Beruflich Dokumente

Kultur Dokumente

Chap2 Belt Drives For Printing

Hochgeladen von

Robie RoqueOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Chap2 Belt Drives For Printing

Hochgeladen von

Robie RoqueCopyright:

Verfügbare Formate

COLLEGE OF ENGINEERING AND ARCHITECTURE

Department of Mechanical Engineering

MACHINE DESIGN 2

Prepared by:

Engr. Arman Ray N. Nisay, MSME

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

2/38

Chapter 2

BELT DESIGN

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

Introduction

3/38

Belts (or belt drives) are flexible transmission elements which

is used to transmit power from one shaft to another by

means of pulleys which rotate at the same speed or at

different speeds.

Belt is a looped strip of flexible material used to mechanically

link two or more rotating shafts.

A belt drive offers smooth transmission of power between

shafts at considerable distances.

Belt drives are used as source of motion to transfer, to

efficiently transmit power, or to track relative movement.

The common belt materials are leather, rubber, stitched

canvass and cotton fabric.

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

4/38

Introduction

Some industrial applications are as follows:

Used in conveying systems (transportation of coals,

mineral ores etc. over a long distance)

Used in power transmission (used for running various

industrial appliances using prime movers such as electric

motors, I.C.E., etc.)

Replacement of rigid type power transmission system (A

gear drive may be replaced by belt transmission system.)

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

5/38

Introduction

Means of power transmission

Rope drive

(lift, crane, hoist, etc.)

Chain drive

(bicycle, motorcycle, etc.)

Flexible

Transmission

Elements

Belt drive

(rice mills, sewing machine, etc.)

Gear train

(automobile, engines, etc.)

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

6/38

Introduction

Advantages of Belt Drive

Belt drives are simple and economical.

Dont require parallel shafts

Can take care of some degree of misalignment between

the driver and driven machines

Can absorb good amount of shock and vibration

Noise and vibration are damped out, thus, machinery life

is increased because load fluctuations are shockabsorbed.

Long distance power transmission is possible

Belts are very economical when distance between shafts

is very large.

Lubrication-free and less maintenance cost

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

7/38

Introduction

Disadvantages of Belt Drive

Angular velocity ratio is not necessarily constant or equal to

the ratio of pulley diameters, because of slipping and

stretching

Heat buildup occurs

Speed is usually limited to 35 m/s

Power transmission is limited to 370 kW

Operating temperature is limited to -35 to 85C

Some adjustment of center distance or use of an idler pulley

is necessary for wearing and stretching of belt drive

compensation

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

Types of Belts

8/38

Flat Belt

is the simplest type, often made from leather of rubber

coated fabric

mostly used in the factories and workshops where a great

amount of power is to be transmitted from one pulley to

another, when the two pulleys are not more than 8 meters

apart

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

Types of Belts

9/38

V-Belt

most widely used type of belt particularly in industrial drives

and vehicular application

mostly used in the factories and workshops where a great

amount of power is to be transmitted from one pulley to

another, when the two pulleys are very near each other

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

10/38

Types of Belts

Toothed Belt (Timing Belt)

is a power transmission belt with evenly spaced teeth on the

bottom side which mesh with grooves cut on the periphery

of the pulley to produce a positive, no slip, constant speed

drive

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

Types of Belts

11/38

Circular Belt

is most widely used in the factories and workshops where a

great amount of power is to be transmitted from one pulley

to another, when two pulleys are more than 8 meters apart

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

12/38

Flat Belt

Advantages of Flat Belt

Can be used with high speed drives

Can be used in dusty and abrasive environment

Allows long distance between shafts

Offers long life,

maintenance

high

efficiency,

low

cost,

and

low

Disadvantages of Flat Belt

The tension must be kept high so as to keep it slow by two

percent

This high tension results in high bearing loads and belt stress

Noise

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

13/38

V-Belt

V-belts are made of fabric or cords molded in rubber and

covered with fabric and rubber.

The included angle for the V-belt is usually from 30 to 40.

