Beruflich Dokumente

Kultur Dokumente

Aerial Lift

Hochgeladen von

HamzaNouman0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

8 Ansichten2 Seitenariel Lift

Copyright

© © All Rights Reserved

Verfügbare Formate

DOC, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenariel Lift

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

8 Ansichten2 SeitenAerial Lift

Hochgeladen von

HamzaNoumanariel Lift

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

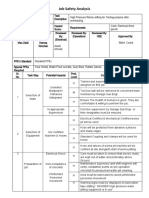

JOB SAFETY ANALYSIS

FACILITIES SERVICES

WORKING IN MAN LIFT (AERIAL LIFT)

TASK

HAZARDS

CONTROLS

Warn people in work area; utilize barricades, cones,

or caution tape to keep bystanders a safe distance

from job; position lift away from traffic, building

overhangs, and power lines; level truck base and

block wheels.

1.

Prepare work area.

Injuries to operator, co-workers, and bystanders

2.

Operate lift.

Falling injuries

Visual inspection and operational check of aerial lift

Secure operator with a body belt and personal

lanyard anchored to boom.

Never exceed the posted lift capacity (including

worker, material, and tools).

Never use lift as a crane or hoist to lift or lower

materials.

Always look in the direction of travel of the bucket

when operating lift; never run boom or bucket into

conductors, cables, poles, trees, etc.

Never move the lift truck when the boom is elevated

in a working position with an operator in the bucket.

No part of the body shall be used to locate or to

attempt to stop a hydraulic leak.

Eye, hand, arm injuries to operator

Wear hard hat, gloves, and safety glasses.

Page 1

Electrical injuries to operator.

Maintain a minimum clearance of 10 feet from

energized conductors rated 50kV phase-to-phase

or less; for lines rated over 50kV phase-to-phase,

the minimum clearance shall be 10 feet plus 4/10

inch for each kilovolt greater than 50 kV phase-tophase.

WARNING: Insulated buckets do not protect

operators from other electrical paths to the ground,

such as those through trees, through a guy wire, or

the path from one phase wire to the second phase

wire, any one of which can be fatal.

Required Training:

1. Operation of aerial lift

2. Electrical safety

3. Fall protection

Required Personal Protective Equipment (PPE)

1. Hard hat

2. Gloves

3. Safety glasses

4. Body belt

5. Lanyard

Page 2

Das könnte Ihnen auch gefallen

- Drilling Safety Induction Rev 1Dokument108 SeitenDrilling Safety Induction Rev 1Sinan Halboob75% (4)

- NPS Drilling Safety Induction Rev 1Dokument108 SeitenNPS Drilling Safety Induction Rev 1Sameer Parambath100% (1)

- Hazard & Control Drilling OprDokument108 SeitenHazard & Control Drilling OprAlton MangiwaNoch keine Bewertungen

- Aerial Lift Safety EnglishDokument4 SeitenAerial Lift Safety EnglishAyehsa JamalNoch keine Bewertungen

- 12N. Cranes and Rigging Equipment: 24590-WTP-GPP-SIND-016/017/018Dokument9 Seiten12N. Cranes and Rigging Equipment: 24590-WTP-GPP-SIND-016/017/018AmeerUlHaqNoch keine Bewertungen

- Boom Lift PDFDokument2 SeitenBoom Lift PDFcityofdarwingisNoch keine Bewertungen

- Aerial - Lifty & Scissor Lift - Safety - TrainingDokument32 SeitenAerial - Lifty & Scissor Lift - Safety - TrainingfawnNoch keine Bewertungen

- Safe Hoisting and Rigging ProceduresDokument3 SeitenSafe Hoisting and Rigging ProceduresAditya Raj MishraNoch keine Bewertungen

- 5 Min AerialLiftSafety 15Dokument3 Seiten5 Min AerialLiftSafety 15Jose MirandaNoch keine Bewertungen

- WORKING AT HEIGHTS SAFETYDokument22 SeitenWORKING AT HEIGHTS SAFETYdarkhorse1981100% (1)

- General Crane SafetyDokument4 SeitenGeneral Crane SafetyEhab Mostafa AliNoch keine Bewertungen

- SCISSOR LIFT SAFETYDokument7 SeitenSCISSOR LIFT SAFETYnatuan74Noch keine Bewertungen

