Beruflich Dokumente

Kultur Dokumente

563 Pulp and Paper A Guide To Steam Conditioning

Hochgeladen von

MuhammadOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

563 Pulp and Paper A Guide To Steam Conditioning

Hochgeladen von

MuhammadCopyright:

Verfügbare Formate

Pulp and Paper

A Guide to Steam

Conditioning

CHP Pulp and Paper Process

CHP in Pulp and Paper

Introduction, What is CHP in Pulp and Paper Industry

Requirement of Steam

Steam Conditioning Applications

CHP (Combined Heat and Power) is an efficient technology for

generating electricity and heat together.

Pulp and Paper, Recovery Cycle

Paper Making

Key Products for Severe Service Applications:

VST-SE

VLB

DRAG

Desuperheaters

A CHP plant is an installation where there is simultaneous generation

of usable heat and power in a single process. Figure 1 shows a possible

configuration for a CHP plant. The heat source can be established from many

different sources. Waste heat from process (e.g. black liquor recovery) and

waste heat from gas turbine (also electricity generator) by a heat recovery

steam generator (HRSG). This heat is used to provide process steam which

is required for the production of pulp and the paper machine. Availability of

steam is of the utmost importance, electricity can be bought via the grid, but

non availability of steam means that production (revenue) will stop.

CHP provides a secure and highly efficient method of generating electricity

and steam at the point of use. Due to the utilization of heat from electricity

generation and the avoidance of transmission losses because electricity

is generated on site, CHP typically achieves a 35% increase in efficiency

compared with power stations and heat only boilers. This can allow

economic savings where there is a suitable balance between the heat and

power loads.

Pulp and Paper A Guide to Steam Conditioning

Why is Steam Required and at What Degree of Superheat?

Steam is required for the paper machine and evaporators at a condition close

to saturation owing to the excellent heat transfer properties of saturated

steam. Paper making, typically requires steam at 3.5 bar a at 145 C. If there is

too much superheat in the steam, then there the heat transfer at the process

will be inefficient and the paper run can be ruined.

Steam is therefore normally available from the steam turbine or its bypass

valve or a combination of both. It should be noted, the requirement of

the power plant is primarily to provide steam for the process (industry)

and generating electricity is merely a benefit as the electrical needs can be

imported if necessary. Steam supply at the correct pressure and temperature

and not electricity is of the utmost importance.

Figure 1: Typical simple CHP scheme with black liquor recovery boiler and

steam turbine.

CHP Pulp and Paper Process

Steam Provided by Steam Turbine

Steam from the (boiler or HRSG), normally high pressure and superheated,

will pass through the steam turbine. For example, steam to the relevant

process can be taken from extraction or the exhaust of a steam turbine of the

backpressure design (refer to Figure 1).

Turbine Extraction/Exhaust

The outlet steam temperature from extraction or exhaust varies depending on

the steam going through the steam turbine(refer to Figure 2). For example,

considering exhaust steam, as the steam flow through the turbine decreases,

the outlet temperature increases. Depending on the exhaust flow in general

as the extraction flow reduces, the extraction steam temperature increases.

Figure 2: Turbine extraction/exhaust

desuperheating

This means to obtain a constant set temperature downstream, the proportion

of spraywater required at low flow is higher than compared to at full flow

where the requirement will be small if any at all.

The exhaust steam supply pipe to paper mill will be large in diameter and

combined with the conditions as detailed above and potentially low flow,

providing good temperature control to the process close to saturation will

need special consideration.

Steam Provided by the Bypass Valve

Figure 3: HP turbine bypass to process

Steam Turbine Bypass to Extraction/Exhaust for Back Pressure

Turbines

The steam turbine bypass reduces the pressure and temperature of the steam

to match the appropriate extraction/exhaust conditions. They are used during

startup, in the event of a turbine trip, non availability of the steam turbine

or supplementing steam to process that may not be available from the steam

turbine.

The bypass valve should:

Be suitable for severe thermal

shock (up to 300 C)

Have high rangeability to

maximize turndown

Modulate in 2-3 seconds or less.

Snap action in this time is not

Provide repeatable tight shutoff

Inline repairability

Be of low noise design

acceptable as the boiler will trip.

