Beruflich Dokumente

Kultur Dokumente

Livelli Olio CA - Eng

Hochgeladen von

Jose MariaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Livelli Olio CA - Eng

Hochgeladen von

Jose MariaCopyright:

Verfügbare Formate

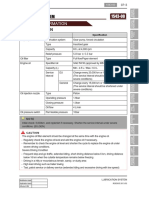

Sheet

ROTOFLUID COUPLING CA

10-017CA-1

INSTRUCTION FOR REPLACEMENT AND VARIATION OF THE

OIL QUANTITY

Date

06-2009

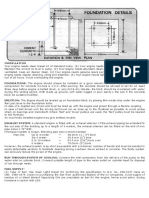

OIL CHANGE:

Tha oil in the coupling must be changed for the first time after 400

working hours and subsequently after each 4000 working hours.

Proceed as follows to change the oil:

1) Rotate the coupling to bring the filling plug to its highest

position.

2) Unscrew and remove the filling plug.

3) Determine the correct filling level by rotating the coupling until

the filling hole corresponds to the current oil level

4) Completely drain the oil in the coupling by bringing the filling

hole to its lowest point.

5) Rotate the coupling again to bring the filling hole to correspond

to the filling level determined at point 3.

6) Pour in the new oil until the oil filling level is reached

The quantity and type of oil recommended is listed inTable 1.

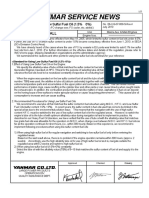

VARIATION OF THE OIL LEVEL (Figures 1 and 2)

According to the type of use and the service required by the

coupling, sometimes the oil filling level must be modified by

increasing

or decreasing

quantity. by decreasing the oil

The following

results the

areoil achieved

quantity:

Slower and more gradual startings (Fig. 3)

Less absorption of startings current

Better protection to the transmission elements in the event of

overload

Higher slip value at running

IMPORTANT: an excessive decrease in the oil quantity can cause

the following problems:

The impossibility of rapidly accelerating the machine due to

insufficient torque

The overheating of the coupling, with consequent damage to

the oil seals

The following results are achieved by increasing the oil

quantity:

Faster startings (Fig. 3)

Lower slip value at running

Higher absortion of starting current during acceleration phases

Greater strain on transmission elements

IMPORTANT: an excessive oil quantity can cause the following

problems:

The overloading of the machine transmission motor

The overturning of the oil seal lip due to internal overpressure

The cracking of the coupling housing due to internal

overpressure caused by the lack of internal space for sufficient

oil expansion.

NOTE: the filling level at 60 must never be exceeded, an d a level

at 45 can be reached only in special cases and aft er previous

WESTCAR consultation.

Types of oil recommended can work standard

Working temperature from -20 C. to +180 C.

- BP

ENERGOL HPL 22

- CASTROL

HYSPIN AWS 22

- ESSO

SPINESSO 22

- MOBIL

VELOCITE OIL D

- OLEOTECNICA

MOVO H 22

- SHELL

TELLUS OIL 22

Types of oil can work continually (longer 5 days)

Working temperature from -15 C. to +180 C.

- BP

ENERGOL HLP Z 46

- CASTROL

HYSPIN AWS 46

OIL QUANTITIES CORRESPONDING TO DIFFERENT

SIZE

CA 55S

CA 55D

CA 65S

CA 65D

CA 75P S

Tab. 1 CA 75PD

CA 80P

FILLING LEVELS

60

65

70

75

80

85

90

95

lt.

33,9

31,9

62,5

59,5

76,5

lt.

lt.

lt.

lt.

lt.

lt.

lt.

17,5

16,3

31,9

30,0

58,7

55,8

71,4

16,3

15,2

29,8

28,0

54,7

52,0

66,0

15,1

14,1

27,7

26,1

50,7

48,2

60,7

14

13,1

25,7

24,2

46,9

44,6

56,0

13,1

12,2

23,8

22,4

43,4

41,3

51,5

12

11,2

21,9

20,6

39,9

38,0

47,0

- ESSO

NUTO H 46

CA 85PS

132,1

122,7

112,8

102,7

92,6

83,1

- MOBIL

DTE 25

CA 85PD

127,8

118,6

109,0

99,1

89,3

80,1

- OLEOTECNICA

MOVO H 46

CA 90P

176,0

166,3

154,0

141,5

129,8

119,1

108,8

98,1

- SHELL

TELLUS 46

The coupling can be also supplied with fire-proof oil or for low

Temperature one(-40C.).For more information ad dress

to WESTCAR

Das könnte Ihnen auch gefallen

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

- SM 03 BDokument34 SeitenSM 03 BMark OreschnickNoch keine Bewertungen

- OilChange DV6Dokument1 SeiteOilChange DV6ismael23Noch keine Bewertungen

- Thornycroft Marine Engine PDFDokument42 SeitenThornycroft Marine Engine PDFAnonymous 3xJyAmcNoch keine Bewertungen

