Beruflich Dokumente

Kultur Dokumente

Model 1

Hochgeladen von

vivek kumarOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Model 1

Hochgeladen von

vivek kumarCopyright:

Verfügbare Formate

WWW.VIDYARTHIPLUS.

COM

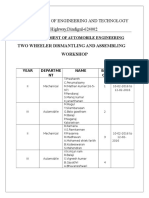

BAM 4L2 Automotive Chassis Components Laboratory Manual

C. Coomarasamy, Professor / Automobile Engineering

EXPERIMENT No: 1

Study, Dismantling & Assembling of Clutch assembly

1. Aim: To study, dismantle, inspect and assemble the given Clutch assembly.

2. Tools required: 1.Hammer 2. Tool set 3. Screw Driver 4. Clutch ring.

3. Function:

1. In an automobile clutch, the flywheel is connected to the engine, and the

clutch plate is connected to the transmission.

2. When your foot is off the pedal, the springs push the pressure plate against

the clutch disc, which in turn presses against the flywheel.

3. This locks the engine to the transmission input shaft, making them spin at the

same speed.

4. The amount of force the clutch can hold depends on the friction between the

clutch plate and the flywheel, and how much force the spring puts on the

pressure plate.

4. Study:

The mechanism that transmits engine power to the rear wheels (in case of rear

wheel driven vehicles) or to the front wheels (in front wheel driven vehicles), or to all

the four wheels (in four wheel driven vehicles) is known as a transmission system.

It comprises of the following main units.

1. Clutch

2. Gear box (manual or automatic), Transfer box (in four wheel driven vehicles)

3. Propeller shaft, Universal joints

4. Final drive, Differential gear assembly

5. Rear axles, wheel

V+ TEAM

Clutch:

1.The purpose of the clutch is to allow the driver to couple or decouple the

engine and transmission.

2. When clutch is in engaged position, the engine power flows to the

transmission through it (clutch).

3. When gears are to be changed while vehicle

is running, the clutch permits temporary decoupling of engine and wheels so

that gears can be shifted.

1.

2.

3.

4.

5.

Principle:

It operates on the principle of friction.

When two surfaces are brought in contact and are held against each other due to

friction between them, they can be used to transmit power.

If one is rotated, then other also rotates.

One surface is connected to engine and other to the transmission system of

automobile.

Thus, clutch is nothing but a combination of two friction surfaces.

5. Requirement :

1. It should ensure smooth engagement without grab or clatter.

2. It should have the clutch with two fold moment of inertia.

3. It should prevent gear clatter due to piston vibration caused by engine

Crank shaft.

4. The effort required to disengage should be minimum.

5. It must be cost effective.

6. It must be easy to maintain and adjust.

6.Dismantling: Given- Single plate clutch assembly:

1. Mark the pressure plate and clutch cover position with respect to each other.

2. Place the clutch assembly on the clutch drive aligning the slot on the clutch

finger with the thrust and seal on the pressure plate.

3. Compress the spring cups by clutch.

4. Loosen the mounting seat screw of the rotating plate on the retaining plate so

removed.

5. Loosen the mounting seat screw of the clutch finger brackets and eccentric

pins

WWW.VIDYARTHIPLUS.COM

V+ TEAM

7. Inspection:

1. Visually check the fly wheel, ring gear and pressure for crankshaft.

2. Check the flatness of friction faces of the pressure plate with straight edge.

3. If flatness is not found within the specific limit without the pressure plate and

flywheel can ground so not ground below the minimum specific thickness.

4. Check the free length and tension of pressure spring.

5. Check the pressure plate tension usually for any damage. Replace the clutch

plate if any torsion spring found damaged.

6. Measure the thickness of clutch lever. Release if thickness of clutch lever is

less than minimum specified.

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

V+ TEAM

8. Assembling:

1. Place the clutch fingers bush in the clutch fingers.

2. Fit the clutch bracket with eccentric pin.

3. Hand tighter the mounting set screw of clutch bracket.

4. Align the marks of clutch plate and pressure plate and place the clutch over the

pressure plate.

5. Compress the spring with clutch finger.

6. Place the pressure pad on the pressure plate and tighten the pad mounting set

screws.

7.Release the load from the spring and remove clutch cover assembly from the clutch

jig.

8.Place the withdrawn plate, retaining plate on the clutch jig finger; tighten mounting set

screws of the withdrawn plate.

9. Result: Thus the given clutch assembly is dismantled, inspected and assembled.

WWW.VIDYARTHIPLUS.COM

V+ TEAM

EXPERIMENT No: 2

Study, Dismantling & Assembling of Gearbox assembly

1. Aim: To study, dismantle, inspect and assemble the given Gearbox assembly.

2. Tools required: 1.Hammer 2. Tool set 3. Screw Driver 4. Sockets

5. Spanner set 6. Pullers

3. Function:

A machine consists of a power source and a power transmission system,

which provides controlled application of the power.

The term transmission refers to the whole drive train, including clutch,

gearbox, prop shaft (for rear-wheel drive), differential, and final drive shafts

In motor vehicles, the transmission generally is connected to the engine

crankshaft via a flywheel and/or clutch and/or fluid coupling.

The output of the transmission is transmitted via driveshaft to one or more

differentials, which in turn, drive the wheels.

4. Study: Gear Box

Often transmission refers simply to the gearbox that uses gears and gear

trains to provide speed and torque conversions from a rotating power source to

another device.

Principle:

1. Gear box contain gearing arrangement to get different speeds.

2. Gears are used to get more than one speed ratios.

3. When both mating gears have same number of teeth, both will rotate at

same number speed.

4.But when one gear has less teeth than other, the gear with less number of

teeth will rotate faster than larger gear.

5. In a typical car, there may be six gears including one reverse gear.

6. First gear gives low speed but high torque.

7. Higher gears give progressively increasing speeds.

8. Gears are engaged and disengaged by a shift lever.

Types of gear boxes:

1. Manual transmission

i. Sliding mesh gear box.

ii. Constant mesh gear box

iii. Synchromesh gear box without overdrive.

iv. Synchromesh gear box with overdrive.