Figure 4: VST-SE bypass valve for fine

control of steam to paper machine

Reliability of this equipment is of the utmost importance. Non availability

means loss of production. The valve illustrated in Figure 4 (VST-SE) meets all

the above criteria. CCI with extensive experience and knowledge can provide

installation guidelines in conjunction with the correct product selection for

the optimum system solution.

Pulp and Paper A Guide to Steam Conditioning

If the steam turbine is not available, then the bypass valves are utilized to

condition the steam to the exact conditions required for the process (refer

to Figure 3). When the steam flow through the turbine does not meet the

process demand the bypass valve must make up the difference between the

process demand and that being supplied by the steam turbine. Availability of

turbine bypass valve is therefore critical to production.

CHP Pulp and Paper Process

Figure 5: Manufacture of pulp and

the recovery cycle

Pulp Manufacture and Recovery Cycle

Pulp and Paper A Guide to Steam Conditioning

The details below are typical for a large pulp and paper mill.

Figure 6: Pulp and paper mill incorporating

recovery cycle

Received wood is cleaned, processed and made into small chips. The bark

that is stripped will be used to burn in the bark boiler that produces steam

at the same pressure as he black liquor recovery boiler described later.

Wood chips are cooked in the digesters. White liquor, hydroxide sulfide

is used in the boiling process to separate fibres from the chemicals in the

wood that bond the fibres together. The remaining water and chemical

mixture is known as white or feed liquor. The mixture is 15% white

liquor and 85% water.

The pulp is refined in the respective fibreline and includes screening,

washing and possibly bleaching (for production of white paper)

Unbleached pulp will be in its natural color and produces cardboard and

brown paper bags etc. The pulp can be packed ready for export or used

for the paper mills on site.

The white liquor goes to the evaporators where water is evaporated and

the chemicals become concentrated until it constitutes over 70% of the

mixture which is known as black liquor and is used in the recovery boiler

for combustion. The ash created is called smelt and is fluid at about 1100 C.

Water is added to the smelt which is known as green liquor and is then

mixed with chalk and becomes white liquor and can be used again at the

beginning of the process with treatment (addition of chemicals.)

The recovery boiler produces 350 T/hr steam at 60 bar and 485 C. There

is also a bark burning boiler which at the same pressure and temperature

produce about 70-80T/hr. There can be 4 headers, 60 bar, 35 bar, 10 bar

and 3 bar. Some of the 60 bar steam is used for the breaking of wood at

full temperature. The evaporators will take steam from the 10 bar header

(approx 70 T/hr) which will be let down to 3 5 bar for evaporating the

water from the white liquor to produce black liquor. 60 bar superheated

steam is used in the flash dryers in the fibreline process, to remove moisture

from the damp pulp. The 3 bar header is used to supply the paper mills and

the 10 bar header may also be used in some of the paper machines.

CHP Pulp and Paper Process

Figure 7: Typical paper machine, showing

heating cylinders

It is important that steam for the paper mill is provided at a condition close

to saturation. Steam that has too high a degree of superheat will result in

possible damaged product, but also reduced output owing to the fact that

superheated steam has poor heat transfer capabilities compared to saturated

and steam and therefore throughput of paper is reduced.

The pulp is blended with water and other chemicals, separated and fed to

the headbox at the right consistency. The raw materials (pulp) material fibres

(99% water) are pumped into head box. The stock is fed evenly onto wire

mesh. As the paper stock flows from the head box onto the wire the water

drains away leaving the tiny fibres as a mat on the mesh. When the mat has

reached the end of the wire section, it has become a sheet of paper, although

very moist and of little strength. It then passes over the press section.

The press consists of a number of cylinders which squeezes moisture from

the paper and the water is drawn away by suction. The Paper then passes to

the drier section, which consist of a large number of steam heated drying

cylinders. The cylinders temperature is normally slightly over

100 C. Synthetic drier fabric carrys the web of paper round the cylinders

until the paper is completely dry. Part of the way through the cylinders, is a

size press, where a solution of water and starch can be added to improve the

surface for printing. For tissue machines, a yankee drum can be used which

is a rely large diameter and relies on the large surface area to dry the tissue

paper. Steam quality at this stage is paramount to the quality and speed the

machine can operate at.

