Beruflich Dokumente

Kultur Dokumente

GAS Wee?: (19) United States

Hochgeladen von

Thang Cao DaiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

GAS Wee?: (19) United States

Hochgeladen von

Thang Cao DaiCopyright:

Verfügbare Formate

US 20110104624A1

(19) United States

(12) Patent Application Publication (10) Pub. N0.: US 2011/0104624 A1

Terushita et al.

(54)

(43) Pub. Date:

METHOD AND APPARATUS OF

(86)

May 5, 2011

PCT No.:

PCT/JP2008/000473

371 (OX1),

(2), (4) Date:

Dec. 3, 2010

CONTROLLING COMBUSTION IN OXYFUEL

COMBUSTION BOILER

(75) Inventors:

Shuuhei Terushita, Tokyo (JP);

Toshihiko Yamada, Tokyo (JP);

Shuzo Watanabe, Tokyo (JP);

Terutoshi Uchida, Tokyo (JP);

Pubhcatlon Classl?catlon

(51) Int- Cl

F23N 3/00

(2006-01)

F22D 5/00

(200601)

Nobuhiro Misawa, Tokyo (JP)

(52)

US. Cl. ...................................... .. 431/12; 122/4481

(57)

(73) Assignees:

A method and an apparatus of controlling combustion in an

oxyfuel combustion boiler are provided Which ensure a suf

IHI CORPORATION, TOKYO

(JP); ELECTRIC POWER

?cient fumace heat absorption through prevention of loWer

ing of ?ame temperature, enabling oxyfuel combustion

DEVELOPMENT CO., LTD.,

TOKYO (JP)

(21) App1.No.:

ABSTRACT

operations to be performed in a stable manner. A boiler

brought-in oxygen density Which is an oxygen density for a

total amount of gases introduced into a coal burning boiler is

12/920,843

calculated and a How rate of total recirculating gases is con

trolled such that the boiler-brought-in oxygen density falls

(22) PcT Filed:

Mar. 6,2008

Within a predetermined range.

ml _____ __

29

21

_ ._ l

28

11

m

6

SECONDARY

RECIRCULATING

EXHAUST

GAS

wee?

l

__________ _ _ l_

PRIMARY RECIRCULATING EXHAUST GAS 2 7G i

L ________________ _ _

_ _ -J

'

19

Patent Application Publication

May 5, 2011 Sheet 2 of4

US 2011/0104624 A1

F I G. 2

31

OXYGEN

COMBUS'ITON

OPERATION

BOILER-BROUGHT-IN OXYGEN DENSITY WHICH IS

OXYGEN DENSITY FOR TOTAL AMOUNT OF GASES

INTRODUCED INTO COAL BURNING BOILER IS

CALCULATED ON THE BASIS OF 02 DENSITIES AND

FLOW RATES DETECTED BY 0 DENSITY MONITORS

AND FLOWMETERS, RESPECTI ELY.

S2

"

BOI LE R-BROUGHT-IN

OXYG EN DENSITY

S3

I

FLOW RATE OF TOTAL RECIRCULATING

EXHAUST GASES IS REDUCED BY

FLOW RATE REGULATING DAMPER.

L___

84

BOILER-BROUGI-IT-I

OXYGEN DENSITY

>30%?

S5

NO

FLOW RATE OF TOTAL RECIRCULATING

EXHAUST GASES IS INCREASED BY

FLOW RATE REGULATING DAMPER.

I____

STABILIED OXYGEN

COMBUSTION OPERATION

END

Patent Application Publication

May 5, 2011 Sheet 3 0f 4

US 2011/0104624 A1

FIG . 3

0 AIR COMBUSTION

E! OXYGEN COMBUSTION

7O "

RANGE ALLOWABLE

IN FURNACE HEAT

ABSORPTION UPON

AIR COMBUSTION

(%)

FHAUBERSNOPCTI

BOlLER-BROUGHT-IN OXYGEN DENSITY

(WET VOL %)

May 5,2011

US 2011/0104624 A1

METHOD AND APPARATUS OF

CONTROLLING COMBUSTION IN OXYFUEL

COMBUSTION BOILER

TECHNICAL FIELD

[0001]

The present invention relates to a method and an

gas is occupied by carbon dioxide With the remainder occu

pied by other gases containing the fuel NOX and SOX, conse

quently achieving a relatively easy liquefaction and separa

tion of the carbon dioxide through cooling of the combustion

exhaust gas.

[0009]

apparatus of controlling combustion in an oxyfuel combus

[Patent Literature 1] JP 5-231609A

SUMMARY OF INVENTION

tion boiler.

Technical Problems

BACKGROUND ART

[0002] An increased carbon dioxide (CO2) density in the

atmosphere has proved to be one of major factors of global

Warming Which has recently come into attention as a global

scale environmental problem. A thermal poWer plant appears

close-up as a ?xed source of discharging these substances.

Fuel for thermal poWer generation may be oil, natural gas and

coal, among Which coal is especially anticipated to have a

large future demand due to its greater potential reserves.

[0010] In a conventional air-combustion coal burning

boiler, nitrogen is a balance gas for oxygen Which is a major

component gas other than oxygen in the air used for combus

tion of pulveriZed coal Whereas in an oxyfuel combustion

boiler, carbon dioxide and steam become balance gases for

oxygen since they are main component gases other than oxy

gen in the recirculating exhaust gas.

[0011]

Thermal properties, hoWever, differ betWeen nitro

gen and carbon dioxide and steam. Hence, there occurs a

Coal contains a higher percentage of carbon as com

problem that When the oxygen density (boiler-brought-in

pared With natural gas and oil, together With other compo

oxygen density) for a total amount of gases introduced into

the oxyfuel combustion boiler is set to approx. 21% Which is

an oxygen density in the air, the ?ame temperature loWers as

[0003]

nents such as hydrogen, nitrogen and sulfur, and ash as an

inorganic component. Therefore, When coal is burned in the

air, most of the composition of the combustion exhaust gas is

compared With the air combustion, resulting in an insuf?cient

furnace heat absorption.

occupied by nitrogen (about 70%), With the remainder occu

pied by carbon dioxide CO2, sulfur oxide SOX, nitrogen oxide

NOX, dust comprising ash and unburned coal particles, and

[0012] The invention Was made in vieW of the above and

has its object to provide a method and an apparatus of con

oxygen (about 4%). The combustion exhaust gas is thus sub

jected to exhaust gas treatments such as denitration, desulfu

riZation and dedusting so that NOX, SOX and particulates fall

under their respective environmental emission standard val

ing a su?icient furnace heat absorption through prevention of

loWering of ?ame temperature to thereby achieve stabiliZed

ues before the emission to the atmosphere through a stack.

[0004]

NOX occurring in the combustion exhaust gas is

divided into a thermal NOX generated from oxidiZation of

nitrogen in the air by oxygen and a fuel NOX generated as a

result of oxidiZation of nitrogen in the fuel. Up until noW, a

combustion method of loWering the ?ame temperature has

been employed for reduction of the thermal NOX Whereas

another combustion method of forming a fuel-excess region

for deoxidiZing NOX Within a burner has been employed for

reduction of the fuel NOX.