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

14/38

V-Belt

Advantages of V-belt over flat belt

It gives compactness due to the small distance between

centers of pulleys.

The drive is positive because the slip between the belt and

the pulley groove is negligible.

The drive is smooth since the v-belt is made endless.

It provides longer life (3 to 5 years)

It can be easily installed and removed.

The operation between the belt and pulley is quiet.

Has the ability to cushion the shock when the machine starts

High velocity ratio (maximum of 10) may be obtained.

May be operated in either direction with tight side of the belt

at the top or bottom and the center line may be horizontal,

vertical or inclined

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

15/38

V-Belt

Disadvantages of V-belt over flat belt

Can not be used with long center distances

Not so durable as flat belts

The construction for pulleys for V-belts is more complicated

than pulleys of flat belts..

Not suitable for constant speed applications (such as

synchronous machines and timing devices) since V-belts are

subjected to certain amount of creep

The belt life is greatly influenced with temperature changes.

Improper belt tension prevents the use of V-belts at speeds

below 5 m/s and above 50 m/s.

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

16/38

Belt Drives

Types of Belt Drives

Open Belt Drive

Crossed or twist belt drive

Quarter turn belt drive

Belt drive with idler pulley

Compound belt drive

Stepped or cone pulley drive

Fast and loose pulley drive

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

17/38

Belt Drives

Types of Belt Drives based on Peripheral Speed

Light Drives are used to transmit small powers at belt speed

up to about 10 m/s such as in agricultural machines and

small machine tools.

Medium Drives are used to transmit medium powers at belt

speeds over 10 m/s but up to 22 m/s such as in machine

tools, cars, etc.

Heavy Drives are used to transmit large powers at belt speed

above 22 m/s such as in compressors, generators and main

drives.

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

Belt Joints

18/38

Types of Belt Joints

Cemented joint

Laced joint

Hinged joint

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

Creep of Belt

19/38

Friction causes the belt to grip the driving sheave, increasing

the tension in one side called the tight side of the drive.

The opposite side of the belt is still under tension at a smaller

value. This side is called the slack side or loose side.

The phenomenon called creep exists because the driving

pulley receive a longer (stretched) belt than it delivers and

the driven pulley receives a shorter belt than it delivers,

giving relative motion between the belt and pulley.

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

20/38

Flat Belt Formulas

Open Belt Connection

Belt Length, L

=

+ + +

Angle of Wrap or Contact,

=

= +

where:

1 diameter of the driving pulley

2 diameter of the driven pulley

center distance

1 angle of contact of the driving pulley

2 angle of contact of the driven pulley

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

21/38

Flat Belt Formulas

Crossed Belt Connection

Belt Length, L

+

=

+ + +

Angle of Wrap or Contact,

= = +

Note:

The crossed belt has the advantage of a

large contact angle and it does very well

where:

1 diameter of the driving pulley

2 diameter of the driven pulley

center distance

1 angle of contact of the driving pulley

2 angle of contact of the driven pulley

at lower speeds.

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

22/38

Flat Belt Formulas

Arc of Contact, s

where:

1 arc of contact of driver pulley

2 arc of contact of driven pulley

1 radius of driver pulley

Centrifugal Force, Fc

2 radius of driven pulley

1 angle of contact of the driving pulley

2 angle of contact of the driven pulley

mass density of the belt

width of the belt

Belt Tension Ratio

thickness of the belt

belt speed of the driver pulley

gravitational constant

1 tension on the tight side of the belt (driver)

2 tension on the slack side of the belt (driven)

Belt Speed,

Note:

Include centrifugal force for leather belting if the belt speed exceeds

35 ft/s (10.675 m/s)

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

23/38

Flat Belt Formulas

Effective Belt Pull (Net Belt Tension), 1 2

=

where:

exponential value (2.718..)

angle of wrap (driver pulley)

coefficient of friction

design stress (allowable stress)

Power Transmitted, P

=

Conversions:

1 = 0.746 = 550

1 = 0.736 = 75

Leather on iron or steel:

= 0.3

Leather on paper pulleys:

= 0.5

For leather:

= 0.035 /3

For rubber:

= 0.0435 /3

1 = 1.014

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

24/38

Flat Belt Formulas

Design Stress,

For good design:

The maximum induced fiber stress should be made equal

to the design or allowable stress.