- 4 AWARE Struck by Caught BetweenDokument41 Seiten4 AWARE Struck by Caught BetweenHamza ShehzadNoch keine Bewertungen

- Bucket Truck Safety GuidelinesDokument4 SeitenBucket Truck Safety GuidelineshazopmanNoch keine Bewertungen

- Working at HeightsDokument21 SeitenWorking at HeightsSanjana GaneshNoch keine Bewertungen

- Crane and Hoist Safety TrainingDokument13 SeitenCrane and Hoist Safety TrainingMAHEBOOB PASHANoch keine Bewertungen

- 04.2.1 SWP 900 - SWP Stepladders, Electric Power-, and Hand Tools, Manual Handling (TCT - OHS Master File 2023)Dokument6 Seiten04.2.1 SWP 900 - SWP Stepladders, Electric Power-, and Hand Tools, Manual Handling (TCT - OHS Master File 2023)Hibon LodgeNoch keine Bewertungen

- MSD - Nov 23Dokument7 SeitenMSD - Nov 23chinmayeducationtrustNoch keine Bewertungen

- 7A. Crane & Hoist SafetyDokument2 Seiten7A. Crane & Hoist SafetySantos RexNoch keine Bewertungen

- Physical Hazards 101Dokument24 SeitenPhysical Hazards 101Mohamed AhmedNoch keine Bewertungen

- Elevating Work PlatformDokument1 SeiteElevating Work PlatformKostan AbdillahNoch keine Bewertungen

- Rigging JSA SafetyDokument5 SeitenRigging JSA SafetyaQiLGunawanNoch keine Bewertungen

- Workingatheights 110623224858 Phpapp02Dokument21 SeitenWorkingatheights 110623224858 Phpapp02naveeduddin2001Noch keine Bewertungen

- Activity Hazard Analysis Concrete Table, Sidewalk, and Ramp InstallationDokument2 SeitenActivity Hazard Analysis Concrete Table, Sidewalk, and Ramp Installationgunnery02Noch keine Bewertungen

- HGT Safe Systems of Work For ForkliftsDokument7 SeitenHGT Safe Systems of Work For ForkliftsVeeramuthu SundararajuNoch keine Bewertungen

- NEWESD Scissor LiftsDokument27 SeitenNEWESD Scissor LiftsAlbadeel Inspection & Conformity Co. ltdNoch keine Bewertungen

- Job Hazard Analysis For Crane DismantlingDokument2 SeitenJob Hazard Analysis For Crane DismantlingVaisham92% (24)

- CN7010 Project Safety ManagementDokument85 SeitenCN7010 Project Safety ManagementShanmugambalu78% (9)

- Construction Manpower SafetyDokument22 SeitenConstruction Manpower Safetyjolmarie llanto0% (1)

- Aerial LiftDokument1 SeiteAerial LiftasknishanNoch keine Bewertungen

- Safe Practices in Material HandlingDokument65 SeitenSafe Practices in Material HandlingAshwani DograNoch keine Bewertungen

- Manlift GuidelinesDokument8 SeitenManlift GuidelinesKaliyamoorthy Samiayya100% (7)

- Aerial Lifts Forklifts Aerial Lifts Safe Work PracticesDokument1 SeiteAerial Lifts Forklifts Aerial Lifts Safe Work PracticesWaqas KhanNoch keine Bewertungen

- Conveyor Safety RulesDokument4 SeitenConveyor Safety RulesAndrada Roxana IonescuNoch keine Bewertungen

- Scissors Lifts TrainingDokument27 SeitenScissors Lifts TrainingpanjemadjoNoch keine Bewertungen

- Crane Safety Checklist: 10+ Tips to Prevent InjuriesDokument20 SeitenCrane Safety Checklist: 10+ Tips to Prevent InjuriesRutuja ShikhareNoch keine Bewertungen

- Pallet Jack Safety: Wear Personal Protective EquipmentDokument2 SeitenPallet Jack Safety: Wear Personal Protective EquipmentRadhaKrishnan R100% (1)

- Safe lifting procedures with cranesDokument5 SeitenSafe lifting procedures with cranesrizki hsb100% (2)

- Tullow Safety Rule 3 Working at Height ChecklistDokument2 SeitenTullow Safety Rule 3 Working at Height ChecklistWanwaniouan Pomme100% (1)

