Beruflich Dokumente

Kultur Dokumente

Lesson 10 - 5

Hochgeladen von

crysCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lesson 10 - 5

Hochgeladen von

crysCopyright:

Verfügbare Formate

Lesson 10 - Reliability of Welding Filler Metals

1 dari 1

Lesson 1

The Basics of Arc

Welding

LESSON X

Lesson 2

Common Electric

Arc Welding

Processes

Lesson 3

Covered Electrodes

for Welding

Mild Steels

Lesson 4

Covered Electrodes

for Welding Low

Alloy Steels

Lesson 5

Welding Filler Metals

for Stainless Steels

http://www.esabna.com/euweb/AWTC/Lesson10_7.htm

Section I.

Power Boilers

Section II.

Material Specifications

Section III.

Nuclear Vessels

Section IV.

Low Pressure Boilers

Section VIII. Unfired Pressure Boilers

10.5.0.1

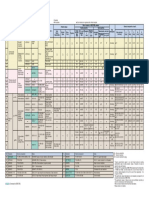

Section II of the code, in which welding filler metals are specified, states that the

ASME has adopted the AWS Filler Metal Specifications verbatim (word for word). However, they do have their own specification designation. For example, AMSE SFA 5.5-96

Go To Test

Print

Specification for Low Alloy Steel Covered Arc Welding Electrodes is the same as AWS

A5.5-96.

10.5.0.2

Under Section III of the code, the ASME issues a Quality System Certificate to

Glossary

manufacturers of materials (including welding electrodes and wire) to be used under the

code. This certificate is issued only after an ASME plant audit and the manufacturers

entire quality assurance program is approved. Its issuance allows the manufacturers

products to be used in boiler and pressure vessel work, as well as on nuclear applications

as specified in the code. Details of the Quality System Certificate will be covered under the

Quality Assurance Section of this lesson.

Lesson 6

Carbon & Low Alloy

Steel Filler Metals GMAW,GTAW,SAW

Current

Chapter

Table of

Contents

10.6

10.6.1

Turn Pages

SHIP CLASSIFICATION SOCIETIES

The American Bureau of Shipping (ABS) - The ABS is a non-profit, interna-

tional ship classification society. It certifies the structural integrity and mechanical fitness of

Lesson 7

Flux Cored Arc

Electrodes Carbon

Low Alloy Steels

merchant ships, offshore drilling rigs, and other marine structures.

10.6.1.1

Annually, the Bureau publishes a listing entitled Approved Welding Electrodes,

Wire-Flux and Wire-Gas Combinations. The approvals of the filler metals are based upon

tests conducted to standards established by the Bureau or by other recognized agencies.

Lesson 8

Hardsurfacing

Electrodes

As requested by the manufacturer, filler metals may be approved to an AWS Filler Metal

Specification, and so listed, or approved to an ABS Grade as shown in Figure 1. In either

Search

Chapter

(Faster

Download)

Search

Document

(Slower

Download)

case, the approval testing must be made in the manufacturers facility in the presence of an

ABS representative. The extent of testing will vary, depending on the type of weld for which

Lesson 9

Estimating &

Comparing Weld

Metal Costs

the product is being qualified (fillet or butt), whether the filler material is being initially tested

as a new product, being tested annually, or whether the product is being upgraded at the

manufacturers request.

10.6.1.2

Lesson 10

Reliability of Welding

Filler Metals

At the time of annual testing, the manufacturing facilities and quality control

procedures are subject to inspection also.

COPYRIGHT 2000 THE ESAB GROUP, INC.

09/12/2013 14:32

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Installation of Stop Contact, Cable Tray and Panel Location on Level 3 & 5Dokument1 SeiteInstallation of Stop Contact, Cable Tray and Panel Location on Level 3 & 5crysNoch keine Bewertungen

- Pt. Intan Anugrah PersadaDokument1 SeitePt. Intan Anugrah PersadacrysNoch keine Bewertungen

- Pt. Intan Anugrah PersadaDokument1 SeitePt. Intan Anugrah PersadacrysNoch keine Bewertungen

- Sound system installation plans for Treepark City CikokolDokument1 SeiteSound system installation plans for Treepark City CikokolcrysNoch keine Bewertungen

- 328 PDFDokument1 Seite328 PDFcrysNoch keine Bewertungen

- Vac 110 PDFDokument1 SeiteVac 110 PDFcrysNoch keine Bewertungen

- Cipta Sukses, PT.: Pt. Intan Anugrah PersadaDokument1 SeiteCipta Sukses, PT.: Pt. Intan Anugrah PersadacrysNoch keine Bewertungen

- Pt. Intan Anugrah Persada: Void VoidDokument1 SeitePt. Intan Anugrah Persada: Void VoidcrysNoch keine Bewertungen

- Vac 112 PDFDokument1 SeiteVac 112 PDFcrysNoch keine Bewertungen

- Pt. Intan Anugrah PersadaDokument1 SeitePt. Intan Anugrah PersadacrysNoch keine Bewertungen

- Vac 105 PDFDokument1 SeiteVac 105 PDFcrysNoch keine Bewertungen

- Clarification 17Dokument1 SeiteClarification 17crysNoch keine Bewertungen

- Vac 113 PDFDokument1 SeiteVac 113 PDFcrysNoch keine Bewertungen

- Sdb-Atap Tower A Db-Fire Atap Tower A Pp-Lift.2A Pp-Lift.1A: Pt. Intan Anugrah PersadaDokument1 SeiteSdb-Atap Tower A Db-Fire Atap Tower A Pp-Lift.2A Pp-Lift.1A: Pt. Intan Anugrah PersadacrysNoch keine Bewertungen

