Beruflich Dokumente

Kultur Dokumente

SWMS 67 - Safe Use of Nail Guns

Hochgeladen von

JonasOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SWMS 67 - Safe Use of Nail Guns

Hochgeladen von

JonasCopyright:

Verfügbare Formate

Safe Work Method Statement

Use of Master Builders Generic Safe Work Method Statements

Disclaimer:

The Master Builders Association of Victoria expressly disclaim all and any liability to any person in respect of anything, and of consequence

of anything done or omitted to be done by any or such person in reliance, whether wholly or partially on this generic safe work method

statement.

Rules for the use of Master Builders generic SWMS

1. This generic SWMS is provided as a sample. It is not to be used by a builder or subcontractor for the purpose of managing safety on their

projects. It can be used as a template to enable builders and subcontractors to produce their own SWMS. Master Builders have carbon

copy pads available for sale to enable builders/subcontractors to produce their own SWMS.

2. Employers intending to use this SWMS as a template for their own SWMS must ensure they consult with their employees, including their

Health and Safety Representatives, prior to its introduction.

3. Builders and subcontractors must ensure that their SWMS is relevant to the project at hand. Generic SWMS should not be used unless

precautions have been taken to ensure that the document adequately addresses the hazards and risks relevant to each particular project.

4. Builders and subcontractors intending to use this sample SWMS as a template for their own generic SWMS, without making any changes

to the detail, must ensure that they adhere to and implement all of the relevant risk controls.

5. The range of generic SWMS provided by Master Builders are not sufficiently broad enough to cover all hazards or risks encountered by

builders and subcontractors. It does not cover the full list of requirements for which SWMS are specifically required under the OHS

Construction Regulations. It is important that the builder or subcontractor undertake their own hazard identification and risk control

process relevant for each particular task.

It is highly recommended that persons who are responsible for preparing and reviewing SWMS undertake training so as to understand the

process of identifying and controlling risks in the workplace.

Remember: Each SWMS should be site specific. Include all workers in the development of the SWMS.

All workers should sign off to verify that they understand all the requirements of this Safe Work Method Statement.

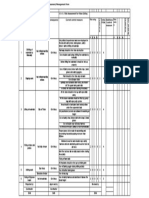

Safe Work Method Statement

Company Name

Site Name

Contractor

Activity

Safe Work Method Statement

67

No ______ Page

Safe use of nail guns

of

Permit to Work Requirement

Yes

No

Tasks

Hazards and Risks

Risk control measures

Who is responsible?

List the tasks required to perform

the activity in the sequence they are

carried out.

What can harm you - Hazards?

What can happen - Risks?

List the control measures required to eliminate or reduce the risk of injury

and detail how the control measures will be put in place.

Write the name of the person

responsible (supervisor or

above) to implement the control

measures identified.

Ensure all workers on

site have received

proper training

Conduct a pre

operation check.

Advise others of nail

gun use.

Insufficient knowledge or experience to

perform tasks that could endanger

themselves or others on the worksite.

Misfire

Advise others of nail

gun use.

Persons below may be shot by misfired

nails, nails passing fully through timber,

broken and fragmented nails.

Load gun with a nail

magazine.

Incorrect type or loading technique may

cause a jam or misfire.

Attach air supply or gas

cylinder.

Misfire, broken or shattered nails.

State legislative required OH&S Induction training.

Site specific safety inductions & Safety Plan

Task specific training

Ensure all nail gun safety devices are operable.

Never attempt to dislodge jammed nails or

components while the compressed air source is

connected to the nail gun.

Never modify or tamper with any safety device

fitted to a nail gun.

Tag any defective tool and remove from service.

Document monthly inspections noting any

maintenance.

Ensure the area around or below the work site is

clear of any personnel.

Cordon off any area using barrier tape or similar if

there is a risk of others accidentally walking

beneath nail gun work.