- Loading Unloading EquipDokument4 SeitenLoading Unloading EquipSyed Fawad Adil100% (1)

- Laying of Pipes and Culverts PDFDokument2 SeitenLaying of Pipes and Culverts PDFcityofdarwingis0% (1)

- Construction SafetyDokument30 SeitenConstruction SafetyGerry TriazNoch keine Bewertungen

- Aerial Lift Safety: Weekly ES&H Toolbox TalkDokument1 SeiteAerial Lift Safety: Weekly ES&H Toolbox TalkrjlafortezaNoch keine Bewertungen

- Risk Assessment - Lifting OperationsDokument6 SeitenRisk Assessment - Lifting OperationsJishad Nalakath83% (87)

- Crane and Forklift Safety GuidelinesDokument4 SeitenCrane and Forklift Safety Guidelinesferry ferdiansyah pradanaNoch keine Bewertungen

- SAFE PROCEDURES FACADE INSTALLATIONDokument12 SeitenSAFE PROCEDURES FACADE INSTALLATIONZaw Ko Ko OoNoch keine Bewertungen

- Aerial Platforms Man LiftsDokument1 SeiteAerial Platforms Man LiftsLuz Ángela Rincón GallegoNoch keine Bewertungen

- CraneDokument24 SeitenCranezawmoe aungNoch keine Bewertungen

- Safety Orientation ProcedureDokument8 SeitenSafety Orientation ProcedureAMIN SHAIKHNoch keine Bewertungen

- Weekly TBT Lifting Operation RequirementsDokument9 SeitenWeekly TBT Lifting Operation RequirementsfatehNoch keine Bewertungen

- Method Statement Analysis: Basic Job Steps Remarks High Risk Iedntified Mitigation Steps To Reduce/Eliminate The RiskDokument14 SeitenMethod Statement Analysis: Basic Job Steps Remarks High Risk Iedntified Mitigation Steps To Reduce/Eliminate The RiskShanavas MuhammedNoch keine Bewertungen

- SAFE PPE AND HAZARDS PROCEDUREDokument7 SeitenSAFE PPE AND HAZARDS PROCEDUREMd Shahin100% (1)

- Gantry Crane PDFDokument2 SeitenGantry Crane PDFcityofdarwingisNoch keine Bewertungen

- The Construction Safety Guide: Injury and Illness Prevention through DesignVon EverandThe Construction Safety Guide: Injury and Illness Prevention through DesignBewertung: 4 von 5 Sternen4/5 (6)

- Aeroplane Flight Training: Lesson Plans for Students & Instructors With Questions - Plus a Lot MoreVon EverandAeroplane Flight Training: Lesson Plans for Students & Instructors With Questions - Plus a Lot MoreBewertung: 3 von 5 Sternen3/5 (2)

- 2005 Nondestructive Testing Guide Equipment Condition AssessmentDokument8 Seiten2005 Nondestructive Testing Guide Equipment Condition AssessmentHamzaNoumanNoch keine Bewertungen

- MC LiftRigBestPractices Poster 11X17Dokument1 SeiteMC LiftRigBestPractices Poster 11X17HamzaNoumanNoch keine Bewertungen

- Balance Plot FormDokument1 SeiteBalance Plot FormHamzaNoumanNoch keine Bewertungen

- Best Practices in Machinery InstallationDokument2 SeitenBest Practices in Machinery InstallationHamzaNoumanNoch keine Bewertungen

- Onboarding Checklist: Best Practices for a Smooth StartDokument1 SeiteOnboarding Checklist: Best Practices for a Smooth StartHamzaNoumanNoch keine Bewertungen

- Fluid Handling System PriceDokument2 SeitenFluid Handling System PriceHamzaNoumanNoch keine Bewertungen

- H Hole MesaurmentDokument2 SeitenH Hole MesaurmentHamzaNoumanNoch keine Bewertungen

- Helium Leak Detector vs Pressure Decay Leak Testing MethodsDokument2 SeitenHelium Leak Detector vs Pressure Decay Leak Testing MethodsHamzaNoumanNoch keine Bewertungen

- Acceptance Criteria of Weld Defects As Per Different CodesDokument17 SeitenAcceptance Criteria of Weld Defects As Per Different CodesShubham ShuklaNoch keine Bewertungen

