Beruflich Dokumente

Kultur Dokumente

Dry Quinching PDF

Hochgeladen von

Neeraj RaushanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Dry Quinching PDF

Hochgeladen von

Neeraj RaushanCopyright:

Verfügbare Formate

Part 2 CCT Overview

Iron Making and General Industry Technologies (Iron Making Technologies)

3A5. Coke Dry Quenching Technology (CDQ)

Outline of technology

1. Overview

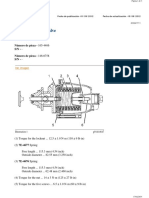

Overview of CDQ (Coke Dry Quenching) system

After it has cooled to approximately 200oC, the coke is ejected

The coke oven consists of plate-like carbonization chambers

from the bottom, while the circulating gas that has been heated

alternately arranged in a sandwich form to achieve higher thermal

to 800oC or higher generates high-temperature and high-

efficiency in carbonization.

pressure steam in the boiler. The gas is purified by a dust

Raw material placed in the carbonization chambers is heated to a

collector and then sent back to the chambers for recycling. The

temperature between approximately 1100 and 1350oC through the

generated steam is used as process steam or for power

combustion of blast furnace gas in the combustion chambers,

generation.

which are located on both sides of the carbonization chambers

Red-hot coke

Processing capacity: 135 t/hr

Temperature: Approx. 1,050oC

beyond the refractory brick. The heated raw material is not

exposed to air for approximately 12 to 14 hours to allow

Energy recovery balance

Boiler inlet gas

temperature:

Approx. 980oC

carbonization to proceed. In this process, the fixed carbon

contained in the raw material fuses and solidifies to become redhot coke in the lower section of the carbonization chambers. The

volatile component in the raw material vaporizes and decomposes,

Process steam:

Approx. 77 t/hr

(6.28 MPa, 485oC)

CDQ

boiler

becoming gas. After escaping from the coke surface, the gas is

CDQ

chambers

collected through a pipe located in the upper section of the

Feed

water

carbonization chambers. When carbonization is complete, the redo

hot coke (approximately 1,050 C) is discharged from the coke

oven and then carried to the top of the chambers. The coke is then

Temperature of

discharged coke:

Approx. 200oC

fed to the chambers and while it descends through the chamber, is

cooled with circulating gas blown from the bottom of the chamber.

Sample CDQ operating data

Chamber inlet gas

temperature:

Approx. 130oC

Boiler outlet gas

temperature:

Approx. 180oC

CDQ plants

56t/hr

Capacity

Company

Works

Coke charge temperature

1000-1050 C

Coke output temperature

200oC

Nippon Steel

Target

furnaces

Coke processing

capacity (t/hr)

(units)

Steam

(t/hr)

Plants

Pressure

(kg/cm2)

Temperature

(oC)

Put into

service

Oita

No. 1, 2

190 (1)

112.0

95

520

Oct. 1988

Oita

No. 3, 4

180 (1)

92.5

93

520

Aug. 1985

Yahata

No. 4, 5

175 (1)

120.0

75

495

Feb. 1987

106 (1)

65.0

117

525

Sept. 1985

Gas inlet temperature

170oC

Gas outlet temperature

800-850oC

Nagoya

No. 1, 2

Steam generation

25t/hr

Nagoya

No. 3

96 (1)

65.0

117

525

Jul. 1995

Steam pressure

40kgf/cm2

Nagoya

No. 4

129 (1)

71.4

117

525

Feb. 1982

Steam temperature

440oC

Kimizu

No. 1, 2, 3

110 (3)

60.0

95

520

Oct. 1982, Aug. 1983

Total gas volume

84,000Nm3/hr

Kimizu

No. 4, 5

170 (1)

108.0

95

520

Jan. 1988

Hokkai Steel

Muroran

No. 5, 6

108 (1)

56.5

64

490

Jul. 1981

JFE Steel

East Japan No. 5

100 (1)

50.0

52.5

436

Apr. 1981

56 (3)

30.0

25.0

228

Jan. 1977

70 (5)

39.0

20

280

Sept. 1976

Nippon Steel

Chemical

Comparison of CDQ coke quality

Wet quenching

(Chiba)