Always use the appropriate gun and gun nail for

the job at hand, this will prevent under/over

penetration of the timber.

ALWAYS use the correct air pressure or gas

volume as specified in the operators manual.

Remember: Each SWMS should be site specific. Include all workers in the development of the SWMS.

All workers should sign off to verify that they understand all the requirements of this Safe Work Method Statement.

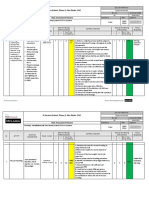

Safe Work Method Statement

Pull enough air line

onto roof

Trip, catch or fall hazard

Position nail gun over

timber intersection,

depress safety switch &

pull trigger

Injury to others

Projectile Hazard

Noise

Ensure all nails finish

flush with the timber

surface

Trip or catch injury

Ensure all hoses & hose couplings are in a

serviceable condition.

Consider purchasing a gas cartridge powered gun

(ie this type eliminates the trip hazard of the air

line).

Be aware while moving across the roof the airline

does not get caught on the roof structure and pull

you off balance.

Be aware of the airline so that it does not become a

trip hazard to you or others.

Be aware of the airline to ensure it does not knock

tools or equipment off the roof onto others below.

Ensure the area below the work site is clear of any

other workers.

ALWAYS wear safety glasses when using a nail

gun.

Be aware of flying splinters off split or shattered

timber.

If attempting to skew-nail timber, ensure a sufficient

angle is used to avoid the nail ricocheting off the

timber especially hardwood timbers.

Be wary of gang nails and speed bracing that may

cause a nail to skew out of the timber or break.

Earmuffs of plugs must be worn if the nail guns

operation exceeds 140db (peak) check owners

manual. Hearing protection should be considered

when nail guns are used.

Fully nail in with a hammer, adjust gun to leave

nails flush or just below timber surface.

Remember: Each SWMS should be site specific. Include all workers in the development of the SWMS.

All workers should sign off to verify that they understand all the requirements of this Safe Work Method Statement.

Safe Work Method Statement

Move along roof

Misfire

I have read and understood the content of this Safe Work Method Statement

Workers name

Signature

NEVER change position or carry the nail gun with

your finger depressing the trigger. Many accidents

have occurred where the nail gun has brushed or

bumped a leg, knee or foot which has depressed

the pressure plate discharging the nail because the

trigger was being held in.

Approved By

Date

Workers name

Signature

Remember: Each SWMS should be site specific. Include all workers in the development of the SWMS.

All workers should sign off to verify that they understand all the requirements of this Safe Work Method Statement.

Das könnte Ihnen auch gefallen

- SWMS 2 Fixing CarpenterDokument3 SeitenSWMS 2 Fixing CarpenterJonasNoch keine Bewertungen

- SWMS - PlumberDokument7 SeitenSWMS - PlumberSiddiqueShaikhNoch keine Bewertungen

- Safe Work Method Statement WorksheetDokument7 SeitenSafe Work Method Statement WorksheetianllagasNoch keine Bewertungen

- Use of Master Builders Generic Safe Work Method StatementsDokument7 SeitenUse of Master Builders Generic Safe Work Method StatementsJonasNoch keine Bewertungen

- Concrete Formwork Suspended SlabDokument5 SeitenConcrete Formwork Suspended SlabKate HopleyNoch keine Bewertungen

- Detailed Excavation Installation of Formwork & Reinforcement ConcretingDokument29 SeitenDetailed Excavation Installation of Formwork & Reinforcement ConcretingRio Handoko100% (2)

- SWMS 71 - Use of Curing ChemicalDokument2 SeitenSWMS 71 - Use of Curing ChemicaleastNoch keine Bewertungen

- Safe Work Method Statement WorksheetDokument3 SeitenSafe Work Method Statement WorksheetSiti Salwani binti Ab RahimNoch keine Bewertungen

- Safe Work Method Statement WorksheetDokument5 SeitenSafe Work Method Statement Worksheetgoodspeed_phNoch keine Bewertungen