- Motor Lub Oil SystemDokument4 SeitenMotor Lub Oil SystemsureshnfclNoch keine Bewertungen

- "Start-Hidro": Oleo-Hydraulic StarterDokument2 Seiten"Start-Hidro": Oleo-Hydraulic StarterDeyvis Rivera VazquezNoch keine Bewertungen

- Chassis LubricationDokument142 SeitenChassis LubricationKen ThungNoch keine Bewertungen

- 23379 ДТАКDokument7 Seiten23379 ДТАК18Noch keine Bewertungen

- C4 Engine Oil Draining and CapacitiesDokument1 SeiteC4 Engine Oil Draining and CapacitieswudangnicNoch keine Bewertungen

- Drill Head Inspectionand Oil LevelsDokument6 SeitenDrill Head Inspectionand Oil LevelsSipa1109Noch keine Bewertungen

- High ViscosityDokument4 SeitenHigh ViscosityAnonymous XtvvG80zuNoch keine Bewertungen

- Thornycroft90 108 PDFDokument42 SeitenThornycroft90 108 PDFvadim vadimNoch keine Bewertungen

- Troubleshooting Hot Gear DrivesDokument8 SeitenTroubleshooting Hot Gear DrivesYuda SatriaNoch keine Bewertungen

- Oil Pan Removal - Installation (MZR-CD (RF Turbo) )Dokument6 SeitenOil Pan Removal - Installation (MZR-CD (RF Turbo) )Anonymous C6Vaod9Noch keine Bewertungen

- Fl-Ti Nr24 Turbolader Psa en WebDokument2 SeitenFl-Ti Nr24 Turbolader Psa en Webdublin33Noch keine Bewertungen

- Service Bulletin - (TB00!99!2090) - Lubrication Oils For Medium Speed EnginesDokument8 SeitenService Bulletin - (TB00!99!2090) - Lubrication Oils For Medium Speed Enginesps_visjehotmailcomNoch keine Bewertungen

- 100-Hour Maintenance and Service Manual for Combi-Lift TruckDokument33 Seiten100-Hour Maintenance and Service Manual for Combi-Lift TruckЕвгений ГубаревNoch keine Bewertungen

- Seal Oil SystemDokument40 SeitenSeal Oil Systemsameer betalNoch keine Bewertungen

- 5000 KW Gearbox High Pinion Bearing Temperatures 1644227029Dokument7 Seiten5000 KW Gearbox High Pinion Bearing Temperatures 1644227029MC ANoch keine Bewertungen

- 912 Oil ChangeDokument4 Seiten912 Oil ChangeGaberNoch keine Bewertungen

- Maintaining Engine Oil Level and QualityDokument4 SeitenMaintaining Engine Oil Level and QualityAbel OviedoNoch keine Bewertungen

- Turbine Lubrication System: A Chemical ApproachDokument33 SeitenTurbine Lubrication System: A Chemical ApproachSanjit SahooNoch keine Bewertungen

- 4.3 V6 Oil Cooler RemovalDokument2 Seiten4.3 V6 Oil Cooler RemovalCosmicdancer RudraNoch keine Bewertungen

- Use of Low Sulfur Fuel OilDokument5 SeitenUse of Low Sulfur Fuel OilRokkosan Giorgio100% (1)

- Turbine Lube Oil Operation GuideDokument34 SeitenTurbine Lube Oil Operation GuideNIHAR BEHERANoch keine Bewertungen

- Lister Cs Manual PDFDokument16 SeitenLister Cs Manual PDFMASSERONNoch keine Bewertungen

- Engine Lubrication System GuideDokument43 SeitenEngine Lubrication System Guidekebaman1986Noch keine Bewertungen

- Turbonetics Installation InstructionsDokument4 SeitenTurbonetics Installation Instructionscharles whiteNoch keine Bewertungen

- Carbon Build-Up Leads to Turbo FailureDokument44 SeitenCarbon Build-Up Leads to Turbo FailureMark Tranter86% (7)

- JAC 4DA1 Series Diesel Engine PDFDokument12 SeitenJAC 4DA1 Series Diesel Engine PDFFerran Alfonso80% (5)

- Oil SepratorsDokument4 SeitenOil SepratorsMohammad Amer0% (1)

- BorgWarner TurboalimentadoresDokument108 SeitenBorgWarner TurboalimentadoresAntonio Monteiro100% (1)

