Beruflich Dokumente

Kultur Dokumente

Template de Métricas para Qualidade

Hochgeladen von

eupasseiCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Template de Métricas para Qualidade

Hochgeladen von

eupasseiCopyright:

Verfügbare Formate

PROJECT QUALITY METRICS TEMPLATE

This Project Quality Metrics Template is free for you to copy and use on your project

and within your organization. We hope that you find this template useful and

welcome your comments. Public distribution of this document is only permitted

from the Project Management Docs official website at:

www.ProjectManagementDocs.com

QUALITY METRICS

<PROJECT NAME>

COMPANY NAME

STREET ADDRESS

CITY, STATE ZIP CODE

DATE

Quality Metrics Template

www.ProjectManagementDocs.com

TABLE OF CONTENTS

INTRODUCTION.................................................................................................................................2

METRICS...........................................................................................................................................2

METRICS MEASUREMENT AND DATA COLLECTION.........................................................................4

QUALITY MANAGEMENT REVIEW....................................................................................................4

Quality Metrics Template

www.ProjectManagementDocs.com

INTRODUCTION

Quality metrics are a key component of an effective quality management plan and are the

measurements used in ensuring customers receive acceptable products or deliverables. Quality

metrics are used to directly translate customer needs into acceptable performance measures in

both products and processes. Project managers must be able to assess the progress, efficiency,

and performance of their projects and metrics are the means which allow project managers to do

this. However, it is important to note that metrics must be established in an effort to directly

improve the product or processes involved in the project. They must be attributable to an

established goal, threshold, or customer requirement or else they provide no value.

ABC Corporation has approved the Beta Tool project which requires the design, building, testing

of the Beta Tool to be used with Argo Tooling Companys proprietary fastening device CamBolt.

In accordance with the Beta Tool Quality Management Plan, ABC Corp. will use various metrics

in order to ensure efficient processes are established and that the product meets the customer

requirements for delivery. All metrics have been reviewed and approved by internal executive

leadership and project sponsor as well as the customer, Argo Tooling Co.

METRICS

This section should list the metrics chosen for this project and a description of each. These

descriptions should include an explanation of how the metric applies to the quality of the product

or process it is being used to measure. Additionally, any thresholds or limits should be clearly

stated in this section. Metrics should always be clear, measurable, controllable, and reportable.

Based on customer product requirements, internal process standards, and applicable industry

standards, the following metrics have been established for the Beta Tool Project. These metrics

have been reviewed and approved internally and with the customer, Argo Tooling Co.:

a. Tensile Strength: The Beta Tool will be used in various industrial environments

under high material stress loads. Based on anticipated customer usage and industry

tooling standards, it has been determined that the tensile strength of the Beta Tool

must meet or exceed 500 mega-pascals (MPa). Tensile strength will be measured for

each prototype of ABC Corp.s tensile bench. The results will be verified by ABC

Corp.s Material Testing Manager and presented to stakeholders in the monthly Beta

Tool Quality Management Review.

b. Shear Strength: The Beta Tool will be subject to potentially high stress torque loads

in various applications. Based on anticipated customer usage and industry tooling

standards, it has been determined that the shear strength of the Beta Tool must meet

or exceed 375 MPa. Shear strength will be measured for each prototype on ABC

Corp.s shear stress bench. The results will be verified by ABC Corp.s Material

Testing Manager and presented to stakeholders in the monthly Beta Tool Quality

Management Review.

c. Customer Satisfaction: The Beta Tool is being developed for usage by Argo Tooling

Co. technicians. Each prototype will be tested by a panel of Argo technicians on

Quality Metrics Template

www.ProjectManagementDocs.com

various criteria. Argo technicians will be asked to rate the Beta Tool on a scale of 1 to

10 for each criteria. The scores will then be calculated to determine a total average

score. Customer satisfaction much be greater than or equal to 8 out of 10 for each

criteria with no individual score lower than a 7. ABC Corp. will then solicit feedback

from Argo technicians on areas for improvement.

1) Customer Satisfaction Criteria: Comfort, Ergonomic Functionality, Adjustability,

Aesthetics, Size, Dexterity

d. Material Scrap: In order to minimize costs and reduce waste, ABC Corp. has

internally established metrics for measuring and controlling material scrap for its tool

manufacturing efforts. The Beta Tool Project will be subject to internal guidelines

regarding material scrap. The Beta Tool manufacturing process must result in

material waste below 1% of the total material used in the manufacturing of one tool.

Waste is defined as material that cannot be re-used or re-allocated for another

purpose. Waste will be calculated for each prototype. No manufacturing process will

be approved unless it yields less than 1% of waste material per unit manufactured.

Only once this has been achieved will the process be approved for operations.

e. Product Defect Rate: In order to minimize costs, reduce waste, and achieve

consistent quality, ABC Corp. has internally established metrics for measuring and

controlling product defects. The Beta Tool Project will be subject to internal

guidelines regarding product defects. The approved manufacturing process must be

repeatable, produce a Beta Tool product which meets previous quality metrics, and

incurs a defect rate less than one item per every five hundred. Product defects result

in wasted costs for manufacturing personnel and equipment, material waste, and rework. In order to minimize the impact of these costs all Beta Tools will be measured

against approved specifications and metrics. Each tool must conform to the metrics

herein while also meeting product specifications within the allowable tolerances

contained in the project scope.