[0005] In case of using a fuel containing sulfur such as coal,

a Wet or dry desulfuriZing device has been provided to remove

SOXoccurring in the combustion exhaust gas as a result of the

combustion.

[0006] It is desired on the other hand that a large amount of

carbon dioxide generated in the combustion exhaust gas be

also separated and removed With high e?iciency. A possible

method of capturing carbon dioxide in the combustion

exhaust gas has hitherto been revieWed Which includes a

method of causing an amine or other absorbing liquid to

absorb it, an adsorption method of causing a solid adsorbent

to adsorb it or a membrane separation method, all of Which

have a loW conversion e?iciency, thus not yet reaching a

practical use level of the CO2 capture from a coal burning

boiler.

[0007] Accordingly, a combustion technology of a fuel

With oxygen instead of air has been proposed as an effective

manner to address at one time both the problem of separation

of carbon dioxide in the combustion exhaust gas and the

trolling combustion in an oxyfuel combustion boiler, ensur

oxyfuel combustion operations.

Solution to Problems

[0013] The invention is directed to a method of controlling

combustion in an oxyfuel combustion boiler Where While

oxygen fed from an air separation unit is introduced into a

coal burning boiler, an exhaust gas in recirculation is intro

duced as primary and secondary recirculating exhaust gases

into a mill and the coal burning boiler, respectively, the pul

veriZed coal pulverized by the mill being transferred by said

primary recirculating exhaust gas to a burner for oxyfuel

combustion With said oxygen and said secondary recirculat

ing exhaust gas, the method comprising

[0014] measuring a boiler-brought-in oxygen density

Which is an oxygen density for a total amount of gases

introduced into the coal burning boiler and

[0015] controlling a ?oW rate of total recirculating

exhaust gases such that the boiler-brought-in oxygen

density falls Within a predetermined range.

[0016] In the method of controlling combustion in the oxy

fuel combustion boiler, preferably, the boiler-brought-in oxy

gen density falls Within a range from 25 to 30%.

[0017] The invention is also directed to an apparatus of

controlling combustion in an oxyfuel combustion boiler

Where While oxygen fed from an air separation unit is intro

duced into a coal burning boiler, an exhaust gas in recircula

tion is introduced as primary and secondary recirculating

exhaust gases into a mill and the coal burning boiler, respec

tively, the pulveriZed coal pulveriZed by the mill being trans

problem of suppression of the thermal NOX (see, for example,

ferred by said primary recirculating exhaust gas to a burner

for oxyfuel combustion With said oxygen and said secondary

Patent Literature 1).

[0008] When coal is burned With oxygen, generation of the

recirculating exhaust gas, the apparatus comprising

[0018] an O2 density monitor for sensing an O2 density of

thermal NOXis not seen and most of the combustion exhaust

oxygen to be introduced into the coal burning boiler,

May 5,2011

US 2011/0104624 A1

[0019]

a ?oWmeter for sensing a How rate of oxygen to be

tion, there can be obtained an excellent effect of ensuring a

introduced into the coal burning boiler,

[0020] an O2 density monitor for sensing an O2 density of

the primary recirculating exhaust gas to be introduced

into the mill,

suf?cient fumace heat absorption through prevention of loW

ering of ?ame temperature to thereby achieve stabiliZed oxy

fuel combustion operations.

[0021] a ?oWmeter for sensing a How rate of the primary

recirculating exhaust gas to be introduced into the mill,

BRIEF DESCRIPTION OF DRAWINGS

[0022] an O2 density monitor for sensing an O2 density of

the secondary recirculating exhaust gas to be introduced

into the coal burning boiler,

[0023] a ?oWmeter for sensing a How rate of the second

ary recirculating exhaust gas to be introduced into the

coal burning boiler,

[0024] a How rate regulator for regulating a How rate of

total recirculating exhaust gases to be introduced into

the mill and the coal burning boiler and

[0025] a controller for calculating a boiler-brought-in

oxygen density Which is an oxygen density for a total

amount of gases introduced into the coal burning boiler

on the basis of the O2 densities sensed by the respective

O2 density monitors and the How rates sensed by the

respective ?oWmeters, the controller outputting a How

rate control signal to the How rate regulator such that the

boiler-brought-in oxygen density falls Within a predeter

mined range.

[0026] The invention is further directed to an apparatus of

controlling combustion in an oxyfuel combustion boiler

Where While oxygen fed from an air separation unit is intro

duced into a coal burning boiler, an exhaust gas in recircula

tion is introduced as primary and secondary recirculating

exhaust gases into a mill and the coal burning boiler, respec

tively, the pulveriZed coal pulveriZed by the mill being trans

ferred by said primary recirculating exhaust gas to a burner

for oxyfuel combustion With said oxygen and said secondary

recirculating exhaust gas, the apparatus comprising

[0027] an O2 density monitor for sensing an O2 density of

oxygen to be introduced into the coal burning boiler,

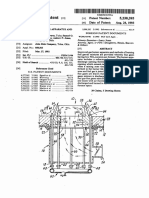

[0035]

FIG. 1 is a general schematic con?guration diagram

of an embodiment of the invention;

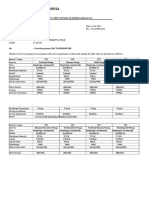

[0036] FIG. 2 is a ?owchart of a How of control in the

embodiment of the invention;

[0037] FIG. 3 is a graph representing a relationship

betWeen boiler-brought-in oxygen density and furnace heat

absorption in a boiler; and

[0038] FIG. 4 is a general schematic con?guration diagram

of a further embodiment of the invention.

REFERENCE SIGNS LIST

[0039]

[0040]

[0041]

[0042]

[0043]

[0044]

[0045]

1 coal bunker

2 coal feeder

3 mill

4 coal burning boiler

5 Wind box

6 burner

7 exhaust gas line

[0046]

[0047]

8 air preheater

10 air separation unit

[0048]

11 forced draft fan

[0049]

[0050]

[0051]

[0052]

12 primary recirculating exhaust gas line

13 cold bypass line

16 secondary recirculating exhaust gas line

17 oxygen feed line for secondary recirculating

exhaust gas

[0053] 18 oxygen feed line for Wind box

[0054] 20 induced draft fan

[0055] 22 O2 density monitor

[0056] 22a O2 density

a ?oWmeter for sensing a How rate of oxygen to be

[0057]

23 ?oWmeter

introduced into the coal burning boiler,

[0029] an O2 density monitor for sensing an O2 density of

[0058]

23a ?oW rate

[0028]

total recirculating exhaust gases to be introduced into

the mill and the coal burning boiler,

[0030] a ?oWmeter for sensing a How rate of total recir

culating exhaust gases to be introduced into the mill and

the coal burning boiler,

[0031] a How rate regulator for regulating a How rate of

the total recirculating exhaust gases to be introduced

into the mill and the coal burning boiler and

[0032] a controller for calculating a boiler-brought-in

oxygen density Which is an oxygen density for a total

amount of gases introduced into the coal burning boiler

on the basis of the O2 densities sensed by the respective

O2 density monitors and the How rates sensed by the

respective ?oWmeters, the controller outputting a How

[0059] 24 O2 density monitor

[0060] 24a O2 density

[0061]

25 ?oWmeter

[0062]

25a ?oW rate

[0063] 26 O2 density monitor

[0064] 26a O2 density

[0065]

27 ?oWmeter

[0066]

27a ?oW rate

[0067]

[0068]

[0069]

28 recirculating exhaust gas line

29 How rate regulating damper (?oW rate regulator)

29a opening degree control signal (?oW rate control

signal)

[0070]

30 controller

[0071] 31 O2 density monitor

[0072] 31a O2 density

rate control signal to the How rate regulator such that the

[0073]

32 ?oWmeter

boiler-brought-in oxygen density falls Within a predeter

[0074]

32a ?oW rate

mined range.

