Beruflich Dokumente

Kultur Dokumente

TD MA SeaWaterDistiller 2012 06 en Tcm25 23436

Hochgeladen von

Lionel RichiCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

TD MA SeaWaterDistiller 2012 06 en Tcm25 23436

Hochgeladen von

Lionel RichiCopyright:

Verfügbare Formate

Subject to modification

GEA SeaWaterDistiller

Technical data | Generation of fresh water

from sea water

The SWD (GEA SeaWaterDistiller) works

The condensation takes place in the con-

This ejector has a double function:

on the well-known vacuum distillation

denser plate bundle located in the upper

Extraction of the surplus sea water

principle. Waste heat from the main

part of the housing. The condenser is

(so-called brine) out of the housing and

engine on board is utilized as heating

cooled by sea water. The latent heat from

vacuum creation by exhaust of the

non-condensable gases.

medium for evaporation. The evapora-

condensation is transferred to the sea

tion takes place in the evaporation plate

water. The condensation/evaporation

bundle located in the lower part of the

temperature varies with the sea water

The distillate quality (salinity) is

housing.

temperature.

monitored at the control panel. If the

A part of the incoming sea water evapo-

A small portion of the heated sea water

(2 10 ppm) the distillate is rejected back

rates due to the high vacuum inside the

is utilized as feed water for the evapora-

to the evaporator via a solenoid valve.

housing. The generated vapour is cleaned

tor bundle. The biggest part is used as

from sea water droplets while flowing

driving medium for the combined

through a wire mesh demister.

air/brine ejector.

salinity exceeds the adjusted set point

Technical Data SeaWaterDistiller

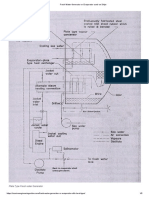

Operating principles and constructional features

1

8

7

10

11

9

12

14

13

16

15

17

1 Thermal oil /

hot water heated

8 Heating water

9 Steam heated

2 Heat exchanger

10 Feed water

3 Jacket water heated

11 Steam

4 Jacket water

12 Ejector

5 Distillate

13 Brine

6 Demister

14 Steam ejector

7 Circulation pump

15 Condensate

16 Sea water

17 Overboard

Features

Standard equipment

Materials

Simple, compact design

Control panel

Plates

Titanium

Distillate pump, control panel,

(built in on left or right side)

chemical dosing equipment

Chemical dosing tank (built in)

Demiister

Stainless steel

Titanium heat exchanger plates

Distillate pump

Housing

Stainless steel

Sea water resistant materials

Set of thermometers

Air/brine ejector

Cast bronze

Hinged hood

and pressure gauges

Frame

Stainless steel

Distillate pump

Stainless steel

Sea water

pipework

PP

Brine pipework

PP

Distillate

Hose

Set of non-return flaps

Optional supply

Feed water valve

Sea water pump

Solenoid valve

(necessary for operation)

Water meter

Re-hardening filter (pH-adjustment)

Salinity measuring cell + indicator

UV-Sterilizer

Application

Heating modules for various

Shipbuilding industry

heat sources e.g.

Offshore

Steam

Hot water

Thermal oil

Sea water inlet

Heating water

outlet

Distillate outlet

Sea water outlet

Heating water

outlet

Technical Data SeaWaterDistiller

Capacity

SWD 10

SWD 15

SWD 20

SWD 25

SWD 30

10 t/d

15 t/d

20 t/d

25 t/d

30 t/d

100 DN

100 DN

Heating water

temperature

70 90 oC

Connections

Sea water inlet

Sea water outlet

65 DN

65 DN

80 DN

80 DN

Heating water inlet

65 DN

Heating water

outlet

65 DN

Distillate

Weight

Empty

600 kg (1323 lb)

617 kg (1360 lb)

626 kg (1380 lb)

642 kg (1415 lb)

642 kg (1415 lb)

In operation

640 kg (1411 lb)

676 kg (1490 lb)

706 kg (1556 lb)

742 kg (1636 lb)

771 kg (1700 lb)

Dimensions in mm (inch)

Type

SWD 10

1358 (53)

SWD 15

1358 (53)

SWD 20

1358 (53)

SWD 25

1637 (64)

SWD 30

1637 (64)

1390 (55)

1423 (56)

2020 (80)

477 (19)

E

D

GEA Germany

GEA Westfalia Separator Group GmbH

Werner-Habig-Strae 1

Tel +49 2522 77-0

sales.germany@gea.com

59302 Oelde, Germany

Fax +49 2522 77-1778

gea.com

The information contained in this brochure merely serves as a non-binding description of our products and is without guarantee. Binding information, in particular relating to capacity data and suitability for specific applications, can only be provided within the framework of

TD_WS-16-08 -0002 EN

concrete inquiries. Printed on chlorine-free bleached paper Printed in Germany Subject to modification Westfalia and Westfalia Separator are registered trademarks of GEA Mechanical Equipment GmbH.