Dry quenching

No. 6, 7

Water content (%)

2-5

0.1-0.3

East Japan No. 1

Ash content (%)

11.35

11.39

(Keihin)

Volatile components (%)

Average particle size (mm)

0.50

65

0.41

55

Powder rate (after cut) (-15 mm%)

10

13

Porosity (%)

49

48

83.5

85.5

DI 15 (%)

12.9

17.9

Coke strength after small reaction (%)

50

52

150

DI 15 (%)

150

Sumitomo Metal

Industries

Composition of circulating gas

Gas

CO2

Concentration (%) 10-15

CO

H2

N2

8-10

2-3

70-75

Kansai Coke

and Chemicals

Nakayama Steel Works

51

70 (3)

39.0

20

280

Jul. 1979

West Japan No. 3, 4

100 (2)

64.9

99.0

330

Aug. to Sep. 1983

(Kurashiki) No. 5, 6

130 (1)

85.0

99.0

330

Jan. 1986

West Japan No. 4

125 (1)

69.0

105

540

Apr. 1986

(Fukuyama) No. 5

200 (1)

116.5

85

520

Feb. 1990

No. 3

185 (1)

111.7

86

523

Jan. 1997

195 (1)

100.0

105.0

545

Mar. 1986

No. 2AB

150 (1)

65.0

105.0

545

Jan. 1984

No. 2

Kagoshima No. 1ABCD

No. 2CD

130 (1)

65.0

105.0

545

Nov. 1981

Wakayama

No. 6

100 (1)

60.0

102

540

Apr. 1994

Kakogawa

No. 1, 2

140 (1)

84.0

112.0

556

Jun. 1987

No. 3, 4

150 (1)

98.0

112.0

556

Oct. 1998

58 (1)

31.0

65

490

May 1991

Funamachi

No. 2

Clean Coal Technologies in Japan

2. Features of CDQ system

The red-hot coke extruded from the coke oven is cooled by spraying it with water. The water used for cooling

Conventional

system

is vaporized and released into the atmosphere. An issue with this conventional system is the energy loss

when the thermal energy of the red-hot coke is converted into heat that is vaporized and released unused.

Another drawback is that the conventional system also produces airborne coke dust.

In the CDQ system, the red-hot coke is cooled by gas circulating in an enclosed system, thereby preventing

CDQ

system

the release of airborne coke dust. The thermal energy of the red-hot coke, which is lost in the conventional

system, is collected and reused as steam in the CDQ system. This technology uses less fossil fuel and

results in lower CO2 emissions, thereby contributing to the prevention of global warming.

Crane

Charger

Power plants

Primary dust catcher

Pre-chamber

Steel works

Boiler

Cooling chamber

Chemical plants

Water pre-heater

Bucket

Ejector

Secondary dust catcher

Gas recirculating fan

Belt conveyor

CDQ process flow

3. Dissemination of coke dry quenching (CDQ) systems

CDQ systems have been installed in many steel works and coke

Reduction of CO2 emissions (expected energy conservation:

heat collected from generated steam = 604.3 Tcal/year)

ovens in Japan as energy-efficient, environmentally-friendly

technology.

Scenario

Through NEDO model projects, the effectiveness of CDQ has also

CO2 emissions

(t-CO2/year)

been recognized in China. The Chinese government specified CDQ

technology as one of the targets in the Tenth 5-year plan in 2000.

CO2 emissions from CDQ project

1,771,569

Baseline CO2 emissions

1,908,311

Steel works in Hanfang, Beijing, Chengde and Hangzhou have

already introduced Japanese CDQ systems.

Expected reduction of CO2 emissions

4. Future prospects

The Asian region is expected to continue increasing its production of

crude steel. Efforts to introduce CDQ are being made in China and

India. CDQ is an established technology that can help Japan to

achieve its Kyoto Protocol target via the use of CDM projects.

