Beruflich Dokumente

Kultur Dokumente

Manual Paso A Paso Click & GO

Hochgeladen von

Jorge Antonio Lu AntaraOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Manual Paso A Paso Click & GO

Hochgeladen von

Jorge Antonio Lu AntaraCopyright:

Verfügbare Formate

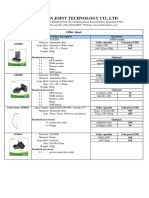

An Ideal Solution for Remote

Monitoring and Alarm Systems

1. Package list

2. Connecting power

3. Connecting to a network

I. If connected correctly, the PWR light should be red and the RDY light should be green.

I.

Connect dashed wire to V+

Connect black wire to V-

Default IP 192.168.127.254

ioLogik E2212

Power

Adaptor

Power Jack

Evaluation Board

CD

Straight or crossover cable

Quick Start

Guide

II. Insert two AAA batteries into the E2212EVB battery holders.

II.

7. Search ioLogik

- ioLogik introduction

video

- Configuration

sample

- Configuration guide

book

- Brochure

- Success stories

- Datasheet

ioLogik E2212 EVB Quick Start Guide

4. Setting the IP address

5. Software installation

6. Open ioAdmin

Go to Start Control Panel Internet Connection Local Area Connection

Properties Internet Protocol (TCP/IP)

Run the CD. Click on Install ioAdmin and follow the wizard to finish installation.

Run ioAdmin by going to Start Program Files Moxa IO Server Utility ioAdmin

Press Start Search to locate ioLogik

Enter IP address and Subent mask accordingly

and press OK when ready

Run ioAdmin to start ioLogik configuration

Click Install ioAdmin

Set IP address as 192.168.127.1

Subnet mask as 255.255.255.0

8. Log in

9. Load test configuration sample. Ignore the warning

signal and click Yes.

10. Initial test

I. Turn on the toggle switches on the evaluation board one at a time to see if each DI triggers

a corresponding DO to light up the LEDs.

Click Right and Choose Import System Config

Go to Server Settings and Login

Toggle switch

IF

DI_0

DI_1 OFF to ON

DI_2

Find directory: CD ROM:\test_sample/E2212EVB_test.txt open file ignore the warning

message restart ioLogik

LED

THEN

DO_0

DO_1 OFF to ON

DO_2

II. Press on push buttons on the evaluation board one at a time to see if each DI triggers a

corresponding DO to light up the LEDs.

Find right directory and press Open

For more information:

www.moxa.com/io

For product questions contact:

io@moxa.com

Push

Push button

IF

DI_3

DI_4 OFF to ON

DI_5

LED

THEN

DO_3

DO_4 OFF to ON

DO_5

2009 Moxa Inc. All rights reserved.

The MOXA logo is a registered trademark of Moxa Inc.

All other logos appearing in this document are the intellectual property of

the respective company, product, or organization associated with the logo.

Experience the Easiness of Click&Go!

How to set up DI to DO control logics

1. Follow steps 6 to 8 on the

front page to open ioAdmin.

Search and log in to start

configuration.

2. Go to Click&Go Logic and enable control logic #0

3. To set up a control logic that turns ON DO_0 when DI_0 is ON and turns it off when DI_0 is OFF, we use the following logic setting to finish the configuration.

IF

THEN

ELSE

DI_0 ON DO_0 ON DO_0 OFF

Step 1: Select DO

Step 1: Click on Click & Go Logic

Go to Server Settings and Login

Step 1: Select DI

Step 2: Double click

on logic setup line

Step 2: Click on Global icon

Step 2: Click on Global icon

Step 2: Click on Global icon

Step 3: Select DO-0

Step 3: Select DO-0

Step 3: Select DI-0

Step 3: Enable control logic

Step 1: Select DO

Step 4: Select OFF

Step 4: Select ON

Step 4: Select ON

Step 5: Press OK

Step 5: Press OK

4. Check control logic

The control logic should read exactly the same as shown.

5. Download configuration file

6. Enable logic

Step 6: Press OK

Step 5: Press OK

7. Test Run

Flip the toggle switch DI_0 to ON position LED DO_0 turns ON

Flip the toggle switch DI_0 to OFF position LED DO_0 turns OFF

Step 2: Restart System

Step 1: Click Run

Step 1: Click Download

Advanced settings:

DI_0 ON

Control logic configuration:

System diagram:

Before getting start, reset the device to default by pressing and hold the

reset button for 5 seconds.