Allowing for weakening of the belt strength due to joints:

=

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

25/38

Flat Belt Formulas

Basic assumptions if the following are not given in the

problem:

For leather belt:

For rubber belt:

Joint factor (belt/joint efficiency)

Cemented joint:

use if not given

Wire laced by machine: = .

Metal hooks:

= .

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

Flat Belt Formulas

26/38

Design of the belt should be based on the pulley where

slippage occurs first.

Slip (or slippage) occurs when the frictional force

between the belt and pulley is not sufficient in which the

belt moves forward slightly on the driving pulley and

causes the driven pulley to rotate at a lower speed.

Slippage occurs first on the pulley whose angle of wrap is

smaller (driver pulley).

When not of the same material, compare the tension

ratios ( ) of the big and small pulleys. Slippage occurs

first on the pulley whose tension ratio is lower.

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

27/38

Flat Belt Formulas

Belt Speed

Slip not mentioned:

(Driver)

(Driven)

Slip mentioned:

(Driver)

= %

(Driven) = + %

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

28/38

With Idler Pulley

Installation of idler pulley:

When idler is placed on the slack side of the belt, the

tight side is unaffected by the set up:

( ) = ( )

If during the installation of idler, the belt and the pulleys

are not changed then the belt speed and the coefficient

of friction remain the same:

() = ()

() = ()

( ) = ( )

Note:

subscript O means original;

subscript N means new

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

29/38

With Idler Pulley

With the presence of idler in the slack side of the angle of

wrap or arc of contact of the driver increases. Hence, the

transmission capacity also increases:

= ( + %)

Determining the new angle of wrap or arc of contact:

= (1 + %)

= (1 + %)

Since:

() = ()

( ) = + % ( )

Note:

subscript O means original;

subscript N means new

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

30/38

With Idler Pulley

For old transmission capacity:

For new transmission capacity:

Hence:

Note:

subscript O means original;

=

= 1 + %

subscript N means new

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

31/38

With Idler Pulley

Power transmitted with the presence of frictional losses:

=

= %

where:

power transmitted by the driver

power transmitted by the driven

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

Additional Elements (Terms)

32/38

Strength of Leather Belt

The strength of leather depends upon the method of tanning

The breaking strength of oak-tanned belting varies from 3 to

more than 6 ksi.

Mineral tanned leather is stronger with breaking strength of 7

to 12 ksi.

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

Additional Elements (Terms)

33/38

Belt Speeds

The tension in the belt due to centrifugal force increases

rapidly above about 2,500 fpm.

Experience suggests that the most economical designs are o

btained for a belt speed of 4,000 to 4,500 fpm.

For leather, speeds of 7,000 to 8,000 fpm are in use (but

consult the vendor).

Flat fabric belts operate up to 20,000 fpm and more.

On high-speed centrifugal blowers, it has been pbserved

that the arc of contact is reduced from 180 at rest to 110

in motion, one of the side effects of speed.

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

Additional Elements (Terms)

34/38

Initial Tension

In order to transmit power, the belt must have some initial

tension (tension at rest).

As suggested by Taylor*, the recommended initial tension of

belt should be 71 lb/in. of width.

Tension pulley is used to maintain initial tension and also

greatly increases the arc of contact on the nearest pulley,

preferably the smaller one.

*Taylor, F. W., Notes on belts, ASME Trans., vol. 15, p. 204

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

Additional Elements (Terms)

35/38

Rubber Belting

Rubber belts are made in layers (say 3 to 12), which are

called plies, of canvas duck impregnated with rubber which

is later vulcanized.

According to the Goodrich Company, the permissible net

belt pull is 13.75 lb/ply per inch of width, which gives a simple

means for quick estimation.