[0075] 33 O2 density monitor

[0076] 33a O2 density

[0033]

In the apparatus for controlling combustion in the

oxyfuel combustion boiler, preferably, the boiler-brought-in

[0077]

34 ?oWmeter

oxygen density falls Within a range from 25 to 30%.

[0078]

34a ?oW rate

ADVANTAGEOUS EFFECTS OF INVENTION

DESCRIPTION OF EMBODIMENTS

[0034] According to a method and an apparatus of control

ling combustion in an oxyfuel combustion boiler of the inven

[0079] Embodiments of the invention Will be described

With reference to the accompanying draWings.

May 5,2011

US 2011/0104624 A1

[0080] Referring to FIGS. 1 to 3 showing an embodiment of

the invention, reference numeral 1 denotes a coal bunker for

coal storage; 2, a coal feeder for feeding coal stored in the

bunker 1; 3, a mill for pulveriZation and drying of the coal

from the feeder 2; 4, a coal burning boiler; 5, a Wind box ?tted

to the boiler 4; 6, a burner disposed in the Wind box 5 for

burning pulverized coal from the mill 3; 7, an exhaust gas line

through Which ?oWs an exhaust gas emitted from the boiler 4;

8, an air preheater for heat exchange of the exhaust gas ?oW

ing through the exhaust gas line 7 With primary and secondary

recirculating exhaust gases; 9, exhaust gas treating devices

such as a desulfuriZer and a dust collector for treatment of the

exhaust gas passing through the air preheater 8; 10, an air

separation unit for production of oxygen; 11, a forced draft

fan (FDF) for forcedly sending the exhaust gas puri?ed by the

treating devices 9 as primary and secondary recirculating

exhaust gases; 12, a primary recirculating exhaust gas line for

leading a part of the exhaust gas forcedly sent by the forced

draft fan 11 to the mill 3 as the primary recirculating exhaust

gas through the air preheater 8 for preheating; 13, a cold

bypass line alloWing a part of the primary recirculating

exhaust gas to be led to the mill 3 to bypass the air preheater

8 to thereby control the temperature of the primary recircu

lating exhaust gas; 14, a How rate regulating damper incor

porated in the primary recirculating exhaust gas line 12 for

regulating a How rate of the primary recirculating exhaust gas

passing through the air preheater 8; 15, a How rate regulating

damper incorporated in the cold bypass line 13 for regulating

a How rate of the primary recirculating exhaust gas bypassing

the air preheater 8; 16, a secondary recirculating exhaust gas

line for leading a part of the exhaust gas forcedly sent by the

forced draft fan 11 to the Wind box 5 as the secondary recir

culating exhaust gas through the air preheater 8 for preheat

ing; 17, an oxygen feed line for the secondary recirculating

exhaust gas Which feeds the secondary recirculating exhaust

gas line 16 With oxygen from the air separation unit 10; 18, an

oxygen feed line for the Wind box Which directly feeds the

Wind box 5 With oxygen from the air separation unit 10; 19, a

capture device for capturing CO2 etc. from the exhaust gas;

20, an induced draft fan (IDF) disposed doWnstream of the

exhaust gas treating devices 9 for inducedly sucking doWn the

exhaust gas; and 21, a stack for emission to the atmosphere of

the exhaust gas puri?ed by the exhaust gas treating devices 9

and induced by the induced draft fan 20.

[0081] Incorporated in the oxygen feed line 18 for the Wind

box are an O2 density monitor 22 and a ?oWmeter 23 for

measuring, respectively, an O2 density 22a and a How rate 23a

of oxygen to be directly fed to the Wind box 5 of the coal

burning boiler 4.

[0082] Incorporated in the primary recirculating exhaust

gas line 12 at an inlet of the mill 3 are an O2 density monitor

24 and a ?oWmeter 25 for sensing, respectively, an O2 density

24a and a How rate 25a of the primary recirculating exhaust

gas to be introduced into the mill 3.

[0083] Incorporated in the secondary recirculating exhaust

acting as a How rate regulator for regulating a How rate of total

recirculating exhaust gases to be introduced into the mill 3

and the coal burning boiler 4.

[0085] Further, a controller 30 is disposed for calculating a

boiler-brought-in oxygen density Which is an oxygen density

for a total amount of gases introduced into the coal burning

boiler 4 on the basis of the O2 densities 22a, 24a and 2611

measured by the O2 density monitors 22, 24 and 26, respec

tively, and the How rates 23a, 25a and 2711 measured by the

?oWmeters 23, 25 and 27, respectively, the controller 30

outputting an opening degree control signal 2911 as How rate

control signal to the How rate regulating damper 29 such that

the boiler-brought-in oxygen density falls Within a predeter

mined range. In place of the How rate regulating damper 29,

any other How rate regulator such as a damper may be used to

Which the How rate control signal is outputted from the con

troller 30.

[0086] As shoWn in FIG. 3, the range of the boiler-brought

in oxygen density is preferably from 25 to 30% and is par

ticularly preferably of the order of 27%. This is based on that

the boiler-brought-in oxygen density satisfying the furnace

heat absorption alloWable range is 25 to 30% in the oxyfuel

combustion environment When a furnace heat absorption

alloWable range is de?ned, from operation results in the air

combustion environment, to be of the order of from 49 to 60%

on the basis of the fact that furnace heat absorption of the coal

burning boiler 4 becomes of the order of 52% in the case of the

air oxygen density of 21%.

[0087]

Operations in the above illustrated embodiment Will

be described.

[0088]

In the normal operation of the coal burning boiler 4

as set forth hereinabove, the coal stored in the coal bunker 1 is

fed by the coal feeder 2 to the mill 3 Where coal is pulveriZed

into pulveriZed coal.A part of the exhaust gas forcedly sent by

the forced draft fan 11 from the recirculating exhaust gas line

28 is led as primary recirculating exhaust gas through the

primary recirculating exhaust gas line 12 into the mill 3 via

the air preheater 8 for preheating; the primary recirculating

exhaust gas dries the coal fed to the mill 3 and transfers the

pulverized coal produced by the mill 3 to the burner 6.