At the end of the process, the paper is smoothed using an, ironing method,

which consist of polished iron rollers. This helps to consolidate, polish and

glaze the surface of the paper. The paper is then reeled and ready for

uss/distribution.

High quality papers can be additionally coated by using clay and other

pigments. These coated papers are usually done on a separate machine, ut in

some cases may also have an on-machine coater for precoating before

being reeled.

The board machine is a similar process, but has several wet ends (headboxes

and wires) producing multiply sheet.

Pulp and Paper A Guide to Steam Conditioning

Figure 8: Paper machine using low pressure

steam close to saturation

Paper Making

CHP Pulp and Paper Products

VST-SE

The VST-SE was designed as a steam turbine bypass to process conditioning

valve. The requirements are to open and close very quickly in response to a

turbine trip, startup or to provide additional steam flow to the process.

The bypass to process with VST-SE will benefit from:

Reliable operation: suitable for up to 300 C thermal shock. Fully

machined circular section valve body.

More revenue owing to higher electrical production: this is achieved by

providing high turndown capability with regard to steam flow by means

of steam atomization.

High performance and stable control: solved by integral water

proportioning.

Reduced maintenance cost & downtime: provide repeatable tight

shutoff despite exposure to thermal shock having unique two piece seat

providing flexibility.

Maximize plant flexibility: the VST-SE provides modulating steam

atomization. Generally standard systems provide on/off atomization

Figure 9: VST-SE steam atomizing and

water proportioning

VLB

The VLB was designed as a steam turbine bypass valve and is widely used for

bypass or dump to condenser.

Pulp and Paper A Guide to Steam Conditioning

The bypass system with VLB will benefit from:

Reliable operation: suitable for up to 300 C thermal shock. Fully

machined circular section valve body.

High performance and stable control: system stability despite

pressure, flow and temperature transients with CCI total system

understanding implemented.

Reduced maintenance cost & downtime: provide repeatable tight

shutoff despite exposure to thermal shock having unique two piece seat

providing flexibility.

Excellent evaporation of water: ensuring trouble free operation when

bypassing to condenser owing to special multiple nozzle configuration

around valve outlet.

Pressure sealed bonnet: maintains tightness regardless of temperature

transients and allows quick and easy access to valve internals.

Accurate control of final steam conditions to condenser: preventing

condenser damage owing to overspray and vibration.

Low noise (DRAG dump tube used if noise requirements are onerous.)

Custom design of bypass valve: inlet/outlet connections to suit

application.

Figure 10: Typical VLB

Figure 11: Bypass to water cooled

condenser

CHP Pulp and Paper Process

CCI will provide the correct total

system solution for the application.

DRAG Velocity Control Technology

High velocity fluid or steam as a result of high pressure drop or large change

in pressure ratio creates velocity, which if to high causes cavitation and or

erosion resulting in valve failure.

CCI DRAG solution is unique in solving this, utilizing multi flow paths and

introducing the required number of pressure reducing stages. Refer to CCI

DRAG brochure.

CCI DRAG Benefits

Low noise: depending on application, noise levels of >85 dBA at 1 m are

possible. Working with CCI can provide reduced total system noise.

Reliable operation: by controlling velocity.

Longer valve life: controlling velocity and pressure head

More revenue owing to higher electrical production: will reduce or

eliminate maintenance activity or process shut down owing to

equipment failure.

High performance and stable control: disk stack can be custom

characterized to suit particular application, such as boiler level control

valve (feedwater control valve.)

Reduced maintenance cost & downtime: provide repeatable tight shutoff

utilizing MSS-SP61 shutoff by pressurized seat design.

Reduced installation cost: valve custom designed including connections

to suit application.

Figure 12: Uncontrolled velocity a

control valves worst enemy

Desuperheating of Process Steam

Controlling desuperheating of extraction and exhaust steam is challenging

owing to the following:

Figure 13: DRAG disk multi-trim/flow path

Low velocity at startup

Insufficient coverage

Large piping diameters dont encourage mixing

Set temperature close to saturation

Desuperheaters subject to transient conditions

Key components for successful desuperheating:

Figure 14: Multi nozzle DAM desuperheater

Small Diameter + High Velocity = Good Mixing

Hotter water (up to 120-130 C) smaller water droplet dia.