WWW.VIDYARTHIPLUS.COM

V+ TEAM

2. Semi-automatic transmission

i. Electric controlled with a fluid drive.

ii. Electric controlled with overdrive.

iii. Fluid torque drive.

3. Automatic transmission

i. Hydrodynamic drive.

ii. Torque-converter drive.

Two-speed manual transmission gearbox

TRANSMISSION GEARS IN HIGH POSITION

WWW.VIDYARTHIPLUS.COM

V+ TEAM

TRANSMISSION GEARS IN LOW POSITION

The Side-View of a Standard 5-Speed Manual Transmission System.

Constant mesh gearbox is a type of Transmission in which all or most of the gears

are always in mesh with one another, as opposed to a sliding-gear transmission, in

which engagement is obtained by sliding some of the gears along a shaft into mesh.

In a constant-mesh manual gearbox, Gear ratios are selected by small Clutches

that connect the various gear sets to their shafts so that power is transmitted through

them.

WWW.VIDYARTHIPLUS.COM

V+ TEAM

5. Requirement :

1. It should have proper mechanism to select the appropriate gear on the output

shaft so that it may be engaged with the corresponding gear on the lay shaft.

2. It should help in smooth running of the vehicle at different speeds.

3. It should provide means to vary the torque ratio between the engine and the

road wheels.

CONSTANT-MESH TRANSMISSION ASSEMBLY

WWW.VIDYARTHIPLUS.COM

V+ TEAM

6.Dismantling: Given- Gear box assembly (Manual- constant mesh type)

1. Mount the gear box on the work stand and remove the selector assembly.

2. Lock the main shaft by engaging only two gears by shifting the respective

slipping sleeve on the gear.

3. Remove the locking pin and driving flange kit.

4. Pull out the flange by using driving flange puller.

5. Remove the gear box rear.

6. Remove the speedometer drive gearbox from the main shaft.

7. Remove the gearbox screw rear.

8. Remove the driveshaft and lay shaft end cover.

9. Drive the lay shaft, place the drive shaft puller. Place distance pieces on the

gear casing below the puller bolt. Ensure that the distance piece do not sit on

any threaded hole of the gear casing.

10. Remove the main shaft from end nut and remove the pilot bearing.

11. Tighten the bolt from the main shaft rear end bearing comes out of gear

housing.

12. Pull out the main shaft along with the bearing.

13. Remove the main shaft from the gear casing.

14. Remove the main shaft gear bushes, fixed dog clutch & sliding dog clutch.

15. Remove the reverse idler gear shaft lock, shaft and idler gear.

16. Remove the lay shaft gear set with the thrust washer.

17. Remove the circlip from the drive shaft.

18. Place the drift on the bearing & press drift from top till bearing out of drive

shaft.

7.Inspection:

1. Clean all the components.

2. Check the parts visually for damages due to wear. Main shaft gear teeth, pilot bearing teeth, reverse idler gear, gear casing,

bearing seats, main shaft spines, bearing on the main shaft, bearing on the

main lay shaft, pinion shaft bushes, sliding dog clutch and fixed dog clutch.

3. Measure the clearance between the bushes, & their respective gears are

placed by bush gears.

4. If the clearance found is more than specific limit, measure the clearance

found more than projection of the bush & above the gear.

8.Assembling:

1. Place the oil seal in the rear end cover & place the drift on the oil seal.

2. Press the oil seal in the cover by the drift & fix it.

3. Mount the gear box casing on the stand & lower down the lay shaft gears in

the gear casing.

4. Clamp the lay shaft in its position temporarily.

5. Fix the lever idler gears along with the shaft & level it.

WWW.VIDYARTHIPLUS.COM

V+ TEAM

6. Place the main shaft on the stand, the pilot bearing on the main bearing and

the main shaft rear & bearing inside.

7. Fix the bearing on the rear & bearing drive shaft & fit a cir clip.

8. Fix the drive shaft by mallet & rotate by hand to ensure pilot in the drive shaft

bore.

9. Place the bearing housing along with gasket on the rear casing & the

speedometer driver gear on the main shaft.

10. Fix all the bearing covers along with gasket on the rear casing.

11. Place the drive flange on the main shaft & lock it by engaging the two gears.

12. Tighten the main shaft rear & nut to the specified torque.

13. Keep all the sliding forks in the sector assembly in neutral position & all gears

in the gear box in neutral position.

14. Place the selector assembly on the gear box & tighten the mounting set

screw.

15. Fill the recommended gear box oil to the given level.

9.Result: Thus the given gearbox assembly is dismantled, inspected and assembled.

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

EXPERIMENT No: 3

Study, Dismantling & Assembling of Differential Unit

1. Aim: To study, dismantle, inspect and assemble the given Differential unit.

2. Tools required: 1.Hammer 2. Socket 3. Extension rod 4.Racket 5. Leverage rod

6. Strain divider

3. Function:

1. A vehicle's wheels rotate at different speeds, mainly when turning corners.

2. The differential is designed to drive a pair of wheels while allowing them to

rotate at different speeds.

3. In vehicles without a differential, such as karts, both driving wheels are forced

to rotate at the same speed, usually on a common axle driven by a simple

chain-drive mechanism.

4. When cornering, the inner wheel needs to travel a shorter distance than the

outer wheel, so with no differential, the result is the inner wheel spinning

and/or the outer wheel dragging, and this results in difficult and unpredictable

handling, damage to tires and roads, and strain on (or possible failure of) the

entire drive train.

5. In automobiles and other wheeled vehicles, a differential is the usual way to

allow the driving road wheels to rotate at different speeds.

6. This is necessary when the vehicle turns, making the wheel that is travelling

around the outside of the turning curve roll farther and faster than the other.

7. The engine is connected to the shaft rotating at an angular velocity. .

8. The driving wheels are connected to the other two shafts, and they are equal.

9. If the engine is running at a constant speed, the rotational speed of each

driving wheel can vary, but the sum (or average) of the two wheels' speeds

can not change.

10. An increase in the speed of one wheel must be balanced by an equal

decrease in the speed of the other.

(If one wheel is rotating backward, which is possible in very tight turns, its

speed should be counted as negative.)

4. Study:

Differential:

1. A differential is a device, usually, but not necessarily, employing gears, which

is connected to the outside world by three shafts, chains, or similar, through

which it transmits torque and rotation.