Another part of the exhaust gas forcedly sent by the forced

draft fan 11 from the recirculating exhaust gas line 28 is led as

secondary recirculating exhaust gas through the secondary

recirculating exhaust gas line 16, via the air preheater 8 for

preheating, into the Wind box 5 of the coal burning boiler 4 to

Which oxygen produced by the air separation unit 10 is

directly fed through the oxygen feed line 18 for Wind box, so

that the pulveriZed coal is subjected to oxyfuel combustion

Within the coal burning boiler 4.

[0089] At the start-up of the coal burning boiler 4, air (not

shoWn) in lieu of the primary recirculating exhaust gas is

introduced into the mill 3 so that the air dries coal fed to the

mill 3 and transfers pulveriZed coal obtained therein to the

burner 6. Air (not shoWn) instead of the secondary recirculat

branch points to the primary and secondary recirculating

ing exhaust gas and oxygen is fed to the Wind box 5 of the coal

burning boiler 4 so that the pulveriZed coal undergoes air

combustion Within the coal burning boiler 4. When the heat

absorption of the coal burning boiler 4 reaches a predeter

mined value, the air is sWitched to the primary recirculating

exhaust gas, the secondary recirculating exhaust gas and oxy

gen for shifting to oxyfuel combustion.

[0090] An exhaust gas from the coal burning boiler 4 is

introduced through the exhaust gas line 7 into the air pre

exhaust gas lines 12 and 16 is a How rate regulating damper 29

heater 8 Where the primary and secondary recirculating

gas line 16 are an O2 density monitor 26 and a ?oWmeter 27

for sensing, respectively, an O2 density 26a and a How rate

27a of the secondary recirculating exhaust gas fed With oxy

gen from the oxygen feed line 17 for secondary recirculating

exhaust gas.

[0084]

Incorporated in the a recirculating exhaust gas line

28 on an outlet side of the forced draft fan 11 and upstream of

May 5,2011

US 2011/0104624 A1

exhaust gases are heated and subjected to heat recovery. The

exhaust gas passing through the air preheater 8 goes to the

exhaust gas treating devices 9 such as a desulfuriZer and a dust

collector for desulfuriZation and dust collection, With the

result that the exhaust gas puri?ed by the exhaust gas treating

devices 9 is inducedly sucked by the induced draft fan 20

before the emission through the stack 21 to the atmosphere.

The exhaust gas passing through the exhaust gas treating

devices 9 is partly recirculated by the forced draft fan 11 and

partly introduced into the capture device 19 for the capture of

[0094] The su?icient fumace heat absorption is thus

obtained through prevention of loWering of the ?ame tem

perature, enabling the oxyfuel combustion operations to be

performed in a stable manner.

[0095] FIG. 4 shoWs a further embodiment of the invention

Where parts similar to those in FIG. 1 are represented by the

same reference numerals. The further embodiment is similar

in fundamental con?guration to that in FIG. 1 and is charac

teristic, as shoWn in FIG. 4, in that an O2 density monitor 31

and a ?oWmeter 32 for sensing, respectively, an O2 density

CO2, etc. from the exhaust gas.

31a and a How rate 3211 of oxygen to be introduced into the

[0091] In the normal operation of the coal burning boiler 4

of the illustrated embodiment, the O2 density 22a of oxygen

coal burning boiler 4 are incorporated in the oxygen feed line

from the air separation unit 10 upstream of a branch point

betWeen the oxygen feed line 17 for secondary recirculating

exhaust gas and the oxygen feed line 18 for Wind box, incor

to be directly fed to the Wind box 5 of the coal burning boiler

4 is sensed by the O2 density monitor 22; the How rate 23a of

oxygen to be directly fed to the Wind box 5 of the coal burning

boiler 4 is sensed by the ?oWmeter 23; the O2 density 24a of

the primary recirculating exhaust gas to be introduced into the

mill 3 is sensed by the O2 density monitor 24; the How rate 2511

of the primary recirculating exhaust gas to be introduced into

the mill 3 is sensed by the ?oWmeter 25; the O2 density 26a of

the secondary recirculating exhaust gas fed With oxygen from

the oxygen feed line 17 for secondary recirculating exhaust

gas is sensed by the O2 density monitor 26; the How rate 27a

of the secondary recirculating exhaust gas fed With oxygen

from the oxygen feed line 17 for secondary recirculating

exhaust gas is sensed by the ?oWmeter 27; and the boiler

brought-in oxygen density Which is an oxygen density to the

total amount of gases introduced into the coal burning boiler

4 is calculated by the controller 30 on the basis of the O2

densities 22a, 24a and 26a sensed by the O2 density monitors

22, 24 and 26, respectively, and the How rates 23a, 25a and

27a sensed by the ?oWmeters 23, 25 and 27, respectively (see

step S1 of FIG. 2).

[0092] It is then determined Whether the boiler-brought-in

oxygen density is bloW 25% (see step S2 of FIG. 2). If a?ir

mative, i.e., if the boiler-brought-in oxygen density is beloW

25%, then an opening degree of the How rate regulating

damper 29 acting as the How rate regulator is reduced in

response to the opening degree control signal 2911 serving as

How rate control signal outputted from the controller 30 to

thereby reduce a How rate of the total recirculating exhaust

gases ?oWing through the recirculating exhaust gas line 28

(see step S3 of FIG. 2).

[0093] If negative, i.e., if the boiler-brought-in oxygen den

sity is not beloW 25%, then it is determined Whether the

boiler-brought-in oxygen density is over 30% (see step S4 of

FIG. 2). If af?rmative, i.e., if the boiler-brought-in oxygen

density is over 30%, then the opening degree of the How rate

regulating damper 29 acting as How rate regulator is increased

in response to the opening degree control signal 2911 serving

porated in the recirculating exhaust gas line 28 being an O2

density monitor 33, a ?oWmeter 34 and a How rate regulating

damper 29 acting as How rate regulator, respectively, for

sensing an O2 density 33a and a How rate 34a of and for

regulating the How rate of the total recirculating exhaust gases

to be introduced into the mill 3 and the coal burning boiler 4,

a boiler-brought-in oxygen density of oxygen introduced into

the coal burning boiler 4 being calculated in the controller 30

on the basis of the O2 densities 31a and 33a sensed by the O2

density monitors 31 and 33, respectively, and the How rates

3211 and 34a sensed by the ?oWmeters 32 and 34, respectively,

an opening degree control signal 29a as How rate control

signal being outputted to the How rate regulating damper 29

such that the boiler-brought-in oxygen density falls Within a

predetermined range (25 to 30%).

