Beruflich Dokumente

Kultur Dokumente

Callidus Flare Gas Recovery Systems Brochure

Hochgeladen von

TONCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Callidus Flare Gas Recovery Systems Brochure

Hochgeladen von

TONCopyright:

Verfügbare Formate

Callidus Flare Gas Recovery Systems

Pre-engineered, Modular Systems

to Reduce Flare Emissions

Modular Flare Gas Recovery System

Manufactured to Industry Standards

Honeywell UOP Callidus is a leading provider of flare systems, flare gas recovery technology and a range

of flare system capabilities. With a heritage of technical expertise, we take pride in providing economical

flares with high destruction efficiency, high smokeless capacity, low noise and low radiation for a broad

range of flare applications. Our team has hundreds of years of combined flare design experience and has

been involved in the fabrication, installation, start-up, and service of thousands of flare systems worldwide.

Dedicated to achieving zero flaring, our Flare Gas Recovery Systems (FGRS) address the growing

concerns regarding flare emissions, while also saving money. We call it Saving made simple.

The Only Flare Gas Recovery System Youll Ever Need

significantly reduce the amount of emissions

Losses to the flare, including process gases, fuel gas, steam, nitrogen and

produced on an annual basis. You may be eligible

natural gas represent the largest source of loss in a refinery or chemical

plant. The cost of these losses can add up quickly. Honeywell UOP Callidus

Modular Flare Gas Recovery System collects process gases from the flare

header before it reaches the flare, compresses them and allows them to be

reused within the facilitys fuel gas system. In some cases, the recovered

gases can also be used as a refinery feedstock. Our industry leading

Modular Flare Gas Recovery System helps refinery owners meet emissions

regulations, reduce risk, extend equipment life and, certainly, add to your

bottom line.

Environment

Worldwide, efforts to reduce emissions have become increasingly

important. By capturing flare gas before it is burned by the flare, we can

for emissions credits when using this technology.

Public image

No one likes to see or hear a flare system,

especially the communities surrounding your

facility. By installing our Flare Gas Recovery

System, owners can significantly decrease the

number of flaring events that occur annually,

limiting the risk of major or emergency cases.

Cost

By capturing and compressing recovered flare

gases, our flare gas recovery system provides

a ready supply of gas that can be used in

your facilitys fuel gas system or as a refinery

feedstock. This allows you to reduce the amount

of gas purchased from outside, or increase your

supply of salable gas to create a higher revenue

stream. Also, by minimizing the number of

flaring events, you significantly reduce steam

consumption, which saves you more money.

Equipment life

Fewer flaring events means that the flare

tip is less exposed to the negative effects of

combustion, extending the flare tip life. This

means fewer spare parts orders and a longer

period between tip replacements.

Single-Skid Modular FGRS Unit

Modular Flare Gas Recovery Systems (FGRS)

Custom made simple

The Honeywell UOP Callidus Modular Flare Gas Recovery System

Modular Flare Gas Recovery Systems are

comprises of several major components the primary component being

pre-engineered, skid-mounted packages for

the compressor unit. We use proven liquid ring technology, which is

faster delivery and startup. Modules can be

capable of addressing a range of process compositions typical in flare

combined to provide increased recovery capacity

applications. Honeywell UOP Callidus Flare Gas Recovery System also

and pre-engineered piping kits provide

integrates seamlessly into an existing flare system.

interconnection between modules. Single skid

modules allow for faster installation and reduced

System Safety

field assembly costs. Multi-module

Installing any flare gas recovery system without evaluating the impact on

configurations provide maintenance efficiency

the flare system can result in poor performance and potentially hazardous

as units share common parts.

conditions. Since the flare gas recovery system is pulling gas from the

flare header, it could potentially create a vacuum condition within the flare

system and pull air in from the flare tip. To prevent this from happening,

we recommend conducting a liquid seal evaluation with every Flare Gas

Recovery System application. We have extensive experience designing

and supplying deep liquid seals, which enable the installation and correct

operation of our Flare Gas Recovery Systems, without compromising

flare system performance. As a world leader in flare system equipment,

Honeywell UOP uses a proprietary liquid seal design to avoid liquid seal

turbulence, which can result in flare pulsing.