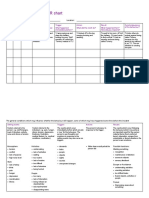

Metric

Tensile Strength

Standard

500 MPa

Frequency

Per prototype

Shear Strength

Customer

Satisfaction

375 MPa

8/10 or higher with

no individual score

below 7

< 1% based on total

material used per

tool

< 1 out of 500

Per prototype

Per prototype

Report

Monthly Quality

Management

Review (QMR)

Monthly QMR

Monthly QMR

Per prototype

Monthly QMR

Per production of

500 tools

As achieved

Material Waste

Product Defect Rate

Quality Metrics Template

www.ProjectManagementDocs.com

METRICS MEASUREMENT AND DATA COLLECTION

This section should describe in detail how metrics measurements will be taken and what will be

done with the data. These measurements are key to the success of the product and project and

there must be clear documentation on how the data will be used.

As each Beta Tool prototype is completed the projects quality manager will measure the tool

against the customer specifications contained in the project scope. These specifications pertain

to the specific dimensions of the tool and its total weight. The quality manager will ensure that

the prototype falls within the allowable specification tolerances and document the findings on the

quality inspection form contained in the Project Quality Management Plan. Additionally, the

manufacturing line manager and Project Manager will calculate material waste by determining

the percentage of waste as compared to the total amount of material used for the tool. The

Project Manager will document these findings and consolidate them to present at the Quality

Management Review.

Once the tool is determined to meet the customer specifications, it will be submitted to the Argo

Technical Manager where Argo technicians will test the tool for 2 days. Upon completion of

testing the Argo Technical Manager will return the tool to the ABC Project Manager along with

the completed customer satisfaction forms contained in the Project Quality Management Plan.

Once the tool is determined to meet customer satisfaction requirements the Project Manager will

submit the tool to the Materials Testing Manager where it will undergo tensile and shear strength

tests in the Material Lab. The Materials Testing Manager and Project Manager will verify and

document all findings and consolidate the data for presentation at the Quality Management

Review.

Once all measurements are completed for each prototype, the Project Manager, Quality Manager,

and Project Team will meet to review and compile data and develop their recommendations

based on the findings. If any of the metrics have not been satisfied, the Project Manager will

include recommendations for correcting the metric in the Quality Management Review. This

may be a small change to a process parameter or consist of a larger scale process or product

quality improvement initiative.

QUALITY MANAGEMENT REVIEW

This section includes a description of what will be included in the Quality Management Review

as well as the frequency of the meetings and who will participate. Some of this information may

also be included in the Quality and Communications Management Plans.

The Beta Tool Quality Management Reviews (QMRs)will be scheduled on a monthly basis

throughout the project lifecycle. The Project Manager is responsible for scheduling the meetings

and ensuring a room is reserved as well as all necessary audio/visual support. The Project

Manager is also responsible for ensuring all required attendees are notified in advance of the

meeting.

Quality Metrics Template

www.ProjectManagementDocs.com

Required attendees include the Beta Tool Project Team, ABC Corp. Materials Testing Manager,

ABC Corp. Quality Manager, Beta Tool Project Sponsor, ABC Corp. Manufacturing Manager,

Argo Co. Technical Manager, and Argo Co. Customer Representative. Other stakeholders may

be invited at the Project Managers discretion.

The QMR will consist of a presentation of all metrics and specifications measurements and a

comparison to previous prototype iterations to show progress. Cumulative data will also be

presented to provide a status of process and product repeatability. For any metrics which did not

meet the established standards, the Project Manager will present recommended course(s) of

action to correct the fault(s). The Project Sponsor is the approving authority for implementation

of any recommended course of action or corrective measures.

Based on the QMR results and corrective measures, the Project Manager is responsible for

updating all project documentation, submitting any changes through the change control process,

and communicating changes to all stakeholders.

This free Project Quality Metrics Template is brought to you by www.ProjectManagementDocs.com

Das könnte Ihnen auch gefallen

- Chapter Um Part 1: BasicsDokument35 SeitenChapter Um Part 1: BasicseupasseiNoch keine Bewertungen

- Tabela de Integrais Das Funções de BesselDokument422 SeitenTabela de Integrais Das Funções de BesseleupasseiNoch keine Bewertungen

- ACECT System Specification: 1. Working EnvironmentDokument2 SeitenACECT System Specification: 1. Working EnvironmenteupasseiNoch keine Bewertungen

- Measurements SystemDokument22 SeitenMeasurements SystemM Rizal Dwi F0% (3)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Mainframes ComputerDokument4 SeitenMainframes ComputerSarita SapaligaNoch keine Bewertungen

- Behaviour Recording Star Chart 1Dokument5 SeitenBehaviour Recording Star Chart 1api-629413258Noch keine Bewertungen