- Demolition by HandDokument6 SeitenDemolition by Handchassas100% (1)

- Demolition Method StatementDokument9 SeitenDemolition Method StatementMuhammad TariqNoch keine Bewertungen

- Use and Refuelling of Portable GeneratorDokument4 SeitenUse and Refuelling of Portable GeneratorJonasNoch keine Bewertungen

- SWMS ScaffoldingDokument4 SeitenSWMS Scaffoldingdox4useNoch keine Bewertungen

- Daily Worksite Checklist For Trenching Excavation SitesDokument2 SeitenDaily Worksite Checklist For Trenching Excavation SitesParth PatelNoch keine Bewertungen

- Safe Work Method StatementDokument11 SeitenSafe Work Method StatementJNoch keine Bewertungen

- Risk Assess T-23 - Hilti Cartridge Tool OperationDokument2 SeitenRisk Assess T-23 - Hilti Cartridge Tool OperationMAB Ali100% (1)

- Rebar PDFDokument1 SeiteRebar PDFjoker batmanNoch keine Bewertungen

- EHS Alert 010 - Concrete Placing Boom OperationDokument1 SeiteEHS Alert 010 - Concrete Placing Boom OperationAbdulKatherNoch keine Bewertungen

- Safe Work Method StatementDokument2 SeitenSafe Work Method Statementbuddyhello1Noch keine Bewertungen

- Fall Prevention Plan For WAHDokument2 SeitenFall Prevention Plan For WAHJimmy LowNoch keine Bewertungen

- Ironbark: Safe Work Method Statement No. WMS-570 Task: Work Practice - Epoxy FlooringDokument12 SeitenIronbark: Safe Work Method Statement No. WMS-570 Task: Work Practice - Epoxy Flooringklp_kedarpNoch keine Bewertungen

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety AnalysisDokument4 SeitenProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety AnalysisJohn100% (1)

- Appointment of Formwork & Support Work SupervisorDokument1 SeiteAppointment of Formwork & Support Work SupervisorRickesh Nunkoo100% (1)

- Job Hazard Analysis (Earth Mounted Tank)Dokument8 SeitenJob Hazard Analysis (Earth Mounted Tank)jay RNoch keine Bewertungen

- Responsibilities Summary: Department of LaborDokument2 SeitenResponsibilities Summary: Department of LaborBonaventure NzeyimanaNoch keine Bewertungen

- Excavation (Company Name) : Phase Hazard AnalysisDokument11 SeitenExcavation (Company Name) : Phase Hazard AnalysisDenease CrummieNoch keine Bewertungen

- Site Specific Safety PlanDokument4 SeitenSite Specific Safety Planapi-315681725Noch keine Bewertungen

- Safety Requirements: Health, Safety & EnvironmentDokument44 SeitenSafety Requirements: Health, Safety & EnvironmentVishal GoswamiNoch keine Bewertungen

- Brick Masonry - EHS Risk AssessmentDokument2 SeitenBrick Masonry - EHS Risk Assessmentnagarjuna100% (3)

- Contract Worker Welfare Management Plan - Short Duration TEMPLATEDokument16 SeitenContract Worker Welfare Management Plan - Short Duration TEMPLATEMandhanNoch keine Bewertungen

- OHS PROC 113 BarricadesDokument9 SeitenOHS PROC 113 BarricadesPhillip L100% (1)

- Concrete Formwork Work Method Statement (SWMS) V8Dokument5 SeitenConcrete Formwork Work Method Statement (SWMS) V8pparreraNoch keine Bewertungen

- Method Statement Concrete Works 2019Dokument8 SeitenMethod Statement Concrete Works 2019محمد فتحىNoch keine Bewertungen

- Fall Prevention PlanDokument6 SeitenFall Prevention PlanMohammed KhatibNoch keine Bewertungen