With our deep understanding of controls, our

Flare Gas Recovery Systems are designed to

integrate and communicate with your existing

controls platforms. Our typical configuration

uses PLC based controls to monitor and control

the system components. However, the system

can also communicate and integrate with

existing customer distributed control systems.

Sizing service

Honeywell UOP Callidus offers a Flare Gas

Recovery sizing service, which monitors and

tracks flare header activity to better match your

process conditions and make recommendations

for the appropriate module configuration. We use

state-of-the-art flow data logging to periodically

record data which can then be used to determine

which configuration is best for your application.

The testing and monitoring services have zero

impact on your existing system.

Powerful savings

Achieving your zero flaring goal has never been

so simple. Reducing emissions, saving money

and extending the life of your flare equipment

all with a pre-engineered, Honeywell UOP

Callidus Modular Flare Gas Recovery System.

Dual module with interconnecting piping

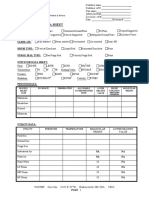

Single Module Specifications

Capacity (ACFM)

670

Gas Inlet Pressure (inch WC)

6+

Gas Outlet Pressure (psig)

~100

Dimensions (feet L x W x H)

48 x 12 x 15

Weight (lbs dry)

75,000

Motor (Hp)

500 compressor, 15 Startup

Instrumentation

Class 1 div 2, group C,D

Piping

B1A2-NACE, B1A1, B1A2

Capacity / MW

Typical

High

Low

MW

23.5

59.7

7.3

Mass flow lb/hr

2312

6000

716

Honeywell UOP Callidus headquarters Tulsa, Oklahoma. USA

Honeywell UOP Callidus combustion test

facility - China

Honeywell UOP Callidus 82,000 sq. ft.

manufacturing and fabrication facility in USA

Global Coverage

Test Facility

Honeywell UOP Callidus reaches the

Honeywell UOP Callidus test facilities

global market through our headquarters

in the U.S. and China are used for

In Addition to Flare

Gas Recovery Systems,

Honeywell UOP Callidus Offers:

located in Tulsa, Oklahoma, USA, with

combustion technology research and

regional direct sales offices and

development, as well as for customer

Ultra-low NOx burners

independent sales representation

demonstrations. Our array of test

around the world. Meeting our

systems allow us to closely match actual

customers expectations and setting the

field operating conditions, providing

standards for the combustion industry

results that will more accurately predict

Field services and parts

have always been our goals. Each

actual measured performance.

CFD Modeling

burner, flare, thermal oxidizer and

Flares, flare systems and flare gas

recovery systems

Thermal oxidizer systems

Training and schools

catalyst system we design and

manufacture is built with those goals

in mind.

ISO 9001:2008 Certification

High-Performance Combustion Solutions

Service Parts Installation

USA Certification

Contact uswere here to help.

CallidusHelp@Honeywell.com

For more information

For more information, please visit

www.callidus.com to find a local

sales representative

Corporate Headquarters

Callidus Technologies

7130 South Lewis Ave.

Suite 335

Tulsa, Oklahoma. 74136

Tel: +1-918-496-7599

www.callidus.com

UOP7326-10

March 2016

Printed in U.S.A.

2016 UOP LLC. All rights reserved.

China Certification

Das könnte Ihnen auch gefallen

- Fluid Velocity ConsiderDokument2 SeitenFluid Velocity ConsiderajaysapruNoch keine Bewertungen

- Global supplier for global demandsDokument9 SeitenGlobal supplier for global demandsTONNoch keine Bewertungen

- Next-Generation Nozzle Check Valve Reduce Operating Costs - Engineer LiveDokument3 SeitenNext-Generation Nozzle Check Valve Reduce Operating Costs - Engineer LiveTONNoch keine Bewertungen

- Klinger QuantumDokument8 SeitenKlinger QuantumTONNoch keine Bewertungen

- Klingersil Flange SecurityDokument8 SeitenKlingersil Flange SecurityTONNoch keine Bewertungen

- How Should I Store My GasketDokument2 SeitenHow Should I Store My GasketTONNoch keine Bewertungen

- Manual Klinger ExpertDokument24 SeitenManual Klinger ExpertTONNoch keine Bewertungen