2. The gears or other components make the three shafts rotate.

3. It may seem illogical that the speed of one input shaft can determine the

speeds of two output shafts, which are allowed to vary.

4. Logically, the number of inputs should be at least as great as the number of

outputs.

5. However, the system has another constraint.

6. Under normal conditions (i.e only small tyre slip), the ratio of the speeds of

the two driving wheels equals the ratio of the radii of the paths around which

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

the two wheels are rolling, which is determined by the track-width of the

vehicle (the distance between the driving wheels) and the radius of the turn.

7. Thus the system does not have one input and two independent outputs.

8. It has two inputs and two outputs.

1 - Differential housing with riveted gear for final drive

2 - Output shaft/drive flange

3 - Tapered roller bearing inner race

4 - Tapered roller bearing outer race

5 - Bearing body for tapered roller bearing

6 - O-ring

7 - O-ring

8 - Adjusting ring for tapered roller bearing

9 - Output shaft/drive flange

10 - Tapered roller bearing outer race

11 - Tapered roller bearing inner race

12 - Speedometer drive bushing

13 - Speedometer drive gear

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

14 - One-piece thrust washer

15 - Small bevel gears

16 - Large bevel gears

17 Circlip

Principle:

1. Input torque is applied to the ring gear (blue), which turns the entire carrier

(blue).

2. The carrier is connected to both sun gears (red and yellow) only through the

planet gear (green).

3. Torque is transmitted to the sun gears through the planet gear.

4. The planet gear revolves around the axis of the carrier, driving the sun gears.

5. If the resistance at both wheels is equal, the planet gear revolves without

spinning about its own axis, and both wheels turn at the same rate.

6. If the left sun gear (red) encounters resistance, the planet gear (green) spins

as well as revolving, allowing the left sun gear to slow down, with an equal

speeding up of the right sun gear (yellow).

5. Requirement :

The differential has three jobs:

1. To aim the engine power at the wheels.

2. To act as the final gear reduction in the vehicle, slowing the rotational speed

of the transmission one final time before it hits the wheels.

3. To transmit the power to the wheels while allowing them to rotate at different

speeds (This is the one that earned the differential its name.)

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

6.Dismantling: Given- Differential unit.

1.

5

6

7

8

9

10

11

12

13

14

15

16

Remove Output shaft/drive flange

Pulling off Tapered roller bearing inner race

Remove Tapered roller bearing outer race

Remove Bearing body for tapered roller bearing

Remove Differential

Remove O-rings

Remove Adjusting ring for tapered roller bearing

Remove Output shaft/drive flange

Remove Tapered roller bearing outer race

Pulling off Tapered roller bearing inner race

Drive out Speedometer drive gear with drift Fit together with driver bushing

Remove small bevel gears, large bevel gears.

Circlip- Do not remove the circlip until after removing the drive flange as

the compression spring is pre-tensioned.

7. Inspection:

1. Visually check the final drive gear. It is riveted onto differential housing

and then machined.

If differential or final drive gear is damaged, replace differential housing

along with riveted final drive gear.

2. Visually check all the spare parts and replace required parts.

Replace O rings always.

8.Assembling:

1. Place, position, install, press and assemble all the spare parts as needed

in the reverse order of dismantling.

9.Result: Thus the given Differential Unit is dismantled, inspected and

assembled.

WWW.VIDYARTHIPLUS.COM

WWW.VIDYARTHIPLUS.COM

EXPERIMENT No: 4

Study, Dismantling & Assembling of a Propeller Shaft unit

1. Aim: To study, dismantle, inspect and assemble the given Propeller Shaft

unit.

2. Tools required: 1.Hammer 2. Spanner set 3. Screw Drivers 4. Sockets 5.

Puller

3. Function: The propeller shaft transmits power from the gear box to the rear

axle.

4. Study:

Propeller shaft-two piece and three piece construction. The propeller shaft unit is

basically made up of:

1. Shaft:

It is a steel type shaft of a diameter and length suitable for the vehicle.

Varying types of chassis construction call for either one, two or three sets of

shafts

2. Universal joint

Main Components of Propeller shaft:

1. Spider (universal joint) (1):

The propeller shaft transfers engine torque to the rear axle through one or more

universal joints.

2. Sleeve (2) and

3. sliding shaft (3):

The splines on the ends at the propeller shaft fit perfectly into the splines in the

sleeve.

This allows a length variation between the driving and the driven unit to vary

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

slightly without damaging the output and input bearings.

4. Main bearing (4):

The main bearing support and guide the propeller shaft.

5. Flange (5):

The flanges connect the propeller shaft to the gearbox.

Principle:

1. The drive shaft, or propeller shaft, connects the transmission output shaft to the

differential pinion shaft.

2. Since all roads are not perfectly smooth, and the transmission is fixed, the drive

shaft has to be flexible to absorb the shock of bumps in the road.

3. Universal, or "U-joints" allow the drive shaft to flex (and stop it from breaking)

when the drive angle changes.

4.

5.

6.

7.

8.

Lubrication of propeller shaft

The cross-shaped inner member of a universal joint is sometimes called a spider.

Universal joints allow for a small variable angle between the axis of the

transmissions output shaft and the axis of the propeller shaft, and between the

axis of the propeller shaft and the axis of the input shaft of the rear axle (1).

The spider (6) ends (3) are called gudgeon.

Around the gudgeons there are rollers (4) kept in place by a cap (5), that allows

them to roll freely.

The Circlip (7) fits into the (2) hole in the yoke and lock the cap.

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

5.Requirement :

For achieving efficient functions, the following are expected in a propeller shaft

(1) High torsional strength:

Therefore, they are made of soild or hollow circular cross section

(2) Toughened and hardened:

Therefore, they are made of superior quality steel and are induction hardened

(3) Efficiently jointed:

Therefore they are generally welded by submerged are carbon di oxide

welding process.

(4) Dynamically balanced:

Since the phenomenon of whirling may be critical at higher speeds, therefore,

propeller shafts are tested on electronic balancing machine.

(5) Reduced thrust loads.