- MPCE 15 InternshipDokument56 SeitenMPCE 15 InternshipRaghavNoch keine Bewertungen

- Dorothy Joy Nadela-Activity 2Dokument2 SeitenDorothy Joy Nadela-Activity 2DOROTHY JOY NADELANoch keine Bewertungen

- Operating System Assignment No-1 Due Date 10 November 2018Dokument6 SeitenOperating System Assignment No-1 Due Date 10 November 2018Umair Shabbir100% (1)

- Music Min Workshop PDFDokument15 SeitenMusic Min Workshop PDFKent Cena RamosNoch keine Bewertungen

- Parenting A Teen Girl: A Crash Course On Conflict, Communication & Connection With Your Teenage DaughterDokument11 SeitenParenting A Teen Girl: A Crash Course On Conflict, Communication & Connection With Your Teenage DaughterNew Harbinger Publications100% (6)

- Chapter 3Dokument3 SeitenChapter 3Ronie Monie50% (2)

- CBSE Class 6 Mathematics Sample Paper Set G - 0Dokument3 SeitenCBSE Class 6 Mathematics Sample Paper Set G - 0ik62299Noch keine Bewertungen

- PhiloDokument4 SeitenPhiloJewil MeighNoch keine Bewertungen

- Solutions Manual For Power System Analysis and Design 5th Edition by Glover PDFDokument15 SeitenSolutions Manual For Power System Analysis and Design 5th Edition by Glover PDFFrederick Cas50% (2)

- Saveetha EngineeringDokument3 SeitenSaveetha Engineeringshanjuneo17Noch keine Bewertungen

- Imeche Guidance Ieng Ceng V 14 MB WRDokument26 SeitenImeche Guidance Ieng Ceng V 14 MB WRRajiv ThambotheranNoch keine Bewertungen

- Reconfigurable Diffractive Antenna Based On Switchable Electrically Induced TransparencyDokument12 SeitenReconfigurable Diffractive Antenna Based On Switchable Electrically Induced TransparencyAnuj SharmaNoch keine Bewertungen

- IEEE 22-Oct - CLE - PlatformDokument10 SeitenIEEE 22-Oct - CLE - Platformhero2006machNoch keine Bewertungen

- 5 e Model Science Lesson Plan TemplateDokument4 Seiten5 e Model Science Lesson Plan TemplateMaestro UseroNoch keine Bewertungen

- The Role of Autonomy Support and Autonomy Orientation in Prosocial Behavior EngagementDokument25 SeitenThe Role of Autonomy Support and Autonomy Orientation in Prosocial Behavior EngagementtrandavescuNoch keine Bewertungen

- Perdev W1 W2 Q2 Summative AssessmentDokument6 SeitenPerdev W1 W2 Q2 Summative AssessmentVERDADERO LevisthoneNoch keine Bewertungen

- PlummerDokument321 SeitenPlummerEnzo100% (3)

- Unit 1 Worksheet 1: Have You Been ?Dokument4 SeitenUnit 1 Worksheet 1: Have You Been ?Alberto SiriNoch keine Bewertungen

- Unit - VDokument75 SeitenUnit - Vgokul100% (1)

- Perrotta Et Al 2022 - Consulation For The 2023 GEM Report On Technology and EducationDokument17 SeitenPerrotta Et Al 2022 - Consulation For The 2023 GEM Report On Technology and EducationT AlencastroNoch keine Bewertungen

- Assesing Learning Thriugh Passion and Compassion Thru DepED Order 31 2020Dokument70 SeitenAssesing Learning Thriugh Passion and Compassion Thru DepED Order 31 2020myline estebanNoch keine Bewertungen

- New Revise Docs of JujuDokument62 SeitenNew Revise Docs of JujuJona MempinNoch keine Bewertungen

- Katia Sachoute Ead 533 Benchmark - Clinical Field Experience D Leading Leaders in Giving Peer Feedback Related To Teacher PerformanceDokument6 SeitenKatia Sachoute Ead 533 Benchmark - Clinical Field Experience D Leading Leaders in Giving Peer Feedback Related To Teacher Performanceapi-639561119Noch keine Bewertungen

- Dissertation Topics in Curriculum and InstructionDokument7 SeitenDissertation Topics in Curriculum and InstructionCustomThesisPapersSingapore100% (1)

- Choose ONE Answer For Each Question by Highlighting It in YELLOWDokument5 SeitenChoose ONE Answer For Each Question by Highlighting It in YELLOWKhánh NgọcNoch keine Bewertungen

- Dokumen Penjajaran Kurikulum Bahasa Inggeris Tingkatan 2 KSSMDokument7 SeitenDokumen Penjajaran Kurikulum Bahasa Inggeris Tingkatan 2 KSSMQhairunisa HinsanNoch keine Bewertungen

- Prof. Ed 2: June Rebangcos Rañola, LPT InstructorDokument25 SeitenProf. Ed 2: June Rebangcos Rañola, LPT InstructorJune RanolaNoch keine Bewertungen

- MicrobesDokument30 SeitenMicrobesVina Rose AlomeaNoch keine Bewertungen