- ASTM F 36 J gasket compression and recovery testingDokument2 SeitenASTM F 36 J gasket compression and recovery testingTONNoch keine Bewertungen

- InstallationStorageInstructionsKLINGERGaskets PDFDokument6 SeitenInstallationStorageInstructionsKLINGERGaskets PDFTONNoch keine Bewertungen

- Abdul Majid 11 PDFDokument233 SeitenAbdul Majid 11 PDFTONNoch keine Bewertungen

- En 13555 ReportDokument16 SeitenEn 13555 ReportTONNoch keine Bewertungen

- How Should I Store My GasketDokument2 SeitenHow Should I Store My GasketTONNoch keine Bewertungen

- Vibration of Valves and PipingDokument6 SeitenVibration of Valves and PipingTONNoch keine Bewertungen

- Amali 2015 IOP Conf. Ser.: Mater. Sci. Eng. 87 012055Dokument8 SeitenAmali 2015 IOP Conf. Ser.: Mater. Sci. Eng. 87 012055TONNoch keine Bewertungen

- Ijesrt: International Journal of Engineering Sciences & Research TechnologyDokument7 SeitenIjesrt: International Journal of Engineering Sciences & Research TechnologyTONNoch keine Bewertungen

- ZCL Corrosion Guide Specification Ag FRP ChemicalstoDokument8 SeitenZCL Corrosion Guide Specification Ag FRP ChemicalstoTONNoch keine Bewertungen

- Behavior of FRP Chimneys Under Thermal and Wind LoadDokument163 SeitenBehavior of FRP Chimneys Under Thermal and Wind LoadandyhrNoch keine Bewertungen

- W044Rev1 PDFDokument41 SeitenW044Rev1 PDFTONNoch keine Bewertungen

- Efi Tank SpecificationDokument11 SeitenEfi Tank Specificationjack-bcNoch keine Bewertungen

- (Report) Storage Tanks (Japan)Dokument179 Seiten(Report) Storage Tanks (Japan)RAJENDRA PRASADNoch keine Bewertungen

- Pipe Fea Using AnsysDokument14 SeitenPipe Fea Using AnsysTONNoch keine Bewertungen

- Full Text 01Dokument260 SeitenFull Text 01TONNoch keine Bewertungen

- Standart Toleransi Spring RateDokument1 SeiteStandart Toleransi Spring RateTONNoch keine Bewertungen

- Thermal Expansion Pressure Increase Liquid EnclosureDokument1 SeiteThermal Expansion Pressure Increase Liquid EnclosureTONNoch keine Bewertungen

- 1Dokument9 Seiten1TONNoch keine Bewertungen

- Mps Katalog Gradior en Kap1Dokument9 SeitenMps Katalog Gradior en Kap1TONNoch keine Bewertungen

- PumpfundaDokument13 SeitenPumpfundasureshbabu7374Noch keine Bewertungen

- Pub 36356Dokument48 SeitenPub 36356TONNoch keine Bewertungen

- Example 1 (2011) : Crane ScheduleDokument2 SeitenExample 1 (2011) : Crane ScheduleTONNoch keine Bewertungen

- 2011PFFCranePlanningQuestionnaire PrincipalContractorInformationProvisionDokument3 Seiten2011PFFCranePlanningQuestionnaire PrincipalContractorInformationProvisionTONNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Ultra FG Flyer Final PDFDokument2 SeitenUltra FG Flyer Final PDFairmacmexNoch keine Bewertungen

- Design of Distillation Column (By Muhammad Faisal)Dokument23 SeitenDesign of Distillation Column (By Muhammad Faisal)EngrFaisalNoch keine Bewertungen

- Material Balances On Reactive SystemsDokument84 SeitenMaterial Balances On Reactive SystemscjNoch keine Bewertungen

- OMV Kadanwari Plant Gas ProcessingDokument62 SeitenOMV Kadanwari Plant Gas ProcessingSyed Haider Abbas Bukhari100% (1)

- Distillation SequencingDokument39 SeitenDistillation SequencingSohail Aziz Ahmad MalikNoch keine Bewertungen

- NaOH Production Process Word FileDokument7 SeitenNaOH Production Process Word FileAnkit MistryNoch keine Bewertungen