Higher

Smaller water droplet diameter = quicker evaporation

Even distribution (across the area of the steam) of the spraywater

Control of downstream temperature

Installation considerations CCI have several innovative styles of

desuperheaters, review and advice of the system is necessary. Aspects

such as liners, enthalpy control, reduced sections of piping, installation

are all aspects necessary to meet performance requirements.

P means better atomization of water (smaller water drop dia.)

Pulp and Paper A Guide to Steam Conditioning

Throughout the world, companies rely

on CCI to solve their severe service

control valve problems. CCI has provided

custom solutions for these and other

industry applications for more than

80 years.

Sales and service locations worldwide.

CCI World Headquarters

California

Telephone: (949) 858-1877

Fax: (949) 858-1878

22591 Avenida Empresa

Rancho Santa Margarita,

California 92688

USA

CCI FK

(Fluid Kinetics)

Telephone: 805 644 5587

Fax: 805 644 1080

2368 Eastman Avenue, Suite 8

Ventura

California 93003

USA

CCI Austria

(Spectris Components GmbH)

Telephone: 43 1 869 27 40

Fax: 43 1 865 36 03

Carlbergergasse 38/Pf.19

AT-1233 Vienna

Austria

CCI Italy

(STI)

Telephone: 39 035 29282

Fax: 39 035 2928247

Via G. Pascoli 10 A-B

24020 Gorle, Bergamo

Italy

CCI China

Telephone: 86 10 6501 0350

Fax: 86 10 6501 0286

Room 567/569

Office Tower, Poly Plaza

14 Dongzhimen South Avenue

Beijing 100027

China

CCI Japan

Telephone: 81 726 41 7197

Fax: 81 726 41 7198

194-2, Shukunosho

Ibaraki-City, Osaka 567-0051

Japan

CCI Korea

Telephone: 82 31 980 9800

Fax: 82 31 985 0552

26-17, Pungmu-Dong

Gimpo City

Kyunggi-Do 415-070

Republic of Korea

CCI Sweden

(BTG Valves)

Telephone: 46 533 689 600

Fax: 46 533 689 601

Box 603

SE-661 29 Sffle

Sweden

CCI Switzerland

(Sulzer Valves)

Telephone: 41 52 262 11 66

Fax: 41 52 262 01 65

Hegifeldstrasse 10

CH-8404 Winterthur

Switzerland

Contact us at:

info@ccivalve.com

Visit us online at:

www.ccivalve.com

DRAG is a registered trademark of CCI.

20 03 CCI

563 3/03 4K

Das könnte Ihnen auch gefallen

- Scope: TIP Category: Data and CalculationsDokument11 SeitenScope: TIP Category: Data and CalculationsManikandan Sigamani100% (2)

- Training ManualDokument63 SeitenTraining ManualMohamad Dpr100% (1)

- Board and Packaging Headbox TechnologyDokument15 SeitenBoard and Packaging Headbox Technologysakariso100% (2)

- Paper Mill READYDokument85 SeitenPaper Mill READYagility dreamsNoch keine Bewertungen

- CHEP 410 (5) Pulp and Paper IndustriesDokument41 SeitenCHEP 410 (5) Pulp and Paper IndustriesCJ SacoboNoch keine Bewertungen

- TAPPI Felt Conditioning Article PDFDokument6 SeitenTAPPI Felt Conditioning Article PDFDiana100% (1)

- Catalytic Role of Process Dust in SO2-To-SO3 ConveDokument9 SeitenCatalytic Role of Process Dust in SO2-To-SO3 ConveabderrahimnNoch keine Bewertungen

- Steam and Kondensat For PapermachineDokument33 SeitenSteam and Kondensat For PapermachinesakarisoNoch keine Bewertungen

- Pulp and Paper Industry: Energy ConservationVon EverandPulp and Paper Industry: Energy ConservationBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Recent Innovations in Paper Recycling Flotation)Dokument4 SeitenRecent Innovations in Paper Recycling Flotation)kayee516Noch keine Bewertungen

- Paper Manufacturing TrainingDokument183 SeitenPaper Manufacturing TrainingMazharul Islam100% (1)

- Topic 13 Papermaking Forming Text PDFDokument34 SeitenTopic 13 Papermaking Forming Text PDFThashna DusoruthNoch keine Bewertungen