Since resonance is dangerous for the life of shaft. It also transmits excessive

dynamic force to the shaft's end supports, and so its occurrence should be

avoided.

6.Dismantling: Given- Propeller shaft unit.

1. Mark the position of the propeller shaft flange, unlock and remove it.

2. Remove the main bearing support and guide and remove the propeller

shaft

3. Using pullers pull out the bearings and then remove sliding shaft.

4. Remove the sleeve and universal joints.

7.Inspection:

1. Check up the straightness. If bent, straighten it.

2. Check up universal joint crosses and bearings, If broken or worn replace

them.

3. Check up propeller shaft supporting mounting, If loose tighten it.

4. Check up universal joint bolt nuts. If loose tighten them.

5. Check up alignment of splines at sliding joint. If not properly aligned align

them with the help of arrows.

6. Check up alignment of intermediate flange. If not properly aligned with

forward propeller shaft yoke, realign them.

7. Check the parts visually for damages due to improper lubrication and rectify.

8.Assembling:

1. Insert the sleeve, place the bearing, top the bearing seat, replace the

bearing rubber, and fit the bracket on the shaft.

2. Tighten the lock nut to the specified torque and lock the nut.

3. Connect propeller shaft and pinion flange, shaft flange and universal joints.

9.Result: Thus the given Propeller Shaft unit is dismantled, inspected and

assembled.

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

EXPERIMENT No: 5

Study, Dismantling & Assembling of a Steering Gear Box

1.Aim: To study, dismantle, inspect and assemble the given Steering Gear

Box.

2.Tools required: 1.Hammer 2. W.E spanners 3. Screw Driver 4. Puller 5. Ring spanners

6. Wrench.

3.Function:

1. The primary function of the steering system is to provide angular motion to

front wheels so that vehicle can negotiate a turn.

2. It also provides directional stability to vehicle when the vehicle moves ahead in

straight line.

3.Its main function is to provide the necessary leverage so that the driver is able

to steer the vehicle without fatigue and the vehicle can be maneuvered easily.

4. Study:

Steering System:

The part of the steering system that is located at the lower end of the steering shaft

which changes the rotary movement of the steering wheel into the linear motion of

the front wheels for steering is called a Steering Gearbox.

1.Front wheels can be turned to left and right by steering system so that the

vehicle can be steered.

2.The steering wheel is placed in front of driver.

3. It is mechanically linked to the wheels to provide the steering control.

4. Now-a-days, many vehicles are equipped with power steering which uses

pressure of a fluid to reduce steering effort.

5. When driver turns the steering wheel, a hydraulic mechanism comes into play to

provide most of the effort needed to turn the wheel.

Principle:

1. Steering system is used to allow a driver to guide the vehicle along the road and

turn it to either direction left or right.

2. Steering arrangement is governed by steering geometry.

3. Steering system consists of front suspension forks, steering stem, steering lock

and handle bar.

4. Front suspension forks carry the front wheel assembly.

5. Steering stem is attached to the top of the front suspension forks.

6. Steering stem permits turning of front wheel and hence the vehicle in the desired

direction.

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

Steering Gears

The steering gearbox provides the driver with a leverage to enable him to exert a

large force at the road wheel with a minimum effort, and to control the direction of

the wheel.

Turning effort on the steering wheel is multiplied through the steering gears to

turn the front wheels, even when the vehicle is at rest.

Therefore, the steering gearbox has two main functions.

It produces a gear reduction between the input steering wheel and the output

drop arm (Pitman arm) and it redirects the input to output axis of rotation through

a right angle.

The overall angular gear ratio between the steering wheel and the road wheel

varies from about 12:1 to 30:1, depending on the load on the road wheels and

the type of steering.

The lower ratio is for the light small vehicles and the higher ratio for heavy

vehicles.

As the ratio is lowered, a more number of turns are required to move the wheels

from lock to lock making it difficult for a rapid change in vehicle direction.

Normally, the steering road wheel stub axles must be able to twist through a

maximum steering angle of 40 degrees either side of straight ahead position.

Therefore, lock to lock drop arm angular displacement amounts to 80 degrees.

Over the years, several types of steering gearbox have been used, these include

:

(i) Screw and nut / Re-circulating ball.

(ii) Rack and pinion.

(iii) Cam and peg.

(iv) Worm and roller.

(v) Worm and sector.

Screw and nut steering gear mechanism / Re-circulating ball gear mechanism

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

(The balls are re-circulated through the ball guides)

The screw and nut type mechanism is the basic form for all the other types

of steering gear box mechanisms.

This mechanism increases both the force and movement ratios.

A small input effort applied to the end of a perpendicular lever fixed to the

screw can move a much larger load axially along the screw, provided the

nut is held against rotating.

If the screw is prevented from moving longitudinally, but revolves once

within its nut, then the nut advances or retracts a distance equal to the

axial length of one complete spiral groove loop.

This distance is termed as the thread pitch or lead (p).

The inclination of the spiral thread to the perpendicular of the screw axis is

known as the helix angle (a).

As the helix angle decreases the nut displaces greater load in an axial

direction.

Principle of rack and pinion steering

Rack-and-pinion steering gear

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

The rack-and-pinion gear mechanism transfers the circular input motion of

the pinion into a linear rack output movement so that side-to-side travel of

the rack is transferred through the tie-rods to the tie-rod steering arms

and the stub-axles.

To transfer the motion from the pinion to the rack, the pinion teeth mesh

with rack teeth along the rack axis for movement in either direction.

The circular pitch of the pinion should be equal to the linear pitch of the

rack for correct mesh.

Cam and peg steering type gear box

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

This type of steering box incorporates, in place of the conventional

screw, a cylindrical shaft, supported between two angular contact ball

bearings.

The shaft carries a deep spiral groove, usually with a variable pitch, on

its surface between the bearings.

The groove has a tapered profile, which narrows towards the bottom.

An integral rocker arm and shaft is placed half-way along the cam. At

the free end of the rocker arm a conical peg is fitted which engages the

groove.

When the steering wheel and shaft rotate the camshaft, one side of

the spiral groove screws the peg axially forward or backward,

depending upon the direction of turning of the cam.