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

Additional Elements (Terms)

36/38

Flat belt drives for nonparallel shafts

Law of belting: The approaching side must approach the

pulley in a direction perpendicular to the pulleys axis.

If two intersecting shafts are to be belt connected, two (2)

guide pulleys must be used, one on the approaching side

and one on the receding side of the belt.

Two shafts at right angles to each other may be connected

by the quarter turn arrangement.

This drive satisfies the law of belting for only one direction

of rotation. If rotation is to be reversed, a guide pulley

may be located to direct the belt properly.

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

Sample Problems

37/38

1. An open belt drive connects a 450 mm driving pulley to

another driven pulley 1000 mm in diameter. The belt is 300

mm wide and 10 mm thick. The coefficient of friction of the

belt drive is 2.8 kg/m of the belt length. The center distance

between shafts is 4 m. The maximum allowable tensile stress

on the belt is 1500 kPa and the speed of driving pulley is 900

rpm.

a.

b.

c.

d.

Determine the density of the belt. (Ans. 0.0337 lb/in3)

Find the angle of contact of the driver and driven pulley

Calculate the arc of contact of both pulleys.

What is the power transmitted in hp and kW? (Ans. 54.7

hp)

e. What are the loads on tight side and slack side?

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

Sample Problems

38/38

2. An electric motor running at 1200 rpm drives a punch press shaft

at 200 rpm by means of a 130 mm wide and 8 mm thick belt.

When the clutch is engaged, the belt slips. To correct this

condition, an idler pulley was installed to increase the angle of

contact but the same belt and pulley were used. The original

contact angle of the 200 mm motor pulley is 160. The original

tension ratio is 2.4 and the net tension is 12 N/mm of the belt

width. An increase in transmission capacity of 20% will prevent

slippage.

a.

b.

c.

d.

Determine the coefficient of friction. (Ans. 0.314)

Determine the net belt tension and the torque transmitted.

Calculate the forces on the tight side and slack side.

Determine the transmitted torque if an increase in transmission

capacity of 20% to prevent slippage.

e. What are the expected new load on the slack side, new

angle of contact, and total load after the increase in

transmission capacity?

513/511 Machine

Design 2

Materials Behavior MeasurementMEMD

& Evaluation

Laboratory

Das könnte Ihnen auch gefallen

- Model 255 Aerosol Generator (Metone)Dokument20 SeitenModel 255 Aerosol Generator (Metone)Ali RizviNoch keine Bewertungen

- Me 313b Fluid Machineries Module Week 10 13 PDF FreeDokument60 SeitenMe 313b Fluid Machineries Module Week 10 13 PDF FreeChris TopherNoch keine Bewertungen

- Me152l - Experiment 5 - AmahmudDokument23 SeitenMe152l - Experiment 5 - AmahmudAli Requiso MahmudNoch keine Bewertungen

- Exp 6Dokument21 SeitenExp 6goblinsbrideNoch keine Bewertungen

- Module 3 Gears - ClassificationDokument19 SeitenModule 3 Gears - ClassificationBilly JhunNoch keine Bewertungen

- BDC 4013 Assignment 2 Sem I 1011Dokument1 SeiteBDC 4013 Assignment 2 Sem I 1011Bahynorerama Dp0% (1)

- Exercises Problem On Spur Gear Nomenclatures: Module 2: Activity No. 2Dokument4 SeitenExercises Problem On Spur Gear Nomenclatures: Module 2: Activity No. 2Leyzer MalumayNoch keine Bewertungen

- Forearm Power Generator MachineDokument5 SeitenForearm Power Generator MachineKamesh Rìó100% (2)

- McDes1 Review Sample Problems Shaft Keys CouplingsDokument20 SeitenMcDes1 Review Sample Problems Shaft Keys CouplingsAngeloTomalonNoch keine Bewertungen

- Dot 1Dokument5 SeitenDot 1Thomas Nathaniel AngNoch keine Bewertungen

- Experiment No. 5 - Measurement of SpeedDokument8 SeitenExperiment No. 5 - Measurement of SpeedNiño Gerard JabagatNoch keine Bewertungen