- SMC Material Safety Data Sheet MethanolDokument9 SeitenSMC Material Safety Data Sheet Methanolanand.srajuNoch keine Bewertungen

- Master Builders SA - Safe Work Method Statement - Timber Roof Truss Installation CraneDokument6 SeitenMaster Builders SA - Safe Work Method Statement - Timber Roof Truss Installation CraneDaniel JulianNoch keine Bewertungen

- Work Method Statement Tiling: Organisation DetailsDokument7 SeitenWork Method Statement Tiling: Organisation DetailsKamagara Roland AndrewNoch keine Bewertungen

- SWP 03 - Hacking WorksDokument3 SeitenSWP 03 - Hacking WorksGerald Wong NttNoch keine Bewertungen

- Ref: Section / Dept: Civil Activity: Risk Assessment For False CeilingDokument1 SeiteRef: Section / Dept: Civil Activity: Risk Assessment For False CeilingJack P100% (2)

- HSE Presentation Accident Prevention Jan 2021 EngDokument37 SeitenHSE Presentation Accident Prevention Jan 2021 EngToureNoch keine Bewertungen

- RAM - Pile CroppingDokument14 SeitenRAM - Pile CroppingDaniel Cryer0% (1)

- Job Safety Analysis: S.No Activities Hazard Risk Control MeasuresDokument2 SeitenJob Safety Analysis: S.No Activities Hazard Risk Control Measureskhaja asifuddin100% (1)

- Appendix-B - Construction Safey Manual at ProjectsDokument112 SeitenAppendix-B - Construction Safey Manual at ProjectsvinodNoch keine Bewertungen

- 1 Excavations and TrenchesDokument2 Seiten1 Excavations and TrenchesAruNoch keine Bewertungen

- RA For Nitoflor FC150Dokument4 SeitenRA For Nitoflor FC150kkhafajiNoch keine Bewertungen

- Lifting and Removing Using The Forklift or Telescopic Loader in SiteDokument3 SeitenLifting and Removing Using The Forklift or Telescopic Loader in SiteAMINNoch keine Bewertungen

- Risk Assessment For Partition MarkingDokument5 SeitenRisk Assessment For Partition Markingkhalid14Noch keine Bewertungen

- GL 01 Welfare Facilities at Labour CampDokument3 SeitenGL 01 Welfare Facilities at Labour Camptp101267100% (1)

- ARK JSA Manual ExcavationDokument8 SeitenARK JSA Manual ExcavationMohammed Ali QaziNoch keine Bewertungen

- Site-Specific Health and Safety Plan1 PDFDokument24 SeitenSite-Specific Health and Safety Plan1 PDFCarl WilliamsNoch keine Bewertungen

- Job HazardDokument2 SeitenJob HazardBre WirabumiNoch keine Bewertungen

- Method Statement For Installation of Temporary Plumbing, Drainage System and Electrical SupplyDokument48 SeitenMethod Statement For Installation of Temporary Plumbing, Drainage System and Electrical SupplyAnandu AshokanNoch keine Bewertungen

- Health and Safety Method Statement: SA Scaffolding LimitedDokument8 SeitenHealth and Safety Method Statement: SA Scaffolding LimitedAnonymous Wq35JtketnNoch keine Bewertungen

- SWMSElevated Work PlatformsDokument4 SeitenSWMSElevated Work PlatformsRay LeeNoch keine Bewertungen

- Safe Working Procedure ExcavationsDokument4 SeitenSafe Working Procedure ExcavationsMunaku TafadzwaNoch keine Bewertungen

- Trestles and StagingDokument2 SeitenTrestles and Stagingdak comeiNoch keine Bewertungen

- Installation of Cabinetry - JoineryDokument4 SeitenInstallation of Cabinetry - JoineryJonas100% (2)

- Demolition Using Plant PDFDokument8 SeitenDemolition Using Plant PDFianllagasNoch keine Bewertungen

