Bewertungen

- Energies: Harmonic Mitigation Using Passive Harmonic Filters: Case Study in A Steel Mill Power SystemDokument16 SeitenEnergies: Harmonic Mitigation Using Passive Harmonic Filters: Case Study in A Steel Mill Power SystemNelson ParijósNoch keine Bewertungen

- GE Ultrasound Parts New Original Imaging AssemblyDokument5 SeitenGE Ultrasound Parts New Original Imaging Assemblydeng mayNoch keine Bewertungen

- NEET UG 2022 Question Paper Solutions by Aakash Code T5 PDFDokument74 SeitenNEET UG 2022 Question Paper Solutions by Aakash Code T5 PDFANGELINE MaduNoch keine Bewertungen

- Ex29007-Pdf BDDokument155 SeitenEx29007-Pdf BDsereptNoch keine Bewertungen

- Scope of WorkDokument28 SeitenScope of WorkShuhan Mohammad Ariful HoqueNoch keine Bewertungen

- Parker GVM 310Dokument16 SeitenParker GVM 310namanbhatia505Noch keine Bewertungen

- Nortel OutdoorDokument7 SeitenNortel OutdoorMarius TrancaNoch keine Bewertungen

- W116-Vacuum-Climate - PNG (PNG Image, 600 × 776 Pixels) - Scaled (84%)Dokument24 SeitenW116-Vacuum-Climate - PNG (PNG Image, 600 × 776 Pixels) - Scaled (84%)Vinco RudiNoch keine Bewertungen

- Internet of Things For Industrial Monitoring and Control Applications PDFDokument5 SeitenInternet of Things For Industrial Monitoring and Control Applications PDFKrishna ReddyNoch keine Bewertungen

- Assignment No. 1Dokument1 SeiteAssignment No. 1Sharjeel AhmadNoch keine Bewertungen

- AD783697 - Military ElectricalsDokument597 SeitenAD783697 - Military ElectricalsVigneshVickeyNoch keine Bewertungen

- SK Telecom DASDokument2 SeitenSK Telecom DASJ.R. ArmeaNoch keine Bewertungen

- High PassDokument2 SeitenHigh PassMamoon BarbhuyanNoch keine Bewertungen

- Raptor Application NotesDokument3 SeitenRaptor Application NotesPaul MazziottaNoch keine Bewertungen

- XPIC System and XPD TestDokument2 SeitenXPIC System and XPD TestDoyi100% (9)

- Panasonic Sa-Akx38ph Sa-Akx38pnDokument70 SeitenPanasonic Sa-Akx38ph Sa-Akx38pnAndrewer100% (1)

- DTC P2759: Torque Converter Clutch Pressure Control Solenoid Control Circuit Electrical (Shift Solenoid Valve Slu)Dokument3 SeitenDTC P2759: Torque Converter Clutch Pressure Control Solenoid Control Circuit Electrical (Shift Solenoid Valve Slu)luisNoch keine Bewertungen

- Av02 2516enDokument13 SeitenAv02 2516enpagol_23_smhNoch keine Bewertungen

- Live BookDokument360 SeitenLive BookfilipeNoch keine Bewertungen

- Medium Power TransformersDokument2 SeitenMedium Power TransformersjosepablohgNoch keine Bewertungen

- Spare Parts Cataloge Focal FN72-20 Retarder OC443057aDokument5 SeitenSpare Parts Cataloge Focal FN72-20 Retarder OC443057aOdim41Noch keine Bewertungen

- D48398 - E PowerWizard Options 4006-4016TAGDokument1 SeiteD48398 - E PowerWizard Options 4006-4016TAGTTIBCCANoch keine Bewertungen

- Rental AgreementDokument2 SeitenRental AgreementVillar MitchiNoch keine Bewertungen

- 2 P&ID PressDokument24 Seiten2 P&ID Presstes2004Noch keine Bewertungen

- Arrestors Default DetectorDokument3 SeitenArrestors Default Detectoragust1988Noch keine Bewertungen

- Ditek'S Dtk-Tss1: Technical SpecificationsDokument1 SeiteDitek'S Dtk-Tss1: Technical SpecificationsCr1234512Noch keine Bewertungen

- Assign IvpDokument6 SeitenAssign IvpRajesh PatilNoch keine Bewertungen