- Nbo-Tc NewDokument24 SeitenNbo-Tc NewHamzaNoumanNoch keine Bewertungen

- Bayyinat ArticleDokument4 SeitenBayyinat ArticleHamzaNoumanNoch keine Bewertungen

- Congratulations On Your Completion: Hamza NomanDokument1 SeiteCongratulations On Your Completion: Hamza NomanHamzaNoumanNoch keine Bewertungen

- The ABC of NDTDokument5 SeitenThe ABC of NDTHamzaNoumanNoch keine Bewertungen

- Shift 2 Schedule (Sept 12 - Sept 20 '22)Dokument1 SeiteShift 2 Schedule (Sept 12 - Sept 20 '22)HamzaNoumanNoch keine Bewertungen

- Certificate of Completion: Hafiz NomanDokument1 SeiteCertificate of Completion: Hafiz NomanHamzaNoumanNoch keine Bewertungen

- Confirmation - Check-InDokument1 SeiteConfirmation - Check-InHamzaNoumanNoch keine Bewertungen

- Calculate your daily water intake based on weightDokument7 SeitenCalculate your daily water intake based on weightSuyenthan SathishNoch keine Bewertungen

- 7 22 2022 Mech - 19596Dokument1 Seite7 22 2022 Mech - 19596HamzaNoumanNoch keine Bewertungen

- JSA For Woma Jet TestingDokument2 SeitenJSA For Woma Jet TestingHamzaNoumanNoch keine Bewertungen

- Advance Cash For Cricket PitchDokument1 SeiteAdvance Cash For Cricket PitchHamzaNoumanNoch keine Bewertungen

- Sr. No. Description Unit: Workshop / Garage Craft IssuesDokument14 SeitenSr. No. Description Unit: Workshop / Garage Craft IssuesHamzaNoumanNoch keine Bewertungen

- Cylinder Test-Certification-ProceduresDokument3 SeitenCylinder Test-Certification-ProceduresHamzaNoumanNoch keine Bewertungen

- Manpower Workshop Garage CraftDokument7 SeitenManpower Workshop Garage CraftHamzaNoumanNoch keine Bewertungen

- Contract Extension of Hafiz Hussain 2021Dokument2 SeitenContract Extension of Hafiz Hussain 2021HamzaNoumanNoch keine Bewertungen

- Scaffolding: Submitted By, Akhilesh.A Production Operator (TR), Forbes Bumiarmada LimitedDokument42 SeitenScaffolding: Submitted By, Akhilesh.A Production Operator (TR), Forbes Bumiarmada LimitedHamzaNoumanNoch keine Bewertungen

- Mechanical Workshop: Inspection & Test PlanDokument4 SeitenMechanical Workshop: Inspection & Test PlanHamzaNoumanNoch keine Bewertungen

- MCBU - Lifting & Rigging Questions and AnswersDokument15 SeitenMCBU - Lifting & Rigging Questions and AnswersBhaiJan59Noch keine Bewertungen

- Incident / Injury Occurrence Report Part A:: Form No: SAF/2/001 Date Prepared: 29 / 09 / 08 Revision: 00Dokument2 SeitenIncident / Injury Occurrence Report Part A:: Form No: SAF/2/001 Date Prepared: 29 / 09 / 08 Revision: 00HamzaNoumanNoch keine Bewertungen

- D Level Safety Meeting Quality Checklist - RevisedDokument1 SeiteD Level Safety Meeting Quality Checklist - RevisedHamzaNoumanNoch keine Bewertungen

- Pakarab Fertilizers IT Help Desk FormDokument1 SeitePakarab Fertilizers IT Help Desk FormHamzaNoumanNoch keine Bewertungen

- Hoisting Systems ExplainedDokument21 SeitenHoisting Systems Explainedsparda94Noch keine Bewertungen

- Digital Logic DesignDokument4 SeitenDigital Logic DesignkiranNoch keine Bewertungen

- Maximum Power Tracking System for Solar Panels Using Automatic ControlDokument79 SeitenMaximum Power Tracking System for Solar Panels Using Automatic ControlHarish VarmaNoch keine Bewertungen

- Material Ease 20Dokument7 SeitenMaterial Ease 20Sorin RipaNoch keine Bewertungen