- SWMS 106 - Traffic ControlDokument2 SeitenSWMS 106 - Traffic ControlJonasNoch keine Bewertungen

- Electrical Safety 2Dokument2 SeitenElectrical Safety 2JonasNoch keine Bewertungen

- Hand & Finger ProtectionDokument2 SeitenHand & Finger ProtectionJonasNoch keine Bewertungen

- Haz ComDokument4 SeitenHaz ComJonasNoch keine Bewertungen

- Risk Assessment Format and Work SheetDokument40 SeitenRisk Assessment Format and Work SheetJonasNoch keine Bewertungen

- Storage & Handling of Dangerous GoodsDokument5 SeitenStorage & Handling of Dangerous GoodsJonasNoch keine Bewertungen

- DEE EHU 4-2-4 Risk RegisterDokument36 SeitenDEE EHU 4-2-4 Risk RegisterJonasNoch keine Bewertungen

- Stress Training For EmployeesDokument24 SeitenStress Training For EmployeesJonasNoch keine Bewertungen

- Be Prepared For EmergenciesDokument2 SeitenBe Prepared For EmergenciesJonasNoch keine Bewertungen

- Toolbox Topics: General Safety - Carbon Monoxide (Co)Dokument2 SeitenToolbox Topics: General Safety - Carbon Monoxide (Co)JonasNoch keine Bewertungen

- Audit of Occupational Safety and Health (OSH) : September 2010Dokument12 SeitenAudit of Occupational Safety and Health (OSH) : September 2010JonasNoch keine Bewertungen

- Controlling Hazards: Remove The HazardDokument4 SeitenControlling Hazards: Remove The HazardJonasNoch keine Bewertungen

- PPE Safety HelmetDokument27 SeitenPPE Safety HelmetAchmad LabibNoch keine Bewertungen

- Appreciating The Hazards, OxyacetyleneDokument2 SeitenAppreciating The Hazards, OxyacetyleneJonasNoch keine Bewertungen

- Installation of Cabinetry - JoineryDokument4 SeitenInstallation of Cabinetry - JoineryJonas100% (2)

- R4R Brochure BowtieDokument1 SeiteR4R Brochure BowtieJonasNoch keine Bewertungen

- SWMS 106 - Traffic ControlDokument2 SeitenSWMS 106 - Traffic ControlJonasNoch keine Bewertungen

- Booster Fan HazardsDokument32 SeitenBooster Fan HazardsJonasNoch keine Bewertungen

- Use and Refuelling of Portable GeneratorDokument4 SeitenUse and Refuelling of Portable GeneratorJonasNoch keine Bewertungen

- CSBP Asbestos Management PlanDokument11 SeitenCSBP Asbestos Management PlanJonasNoch keine Bewertungen

- Cats and Dogs Compare and Contrast EssayDokument8 SeitenCats and Dogs Compare and Contrast Essayjvscmacaf100% (2)

- 14-Anterior and Medial Thigh PDFDokument18 Seiten14-Anterior and Medial Thigh PDFANSHU PATELNoch keine Bewertungen

- BurnsDokument80 SeitenBurnsAlina IlovanNoch keine Bewertungen

- Berlingo / Partner Electric: Electric Vehicles Rescue ManualDokument32 SeitenBerlingo / Partner Electric: Electric Vehicles Rescue ManualClaudiu LupuNoch keine Bewertungen

- Glass StirringDokument4 SeitenGlass StirringAdonis GaleosNoch keine Bewertungen

- Cask of Amontillado TextDokument13 SeitenCask of Amontillado TextAmmar ElMerhbi100% (2)

- Automatic Transfer Circuit Breaker: User's ManualDokument28 SeitenAutomatic Transfer Circuit Breaker: User's ManualSaranga JayawardanaNoch keine Bewertungen