[0096] In the normal operation of the coal burning boiler 4

of this illustrated embodiment, the O2 density 31a and the

How rate 3211 of oxygen introduced into the coal burning

boiler 4 are sensed by the O2 density monitor 31 and the

?oWmeter 32, respectively; the O2 density 33a and the How

rate 34a of the total recirculating exhaust gases to be intro

duced into the mill 3 and the coal burning boiler 4 are sensed

by the O2 density monitor 33 and the ?oWmeter 34, respec

tively. The boiler-brought-in oxygen density of oxygen intro

duced into the coal burning boiler 4 is calculated in the con

troller 30 on the basis of the O2 densities 31a and 33a sensed

by the O2 density monitors 31 and 33, respectively, and the

How rates 3211 and 34a sensed by the ?oWmeters 32 and 34,

respectively (see step S1 of FIG. 2). It is determined Whether

the boiler-brought-in oxygen density is beloW 25% (see step

S2 of FIG. 2); if a?irmative, i.e., if the boiler-brought-in

oxygen density is beloW 25%, the opening degree of the How

rate regulating damper 29 acting as How rate regulator is

reduced in response to the opening degree control signal 2911

serving as How rate control signal outputted from the control

ler 30 to thereby reduce the How rate of the total recirculating

as How rate control signal outputted from the controller 30 to

exhaust gases ?oWing through the recirculating exhaust gas

line 28 (see step S3 of FIG. 2); if negative, i.e., if the boiler

brought-in oxygen density is not beloW 25%, it is determined

thereby increase the How rate of the total recirculating

Whether the boiler-brought-in oxygen density is over 30%

exhaust gases ?oWing through the recirculating exhaust gas

line (see step S5 of FIG. 2). As a result, the boiler-brought-in

(see step S4 of FIG. 2); and if af?rmative, i.e., if the boiler

brought-in oxygen density is over 30%, the opening degree of

the How rate regulating damper 29 acting as How rate regula

oxygen density falls Within a predetermined range (25 to

30%) to prevent the ?ame temperature from loWering, to

obtain a su?icient furnace heat absorption lying Within a

range of the order of 15% of the furnace heat absorption

obtained from the operation results in the air combustion

environment, thereby achieving stabiliZed oxyfuel combus

tion operations.

tor is increased in response to the opening degree control

signal 29a serving as How rate control signal outputted from

the controller 30 to thereby increase the How rate of the total

recirculating exhaust gases ?oWing through the recirculating

exhaust gas line 28 (see step S5 of FIG. 2), Whereupon the

boiler-brought-in oxygen density falls Within the predeter

May 5,2011

US 2011/0104624 A1

mined range (25 to 30%) to prevent the ?ame temperature

from lowering, to obtain a su?icient furnace heat absorption

lying Within a range of the order of 15% of the furnace heat

absorption obtained from the operation results in the air com

bustion environment, thereby achieving stabilized oxyfuel

combustion operations.

[0097]

Thus, similar to the FIG. 1 embodiment, FIG. 4

embodiment also ensures a su?icient furnace heat absorption

through prevention of loWering of the ?ame temperature,

enabling the oxyfuel combustion operations to be performed

in a stable manner.

[0098]

FIG. 4 embodiment may employ a less number of

O2 density monitors and ?oWmeters as compared With the

FIG. 1 embodiment.

[0099] It is to be understood that a method and an apparatus

a ?oWmeter for sensing a How rate of the primary recircu

lating exhaust gas to be introduced into the mill,

an O2 density monitor for sensing an O2 density of the

secondary recirculating exhaust gas to be introduced

into the coal burning boiler,

a ?oWmeter for sensing a How rate of the secondary recir

culating exhaust gas to be introduced into the coal burn

ing boiler,

a How rate regulator for regulating a How rate of total

recirculating exhaust gases to be introduced into the mill

and the coal burning boiler and

a controller for calculating a boiler-brought-in oxygen den

sity Which is an oxygen density for a total amount of

gases introduced into the coal burning boiler on the basis

of the O2 densities sensed by the respective O2 density

monitors and the How rates sensed by the respective

?oWmeters, the controller outputting a How rate control

signal to the How rate regulator such that the boiler

brought-in oxygen density falls Within a predetermined

of the invention for controlling combustion in an oxyfuel

combustion boiler are not limited to the above embodiments

and that various changes and modi?cations may be made

Without departing from the scope of the invention.

1. A method of controlling combustion in an oxyfuel com

bustion boiler Where While oxygen fed from an air separation

unit is introduced into a coal burning boiler, an exhaust gas in

recirculation is introduced as primary and secondary recircu

lating exhaust gases into a mill and the coal burning boiler,

respectively, the pulveriZed coal pulveriZed by the mill being

transferred by said primary recirculating exhaust gas to a

burner for oxyfuel combustion With said oxygen and said

secondary recirculating exhaust gas, the method comprising

measuring a boiler-brought-in oxygen density Which is an

oxygen density for a total amount of gases introduced

into the coal burning boiler and

controlling a How rate of total recirculating exhaust gases

such that the boiler-brought-in oxygen density falls

Within a predetermined range.

2. A method of controlling combustion in an oxyfuel com

bustion boiler as claimed in claim 1, Wherein the boiler

brought-in oxygen density falls Within a range from 25 to

30%.

3. An apparatus of controlling combustion in an oxyfuel

combustion boiler Where While oxygen fed from an air sepa

ration unit is introduced into a coal burning boiler, an exhaust

gas in recirculation is introduced as primary and secondary

recirculating exhaust gases into a mill and the coal burning

boiler, respectively, the pulveriZed coal pulveriZed by the mill

being transferred by said primary recirculating exhaust gas to

a burner for oxyfuel combustion With said oxygen and said

secondary recirculating exhaust gas, the apparatus compris

ing

an O2 density monitor for sensing an O2 density of oxygen

to be introduced into the coal burning boiler,

range.

4. An apparatus of controlling combustion in an oxyfuel

combustion boiler Where While oxygen fed from an air sepa

ration unit is introduced into a coal burning boiler, an exhaust

gas in recirculation is introduced as primary and secondary

recirculating exhaust gases into a mill and the coal burning

boiler, respectively, the pulverized coal pulveriZed by the mill

being transferred by said primary recirculating exhaust gas to

a burner for oxyfuel combustion With said oxygen and said

secondary recirculating exhaust gas, the apparatus compris

ing

an O2 density monitor for sensing an O2 density of oxygen

to be introduced into the coal burning boiler,

a ?oWmeter for sensing a How rate of oxygen to be intro

duced into the coal burning boiler,

an O2 density monitor for sensing an O2 density of total

recirculating exhaust gases to be introduced into the mill

and the coal burning boiler,

a ?oWmeter for sensing a How rate of total recirculating

exhaust gases to be introduced into the mill and the coal

burning boiler,

a How rate regulator for regulating a How rate of the total

recirculating exhaust gases to be introduced into the mill

and the coal burning boiler and a controller for calculat

ing a boiler-brought-in oxygen density Which is an oxy

gen density for a total amount of gases introduced into

the coal burning boiler on the basis of the O2 densities

sensed by the respective O2 density monitors and the

How rates sensed by the respective ?oWmeters, the con

troller outputting a How rate control signal to the How

rate regulator such that the boiler-brought-in oxygen

density falls Within a predetermined range.