52

136,742

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- ELECTRIC DRIVES Ion Boldea Fellow IEEE University Politehnica Timisoara, Romania S. A. Nasar Life Fellow IEEE University of Kentucky Lexington, KY CRC Press Boca Raton London New York Washington, D.CDokument7 SeitenELECTRIC DRIVES Ion Boldea Fellow IEEE University Politehnica Timisoara, Romania S. A. Nasar Life Fellow IEEE University of Kentucky Lexington, KY CRC Press Boca Raton London New York Washington, D.CNeeraj RaushanNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- ABB ACS850 Drive ModulesDokument125 SeitenABB ACS850 Drive ModulesNeeraj RaushanNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Choose A Plan - Scribd Upload A Doc To Download ADokument2 SeitenChoose A Plan - Scribd Upload A Doc To Download ANeeraj RaushanNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Choose A Plan - Scribd Upload A Doc To Download ADokument2 SeitenChoose A Plan - Scribd Upload A Doc To Download ANeeraj RaushanNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Acs850 Hardware Manual - Google SearchDokument2 SeitenAcs850 Hardware Manual - Google SearchNeeraj RaushanNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Web Proxy To Bypass School, University and Office Firewalls. Facebook, Youtube, Gmail UnblockerDokument19 SeitenWeb Proxy To Bypass School, University and Office Firewalls. Facebook, Youtube, Gmail UnblockerNeeraj RaushanNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- How To Upload A Document - Scribd To Download DocumentDokument3 SeitenHow To Upload A Document - Scribd To Download DocumentNeeraj RaushanNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Abb Machinery Drives Catalog Acs850Dokument24 SeitenAbb Machinery Drives Catalog Acs850Neeraj RaushanNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- B.tech EEE Syllabus OutlineDokument4 SeitenB.tech EEE Syllabus OutlineNeeraj RaushanNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- 2013 AeroDokument7 Seiten2013 AeroNeeraj RaushanNoch keine Bewertungen

- Readme PDFDokument2 SeitenReadme PDFDorothy SaikiaNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- How To Lock Parameter Change On Acs 880 Drive - (Drives Tags Configuration Acs880 - Acs800 Series)Dokument1 SeiteHow To Lock Parameter Change On Acs 880 Drive - (Drives Tags Configuration Acs880 - Acs800 Series)Neeraj RaushanNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- An Overview of Grounding System UngroundedDokument4 SeitenAn Overview of Grounding System UngroundedBrijesh B NaikNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Readme PDFDokument2 SeitenReadme PDFDorothy SaikiaNoch keine Bewertungen

- Free Access Hum Do Me A FvourDokument1 SeiteFree Access Hum Do Me A FvourNeeraj RaushanNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Free Access HumDokument1 SeiteFree Access HumNeeraj RaushanNoch keine Bewertungen

- Let Me Do A Fu CKDokument1 SeiteLet Me Do A Fu CKNeeraj RaushanNoch keine Bewertungen

- Free Access Hum Do Me A FvourDokument1 SeiteFree Access Hum Do Me A FvourNeeraj RaushanNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- KJJKDSF 87981234klDokument1 SeiteKJJKDSF 87981234klNeeraj RaushanNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- SMD Documents Can Be OpenedDokument1 SeiteSMD Documents Can Be OpenedNeeraj RaushanNoch keine Bewertungen

- This Sis Very ImportantDokument1 SeiteThis Sis Very ImportantNeeraj RaushanNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- SMD Documents Can Be OpenedDokument1 SeiteSMD Documents Can Be OpenedNeeraj RaushanNoch keine Bewertungen

- This Sis Very ImportantDokument1 SeiteThis Sis Very ImportantNeeraj RaushanNoch keine Bewertungen

- Dsht12 Checked 2016Dokument1 SeiteDsht12 Checked 2016Neeraj RaushanNoch keine Bewertungen

- Dsht12 Checked 2016Dokument1 SeiteDsht12 Checked 2016Neeraj RaushanNoch keine Bewertungen

- Volume Checked 2016Dokument1 SeiteVolume Checked 2016Neeraj RaushanNoch keine Bewertungen

- Hots A Necessity 2008Dokument3 SeitenHots A Necessity 2008Neeraj RaushanNoch keine Bewertungen

- Catalogue ANSI PostDokument20 SeitenCatalogue ANSI PostElectricEngineeringNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- CT Nut Forged GGCDokument32 SeitenCT Nut Forged GGCanderson_bicudoNoch keine Bewertungen