This forces the rocker arm to pivot about its shaft axis and as a result a

similar angular motion is transferred to the drop arm, which is attached

to the shafts outer end.

Worm and Roller Type Steering Gear

The worm and roller steering box was introduced in 1926 to combat

friction and is still used today.

It works on a similar principle to the worm and sector box, with section

gear replaced by a roller attached to a cross shaft.

As the steering wheel turns, the worm rotates and causes the roller to

turn.

This causes the cross shaft to twist, moving the pitman arm and forcing

the wheels to change direction.

According to carbibles.com, the worm gear is typically an hourglass

shape, designed to be wider at the ends.

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

Worm and Sector Steering Gearbox

This type of gear box is the outcome of advancement of the old worm

and wheel type designs.

A case-hardened steel worm and sector are located by bearings in a

malleable iron or light alloy casing.

Figure represents the worn and sector steering mechanism.

The worm is connected to the inner column and the sector forms a part

of the rocker shaft in the steering gear box.

Worm and sector steering box.

Similar to many other boxes, the layout also can have adjustments,

which include;

(i) End-float of inner column is adjusted using shim.

(ii) End-float of rocker shaft is adjusted using shim or screw.

(iii) Backlash between gears is adjusted by moving the gears.

Since maximum wear occurs in the straight ahead position of the box,

the gear is normally provided with a larger backlash in the lock

positions.

This reduces the risk of seizure at full lock when the box is adjusted to

compensate for wear.

It is essential to reduce end float and backlash to a minimum.

Steering box lubrication is provided by filling the box to the level of the

plug with normal gear oil.

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

5. Requirement :

The steering gears are required which are mounted on the lower end of

the steering column and are used to multiply driver turning force.

The main aim of the gearbox is to sustain more loads with least effort.

It is required to convert the rotary motion of the steering wheel into the

to-and-fro motion of the link rod of the steering linkage.

6.Dismantling: Given- Steering Gear Box:

1. Any work on the steering column requires removal of steering wheel.

The upper trim, often a horn button, bar or ring must be removed to separate

steering wheel.

2. Remove upper trim, it exposes the steering wheel nut.

3. Remove the nut.

4. Pull the steering wheel from a set of splines on the steering shaft using

pullers

5. Removal of steering wheel exposes the turn signal switch mechanism.

6. Note the master spline position to reinstall the steering wheel.

7. Remove the bearing and steering stem.

7.Inspection:

Examine the steering column and steering wheel to see if they are bent,

cracked, or damaged in any way.

Look for leaking seals and gaskets.(3 oil seals and two gaskets).Always

replace.

Even if the seals and gaskets are not leaking, check the lube level in the

steering gear housing.

Check the mounting brackets and bolts for secure mounting. Use a wrench

to see if the bolts are tight.

Check for too much free play (slack) in the steering system.

Remember that steering gears are designed to have very little free play

when the wheels are straight ahead.

8.Assembling:

Now reassemble all the parts of reverse order of dismantling.

9.Result: Thus the given Steering Gear box is dismantled, inspected and assembled.

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

EXPERIMENT No: 6

To take measurements of a given Chassis

1.Aim: To take measurements of the Ashok Leyland Chassis.

2.Tools required: 1. Scales 2. Measuring tape 3. Plumb knob .

3.Function:

1. To carry load of the passengers or goods carried in the body.

2. To support the load of the body, engine, gear box etc.,

3. To withstand the forces caused due to the sudden braking or

acceleration

4. To withstand the stresses caused due to the bad road condition.

5. To withstand centrifugal force while cornering

6. For a good chassis design and for its good performance it must have fast

pick up, strength, safety, durability, dependability, ease of control,

quietness, speed, economy of operation, low centre of gravity, stability, load

clearance, braking ability, simplicity of lubrication, etc. the chassis frame

and front and rear suspension systems without abnormally raising the frame

or transmitting shock to the frame due to road irregularities.

4.Study:

Automobile Chassis:

WWW.VIDYARTHIPLUS.COM

A vehicle without body is called a chassis.

It is the backbone of the vehicle.

All moving parts of the vehicle are fitted to it.

It is made of steel.

To give it extra strength, it is provided with bolted, riveted or welded

crosspieces.

The chassis in general is equipped with I beam construction front

axles.

Main components of the Chassis

1. Frame: it is made up of long two members called side members

riveted together with the help of number of cross members.

2. Engine or Power plant: It provides the source of power

3. Clutch: It connects and disconnects the power from the engine fly

wheel to the transmission system.

4. Gear Box

5. U Joint

6. Propeller Shaft

7. Differential

Types of chassis

Classification of Chassis with respect to its controls

1. Conventional control chassis

2. Semi-forward control chassis

3. Full forward control chassis

Classification of Chassis with respect to engine fitting

1. Engine at front

2. Bus chassis

3. Engine fitted at back

4. Engine fitted in front but cross wise

5. Semi-forward chassis

6. Engine fitted at the centre of the chassis

Types of chassis frames:

There are three types of frames

1. Conventional frame

2. Integral frame

3. Semi-integral frame

1. Conventional frame: It has two long side members and 5 to 6 cross

members joined together with the help of rivets and bolts. The frame

sections are used generally.

a. Channel Section - Good resistance to bending

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

b. Tabular Section - Good resistance to Torsion

c. Box Section-Good resistance to both bending and torsion

2. Integral Frame: This frame is used now a days in most of the cars.

There is no frame and all the assembly units are attached to the body.

All the functions of the frame carried out by the body itself.

Due to elimination of long frame it is cheaper and due to less weight most

economical also.

Only disadvantage is repairing is difficult.

3. Semi - Integral Frame: In some vehicles half frame is fixed in the front end

on which engine gear box and front suspension is mounted.

It has the advantage when the vehicle is met with accident the front frame

can be taken easily to replace the damaged chassis frame.

This type of frame is used in FIAT cars and some of the European and

American cars.

Various loads acting on the frame:

1. Short duration Load

- While crossing a broken patch.

2. Momentary duration Load - While taking a curve.

3. Impact Loads

- Due to the collision of the vehicle.

4. Inertia Load

- While applying brakes.

5. Static Loads

- Loads due to chassis parts.

6. Over Loads

- Beyond Design capacity.