5. An apparatus of controlling combustion in an oxyfuel

a ?oWmeter for sensing a How rate of oxygen to be intro

combustion boiler as claimed in claim 3 or 4, Wherein the

duced into the coal burning boiler,

an O2 density monitor for sensing an O2 density of the

primary recirculating exhaust gas to be introduced into

the mill,

boiler-brought-in oxygen density falls Within a range from 25

to 30%.

Das könnte Ihnen auch gefallen

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasVon EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNoch keine Bewertungen

- European Patent Application: Method of Controlling Combustion in Oxygen Combustion Boiler and Apparatus ThereforDokument14 SeitenEuropean Patent Application: Method of Controlling Combustion in Oxygen Combustion Boiler and Apparatus ThereforThang Cao DaiNoch keine Bewertungen

- Methods For Utilizing Tail Gas and Flue Gas From A Carbon Black Production ProcessDokument17 SeitenMethods For Utilizing Tail Gas and Flue Gas From A Carbon Black Production ProcessSRINIVASAN TNoch keine Bewertungen

- U.S. Patent 4,293,314: Gelled Fuel-Air Explosive October 6, 1981.Von EverandU.S. Patent 4,293,314: Gelled Fuel-Air Explosive October 6, 1981.Noch keine Bewertungen

- An Experimental Investigation of A Flue GasDokument9 SeitenAn Experimental Investigation of A Flue GasmichaelNoch keine Bewertungen

- Synthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsVon EverandSynthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsTilman J. SchildhauerNoch keine Bewertungen

- Fugitive and Stationary Source Emissions From Coke PlantsDokument62 SeitenFugitive and Stationary Source Emissions From Coke PlantsLuigi OlivaNoch keine Bewertungen

- Oxy-fuel Combustion: Fundamentals, Theory and PracticeVon EverandOxy-fuel Combustion: Fundamentals, Theory and PracticeChuguang ZhengNoch keine Bewertungen

- Combustion Principles and ControlDokument32 SeitenCombustion Principles and ControlThalia de la FuenteNoch keine Bewertungen

- Journal of The Energy Institute: Luning Tian, Wei Yang, Zhenhui Chen, Xianhua Wang, Haiping Yang, Hanping ChenDokument7 SeitenJournal of The Energy Institute: Luning Tian, Wei Yang, Zhenhui Chen, Xianhua Wang, Haiping Yang, Hanping ChenBill ChenNoch keine Bewertungen

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"Von EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"Noch keine Bewertungen

- International Journal of Thermal Sciences: Sen Li, Tongmo Xu, Qulan Zhou, Houzhang Tan, Shien HuiDokument9 SeitenInternational Journal of Thermal Sciences: Sen Li, Tongmo Xu, Qulan Zhou, Houzhang Tan, Shien HuiMatias MancillaNoch keine Bewertungen

- Carbon Capture Technologies for Gas-Turbine-Based Power PlantsVon EverandCarbon Capture Technologies for Gas-Turbine-Based Power PlantsNoch keine Bewertungen

- 1 s2.0 S1743967117307869 MainDokument13 Seiten1 s2.0 S1743967117307869 Maindigitalginga2Noch keine Bewertungen

- TP PC 11 02Dokument16 SeitenTP PC 11 02Khoirul Walad100% (1)

- Evaluation of The Co2 Re Activity of Chars Obtained Under Conventional and Oxyfuel AtmospheresDokument5 SeitenEvaluation of The Co2 Re Activity of Chars Obtained Under Conventional and Oxyfuel AtmospheresjulianapohlmannufrgsNoch keine Bewertungen

- Quantifying NOx EmissionsDokument28 SeitenQuantifying NOx EmissionsEmilie MasellaNoch keine Bewertungen

- Handbook Nitrogen Oxides Pollution Prevention and ControlDokument5 SeitenHandbook Nitrogen Oxides Pollution Prevention and ControlrupigapigaNoch keine Bewertungen

- Use of Steam and Co2 As Activating AgentsDokument9 SeitenUse of Steam and Co2 As Activating AgentsvinodNoch keine Bewertungen

- COMPLEX PROBEM IcDokument2 SeitenCOMPLEX PROBEM Ichafizarslanmushtaq0Noch keine Bewertungen

- Oxy Fuel CombustionDokument18 SeitenOxy Fuel CombustionLmaoNoch keine Bewertungen

- Design, Process Simulation and Construction of An Atmospheric Dual Fluidized Bed CombustionDokument9 SeitenDesign, Process Simulation and Construction of An Atmospheric Dual Fluidized Bed Combustionapi-3799861Noch keine Bewertungen

- 49 1 Anaheim 03-04 0837Dokument2 Seiten49 1 Anaheim 03-04 0837castelo_grandeNoch keine Bewertungen

- Theory of CombustionDokument19 SeitenTheory of CombustionDevendra Singh DhakreyNoch keine Bewertungen

- Hong AnalysisDokument38 SeitenHong AnalysisleovenuNoch keine Bewertungen

- Natural Gas CombustionDokument10 SeitenNatural Gas CombustionLakshmi Pathi BojjaNoch keine Bewertungen

- Topic 4-Control of Nitrogen OxidesDokument36 SeitenTopic 4-Control of Nitrogen OxidesalyaNoch keine Bewertungen

- Combustion and Emission Characteristics of Rice Husk in A Rectangular Fluidized Bed CombustorDokument4 SeitenCombustion and Emission Characteristics of Rice Husk in A Rectangular Fluidized Bed CombustorfelramNoch keine Bewertungen

- United States Patent (19) : (11) Patent Number: 5,238,395 (45) Date of Patent: Aug. 24, 1993Dokument10 SeitenUnited States Patent (19) : (11) Patent Number: 5,238,395 (45) Date of Patent: Aug. 24, 1993KrozeNoch keine Bewertungen

- Development of The "Micro Combustor"Dokument6 SeitenDevelopment of The "Micro Combustor"Haris AbdullaNoch keine Bewertungen

- 04 - Control Method For Low Oxygen Concentration in Reheating Furnace PDFDokument8 Seiten04 - Control Method For Low Oxygen Concentration in Reheating Furnace PDFVăn Tuấn NguyễnNoch keine Bewertungen

- WINSEM2021-22 CHE2006 TH VL2021220501413 Reference Material I 11-03-2022 Module-5 CombustionDokument63 SeitenWINSEM2021-22 CHE2006 TH VL2021220501413 Reference Material I 11-03-2022 Module-5 Combustionswastik vijayNoch keine Bewertungen

- Gas Natural PDFDokument10 SeitenGas Natural PDFCristian Andres Muñoz AguilarNoch keine Bewertungen

- Complex ProblemDokument1 SeiteComplex Problemhafizarslanmushtaq0Noch keine Bewertungen

- In - Situ CombustionDokument21 SeitenIn - Situ Combustionحسين رامي كريم A 12Noch keine Bewertungen

- Kiln Emissions - More Than Just Hot Air: Authoer:WCEO-AdminDokument8 SeitenKiln Emissions - More Than Just Hot Air: Authoer:WCEO-AdminGilberto PérezNoch keine Bewertungen