- Module 6 Reciprocating COMPRESSORDokument30 SeitenModule 6 Reciprocating COMPRESSORSylvesterNoch keine Bewertungen

- Front Page and Expirement Number 1Dokument3 SeitenFront Page and Expirement Number 1Ron Kristian OpolintoNoch keine Bewertungen

- Design Procedure For Flat BeltDokument2 SeitenDesign Procedure For Flat BeltKutty AravindNoch keine Bewertungen

- Fans and BlowersDokument2 SeitenFans and BlowersNeil RubsNoch keine Bewertungen

- Powerplant and Industrial Plant Engineering Trial 1: 1 PointsDokument8 SeitenPowerplant and Industrial Plant Engineering Trial 1: 1 PointsJerdNoch keine Bewertungen

- Module 1 - Activity No. 1 (Prelim)Dokument2 SeitenModule 1 - Activity No. 1 (Prelim)Leyzer MalumayNoch keine Bewertungen

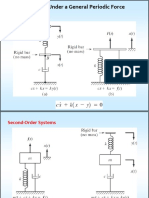

- Review Questions : G(S) C(S)Dokument7 SeitenReview Questions : G(S) C(S)Angel CallejebrioNoch keine Bewertungen

- Belt Drives Practice ProblemsDokument1 SeiteBelt Drives Practice ProblemsEdelene Balitaosan100% (1)

- Me2352 DTS PDFDokument114 SeitenMe2352 DTS PDFSathrudhan ChoudharyNoch keine Bewertungen

- Uniform Mechanical Code - 2009 Chapter 1Dokument10 SeitenUniform Mechanical Code - 2009 Chapter 1memosplumbingNoch keine Bewertungen

- Machine Design Test 4 - StressesDokument8 SeitenMachine Design Test 4 - Stressessylvanaz01Noch keine Bewertungen

- Arcilla, Zoren - Me Lab1 - Exp4 - M4act5Dokument12 SeitenArcilla, Zoren - Me Lab1 - Exp4 - M4act5dracarysNoch keine Bewertungen

- Engineering Management: Oliver N. OliverosDokument14 SeitenEngineering Management: Oliver N. OliverosJ. Robert TanNoch keine Bewertungen

- Problems in Keys and CouplingsDokument4 SeitenProblems in Keys and CouplingsDaryl CalderonNoch keine Bewertungen

- Me152l - Experiment 6 - AmahmudDokument25 SeitenMe152l - Experiment 6 - AmahmudAli Requiso MahmudNoch keine Bewertungen

- Anto ME463 Plate No. 3Dokument18 SeitenAnto ME463 Plate No. 3Eman Lampago AntoNoch keine Bewertungen

- SOLUTIONDokument11 SeitenSOLUTIONKim Howard CastilloNoch keine Bewertungen

- Air Changes Per HourDokument4 SeitenAir Changes Per HourDIPAK S100% (1)

- Question Number 1Dokument82 SeitenQuestion Number 1Ryan Llona FernandezNoch keine Bewertungen

- Example 1: Solution 740 MM of HGDokument3 SeitenExample 1: Solution 740 MM of HGBadresh JellaNoch keine Bewertungen

- Acquired Books Prof ENGG. 2012 2016 RevDokument27 SeitenAcquired Books Prof ENGG. 2012 2016 RevFrei Magsino100% (1)

- MAGATDokument1 SeiteMAGATReden LopezNoch keine Bewertungen

- Quiz No. 4Dokument1 SeiteQuiz No. 4Remae GarciNoch keine Bewertungen

- Section 16Dokument97 SeitenSection 16Carolina FerrerNoch keine Bewertungen

- CE5620 Intro 2016 8Dokument67 SeitenCE5620 Intro 2016 8Phanendra Kumar AttadaNoch keine Bewertungen

- Introduction To PumpsDokument33 SeitenIntroduction To PumpsArgie CayabyabNoch keine Bewertungen