Operating principles and constructional features

Das könnte Ihnen auch gefallen

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingVon EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingBewertung: 5 von 5 Sternen5/5 (3)

- FWGDokument30 SeitenFWGNor AshimyNoch keine Bewertungen

- Oil and Gas Artificial Fluid Lifting TechniquesVon EverandOil and Gas Artificial Fluid Lifting TechniquesBewertung: 5 von 5 Sternen5/5 (1)

- Fresh Water Geberator and Osmosis ProcessesDokument62 SeitenFresh Water Geberator and Osmosis ProcessesSuhas KassaNoch keine Bewertungen

- Simple Plumbing Repairs for the Home and FarmsteadVon EverandSimple Plumbing Repairs for the Home and FarmsteadNoch keine Bewertungen

- MarineDokument10 SeitenMarinewaseemNoch keine Bewertungen

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsVon EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNoch keine Bewertungen

- Technical Data - Generation of Fresh Water From Sea Water: Gea Westfalia Separator SeawaterdistillerDokument4 SeitenTechnical Data - Generation of Fresh Water From Sea Water: Gea Westfalia Separator SeawaterdistillerVolodymyr KhmelnytskyiNoch keine Bewertungen

- Large Chilled Water SystemDokument314 SeitenLarge Chilled Water SystemEsteban Lopez Arboleda100% (3)

- Naval DiagramsDokument39 SeitenNaval DiagramsAsif AliNoch keine Bewertungen

- Fresh Water Generator DesignDokument4 SeitenFresh Water Generator DesignVikk Suriya100% (1)

- Fresh Water Generator On ShipsDokument11 SeitenFresh Water Generator On ShipsGuruNoch keine Bewertungen

- FreshWater Generator On ShipsDokument22 SeitenFreshWater Generator On Shipschristian pope100% (1)

- Wartsila o Water Fresh GeneratorsDokument2 SeitenWartsila o Water Fresh Generatorsferdiaus_hasanNoch keine Bewertungen

- Operation - Manual Sondex A/S SFD 6: Customer: Newbuilding No: Order No.: Sondex Order No.: Encl.Dokument132 SeitenOperation - Manual Sondex A/S SFD 6: Customer: Newbuilding No: Order No.: Sondex Order No.: Encl.AlexDor100% (1)

- This Doc. Is in Used Base On Simulator Class TutorialsDokument9 SeitenThis Doc. Is in Used Base On Simulator Class TutorialsFatih KayalarNoch keine Bewertungen

- DPU, Two-Stage Titanium Plate Type Fresh Water GeneratorDokument4 SeitenDPU, Two-Stage Titanium Plate Type Fresh Water GeneratorIvana SeputNoch keine Bewertungen

- ECOTherms Feed Water TanksDokument4 SeitenECOTherms Feed Water TanksFadzil NorNoch keine Bewertungen

- B1 Freshwater GeneratorDokument32 SeitenB1 Freshwater GeneratorAhmad Aslam MohamadNoch keine Bewertungen

- Alfa Laval AQUA Blue S-Type: Single-Stage Freshwater GeneratorDokument4 SeitenAlfa Laval AQUA Blue S-Type: Single-Stage Freshwater GeneratorThái HọcNoch keine Bewertungen

- Sondex SFD6Dokument160 SeitenSondex SFD6a.amangazinov1995Noch keine Bewertungen

- Chapter 8 Steam CondenserDokument53 SeitenChapter 8 Steam CondenserPHƯƠNG ĐẶNG YẾNNoch keine Bewertungen

- Fresh Water GeneratorDokument13 SeitenFresh Water GeneratorPrem Cesc NathNoch keine Bewertungen

- Apv H35Dokument18 SeitenApv H35petrakou aglaia100% (1)

- Alfa LavalDokument29 SeitenAlfa LavallipovanychNoch keine Bewertungen

- Evaporators 2020Dokument28 SeitenEvaporators 2020Rakesh SainiNoch keine Bewertungen

- Fresh Water Generator GME 37Dokument30 SeitenFresh Water Generator GME 37srinidhi246100% (1)

- Deron Swimming Pool Heat Pump CatalogueDokument19 SeitenDeron Swimming Pool Heat Pump Catalogueocean220220Noch keine Bewertungen

- KSS On Generator Cooling SystemDokument38 SeitenKSS On Generator Cooling SystemSakthi MuruganNoch keine Bewertungen

- Feed Water TanksDokument4 SeitenFeed Water TanksvirtualmecanicaNoch keine Bewertungen

- Header BowmanDokument12 SeitenHeader BowmanMehrdad SakhaieNoch keine Bewertungen

- FWGDokument8 SeitenFWGSWASTIK MISHRANoch keine Bewertungen

- Selecting HEX in OffshoreDokument44 SeitenSelecting HEX in OffshoreRendy CkNoch keine Bewertungen

- Fresh Water Generator or Evaporator Used On Ships BRAVO 2Dokument5 SeitenFresh Water Generator or Evaporator Used On Ships BRAVO 2Dan EzraNoch keine Bewertungen