- Ando-Ignition Control DeviceDokument17 SeitenAndo-Ignition Control DeviceOtgonbat PionyerNoch keine Bewertungen

- Steam GeneratorDokument7 SeitenSteam Generatoragung inspirasiNoch keine Bewertungen

- Combustion Note 1Dokument2 SeitenCombustion Note 1Haradip MahilaryNoch keine Bewertungen

- Lecture 18Dokument5 SeitenLecture 18Ahmad Wildan ZakawaliNoch keine Bewertungen

- Synthesis GasDokument8 SeitenSynthesis GasTotok IswantoNoch keine Bewertungen

- Combustion Lab Manual Comb SolidDokument6 SeitenCombustion Lab Manual Comb SolidDiego FrancoNoch keine Bewertungen

- Environmental Impact and Forecast of Pollutants From Coke Oven Gas and Natural Gas CombustionDokument4 SeitenEnvironmental Impact and Forecast of Pollutants From Coke Oven Gas and Natural Gas CombustionIJERDNoch keine Bewertungen

- Coal Gasification Using AspenDokument6 SeitenCoal Gasification Using AspenTaniadi Suria100% (1)

- 02-Stoichiometric CalculationsDokument47 Seiten02-Stoichiometric CalculationsHandayani KesumadewiNoch keine Bewertungen

- Mechanism Analysis On The Pulverized Coal Combustion Ame Stability and Nox Emission in A Swirl Burner With Deep Air StagingDokument14 SeitenMechanism Analysis On The Pulverized Coal Combustion Ame Stability and Nox Emission in A Swirl Burner With Deep Air StagingPSS PrasadNoch keine Bewertungen

- Burner TechnologyDokument9 SeitenBurner TechnologyTint TigerNoch keine Bewertungen

- 2.0 Combustion Source and Pollutant DescriptionsDokument4 Seiten2.0 Combustion Source and Pollutant DescriptionshariprakavNoch keine Bewertungen

- Combustion Theory PPT OriginalDokument30 SeitenCombustion Theory PPT Originalsameer betalNoch keine Bewertungen

- Co AnalyserDokument6 SeitenCo Analysersanjay sharmaNoch keine Bewertungen

- Waste Heat BoilerDokument7 SeitenWaste Heat Boilerabdul karimNoch keine Bewertungen

- Prediction of NOx Emissions in Recovery Boilers PDFDokument14 SeitenPrediction of NOx Emissions in Recovery Boilers PDFNilesh KhadeNoch keine Bewertungen

- Chemical-Looping Combustion of Solid Fuels in A 10 KW Pilot - Batch Tests With Five FuelsDokument8 SeitenChemical-Looping Combustion of Solid Fuels in A 10 KW Pilot - Batch Tests With Five FuelsAzharuddin Ehtesham FarooquiNoch keine Bewertungen

- Fuel L2 (1) ,,ATDokument30 SeitenFuel L2 (1) ,,ATVishvas SinghhNoch keine Bewertungen

- 1.4 Natural Gas CombustionDokument11 Seiten1.4 Natural Gas Combustionnoorul786Noch keine Bewertungen

- European Patent Application: Process and Plant For Ammonia-Urea ProductionDokument16 SeitenEuropean Patent Application: Process and Plant For Ammonia-Urea ProductionRashminda AttanayakeNoch keine Bewertungen

- Combustion FundamentalsDokument40 SeitenCombustion Fundamentalsbinu vaNoch keine Bewertungen

- Experiences From Oxy Fuel Combustion of Bituminous Coal in A 150 KWTH Circulating Fluidized Bed Pilot FacilityDokument7 SeitenExperiences From Oxy Fuel Combustion of Bituminous Coal in A 150 KWTH Circulating Fluidized Bed Pilot FacilityjdfhakfdNoch keine Bewertungen

- United States: (12) Patent Application Publication (10) Pub. No.: US 2010/0326337 A1Dokument15 SeitenUnited States: (12) Patent Application Publication (10) Pub. No.: US 2010/0326337 A1Thang Cao DaiNoch keine Bewertungen

- PID Control System Analysis and DesignDokument10 SeitenPID Control System Analysis and DesignSandro MoreroNoch keine Bewertungen

- PID Control System Analysis & DesignDokument11 SeitenPID Control System Analysis & DesignNAYEEMNoch keine Bewertungen

- E 10% - % E 121 Pipe2: United StatesDokument9 SeitenE 10% - % E 121 Pipe2: United StatesThang Cao DaiNoch keine Bewertungen

- Us4177950 PDFDokument7 SeitenUs4177950 PDFThang Cao DaiNoch keine Bewertungen

- PDFDokument180 SeitenPDFThang Cao DaiNoch keine Bewertungen

- EP0081114A2Dokument14 SeitenEP0081114A2Thang Cao DaiNoch keine Bewertungen

- TEPZZ 7785 4A - T: European Patent ApplicationDokument12 SeitenTEPZZ 7785 4A - T: European Patent ApplicationThang Cao DaiNoch keine Bewertungen

- Benson BoilersDokument20 SeitenBenson BoilersPrasanna Kumar100% (1)

- 4 Air CirculationDokument19 Seiten4 Air CirculationThang Cao DaiNoch keine Bewertungen

- 2 Retrofitting Steam TurbinesDokument16 Seiten2 Retrofitting Steam TurbinesCesillia MardillaNoch keine Bewertungen

- The characteristics of super-critical power generation unit coordinated and feed water control system are strong coupling of multiple inputs and multiple outputs, nonlinearity, time-varying parameters. Design object of the study work is that controlled systems are controllable and stable. Two type of the practical running power were used as research object, the control system was designed accordingly. At first, the preconditions and proofs of stability of coordinated control system (CCS) and feed water control system (FWCS) were given respectively, then stability analysis for CCS and FWCS were made by mathematical derivation according to the technical problems of FWCS. The application results of super critical power unit show effectiveness and practicability.Dokument5 SeitenThe characteristics of super-critical power generation unit coordinated and feed water control system are strong coupling of multiple inputs and multiple outputs, nonlinearity, time-varying parameters. Design object of the study work is that controlled systems are controllable and stable. Two type of the practical running power were used as research object, the control system was designed accordingly. At first, the preconditions and proofs of stability of coordinated control system (CCS) and feed water control system (FWCS) were given respectively, then stability analysis for CCS and FWCS were made by mathematical derivation according to the technical problems of FWCS. The application results of super critical power unit show effectiveness and practicability.பிரசன்னகுமார் ஆனந்தன்Noch keine Bewertungen

- Tutorial Exp 4Dokument4 SeitenTutorial Exp 4Faris Hamir100% (4)

- Union Engineering PDFDokument25 SeitenUnion Engineering PDFCristian ParaschivNoch keine Bewertungen

- A Case Study On Thermodynamic Analysis of Cogeneration Power Plant (IRJET-V2I9163)Dokument5 SeitenA Case Study On Thermodynamic Analysis of Cogeneration Power Plant (IRJET-V2I9163)luis hyungNoch keine Bewertungen