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

5. Measurement: Measurements were taken - Given Ashok Leyland truck chassis.

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

1.

2.

3.

4.

5.

6.

7.

Wheel base

Front overhang

Rear overhang

Overall length

Maximum width

Length of rear leaf spring

Length of front leaf spring

:

:

:

:

:

:

:

8. Thickness

9. Web

10. Legs (Flange width)

11. No. of leaf spring in the front axle

12. No. of leaf spring in the rear axle

:

:

:

:

:

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

19

32

6.Result: Thus the study of vehicle chassis was done and main dimensions

were noted.

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

EXPERIMENT No: 7

Study, Dismantling & Assembling of a Disc Brake

1. Aim: To study, dismantle, inspect and assemble the given Disc Brake.

2. Tools required: 1.Hammer 2. Tool set 3. Screw Driver 4.Puller 5.Brake pad kit

6.Socket and wrench 7. Assorted wrenches 8. Needle-nose pliers

3. Function:

Brakes are employed to stop or slow down the speed of a vehicle

depending upon the driving needs.

When braked, each wheel of the vehicle builds-up a certain braking force.

For this reason, greater the number of wheels braked, greater will be the

braking effort and sooner will the vehicle come to halt.

Modern vehicles are therefore equipped with brakes on all the wheels.

4. Study: Braking system:

Types of brakes.

Different types of brakes are used on various categories of vehicles.

These can be classified according to following considerations.

1. On the basis of purpose served

(a) Main (service or primary) operational brakes

(b) Parking (secondary) brakes

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

2. On the basis of drivers ergonomics

(a) Foot brakes

(b) Hand brakes

3. On the basis of actuating method

(a) Mechanical brakes

(b) Hydraulic brakes

(c) Pneumatic (air) brakes

(d) Electric brakes

4. On the basis of construction

(a) Drum brakes

(b) Disc brakes

(c) Band brakes

5. On the basis of application of braking effort

(a) Manual brakes

(b) Servo (power assisted) brakes

(c) Power brakes

Disc Brakes:

1. Because a disc brake assembly can absorb more heat than a drum brake

assembly, most cars use disc brakes for their front brake systems.

2. When the brake pedal is pushed, brake fluid from the master cylinder

compresses the brake pads against the rotors attached to the vehicle's

front wheels.

3. The friction between the stationary pads and the revolving rotors causes

the rotors and wheel to slow and stop.

4. In day to-day driving, these rotors and pads are subject to much abuse, and

Principle:

Braking system:

While operating the braking system the kinetic energy of moving vehicle is

converted in to heat energy.

5. Requirement :

1. It should work efficiently irrespective of road condition and quality.

2. The retardation must be uniform throughout its application.

3. The pedal effort must be within the convenient capacity of the driver.

4. It must be reliable and should not be affected by heat water and dust.

5. It should be in minimum weight.

6. It should have long life.

7. It should be easy to maintain and adjust.

8. Noise and vibrations are to be minimum.

9. There should be provision for secondary brake or parking brake.

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

6.Dismantling:

1.Loosen the lug nuts on the wheel before you jack the vehicle.

2.Now raise the vehicle and support it safely.

REMEMBER: To avoid a bone crushing injury, or death even, it's a good idea to place a

safety stand under the raised part of the vehicle.

3.Remove wheel and loosen the caliper bolts.

If your vehicle has a two-piece caliper, like some late GM models, loosen all the

bolts before removing the caliper.

4.Remove caliper mounting bolts and the caliper itself from the steering knuckle.

REMEMBER: Never let the caliper hang freely by the brake hose if you don't want to

ruin it. Using the 12" tie straps, tie the caliper up to another part of the vehicle to prevent

any damage to the hose.

5.Separate the caliper sections if needed, then remove the brake pads and any shims

or anti-rattle clips.

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

6.Clean the caliper with some brake cleaning spray. Check the caliper for wear or

damage to pistons, seals, bleeder screws, bushings or structural damage. Replace

accordingly.

7.Remove the caliper bolts/sliders from the caliper. Does it look stripped, pitted, rusty or

damaged? Replace if necessary.

8.Add lube to the bolts/sliders by applying a good chunk of caliper lube to parts the

caliper slides on. It's also a good idea to apply lube to the inside of the bushings where

the sliders go through.

9.Install the bolts and sliders back into the caliper.

REMEMBER: Properly lubed and functioning caliper bolts/sliders will help prevent

premature wear and failure of brake pads, rotors and calipers.

10.If you're replacing or machining the rotors, now's the time to remove them. If not, go

to Installing Disc Brakes.

11.With some cars removing the rotor is as simple as sliding it off the hub assembly

once the caliper is removed. Be sure to mark the rotor in relation to the hub so it can be

reinstalled in its original position. Other vehicles may have the rotor and hub

incorporated into one part. This is more common on RWD trucks, vans and some older

RWD cars. To remove this type of rotor, remove the grease cap, cotter pin, nut, washer

and outer bearing from the spindle, and then slide the rotor off.

Any time you have this type of rotor removed; always repack the bearings with

new grease. It's also a good time to check all off the seals and bearings and

replace them if needed.

12.If you are reusing old rotors, remove any bearings and seals and take them to your

local PartSource store for inspection and machining. You'll have a better idea of how

long the rotors will last. Also, new brake pads will work better on a freshly machined

surface.

Always clean machined rotors with brake cleaner before use.

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

7.Inspection:

Inspect both sides of the rotor for signs of excessive wear, cracks, scoring, corrosion,

discoloration, or unevenness,

If any of these conditions are detected, consult a qualified mechanic.

Find the inspection hole on the caliper.

This hole allows you to view one or both linings and judge the extent of wear without

removing the caliper-provided the pads are bonded to the backing plates.

If the pads are riveted, it is not possible to accurately judge the extent of wear using

the inspection hole.

If necessary, remove the caliper and pads to inspect the pads.

8.Assembling:

1.Install any bearings or seals needed, then simply reinstall the rotors the same way

you took them off.

FIGURE B - Disc Brakes

On rotors that don't incorporate the hub with the rotor, clean any rust or debris

from the seating area with a wire brush so it will sit straight. Using anti-seize on

the area where the rotors seats to the hub will make it easier to remove the rotor

next time.