- Costa Cálida Chronicle July 2014Dokument104 SeitenCosta Cálida Chronicle July 2014costacalidachronicleNoch keine Bewertungen

- The Foot Core System. A New Paradigm For Understanding Intrinsic Foot Muscle FunctionDokument9 SeitenThe Foot Core System. A New Paradigm For Understanding Intrinsic Foot Muscle FunctionVictor GonzálezNoch keine Bewertungen

- Tech Manual ZX110MF PDFDokument479 SeitenTech Manual ZX110MF PDFtaufiqharto100% (3)

- Tibial PlateauDokument43 SeitenTibial Plateauamal.fathullahNoch keine Bewertungen

- International Journal of CrashworthinessDokument11 SeitenInternational Journal of Crashworthinessranjeethkumar_1001Noch keine Bewertungen

- BC182, BC182A, BC182B Amplifier Transistors: NPN SiliconDokument5 SeitenBC182, BC182A, BC182B Amplifier Transistors: NPN SiliconGrigoras Laura IoanaNoch keine Bewertungen

- Health Lesson Plan-BandagesDokument8 SeitenHealth Lesson Plan-BandagesJaybee MacadangdangNoch keine Bewertungen

- Risk Assesment of Brick & Block WorkDokument3 SeitenRisk Assesment of Brick & Block WorkGyanendra SrivastavaNoch keine Bewertungen

- Risk Assessment For Installation of Fire Alarm System & PAVA SystemDokument11 SeitenRisk Assessment For Installation of Fire Alarm System & PAVA SystemAnandu Ashokan88% (8)

- Understand How To Recognize and Respond To Emergencies: Essential Standard Objective Essential QuestionsDokument9 SeitenUnderstand How To Recognize and Respond To Emergencies: Essential Standard Objective Essential QuestionsClaudia Delgado JiménezNoch keine Bewertungen

- BoudoirDokument24 SeitenBoudoirRoberto Mendoza MariscalNoch keine Bewertungen

- Crimes Against PersonsDokument1 SeiteCrimes Against PersonsBenn DegusmanNoch keine Bewertungen

- Reservation ContractDokument3 SeitenReservation ContractRani PatelNoch keine Bewertungen

- Clinical Practice Guidelines Paramedic V33 - March 2019Dokument343 SeitenClinical Practice Guidelines Paramedic V33 - March 2019Alisha Reibel100% (1)

- Occt 630 - Occupational Profile and Intervention Plan - PortfolioDokument21 SeitenOcct 630 - Occupational Profile and Intervention Plan - Portfolioapi-279916752Noch keine Bewertungen

- Ankle LectureDokument19 SeitenAnkle Lecturegunawan crisNoch keine Bewertungen

- Health Week 1-3 - 3rd QuarterDokument8 SeitenHealth Week 1-3 - 3rd QuarterNoemelyn VecinaNoch keine Bewertungen

- Manual TM 9-2520-238-34 Manual Servicio Transf. Mando y DiferencialDokument336 SeitenManual TM 9-2520-238-34 Manual Servicio Transf. Mando y DiferencialTorque100% (2)

- Pelvic Trauma Final 210409Dokument8 SeitenPelvic Trauma Final 210409Dwi ApriliziaNoch keine Bewertungen

- Review University For Midwives, Inc.: Successfully Training Filipino Nurses and Midwives For Global SettingDokument8 SeitenReview University For Midwives, Inc.: Successfully Training Filipino Nurses and Midwives For Global SettingKelly Posadas-MesinaNoch keine Bewertungen

- Important Questions - FMTDokument11 SeitenImportant Questions - FMTPitty PrarthanaNoch keine Bewertungen

- (2004) 1 SLR (R) 0479Dokument20 Seiten(2004) 1 SLR (R) 0479Sulaiman CheliosNoch keine Bewertungen

- Method Statement For Cable Laying 03Dokument8 SeitenMethod Statement For Cable Laying 03paulloh64Noch keine Bewertungen