- Pipe Network Analysis Using Hardy Cross Method PDFDokument19 SeitenPipe Network Analysis Using Hardy Cross Method PDFRasak Adepoju100% (1)

- Smr-Mep Method Statement 20072020Dokument10 SeitenSmr-Mep Method Statement 20072020Im Chinith67% (3)

- Sundyne Pumps & Compressors Training Course: THREE DAYS (Theoretical and Practical)Dokument3 SeitenSundyne Pumps & Compressors Training Course: THREE DAYS (Theoretical and Practical)önder KarakayaNoch keine Bewertungen

- HGE Refresher QuestionsDokument8 SeitenHGE Refresher QuestionsCj SuarezNoch keine Bewertungen

- Pipe Identification Tape To ISO 14726: Regulations 50mm (2") Reference Color and CodeDokument1 SeitePipe Identification Tape To ISO 14726: Regulations 50mm (2") Reference Color and CodeMilkovic DinoNoch keine Bewertungen

- Clariant Brochure Catalysts and Adsorbents For Syngas 2017 ENDokument9 SeitenClariant Brochure Catalysts and Adsorbents For Syngas 2017 ENAbdul Wasay100% (1)

- WBUT Btech 2nd Sem 2011 ThemodynamicsDokument7 SeitenWBUT Btech 2nd Sem 2011 ThemodynamicsBapi SarkarNoch keine Bewertungen

- IWCF Comb. Driller Equip. 01Dokument21 SeitenIWCF Comb. Driller Equip. 01andrzema67% (3)

- NK 50-200-210 - 98318043 - Genoa PlasticDokument4 SeitenNK 50-200-210 - 98318043 - Genoa PlasticSajidNoch keine Bewertungen

- Aust Domestic Copper Tube To AS1571Dokument2 SeitenAust Domestic Copper Tube To AS1571starykltNoch keine Bewertungen

- Supracell Circular Daf: Dissolved Air Flotation ClarifierDokument2 SeitenSupracell Circular Daf: Dissolved Air Flotation ClarifierKevin KeaneNoch keine Bewertungen

- UOP Oleflex Process PDFDokument2 SeitenUOP Oleflex Process PDFFernadez Ramos CarolayNoch keine Bewertungen

- CM9 - (Fluid Mechanics) v2Dokument15 SeitenCM9 - (Fluid Mechanics) v2Erica AbelardoNoch keine Bewertungen

- Piping 30000Dokument14 SeitenPiping 30000Prasanta Kumar BeheraNoch keine Bewertungen

- Fluid Mechanics (UAMCC04)Dokument10 SeitenFluid Mechanics (UAMCC04)Suresh PeguNoch keine Bewertungen

- HeuristicsDokument78 SeitenHeuristicsJames Edward DoolittleNoch keine Bewertungen

- Overall Heat Transfer CoefficientDokument5 SeitenOverall Heat Transfer CoefficientPaulAngeloPascuaNoch keine Bewertungen

- SSSPDokument68 SeitenSSSPPrashant NirpharakeNoch keine Bewertungen

- FM200Dokument18 SeitenFM200a_salehiNoch keine Bewertungen

- 416 Water Injection System OperationDokument4 Seiten416 Water Injection System OperationAmapola VillalobosNoch keine Bewertungen

- Technical Data Sheet (TDS) : Puma Premium Motor Oil 15W-40Dokument2 SeitenTechnical Data Sheet (TDS) : Puma Premium Motor Oil 15W-40Mohamed IsmailNoch keine Bewertungen

- PerpanDokument7 SeitenPerpanT Bagus Tri LusmonoNoch keine Bewertungen

- Vacancy - CFSPP Sulut-1 All PositionDokument43 SeitenVacancy - CFSPP Sulut-1 All PositionYahya AlmundzirNoch keine Bewertungen

- Pt. Deka Adhinusa: Re: Precision pump-LOW TWMPERATUREDokument4 SeitenPt. Deka Adhinusa: Re: Precision pump-LOW TWMPERATUREn.hartonoNoch keine Bewertungen

- Dust CollectorDokument16 SeitenDust Collectorchathura buddhikaNoch keine Bewertungen

- UNILOK CatalogueDokument175 SeitenUNILOK CatalogueKainNoch keine Bewertungen

- Table 3.10: Design Criteria For Pin Connections: T D D D F EDokument2 SeitenTable 3.10: Design Criteria For Pin Connections: T D D D F EDev lamichhaneNoch keine Bewertungen

- Practical Reservoir Engineering and CharacterizationVon EverandPractical Reservoir Engineering and CharacterizationBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Enhanced Oil Recovery Handout: A Focus on WaterfloodingVon EverandEnhanced Oil Recovery Handout: A Focus on WaterfloodingNoch keine Bewertungen

- Pocket Guide to Flanges, Fittings, and Piping DataVon EverandPocket Guide to Flanges, Fittings, and Piping DataBewertung: 3.5 von 5 Sternen3.5/5 (22)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesVon EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNoch keine Bewertungen

- Gas-Liquid And Liquid-Liquid SeparatorsVon EverandGas-Liquid And Liquid-Liquid SeparatorsBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Well Testing Project Management: Onshore and Offshore OperationsVon EverandWell Testing Project Management: Onshore and Offshore OperationsNoch keine Bewertungen

- Machine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsVon EverandMachine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsBewertung: 4 von 5 Sternen4/5 (4)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideVon EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideBewertung: 2 von 5 Sternen2/5 (1)

- Fundamentals and Applications of Bionic Drilling FluidsVon EverandFundamentals and Applications of Bionic Drilling FluidsNoch keine Bewertungen

- Well Control for Completions and InterventionsVon EverandWell Control for Completions and InterventionsBewertung: 4 von 5 Sternen4/5 (10)

- Heavy and Extra-heavy Oil Upgrading TechnologiesVon EverandHeavy and Extra-heavy Oil Upgrading TechnologiesBewertung: 4 von 5 Sternen4/5 (2)

- Essentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesVon EverandEssentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesBewertung: 5 von 5 Sternen5/5 (5)

- Advanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityVon EverandAdvanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityBewertung: 3 von 5 Sternen3/5 (2)

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsVon EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsBewertung: 4 von 5 Sternen4/5 (6)

- Asset Integrity Management for Offshore and Onshore StructuresVon EverandAsset Integrity Management for Offshore and Onshore StructuresNoch keine Bewertungen

- Advanced Production Decline Analysis and ApplicationVon EverandAdvanced Production Decline Analysis and ApplicationBewertung: 3.5 von 5 Sternen3.5/5 (4)

- Gas and Oil Reliability Engineering: Modeling and AnalysisVon EverandGas and Oil Reliability Engineering: Modeling and AnalysisBewertung: 4.5 von 5 Sternen4.5/5 (6)

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&AVon EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ANoch keine Bewertungen

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryVon EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryBewertung: 5 von 5 Sternen5/5 (3)