- Tyre Dimension EliteXPDokument2 SeitenTyre Dimension EliteXPShean TanNoch keine Bewertungen

- Ko Large Bore PistonsDokument0 SeitenKo Large Bore PistonsvshalimovNoch keine Bewertungen

- Section 13 Part 2 Mortar and GroutDokument6 SeitenSection 13 Part 2 Mortar and GroutRotsapNayrbNoch keine Bewertungen

- KZCO AllcatalogDokument76 SeitenKZCO AllcatalogJaime SuaNoch keine Bewertungen

- Axminster 22 - Outdoor & Gardening - p648-p670Dokument23 SeitenAxminster 22 - Outdoor & Gardening - p648-p670Pierre799esNoch keine Bewertungen

- Vapour Pressure DataDokument44 SeitenVapour Pressure Dataramsrivatsan50% (2)

- Um DEDokument56 SeitenUm DEalvaroNoch keine Bewertungen

- Exhaust Bypass ValveDokument3 SeitenExhaust Bypass ValveHugo CiprianiNoch keine Bewertungen

- Larsen & Toubro Limited: 2206-330Mw Combined Cycle Power Plant at PillaiperumanallurDokument6 SeitenLarsen & Toubro Limited: 2206-330Mw Combined Cycle Power Plant at PillaiperumanallurAnand.5100% (1)

- PLC Based Pneumatic Punching Machine: (Minor Project)Dokument5 SeitenPLC Based Pneumatic Punching Machine: (Minor Project)Pinnn2Noch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Av en Valves PDFDokument246 SeitenAv en Valves PDFWahyuNoch keine Bewertungen

- Annex A Psi-Guidelines-For-Structural-Engineers-2Dokument4 SeitenAnnex A Psi-Guidelines-For-Structural-Engineers-2dianfeng.envistaNoch keine Bewertungen

- Boiler AnnexDokument66 SeitenBoiler Annexrenjithv_4Noch keine Bewertungen

- Aliplast Katalog enDokument140 SeitenAliplast Katalog enJelena GraovčevićNoch keine Bewertungen

- IncineratorDokument72 SeitenIncineratorWajih100% (3)

- Posi Test atDokument5 SeitenPosi Test atsudhir5441Noch keine Bewertungen

- BdeM Taller No. 2Dokument2 SeitenBdeM Taller No. 2Luisfer PriceNoch keine Bewertungen

- MIL-PRF-81309 REV. H - Part17Dokument1 SeiteMIL-PRF-81309 REV. H - Part17David WongNoch keine Bewertungen

- Effects of Processing Condition On The Filtration Performances of Nonwovens For Bag Filter MediaDokument6 SeitenEffects of Processing Condition On The Filtration Performances of Nonwovens For Bag Filter Mediaapi-3733260Noch keine Bewertungen

- Sonja ResumeDokument2 SeitenSonja Resumeapi-283801127Noch keine Bewertungen

- Flexpipe PDS FlexCord EnglishDokument2 SeitenFlexpipe PDS FlexCord EnglishpsycopaulNoch keine Bewertungen

- Accelerating Admixtures For ShotcreteDokument7 SeitenAccelerating Admixtures For Shotcreteneen61Noch keine Bewertungen

- Private Employers - GurgaonDokument51 SeitenPrivate Employers - Gurgaonsaurabh_shuklaNoch keine Bewertungen

- Degree o FreedomDokument27 SeitenDegree o FreedomHassan BhinderNoch keine Bewertungen

- Ratliperl: The Modern Solution For Energy Efficient BuildingDokument18 SeitenRatliperl: The Modern Solution For Energy Efficient BuildingAdhil Ramsurup100% (1)

- List of Indian StandardsDokument3 SeitenList of Indian StandardsGarima GuptaNoch keine Bewertungen

- E CombusDokument2 SeitenE CombusalexNoch keine Bewertungen

- Tofflon Service Engineer JD - IndonesiaDokument4 SeitenTofflon Service Engineer JD - IndonesiaTamilNoch keine Bewertungen