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

2.For spindle type rotors, be sure to follow proper spindle nut torque procedures for the

application.

3.Before installing new brake pads the caliper piston needs to be compressed. This will

cause brake fluid to be pushed back up the lines into the master cylinder. It may cause

the master cylinder to overflow. Its best if you remove the cap and some brake fluid

from the master cylinder before compressing the caliper piston. Compress the piston

very slowly! Otherwise, you'll damage your master cylinder.

REMEMBER: Brake fluid is corrosive. Unless you want to alter the colour of your car,

DO NOT spill any of it. There are different ways to compress different calipers. If you do

it the wrong way you'll ruin the caliper completely. If you're unsure about anything, use

the PartSource Loan a Tool Kit #18, or use Mitchell on Demand, to avoid any costly

mistakes.

4.Once the caliper is compressed, install any shims, and anti-rattle clips. Don't reuse old

shims or anti-rattle clips. It's not a good idea to reuse these items.

5.Apply disc brake quiet to the backside of the brake pads.

6.Install new brake pads onto the caliper, paying attention to inboard and outboard pad

position.

7.Now apply anti-seize to caliper bolt threads, and install the caliper. Be sure to use

proper torque setting on caliper bolts.

8.If the outer pads have locking "ears", use large pliers to bend them over until they

touch the caliper to prevent any pad movement.

9.Everything should be ready now. Double check your work, and re-check those torque

specs just to be sure.

9.Result: Thus the given Disc Brake is dismantled, inspected and assembled.

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

EXPERIMENT No: 8

Study, Dismantling & Assembling of a Drum Brake

1. Aim: To study, dismantle, inspect and assemble the given Drum Brake.

2.Tools required: 1.Hammer 2. Tool set 3. Screw Driver 4.Puller 5.Brake pad kit

6.Socket and wrench 7. Assorted wrenches 8. Needle-nose pliers

3.Function:

Brakes are employed to stop or slow down the speed of a vehicle

depending upon the driving needs.

When braked, each wheel of the vehicle builds-up a certain braking

force.

For this reason, greater the number of wheels braked, greater will be

the braking effort and sooner will the vehicle come to halt.

Modern vehicles are therefore equipped with brakes on all the

wheels.

4. Study:

Drum Brakes

1. Drum brakes work the opposite way from disc brakes.

2. Instead of squeezing in on a disc to slow your vehicle, drum brakes push brake

shoes outwards against the inner surface of a drum.

3. The resulting friction brings your vehicle to a stop.

4. When you release the brake pedal, internal springs return the shoes to their

original position.

5. Just like the pads in disc brakes, the shoes in drum brakes also wear away

over time and must be replaced to prevent severe damage to your braking

assembly.

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

Drum Brakes

Construction and working of Master Cylinder

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

Air Brake System

Construction and working of Wheel Cylinder

Principle:

Braking system:

While operating the braking system the kinetic energy of moving vehicle is

converted in to heat energy.

5.Requirement :

1. It should work efficiently irrespective of road condition and quality.

2. The retardation must be uniform throughout its application.

3. The pedal effort must be within the convenient capacity of the driver.

4. It must be reliable and should not be affected by heat water and dust.

5. It should be in minimum weight.

6. It should have long life.

7. It should be easy to maintain and adjust.

8. Noise and vibrations are to be minimum.

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

9. There should be provision for secondary brake or parking brake.

6.Dismantling:

1.Loosen the lug nuts on the wheel before you jack up the vehicle.

2.Now raise the vehicle and support it safely.

REMEMBER: If the drums don't come off, don't pry any tools against the backing plate,

or things will get ugly.

3.Depending on the car, there will be an access hole in either the drum or backing plate

to access the adjuster. If there is a rubber plug in the hole, remove it.

4.Using the brake adjuster tool or a small screwdriver, turn the star shaped adjuster

wheel inside until the drum spins freely and can be removed.

Drum Brakes

On some vehicles, like Chryslers, you may have to remove the grease cap, cotter pin,

lock nut and washer before the drum will come off. On other vehicles, like my mother-inlaw's Ford Tempo, you can use an Impact Driver to remove stubborn screws that are

holding on the rear drum. An impact driver is a tool you hit with a hammer to loosen

rusted and hard to turn screws.

5.Once the drum is removed, take a look at the brake set-up and make a mental note of

how everything goes together. Also look for any wet-looking parts. If anything does look

wet, you probably have a leaking wheel cylinder, or rear wheel seal. This will have to be

replaced. If you don't replace these, the leaking fluid will ruin the new shoes you're

about to install.

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

6.Remove the return springs that pull the shoe against the wheel cylinder.

7.Remove the hold down springs on the shoes.

8.Remove parking brake cable (if applicable).

9.By pulling each shoe away from the center, both brake shoes should be able to come

off together.

10.Remove the adjusting screw assembly and spring from the shoes.

11.Remove any remaining hardware, retaining rings or parking brake levers still

attached to the shoes.

7.Inspection:

Once all the parts are removed check for abnormal wear and damage.

If you're reusing the brake drums it's a good idea to take them to your local part source

for inspection and machining.

Always clean machined drums with brake clean before installing them.

Clean the backing plate with brake clean and use silicone lube on any contact points.

.8.Assembling:

1.Attach new hardware and any reused parts to the new brake shoes.

2.Apply anti-seize to the adjuster threads.

3.Install the shoes in reverse of order of removal. Make sure all the parts are in the right

position.

If you're not sure how to put everything back together, or want to double check

your work, take the drum off the other side of the car and use that side as a

reference or call PartSource.

4.Install your new or freshly machined drums. If they're fastened with a lock nut make

sure you follow the right torque specs.

5.Double check all your work and make sure the drum spins freely.

REMEMBER: If you're replacing rear brake shoes and/or drums you may have to adjust

the parking brake cables so it functions properly. Specific vehicle instructions are

WWW.VIDYARTHIPLUS.COM

V+ TEAM

WWW.VIDYARTHIPLUS.COM

available from Mitchell on Demand at your local PartSource store and can be printed

out for free.

6.Once you're satisfied and everything looks good, install the wheel and repeat for the

other side of the car.