Construct an automatic water pumping system in 10 mins

DI_0 OFF

DO_0 ON

DO_0 OFF

Set channel alias names as below:

2. Log into ioAdmin and set channel alias names

1. Run the CD and install AOPC Server

SCADA

I/O tag update

Application scenario:

Step 1: Go to I/O Configuration

OPC Server

Step 3: Click on Alias Name

ioLogik E2212

1. If water level drops to low, then start pumping water

2. If water level reaches high, then stop pumping water

3. If it is 9pm and water does not reach high, then start pumping. If not,

stop pumping

4. The ioLogik updates I/O tag to Active OPC Server

Step 4: Change Name to High Float

Step 2: Double Click on (DI) : 00

Click Install Active OPC Server

Pump

If High level contact ON, Then pump stop pumping

Benefits:

If Low level contact ON, Then pump start pumping

1. Pump water tank full when electricity is cheaper at night

2. To save electricity and costs, pump the water during the day only when it

is necessary

Water Tube

Step 5: Click Apply

Water Storage Tank

IF

Digital Inputs

THEN

Digital Outputs

3. How to set the control logic to turn the pump ON during night time to save electricity

IF

THEN

Schedule at 2100 everyday and high flow is OFF (tank is not full)

Pump turns ON

Step 1: Select Schedule

Step 2: Click on Global icon

Step 3: Set Time Range

from 21:00 to 00:00

4. How to set the control logic to turn the pump ON when the water drops to low during day time

IF

THEN

High low float is ON (water level too low)

Pump turns ON

Set the second IF condition

Step 1: Select DI

Set the THEN condition to start pump

Step 2: Click on Global icon

Step 1: Select DO

Enable control logic #1 and set IF logic

Step 2: Click on Global icon

Step 1: Select DI

Step 1: Select DO

Step 2: Click on Global icon

Step 2: Click on Global icon

Step 3: Select Low Float-1

Step 3: Select High Float-0

Step 3: Select Pump-0

Step 3: Select Pump-0

Step 4: Set Recurrence Everyday

Step 5: Press OK

Step 4: Select ON

Step 4: Select ON

Step 4: Select OFF

Step 4: Select ON

Step 5: Press OK

Step 5: Press OK

Step 5: Press OK

Step 5: Press OK

Go to Click&Go Logic and enable control logic #0

Set the schedule

Set the THEN condition to start the pump

5. How to set the control logic to turn the pump OFF when the water is full

IF

THEN

High float contact is ON

Pump turns OFF

6. Check the control logic, restart system, and click Run

The control logic should read exactly the same as shown.

7. Data acquisition through Active OPC Server

Set up the Active OPC Server IP address and restart the system

Step 1: Go to Active Tags

Enable control logic #2 and set IF condition

Step 1: Select DI

Set the THEN condition to shut down pump

Step 2: Click on Global icon

Step 3: Select High Float-0

Step 4: Select ON

Step 1: Select DO

Step 3: Set Server IP

at 192.168.127.1

Step 2: Click on Global icon

Checkmark the I/O channels that update to Active OPC Server

Step 1: Check on CH00 and CH01

Step 3: Click Create Tags

Step 4: Click OK

Step 3: Select Pump-0

Step 2: Check on CH00

Step 4: Select OFF

Step 2: Click on Global icon

Step 5: Press OK

8. Test run

I. Go to Start Program Files MOXA I/O Server Active OPC

Active OPC

Step 5: Press OK

II. In Active OPC Server, you should see the I/O status being updated

automatically

III. When time reaches 2100 pm DI_0 turns ON

2100 PM

Flip the toggle switches to see if the values change.

DO_0 ON

(Pump ON)

IV. When DO_0 is ON DI_0 turns ON DO_0 turns OFF

DO_0 ON

(Pump ON)

DI_0 ON

(High Float ON

Water Full)

V. When DI_1 turns ON DO_0 turns ON

DO_0 OFF

(Pump OFF)

DI_1 ON

(Low Float oN

Water Low)

DO_0 ON

(Pump ON)

For more information, please go to www.moxa.com/io

Das könnte Ihnen auch gefallen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Creative WritingDokument2 SeitenCreative WritingSharmaine AsoyNoch keine Bewertungen

- Finimpianti Power EngDokument2 SeitenFinimpianti Power EngJosip GrlicaNoch keine Bewertungen

- God in The Quran A Metaphysical StudyDokument133 SeitenGod in The Quran A Metaphysical StudyFaisal Ali Haider LahotiNoch keine Bewertungen