- 120 TPD Karft Paper MachineDokument32 Seiten120 TPD Karft Paper MachineYonas Mulu100% (1)

- Dip PDFDokument27 SeitenDip PDFolenin64Noch keine Bewertungen

- Headbox Tappi2000cDokument11 SeitenHeadbox Tappi2000cKrishnamoorthyRajanbabuNoch keine Bewertungen

- The Application of Modified Starches at The Size PressDokument18 SeitenThe Application of Modified Starches at The Size PressPeter de Clerck100% (1)

- Chemical Pulping ProcessDokument19 SeitenChemical Pulping ProcessSyahmi HarizNoch keine Bewertungen

- Pulp and Paper Industry PDFDokument67 SeitenPulp and Paper Industry PDFMahesh Indla100% (1)

- Stock Prep RefiningDokument78 SeitenStock Prep RefiningVIKASNoch keine Bewertungen

- DoctoringTraining Rev Tim PDFDokument32 SeitenDoctoringTraining Rev Tim PDFtao dao ngocNoch keine Bewertungen

- Surface Sizing Basics PDFDokument4 SeitenSurface Sizing Basics PDFPeter de ClerckNoch keine Bewertungen

- Showering in The Wire and Press Section - in Which Direction PDFDokument20 SeitenShowering in The Wire and Press Section - in Which Direction PDFF Cikal AntariksaNoch keine Bewertungen

- Paper Pulp - Revised - BREF - 2015 PDFDokument906 SeitenPaper Pulp - Revised - BREF - 2015 PDFLuis E. Rodríguez100% (1)

- Topic 14 Papermaking Pressing TextDokument21 SeitenTopic 14 Papermaking Pressing Textronaldsacs100% (1)

- Paper Making Vacuum 3Dokument7 SeitenPaper Making Vacuum 3Santosh PoddarNoch keine Bewertungen

- Optimization of Wire Vacuum by D K SinghalDokument7 SeitenOptimization of Wire Vacuum by D K SinghalnazeerNoch keine Bewertungen

- Pulp and Paper IndustriesDokument14 SeitenPulp and Paper Industriesdaabgchi0% (1)

- Sulzer Pumps For Paper IndustryDokument4 SeitenSulzer Pumps For Paper IndustryBapu612345Noch keine Bewertungen

- Pulp & PaperDokument71 SeitenPulp & PaperAleem AhmedNoch keine Bewertungen

- Grades of PaperDokument25 SeitenGrades of PaperRohit SinghNoch keine Bewertungen

- InTech-Fundamentals of Paper Drying Theory and Application From Industrial PerspectiveDokument49 SeitenInTech-Fundamentals of Paper Drying Theory and Application From Industrial PerspectiveSushil MeshramNoch keine Bewertungen

- Manual Paper Recycling Machine DesignDokument6 SeitenManual Paper Recycling Machine DesignJashandeep SinghNoch keine Bewertungen

- Shoe Press c3Dokument32 SeitenShoe Press c3Nipun DograNoch keine Bewertungen

- White Liquor Composition and CalculationDokument52 SeitenWhite Liquor Composition and Calculationjohark01100% (2)

- 1461 e 2015-07-14 Brochure Compact-Dispersion-System en InteraktivDokument8 Seiten1461 e 2015-07-14 Brochure Compact-Dispersion-System en InteraktivelcarpaneziNoch keine Bewertungen

- Bürkle Press LineDokument14 SeitenBürkle Press LineWim VerschaeveNoch keine Bewertungen

- 15.quality Control System For Paper Machines (Read-Only) (Compatibility Mode)Dokument19 Seiten15.quality Control System For Paper Machines (Read-Only) (Compatibility Mode)Sudhakara RaoNoch keine Bewertungen

- Paper and Surface Chemicals - Part2 PDFDokument13 SeitenPaper and Surface Chemicals - Part2 PDFHgagselim SelimNoch keine Bewertungen

- OptiCalender Metal Belt Typical Training Material enDokument52 SeitenOptiCalender Metal Belt Typical Training Material enjavier_khanNoch keine Bewertungen

- Low Consistency RefiningDokument65 SeitenLow Consistency RefiningLaboratorio PapelesRegionalesNoch keine Bewertungen