- Supplier Deviation Request FormDokument2 SeitenSupplier Deviation Request Formjainik shahNoch keine Bewertungen

- As 2560.2.1-2003 Sports Lighting Specific Applications - Lighting For Outdoor TennisDokument7 SeitenAs 2560.2.1-2003 Sports Lighting Specific Applications - Lighting For Outdoor TennisSAI Global - APAC0% (1)

- Strategic Supply Chain Management and LogisticsDokument16 SeitenStrategic Supply Chain Management and LogisticsNalaka Manawadu67% (3)

- Electricity Scavenger HuntDokument1 SeiteElectricity Scavenger HuntksonicoNoch keine Bewertungen

- Standardization of Welding ElectrodesDokument8 SeitenStandardization of Welding ElectrodesAqsa BanoNoch keine Bewertungen

- Petri Net Modeling and ApplicationsDokument13 SeitenPetri Net Modeling and ApplicationsRishiraj SenguptaNoch keine Bewertungen

- Linthwaite: Conservatio N AreaDokument26 SeitenLinthwaite: Conservatio N Areabill baileyNoch keine Bewertungen

- Insulation Castables Application Procedure - Rev-2 - PDFDokument10 SeitenInsulation Castables Application Procedure - Rev-2 - PDFNatarajan MurugesanNoch keine Bewertungen

- Escorts F-15: Hydraulic Mobile Pick-n-Carry CraneDokument2 SeitenEscorts F-15: Hydraulic Mobile Pick-n-Carry CraneChandra MouliNoch keine Bewertungen

- Gas Sensors: Jiturvi Chokshi ENPM-808BDokument27 SeitenGas Sensors: Jiturvi Chokshi ENPM-808Banon_44955929Noch keine Bewertungen

- Fisher Poistioner CatalogueDokument12 SeitenFisher Poistioner CatalogueUsama IqbalNoch keine Bewertungen

- Theory of Metal Cutting-Module 1Dokument116 SeitenTheory of Metal Cutting-Module 1rejeesh_rajendranNoch keine Bewertungen

- FTS ScaleoEUserManualEN 10 1082177Dokument2.044 SeitenFTS ScaleoEUserManualEN 10 1082177JNoch keine Bewertungen

- WTS 12 ElectrodynamicsDokument28 SeitenWTS 12 ElectrodynamicsTondani100% (1)

- Lab Report Experiment 5Dokument4 SeitenLab Report Experiment 5Czarina mantuano100% (2)

- Grove GMK 4080Dokument6 SeitenGrove GMK 4080Deiver BarrazaNoch keine Bewertungen

- Emp2 Box Pressure TransmitterDokument8 SeitenEmp2 Box Pressure TransmitterAsif HameedNoch keine Bewertungen

- Multiple-Choice QuestionsDokument8 SeitenMultiple-Choice Questionsvijayganesh pinisettiNoch keine Bewertungen

- RTJ Dimension ASME B16.5/B16.47Dokument1 SeiteRTJ Dimension ASME B16.5/B16.47parayilomer0% (1)

- Sheds Direct Ireland's Wooden BrochureDokument12 SeitenSheds Direct Ireland's Wooden BrochureVictor Celestino Montañez CarranzaNoch keine Bewertungen

- Construction of Multistoried Boys Hostel by Kanwarjot SinghDokument22 SeitenConstruction of Multistoried Boys Hostel by Kanwarjot SinghvipinNoch keine Bewertungen

- Quick Union Reference Tables: Pressure Control EquipmentDokument1 SeiteQuick Union Reference Tables: Pressure Control EquipmentMiguel FNoch keine Bewertungen

- Internship Report-1Dokument64 SeitenInternship Report-1VIJAY SPNoch keine Bewertungen

- HVCB Timing ApplicationDokument52 SeitenHVCB Timing Applicationbhuban mohanNoch keine Bewertungen

- G.25-GEMSS-G-02 Rev 01plant Design CriteriaDokument13 SeitenG.25-GEMSS-G-02 Rev 01plant Design Criteriamohammad kassarNoch keine Bewertungen

- Ansul Wheeled RedLine 150lb F-2002046Dokument4 SeitenAnsul Wheeled RedLine 150lb F-2002046German Duvan HernandezNoch keine Bewertungen