- Statement of The The Problem Mapua University Building ComplexDokument3 SeitenStatement of The The Problem Mapua University Building ComplexJoshua Phillip Austero FederisNoch keine Bewertungen

- Section 16 PDFDokument97 SeitenSection 16 PDFherrerafaridNoch keine Bewertungen

- Refrigeration-Systems Part 1Dokument11 SeitenRefrigeration-Systems Part 1Sean GuanzonNoch keine Bewertungen

- Ass No. 3Dokument2 SeitenAss No. 3Ako C. IvanNoch keine Bewertungen

- 3 Diesel PerformanceDokument10 Seiten3 Diesel PerformanceyanyanNoch keine Bewertungen

- A Keyed Sprocket Delivers A Torque of 778Dokument2 SeitenA Keyed Sprocket Delivers A Torque of 778arcelio emiyaNoch keine Bewertungen

- The Development of Pedal Powered Water Pump As An Alternative For Crop Gasoline Powered Water PumpDokument3 SeitenThe Development of Pedal Powered Water Pump As An Alternative For Crop Gasoline Powered Water PumpPerez Keith Jeswel N.Noch keine Bewertungen

- Chapter 1Dokument8 SeitenChapter 1Von A. Damirez0% (1)

- MD2 Brakes 3Dokument16 SeitenMD2 Brakes 3Chrstn VllmrNoch keine Bewertungen

- Be Paper 1Dokument852 SeitenBe Paper 1Vishal Gaurav100% (2)

- Ilovepdf Merged PDFDokument77 SeitenIlovepdf Merged PDFadrian paul relayosaNoch keine Bewertungen

- Machine ElementsDokument4 SeitenMachine Elementsdonjon019Noch keine Bewertungen

- Machine Elements: Cams: Group 7 Charlie Dionisio R - Jhun Lemos Jerphoenix Mullaneda Arsilio SilverioDokument21 SeitenMachine Elements: Cams: Group 7 Charlie Dionisio R - Jhun Lemos Jerphoenix Mullaneda Arsilio SilverioDeniell Joyce MarquezNoch keine Bewertungen

- Diesel Power Plant With Tons of IceDokument124 SeitenDiesel Power Plant With Tons of IceMycky VillanuevaNoch keine Bewertungen

- Fluid Machinery 1Dokument30 SeitenFluid Machinery 1Shashi Bhushan Kumar0% (1)

- Keys Coupling With SampleDokument9 SeitenKeys Coupling With SampleGen ReyesNoch keine Bewertungen

- Compressor - Problem SolvingDokument11 SeitenCompressor - Problem SolvingLorenz Banada0% (1)

- 3 Belts&BeltingDokument23 Seiten3 Belts&BeltingRonald Vega SolisNoch keine Bewertungen

- Belt DesignDokument56 SeitenBelt DesignJade Jazzrel Maglente Aclaro0% (1)

- Ijresm V4 I7 100Dokument9 SeitenIjresm V4 I7 100saxadi4814Noch keine Bewertungen

- Belt Drive Chapter 2Dokument51 SeitenBelt Drive Chapter 2Raja SekarNoch keine Bewertungen

- Timing BeltsDokument6 SeitenTiming BeltsIrvan AdriansyahNoch keine Bewertungen

- DTS Two Marks Q&ADokument20 SeitenDTS Two Marks Q&AKesava Prasad100% (1)

- Teaching Profession - Educational PhilosophyDokument23 SeitenTeaching Profession - Educational PhilosophyRon louise PereyraNoch keine Bewertungen

- Government College of Nursing Jodhpur: Practice Teaching On-Probability Sampling TechniqueDokument11 SeitenGovernment College of Nursing Jodhpur: Practice Teaching On-Probability Sampling TechniquepriyankaNoch keine Bewertungen

- Journal of Biology EducationDokument13 SeitenJournal of Biology EducationFarah ArrumyNoch keine Bewertungen