- p5 5S-FE+ENGINE+REPAIR+MANUALDokument23 Seitenp5 5S-FE+ENGINE+REPAIR+MANUALkavindaNoch keine Bewertungen

- Lub of Bolero SLXDokument21 SeitenLub of Bolero SLXRohit PantNoch keine Bewertungen

- Caution: Applicable Model Turbocharger SystemDokument1 SeiteCaution: Applicable Model Turbocharger SystemanggieNoch keine Bewertungen

- Checking engine oil level procedure for Mercedes-BenzDokument2 SeitenChecking engine oil level procedure for Mercedes-Benz1LEFFENoch keine Bewertungen

- Wet SumpingDokument3 SeitenWet SumpingBimal Amarnath MenonNoch keine Bewertungen

- Fuel Oil System by P.KDokument28 SeitenFuel Oil System by P.Kkr_abhijeet72356587100% (1)

- OIL CHANGE GUIDE FOR MZ-CD 3.2 I5 ENGINEDokument1 SeiteOIL CHANGE GUIDE FOR MZ-CD 3.2 I5 ENGINESouth East Queensland 4x4Noch keine Bewertungen

- Oiling System 101: To Restrict or Not To Restrict?: - From Dart Cylinder HeadsDokument7 SeitenOiling System 101: To Restrict or Not To Restrict?: - From Dart Cylinder Headsm_najmanNoch keine Bewertungen

- Engine Lubrication SystemsDokument8 SeitenEngine Lubrication SystemsMentsnot GetuNoch keine Bewertungen

- Gear Oil: The Trademark and Name of Commendatory Gear OilDokument12 SeitenGear Oil: The Trademark and Name of Commendatory Gear OilPreett Rajin MenabungNoch keine Bewertungen

- The Turbine Lubricating Oil System: ObjectivesDokument23 SeitenThe Turbine Lubricating Oil System: Objectivesefmaggio100% (2)

- ABB Turbocharger Tips For The OperatorDokument44 SeitenABB Turbocharger Tips For The Operatorsevero97100% (4)

- Cyl LubricationDokument7 SeitenCyl LubricationThuria TunNoch keine Bewertungen

- Selecting Proper Lubricants for Compressor Frames and CylindersDokument18 SeitenSelecting Proper Lubricants for Compressor Frames and CylindersYurvis VasquezNoch keine Bewertungen

- VQ37HR Oil Consumption TSB - Nissan 370zDokument8 SeitenVQ37HR Oil Consumption TSB - Nissan 370zcheshirecat79Noch keine Bewertungen

- Lubrication System (2Az-Fe) : On-Vehicle InspectionDokument22 SeitenLubrication System (2Az-Fe) : On-Vehicle InspectionTung NguyenNoch keine Bewertungen

- F430 Gearbox Oil ChangeDokument3 SeitenF430 Gearbox Oil ChangetomNoch keine Bewertungen

- Hoja Reclamación deDokument4 SeitenHoja Reclamación deOvidioNoch keine Bewertungen

- Owners Manual v3 6.6VGTDokument398 SeitenOwners Manual v3 6.6VGTpoknik 1400Noch keine Bewertungen

- Unit Description SpecificationDokument6 SeitenUnit Description SpecificationPeter O'neill100% (1)

- CHAPTER 8 Engine Lubrication and CoolingDokument30 SeitenCHAPTER 8 Engine Lubrication and CoolingRushabh PatelNoch keine Bewertungen

- Image Server HandlerDokument12 SeitenImage Server Handlerbobcat1810Noch keine Bewertungen

- Kbu Prelube CompressorDokument2 SeitenKbu Prelube Compressornicol_sgNoch keine Bewertungen

- r185nm ManualDokument36 Seitenr185nm Manualjohnysonycum100% (2)

- Damage Brochure MAHLE Original TurbochargersDokument16 SeitenDamage Brochure MAHLE Original Turbochargerszhengdong618Noch keine Bewertungen

- Essex Terraplane Six 1933 Owner's Manual of InformationVon EverandEssex Terraplane Six 1933 Owner's Manual of InformationNoch keine Bewertungen

- Automotive Seals GuideDokument109 SeitenAutomotive Seals GuideJose Maria50% (2)

- ManualDokument3 SeitenManualJose MariaNoch keine Bewertungen

- PC Brakes Bzfmv7 16 GBDokument15 SeitenPC Brakes Bzfmv7 16 GBJose MariaNoch keine Bewertungen

- BZFMV7e (Intructions)Dokument21 SeitenBZFMV7e (Intructions)Jose MariaNoch keine Bewertungen

- Hydraulic Puller Operating InstructionsDokument5 SeitenHydraulic Puller Operating InstructionsMasterrNoch keine Bewertungen