- New Drying and Dewatering Processes in PDokument23 SeitenNew Drying and Dewatering Processes in PvenkNoch keine Bewertungen

- Pulp and Paper Production From EFBDokument9 SeitenPulp and Paper Production From EFBEddie TaiNoch keine Bewertungen

- Stock Preparation PresentationDokument83 SeitenStock Preparation PresentationvivekbhuchemNoch keine Bewertungen

- PulpDokument382 SeitenPulpBeerBie100% (1)

- Improving The Efficiency of A Brown Stock Washing LineDokument91 SeitenImproving The Efficiency of A Brown Stock Washing LineHuy NguyenNoch keine Bewertungen

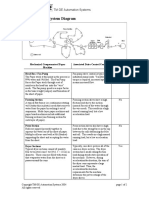

- Paper Machine System Diagram: TM GE Automation SystemsDokument2 SeitenPaper Machine System Diagram: TM GE Automation SystemsWudassie AyeleNoch keine Bewertungen

- Alkaline PulpingDokument77 SeitenAlkaline Pulpingvivekbhuchem100% (1)

- Flaekt DryerDokument8 SeitenFlaekt DryerTim Ku100% (1)

- Paper Fan PumpsDokument8 SeitenPaper Fan PumpsnazeerNoch keine Bewertungen

- Mechanism of Refining - TMP Low ConsistencyDokument71 SeitenMechanism of Refining - TMP Low ConsistencyLaboratorio PapelesRegionalesNoch keine Bewertungen

- Report of Paper and PulpDokument36 SeitenReport of Paper and PulpMahesh IndlaNoch keine Bewertungen

- Book - Paper Products Physics and Technology PDFDokument356 SeitenBook - Paper Products Physics and Technology PDFVuNoch keine Bewertungen

- 07 NipcoFlex Shoe Press En-1 21Dokument4 Seiten07 NipcoFlex Shoe Press En-1 21venkNoch keine Bewertungen

- Screen CleanDokument182 SeitenScreen CleanKristin Weber100% (2)

- Deculator Article 5 03Dokument4 SeitenDeculator Article 5 03tsvmpm1765100% (3)

- Technology, Energy Efficiency and Environmental Externalities in The Pulp and Paper Industry - AIT, ThailandDokument140 SeitenTechnology, Energy Efficiency and Environmental Externalities in The Pulp and Paper Industry - AIT, ThailandVishal Duggal100% (1)

- FRIM Centrifugal CleanersDokument12 SeitenFRIM Centrifugal CleanersKristin WeberNoch keine Bewertungen

- Recovered Fiber Pulping NoteDokument28 SeitenRecovered Fiber Pulping Noteteewee_cuteNoch keine Bewertungen

- Scope: Approved by The Pulp Properties Committee of The Process and Product Quality DivisionDokument4 SeitenScope: Approved by The Pulp Properties Committee of The Process and Product Quality DivisionRaNoch keine Bewertungen

- Kraft Process Of Pulping A Complete Guide - 2020 EditionVon EverandKraft Process Of Pulping A Complete Guide - 2020 EditionNoch keine Bewertungen

- Kraft process of pulping A Complete Guide - 2019 EditionVon EverandKraft process of pulping A Complete Guide - 2019 EditionNoch keine Bewertungen

- Mep002 List of DrawingsDokument1 SeiteMep002 List of DrawingsMuhammadNoch keine Bewertungen

- Curriculam Vitae: Position Applied For: Electrical EngineerDokument3 SeitenCurriculam Vitae: Position Applied For: Electrical EngineerMuhammadNoch keine Bewertungen

- PlumbingDokument5 SeitenPlumbingMuhammadNoch keine Bewertungen

- Fire Fighting Course Outline NWDokument5 SeitenFire Fighting Course Outline NWMuhammadNoch keine Bewertungen

- Fire Fighting Course Outline NWDokument5 SeitenFire Fighting Course Outline NWMuhammadNoch keine Bewertungen

- "Kraft Recovery Boilers" by T. N. Adams, W. J. Frederic, T. M. Grace, M. Hupa, K. Iisa, A. K. Jones, H. TranDokument16 Seiten"Kraft Recovery Boilers" by T. N. Adams, W. J. Frederic, T. M. Grace, M. Hupa, K. Iisa, A. K. Jones, H. Tranvictor japposanNoch keine Bewertungen