REMEMBER: Always torque wheel lug nuts properly. And for Pete's sake, don't use an

impact gun on lug nuts! Over torqued lug nuts can ruin new rotors by causing them to

warp.

9.Result: Thus the given Drum Brake is dismantled, inspected and assembled.

WWW.VIDYARTHIPLUS.COM

C. Coomarasamy

Professor / Automobile Engineering

V+ TEAM

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Operational Guidelines: Pradhan Mantri Kisan Samman Nidhi Scheme (Pm-Kisan Scheme)Dokument12 SeitenOperational Guidelines: Pradhan Mantri Kisan Samman Nidhi Scheme (Pm-Kisan Scheme)vivek kumarNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- 2014 Recruitment ALERT.... PCL Construction Enterprises IncDokument1 Seite2014 Recruitment ALERT.... PCL Construction Enterprises Incvivek kumarNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Lecture3 PDE 2016 PDFDokument20 SeitenLecture3 PDE 2016 PDFvivek kumarNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- 2845-MA7169-Advanced Numerical Methods PDFDokument12 Seiten2845-MA7169-Advanced Numerical Methods PDFvivek kumarNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- At6311 Ac Lab ManualDokument78 SeitenAt6311 Ac Lab Manualvivek kumarNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Fmea Report TableDokument1 SeiteFmea Report Tablevivek kumarNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- SSM Institute of Engineering and Technology Palani Highway, Dindigul-624002Dokument3 SeitenSSM Institute of Engineering and Technology Palani Highway, Dindigul-624002vivek kumarNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Effect of Structure-Directing Agent On AlPO4-n Synthesis From Aluminum DrossDokument5 SeitenEffect of Structure-Directing Agent On AlPO4-n Synthesis From Aluminum DrossXantos YulianNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Agritech Graduate Trainee Electrical & ElectronicsTest Past Paper 2021Dokument15 SeitenAgritech Graduate Trainee Electrical & ElectronicsTest Past Paper 2021Ahsan RaoNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Flow Properties Testing and Powder Flowability - Powder & Bulk Solids Solutions PDFDokument3 SeitenFlow Properties Testing and Powder Flowability - Powder & Bulk Solids Solutions PDFSukaran SinghNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- S.MORRIS 2006: This Powerpoint Is Hosted On Please Visit For 100's More Free PowerpointsDokument20 SeitenS.MORRIS 2006: This Powerpoint Is Hosted On Please Visit For 100's More Free PowerpointsDedy SatriyoNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- RheologyDokument33 SeitenRheologyLindsey Barber100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Slides - Chapter 09Dokument88 SeitenSlides - Chapter 09Mohammad ShawqiNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Johann Wolfgang DöbereinerDokument5 SeitenJohann Wolfgang Döbereiner怡霖Noch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Orthogonal Trajectories in Cartesian CoordinatesDokument35 SeitenOrthogonal Trajectories in Cartesian CoordinatesWASEEM_AKHTER100% (1)

- Hkdse Chemistry - A Modern View (Chemistry) : Coursebook 3 Suggested AnswersDokument60 SeitenHkdse Chemistry - A Modern View (Chemistry) : Coursebook 3 Suggested AnswersAlexis Wong100% (3)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- SEAM-Maths1-1.2 SD-Trigonometric Functions 28-8-19 SPCEDokument13 SeitenSEAM-Maths1-1.2 SD-Trigonometric Functions 28-8-19 SPCESatish BarotNoch keine Bewertungen

- 0 B264 D 01Dokument18 Seiten0 B264 D 01didikkrisNoch keine Bewertungen

- Problem Set 6 4Dokument4 SeitenProblem Set 6 4SowmitraDasNoch keine Bewertungen

- 4 - Rate Laws and Stoichiometry - StuDokument62 Seiten4 - Rate Laws and Stoichiometry - StuTiệp MatícNoch keine Bewertungen

- 4 TH BatchDokument37 Seiten4 TH Batchanil kumarNoch keine Bewertungen

- States of Matter-I Gas: Course OutlineDokument9 SeitenStates of Matter-I Gas: Course OutlineMansoor SarwarNoch keine Bewertungen

- MAAE 3202 Mid Term Assignment 2014Dokument11 SeitenMAAE 3202 Mid Term Assignment 2014Moustafa SohdyNoch keine Bewertungen

- Electron Irradiation Effect On Al2O3Dokument63 SeitenElectron Irradiation Effect On Al2O3younessinaNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- 01-Beginning Vibration AnalysisDokument153 Seiten01-Beginning Vibration AnalysisAnonymous ffje1rpa100% (1)

- (C. Grosche F. Steiner) Handbook of Feynman Path I (B-Ok - Xyz)Dokument459 Seiten(C. Grosche F. Steiner) Handbook of Feynman Path I (B-Ok - Xyz)gog100% (1)

- Simulation Structure With SW Motion-Remote LoadDokument21 SeitenSimulation Structure With SW Motion-Remote LoadAlexDiazNoch keine Bewertungen

- 신소재과학 시험문제모음Dokument9 Seiten신소재과학 시험문제모음Hanjin SeoNoch keine Bewertungen

- EM 3000 Conzerv MeterDokument4 SeitenEM 3000 Conzerv Metersbhatta73Noch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Language of Our Dna Scalar EnergyDokument5 SeitenThe Language of Our Dna Scalar EnergyNat Silva100% (1)

- TransformerDokument5 SeitenTransformerJose GalvanNoch keine Bewertungen

- Hadron ColliderDokument121 SeitenHadron ColliderDeepak VermaNoch keine Bewertungen

- Fluid Mechanics, Lecture 3Dokument22 SeitenFluid Mechanics, Lecture 3Adhi FebrianNoch keine Bewertungen

- MD VI Shaft DesignDokument11 SeitenMD VI Shaft DesignShatendra SahuNoch keine Bewertungen

- Power Divider, Combiner and CouplerDokument60 SeitenPower Divider, Combiner and Couplergaurav_juneja_4Noch keine Bewertungen

- Model and Analysis On Car Seat Mounting BracketDokument6 SeitenModel and Analysis On Car Seat Mounting BracketseventhsensegroupNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)