- Fresh Water Generator: Operation, Construction and FunctionsDokument12 SeitenFresh Water Generator: Operation, Construction and FunctionsSGkNoch keine Bewertungen

- Evaporator and DistillersDokument41 SeitenEvaporator and DistillersPedro Oporto IIINoch keine Bewertungen

- Unit 22 CondensersDokument42 SeitenUnit 22 CondenserssprotkarNoch keine Bewertungen

- SFD 13 Samlet ManualDokument95 SeitenSFD 13 Samlet ManualHüseyin TekinNoch keine Bewertungen

- 1 GeneratorDokument17 Seiten1 GeneratorSuparnoWitoradyoNoch keine Bewertungen

- Emd00099en JWP26CDokument4 SeitenEmd00099en JWP26CLupu Ane MarieNoch keine Bewertungen

- Fresh Water Generator On ShipsDokument19 SeitenFresh Water Generator On ShipsSheshraj VernekarNoch keine Bewertungen

- Wartsila O Env Multi Stage Flash EvaporatorsDokument2 SeitenWartsila O Env Multi Stage Flash EvaporatorsRichard Periyanayagam0% (1)

- Operation and Protection of 210 MW Turbine Condensation Extracton Pump and Condensation CycleDokument31 SeitenOperation and Protection of 210 MW Turbine Condensation Extracton Pump and Condensation CycleAshish Lanjewar100% (1)

- Alfawatercoolcondenser PDFDokument24 SeitenAlfawatercoolcondenser PDFyeshig2000Noch keine Bewertungen

- G S Water SystemDokument23 SeitenG S Water Systemsameer betalNoch keine Bewertungen

- ME-803 RAC Refrigeration and Air CondtitioningDokument29 SeitenME-803 RAC Refrigeration and Air CondtitioningdeepaknayanNoch keine Bewertungen

- 2 ND BatchDokument22 Seiten2 ND Batchanil kumarNoch keine Bewertungen

- CONDENSER SchemeDokument47 SeitenCONDENSER SchemeAbhishek SinhaNoch keine Bewertungen

- Cooling Tower PresentationDokument44 SeitenCooling Tower PresentationAmi Desai100% (1)

- Week 1Dokument6 SeitenWeek 1Daniel OpeñaNoch keine Bewertungen

- Cooling Circulating Water, Purge Water & Cooling Tower SystemDokument22 SeitenCooling Circulating Water, Purge Water & Cooling Tower SystemSCE CCGT3Noch keine Bewertungen

- Condenser Performance Analysis and Its ImprovementDokument23 SeitenCondenser Performance Analysis and Its Improvementanup_nair100% (1)

- Technical YPCDokument6 SeitenTechnical YPCnairam2003Noch keine Bewertungen

- Cooling Tower Operation in Extreme Cold 2.2Dokument4 SeitenCooling Tower Operation in Extreme Cold 2.2Ajay TulpuleNoch keine Bewertungen

- Feed Water Heaters SeimnarDokument50 SeitenFeed Water Heaters SeimnarRam100% (1)

- Block Ice Machine Bk50tDokument6 SeitenBlock Ice Machine Bk50tWisermenNoch keine Bewertungen

- Marine Ship Desaliner and HeaterDokument1 SeiteMarine Ship Desaliner and HeaterTempcoNoch keine Bewertungen

- Cooling SystemDokument5 SeitenCooling SystemAayush AgrawalNoch keine Bewertungen

- Maintanance: Picture: Cleaning With Water JetDokument3 SeitenMaintanance: Picture: Cleaning With Water Jetomer faruqeNoch keine Bewertungen

- HP and LP Boiler PresentationDokument35 SeitenHP and LP Boiler PresentationNevermoreNoch keine Bewertungen

- Bases Neurales de La Violencia HumanaDokument9 SeitenBases Neurales de La Violencia HumanaJoji von SchwedlerNoch keine Bewertungen

- 11 BPFuelOilSystemsDokument120 Seiten11 BPFuelOilSystemsLionel RichiNoch keine Bewertungen

- A Masters Guide To Using Fuel Oil Onboard ShipsDokument74 SeitenA Masters Guide To Using Fuel Oil Onboard ShipsPatetico Pianto LupoNoch keine Bewertungen

- Bunkering Safety Checklist PDFDokument1 SeiteBunkering Safety Checklist PDFLionel RichiNoch keine Bewertungen

- TD MA SeaWaterDistiller 2012 06 EN - tcm25 23436 PDFDokument4 SeitenTD MA SeaWaterDistiller 2012 06 EN - tcm25 23436 PDFLionel RichiNoch keine Bewertungen

- Libro de Sistemas y EquiposDokument233 SeitenLibro de Sistemas y EquiposAna Lorena RomeroNoch keine Bewertungen

- 23 AuxiliaryMarineMachinery 000 PDFDokument55 Seiten23 AuxiliaryMarineMachinery 000 PDFLionel Richi100% (1)