- BLRBACEmergencyShutdownProcedureOctober2009 PDFDokument17 SeitenBLRBACEmergencyShutdownProcedureOctober2009 PDFjeanpaul CAYTANNoch keine Bewertungen

- Corrosion On BoilersDokument105 SeitenCorrosion On BoilersPlínio Silveira100% (1)

- Paper PulpDokument28 SeitenPaper PulpFACEtubeNoch keine Bewertungen

- Petcoke For Lime KilnDokument44 SeitenPetcoke For Lime KilnHuyentrang Nguyen75% (4)

- Iii. Recovery BoilerDokument9 SeitenIii. Recovery BoilerSai SwaroopNoch keine Bewertungen

- Thermochemistry of Salts 0703Dokument142 SeitenThermochemistry of Salts 0703kkakosimNoch keine Bewertungen

- Bhaskar Steel & Ferro Alloys Ltd. (BSFAL) 8 MW Captive Power Generation Through Waste HeatDokument47 SeitenBhaskar Steel & Ferro Alloys Ltd. (BSFAL) 8 MW Captive Power Generation Through Waste HeatjulianoducaNoch keine Bewertungen

- Consensus Tube SamplingDokument33 SeitenConsensus Tube SamplingjycortesNoch keine Bewertungen

- KRBFullDokument246 SeitenKRBFullPamella SandovalNoch keine Bewertungen

- Aalborg Av 6nDokument2 SeitenAalborg Av 6nAmit SarkarNoch keine Bewertungen

- A1. App ThermalDokument22 SeitenA1. App ThermalMarcos DuarteNoch keine Bewertungen

- Lignin 3Dokument61 SeitenLignin 3Arpit DubeyNoch keine Bewertungen

- SSPBML - Kra Plant Jan-Mar 15-2-13 v7Dokument756 SeitenSSPBML - Kra Plant Jan-Mar 15-2-13 v7Gaurav ChaurasiaNoch keine Bewertungen

- Safe Firing of Black Liquor (October 2012) - 0Dokument5 SeitenSafe Firing of Black Liquor (October 2012) - 0Daniel Ferreira Dos SantosNoch keine Bewertungen

- Automation of System of BoilerDokument52 SeitenAutomation of System of BoilerHarshil SanghaviNoch keine Bewertungen

- Hand Hole PlateDokument37 SeitenHand Hole PlateRajkumar MaityNoch keine Bewertungen

- TJ0621 405-412sretenovicDokument8 SeitenTJ0621 405-412sretenovicIvanNoch keine Bewertungen

- Project On Finance Performnce TNPLDokument25 SeitenProject On Finance Performnce TNPLVenkatram PrabhuNoch keine Bewertungen

- The Kraft Chemcial Recovery Process: February 2016Dokument9 SeitenThe Kraft Chemcial Recovery Process: February 2016SamyakJainNoch keine Bewertungen

- Ion Exchange TechDokument7 SeitenIon Exchange TechclintoncNoch keine Bewertungen

- Balance Steam Supply With Demand - Then Save Energy and Reduce Carbon FootprintDokument8 SeitenBalance Steam Supply With Demand - Then Save Energy and Reduce Carbon FootprintmansoursabicNoch keine Bewertungen

- Soot Blower Lance Tube CorrosionDokument11 SeitenSoot Blower Lance Tube CorrosionKECS_kck100% (1)

- Recommended Guidelines For Materials & Welding in BoilersDokument56 SeitenRecommended Guidelines For Materials & Welding in BoilersAnsar HayatNoch keine Bewertungen

- MTC IndicationDokument31 SeitenMTC IndicationLILISNoch keine Bewertungen

- Rotork Microsoft Word - Rev 4 September 1stDokument26 SeitenRotork Microsoft Word - Rev 4 September 1stLeonardo Silva SilvaNoch keine Bewertungen

- Incineration of Dilute Non-Condensable Gasses in The Recovery Boiler at Pacifica Papers, Powell River, British ColumbiaDokument25 SeitenIncineration of Dilute Non-Condensable Gasses in The Recovery Boiler at Pacifica Papers, Powell River, British ColumbiaErickNoch keine Bewertungen