- Economic Aspects of Setting Up Purge Gas Recovery Unit (PGRU) With Ammonia Production ProcessDokument7 SeitenEconomic Aspects of Setting Up Purge Gas Recovery Unit (PGRU) With Ammonia Production ProcessWilly ChandraNoch keine Bewertungen

- Safe preparation of compressed oxidant-fuel gas mixturesDokument40 SeitenSafe preparation of compressed oxidant-fuel gas mixturesVan SotNoch keine Bewertungen

- GE-07 Fire Safety Test Pass 95Dokument4 SeitenGE-07 Fire Safety Test Pass 95Gilmar ShuenckNoch keine Bewertungen

- Petrochemicals: Petrochemicals Are Chemical Products Made From TheDokument3 SeitenPetrochemicals: Petrochemicals Are Chemical Products Made From TheRaj Sunil KandregulaNoch keine Bewertungen

- May 2007 MpiDokument65 SeitenMay 2007 MpiseguntaiwoNoch keine Bewertungen

- Liquid-Liquid ExtractionDokument11 SeitenLiquid-Liquid ExtractionRo TuliaoNoch keine Bewertungen

- EorDokument13 SeitenEorAnuragNoch keine Bewertungen

- Crude Oil Gravity Density and Specific: API: Is A Measure of The Quality of Crude OilDokument9 SeitenCrude Oil Gravity Density and Specific: API: Is A Measure of The Quality of Crude OilMohamed AKNoch keine Bewertungen

- Condensed Flare DatasheetDokument4 SeitenCondensed Flare Datasheetbraviross_418157489Noch keine Bewertungen

- Thermodynamic Analysis of Optimal Condensing Temperature of Cascade-Condenser in CO /NH Cascade Refrigeration SystemsDokument9 SeitenThermodynamic Analysis of Optimal Condensing Temperature of Cascade-Condenser in CO /NH Cascade Refrigeration Systemslog duongNoch keine Bewertungen

- Chemical Process Design and OptimizationDokument21 SeitenChemical Process Design and OptimizationLam DesmondNoch keine Bewertungen

- LIST OF FUEL STATIONSDokument820 SeitenLIST OF FUEL STATIONSUtkarsh SakhalkarNoch keine Bewertungen

- Chapter IIIDokument8 SeitenChapter IIImonkey d. luffyNoch keine Bewertungen

- Propylene ProductionDokument24 SeitenPropylene ProductionFadlan BaharNoch keine Bewertungen

- Department of Petroleum and Mining Engineering Military Institute of Science and TechnologyDokument12 SeitenDepartment of Petroleum and Mining Engineering Military Institute of Science and TechnologyNakib Jr.Noch keine Bewertungen

- Flash CalculationDokument24 SeitenFlash Calculationproabbey100% (1)

- ZLD Systems Xzero PDFDokument15 SeitenZLD Systems Xzero PDFlkumar4454Noch keine Bewertungen

- Bioresource Technology: Oscar Pardo-Planas, Hasan K. Atiyeh, John R. Phillips, Clint P. Aichele, Sayeed MohammadDokument8 SeitenBioresource Technology: Oscar Pardo-Planas, Hasan K. Atiyeh, John R. Phillips, Clint P. Aichele, Sayeed Mohammadmohsen ranjbarNoch keine Bewertungen

- CHE 318 Industrial Chemical Processes Course OutlineDokument143 SeitenCHE 318 Industrial Chemical Processes Course OutlineDavid JohnNoch keine Bewertungen

- What Is Produced Water and How It Is TreatedDokument5 SeitenWhat Is Produced Water and How It Is TreatedRizwan FaridNoch keine Bewertungen

- Chemical Kinetics Rate EquationsDokument20 SeitenChemical Kinetics Rate EquationsShimon LalNoch keine Bewertungen

- YoutuDokument16 SeitenYoutuAna Laura Mendoza AriasNoch keine Bewertungen

- Eiga-36 - 19 (2019)Dokument120 SeitenEiga-36 - 19 (2019)JDNoch keine Bewertungen

- Hydrodealkylation ProcessesDokument6 SeitenHydrodealkylation ProcessesCluisantony Jayco Dize100% (1)