- Diaphragms Chords CollectorsDokument219 SeitenDiaphragms Chords CollectorsElio Saldaña100% (1)

- Box Transferring MCDokument14 SeitenBox Transferring MCBhuvnesh VermaNoch keine Bewertungen

- Válvula de Alivio Vicking - AGF 7000Dokument2 SeitenVálvula de Alivio Vicking - AGF 7000Maurilio Batista de LimaNoch keine Bewertungen

- D 6Dokument47 SeitenD 6gilmer flores mamaniNoch keine Bewertungen

- Catalog 40 Spare PartsDokument54 SeitenCatalog 40 Spare PartsMiticaVladNoch keine Bewertungen

- Parts Guide: AL-1217 AL-1226Dokument38 SeitenParts Guide: AL-1217 AL-1226AAAMARONoch keine Bewertungen

- CVT PatriotDokument37 SeitenCVT PatriotErnesto Rivas SoteloNoch keine Bewertungen

- Catalogo Repuestos YBR125DX 2008 ColombiaDokument58 SeitenCatalogo Repuestos YBR125DX 2008 ColombiaadrielairaldoNoch keine Bewertungen

- Fig. 980 ANSI Ductile Iron Fully Lugged Butterfly Valve Class 150Dokument1 SeiteFig. 980 ANSI Ductile Iron Fully Lugged Butterfly Valve Class 150kikokiko KarimNoch keine Bewertungen

- BP Heating ManualDokument44 SeitenBP Heating ManualpasabeyNoch keine Bewertungen

- Control Cables PDFDokument28 SeitenControl Cables PDFPandurang NalawadeNoch keine Bewertungen

- High Pressure Gear Pump GuideDokument12 SeitenHigh Pressure Gear Pump GuideMauricio Ariel H. OrellanaNoch keine Bewertungen

- DP09toc PDFDokument1 SeiteDP09toc PDFNerio CanadellNoch keine Bewertungen

- Technical Description MPPUDokument10 SeitenTechnical Description MPPUNinaNoch keine Bewertungen

- SK 19517Dokument2 SeitenSK 19517Carey C Jones100% (1)

- Fluid Flow Measurement Techniques and DevicesDokument75 SeitenFluid Flow Measurement Techniques and DevicesArah Louise ApostolNoch keine Bewertungen

- VRF Technical Data Book Highlights Key Specs (38k-61k BTU, 3-4.5 TonDokument55 SeitenVRF Technical Data Book Highlights Key Specs (38k-61k BTU, 3-4.5 TonFred BensimonNoch keine Bewertungen

- Nia Audina Sitanggang CBR Temperature and Heat BMH J 17-18Dokument9 SeitenNia Audina Sitanggang CBR Temperature and Heat BMH J 17-18NIA AUDINA SITANGGANGNoch keine Bewertungen

- Fisher Control Valve Sourcebook - Power and Severe ServiceDokument220 SeitenFisher Control Valve Sourcebook - Power and Severe Servicemtrj59Noch keine Bewertungen

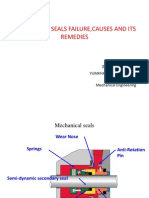

- MECHANICAL SEALS FAILURE CAUSESDokument26 SeitenMECHANICAL SEALS FAILURE CAUSESFaruque Khan Yumkhaibam100% (6)

- Simple Stress: Simple Stresses Are Expressed As The Ratio of The Applied Force Divided by The Resisting Area orDokument36 SeitenSimple Stress: Simple Stresses Are Expressed As The Ratio of The Applied Force Divided by The Resisting Area orEric UrrizaNoch keine Bewertungen

- Kirloskar SP 3HH Leaflet (A)Dokument2 SeitenKirloskar SP 3HH Leaflet (A)Imran_firdousiNoch keine Bewertungen

- 793F, 793F, WTR, Oem PDFDokument18 Seiten793F, 793F, WTR, Oem PDFDennis OlayaNoch keine Bewertungen

- Operating Manual - Dehumidifier TTK 31 EDokument17 SeitenOperating Manual - Dehumidifier TTK 31 EEşanu ViorelNoch keine Bewertungen

- Assignment 2 Ch2 3Dokument10 SeitenAssignment 2 Ch2 3Zuhairi ZakariaNoch keine Bewertungen

- Shaft Alignment Using Strain Gauges - Case StudiesDokument16 SeitenShaft Alignment Using Strain Gauges - Case StudiesAndre BlueNoch keine Bewertungen

- Epiroc-Hidraulicna Busilica Simba k102Dokument5 SeitenEpiroc-Hidraulicna Busilica Simba k102Nani NaniNoch keine Bewertungen

- Rav M05 0001Dokument40 SeitenRav M05 0001DanielDeFrancescoNoch keine Bewertungen