- DLP - Light Science 7Dokument6 SeitenDLP - Light Science 7Samara M. SalacayanNoch keine Bewertungen

- Head Coverings BookDokument86 SeitenHead Coverings BookRichu RosarioNoch keine Bewertungen

- Kiritsis SolutionsDokument200 SeitenKiritsis SolutionsSagnik MisraNoch keine Bewertungen

- SOL LogicDokument21 SeitenSOL LogicJa RiveraNoch keine Bewertungen

- Gas Dynamics and Jet Propulsion 2marksDokument15 SeitenGas Dynamics and Jet Propulsion 2marksAbdul rahumanNoch keine Bewertungen

- Latched, Flip-Flops, and TimersDokument36 SeitenLatched, Flip-Flops, and TimersMuhammad Umair AslamNoch keine Bewertungen

- Apexi Powerfc Instruction ManualDokument15 SeitenApexi Powerfc Instruction ManualEminence Imports0% (2)

- Miniature Daisy: Crochet Pattern & InstructionsDokument8 SeitenMiniature Daisy: Crochet Pattern & Instructionscaitlyn g100% (1)

- Sveba Dahlen - SRP240Dokument16 SeitenSveba Dahlen - SRP240Paola MendozaNoch keine Bewertungen

- Where We Are in Place and Time "We Are Part of The Universe and Feel Compelled To Explore It."Dokument1 SeiteWhere We Are in Place and Time "We Are Part of The Universe and Feel Compelled To Explore It."Safia-umm Suhaim- FareedNoch keine Bewertungen

- Bom Details FormatDokument6 SeitenBom Details FormatPrince MittalNoch keine Bewertungen

- Apple Change ManagementDokument31 SeitenApple Change ManagementimuffysNoch keine Bewertungen

- Pg2022 ResultDokument86 SeitenPg2022 ResultkapilNoch keine Bewertungen

- W25509 PDF EngDokument11 SeitenW25509 PDF EngNidhi SinghNoch keine Bewertungen

- Sample - SOFTWARE REQUIREMENT SPECIFICATIONDokument20 SeitenSample - SOFTWARE REQUIREMENT SPECIFICATIONMandula AbeyrathnaNoch keine Bewertungen

- Systems Analysis and Design in A Changing World, Fourth EditionDokument41 SeitenSystems Analysis and Design in A Changing World, Fourth EditionKoko Dwika PutraNoch keine Bewertungen

- Cooperative Learning: Complied By: ANGELICA T. ORDINEZADokument16 SeitenCooperative Learning: Complied By: ANGELICA T. ORDINEZAAlexis Kaye GullaNoch keine Bewertungen

- How To Block HTTP DDoS Attack With Cisco ASA FirewallDokument4 SeitenHow To Block HTTP DDoS Attack With Cisco ASA Firewallabdel taibNoch keine Bewertungen

- PMP Assesment TestDokument17 SeitenPMP Assesment Testwilliam collinsNoch keine Bewertungen

- PDF Chapter 5 The Expenditure Cycle Part I Summary - CompressDokument5 SeitenPDF Chapter 5 The Expenditure Cycle Part I Summary - CompressCassiopeia Cashmere GodheidNoch keine Bewertungen

- Progressive Muscle RelaxationDokument4 SeitenProgressive Muscle RelaxationEstéphany Rodrigues ZanonatoNoch keine Bewertungen

- QSP 04bDokument35 SeitenQSP 04bakrastogi94843Noch keine Bewertungen

- Standard Answers For The MSC ProgrammeDokument17 SeitenStandard Answers For The MSC ProgrammeTiwiNoch keine Bewertungen

- Case CapsuleDokument8 SeitenCase CapsuleLiza BulsaraNoch keine Bewertungen

- Microsmart GEODTU Eng 7Dokument335 SeitenMicrosmart GEODTU Eng 7Jim JonesjrNoch keine Bewertungen

- Heimbach - Keeping Formingfabrics CleanDokument4 SeitenHeimbach - Keeping Formingfabrics CleanTunç TürkNoch keine Bewertungen