- Atpl Formula MergedDokument74 SeitenAtpl Formula Mergeddsw78jm2mxNoch keine Bewertungen

- An Overview On Recognition of State in International LawDokument17 SeitenAn Overview On Recognition of State in International LawRamanah VNoch keine Bewertungen

- HIBAH PKSM Sps 2021Dokument9 SeitenHIBAH PKSM Sps 2021Gargazi Bin HamidNoch keine Bewertungen

- Basf Masteremaco Application GuideDokument15 SeitenBasf Masteremaco Application GuideSolomon AhimbisibweNoch keine Bewertungen

- EN6VC IIIa 6.2 - 2023 2024Dokument2 SeitenEN6VC IIIa 6.2 - 2023 2024Ma. Feliza SaliganNoch keine Bewertungen

- Development Drop - Number - Peformance - For - EstimateDokument11 SeitenDevelopment Drop - Number - Peformance - For - Estimateanon_459056029Noch keine Bewertungen

- An Introduction To Muscle Response Testing MRTDokument14 SeitenAn Introduction To Muscle Response Testing MRTJuan Aguilar HernándezNoch keine Bewertungen

- Marginal Field Development Concepts (Compatibility Mode)Dokument17 SeitenMarginal Field Development Concepts (Compatibility Mode)nallay1705100% (1)

- Methanol Technical Data Sheet FactsDokument1 SeiteMethanol Technical Data Sheet FactsmkgmotleyNoch keine Bewertungen

- Section 3.4 The Conditional and Related StatementsDokument11 SeitenSection 3.4 The Conditional and Related Statementsmister sparklesNoch keine Bewertungen

- Advances in X-Ray Analysis - Volume 33 - 1989Dokument685 SeitenAdvances in X-Ray Analysis - Volume 33 - 1989CVNoch keine Bewertungen

- Theories of SelfDokument5 SeitenTheories of SelfTd Devi AmmacayangNoch keine Bewertungen

- CM Group Marketing To Gen Z ReportDokument20 SeitenCM Group Marketing To Gen Z Reportroni21Noch keine Bewertungen

- Lesson Plan 2 Sine Rule and Cosine RuleDokument8 SeitenLesson Plan 2 Sine Rule and Cosine Ruleapi-280114661Noch keine Bewertungen

- Drive Test For BeginnerDokument88 SeitenDrive Test For Beginnerahwaz96100% (1)

- 8.9 Basic Maths For Well PlanningDokument9 Seiten8.9 Basic Maths For Well PlanningKhanh Pham MinhNoch keine Bewertungen

- Facts & Figures of Nepalese HydroDokument11 SeitenFacts & Figures of Nepalese Hydromark bingNoch keine Bewertungen

- Toaz - Info Interchange 2 Quiz Units 5 Ampamp 6 Revision Del Intento PRDokument5 SeitenToaz - Info Interchange 2 Quiz Units 5 Ampamp 6 Revision Del Intento PRMarco Antonio Gonzalez CastilloNoch keine Bewertungen

- 3ADW000379R0301 DCS550 Manual e CDokument310 Seiten3ADW000379R0301 DCS550 Manual e CLaura SelvaNoch keine Bewertungen

- Training Needs Analysis (Managing Training & Development)Dokument78 SeitenTraining Needs Analysis (Managing Training & Development)Henrico Impola100% (1)

- The Machine-Room-Less Elevator: Kone E MonospaceDokument8 SeitenThe Machine-Room-Less Elevator: Kone E MonospaceAbdelmuneimNoch keine Bewertungen

- Delhi University SEC Exam Date Sheet March 2023Dokument2 SeitenDelhi University SEC Exam Date Sheet March 2023aamir9ali-42Noch keine Bewertungen

- Vehicle Tracker Offer SheetDokument1 SeiteVehicle Tracker Offer SheetBihun PandaNoch keine Bewertungen

- Check List of MossesDokument319 SeitenCheck List of MossesAshen NirodyaNoch keine Bewertungen

- SECURE ROAD BLOCKERS PREVENT VEHICLE ATTACKSDokument2 SeitenSECURE ROAD BLOCKERS PREVENT VEHICLE ATTACKSMuhammad Tahir QamarNoch keine Bewertungen

- LTE Interview QuestionsDokument10 SeitenLTE Interview QuestionsMahesh Pratap100% (1)

- Trends in Structural Systems and Innovations for High-Rise Buildings over the Last DecadeDokument53 SeitenTrends in Structural Systems and Innovations for High-Rise Buildings over the Last DecadeNarasimhaReddy PangaNoch keine Bewertungen