- Summary Progress & Status Piping Work-Cut of Date 16 Des 2017Dokument16 SeitenSummary Progress & Status Piping Work-Cut of Date 16 Des 2017crysNoch keine Bewertungen

- Assembling Flanged Joints Procedure1 PDFDokument34 SeitenAssembling Flanged Joints Procedure1 PDFcrysNoch keine Bewertungen

- Lift Dan Gondola 06-11-2015Dokument8 SeitenLift Dan Gondola 06-11-2015crysNoch keine Bewertungen

- PASCAL Check Valves CatalogueDokument19 SeitenPASCAL Check Valves Cataloguecrys100% (1)

- Asme31 3Dokument1 SeiteAsme31 3crysNoch keine Bewertungen

- Indonesia LNGDokument22 SeitenIndonesia LNGcrys100% (1)

- Spec PDFDokument1 SeiteSpec PDFcrysNoch keine Bewertungen

- CV FreasmanDokument2 SeitenCV FreasmancrysNoch keine Bewertungen

- RFCC-T-PJ-GS-0900 Project Quality Plan (B) PDFDokument23 SeitenRFCC-T-PJ-GS-0900 Project Quality Plan (B) PDFcrysNoch keine Bewertungen

- RFCC T PJ GS 0900 Project Quality Plan (B)Dokument44 SeitenRFCC T PJ GS 0900 Project Quality Plan (B)crysNoch keine Bewertungen

- 72957d3bb1659d7c77dbf6b6c550abeeDokument41 Seiten72957d3bb1659d7c77dbf6b6c550abeerasheedillikkalNoch keine Bewertungen

- PT Alphacon's Single V Butt Joint WPSDokument20 SeitenPT Alphacon's Single V Butt Joint WPScrys0% (1)

- GENERATOR SET CSTS INSTALLATION STATUS AND PROGRESS REPORTDokument1 SeiteGENERATOR SET CSTS INSTALLATION STATUS AND PROGRESS REPORTcrysNoch keine Bewertungen

- Aluminium Valve FinalDokument5 SeitenAluminium Valve FinalcrysNoch keine Bewertungen

- ITP Installation of Boiler - R1Dokument14 SeitenITP Installation of Boiler - R1crys100% (4)

- Spark Arrestor Safety GuideDokument6 SeitenSpark Arrestor Safety GuidecrysNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Thrust Block Calculator - 201708230926201609Dokument1 SeiteThrust Block Calculator - 201708230926201609Ramachandra SahuNoch keine Bewertungen

- Fuel Pump With Brushless Motor For High Vibration ApplicationsDokument4 SeitenFuel Pump With Brushless Motor For High Vibration Applicationsddi11100% (1)

- How Works: Drain-Waste-Vent SystemsDokument2 SeitenHow Works: Drain-Waste-Vent SystemsRadu GenescuNoch keine Bewertungen

- Scania CatalougeDokument4 SeitenScania CatalougeMohamadr KmlNoch keine Bewertungen

- WEISS Produktkatalog en WebDokument220 SeitenWEISS Produktkatalog en WebBurak KoyuncuogluNoch keine Bewertungen

- Field Assembly HD787!7!7001 UpDokument200 SeitenField Assembly HD787!7!7001 Upjosecall100% (1)

- Rope TorqueDokument4 SeitenRope TorqueMarcus AlvarezNoch keine Bewertungen

- McMillan CHPT 1Dokument110 SeitenMcMillan CHPT 1CharleneKronstedt100% (1)

- ME 185/287 Intro Continuum MechanicsDokument2 SeitenME 185/287 Intro Continuum MechanicskakiNoch keine Bewertungen

- Statical Calculation of 50m TowerDokument25 SeitenStatical Calculation of 50m TowerAntenasmNoch keine Bewertungen

- MR 307 Laguna 2Dokument86 SeitenMR 307 Laguna 2Johne DoeeNoch keine Bewertungen

- Cat4100 o LokDokument76 SeitenCat4100 o LokavonegNoch keine Bewertungen

- Statement:: PROBLEM 2-11Dokument1 SeiteStatement:: PROBLEM 2-11GUSTAVO VINICIUS VIEIRA MELLONoch keine Bewertungen

- Introduction To Quantum Physics NotesDokument9 SeitenIntroduction To Quantum Physics NotesViraj BukitagarNoch keine Bewertungen

- Calculate IDMT Over Current Relay Setting (50 - 51) - Electrical Notes & ArticlesDokument3 SeitenCalculate IDMT Over Current Relay Setting (50 - 51) - Electrical Notes & ArticlesSheraz KhanNoch keine Bewertungen

- 8.hydraulics of Tangential Vortex Intake For Urban DrainageDokument11 Seiten8.hydraulics of Tangential Vortex Intake For Urban Drainageローズ サンティアゴNoch keine Bewertungen

- Equation of State - WikipediaDokument78 SeitenEquation of State - WikipediaPrecious OluwadahunsiNoch keine Bewertungen

- Labrie Optimizer Maintenance Manual PDFDokument81 SeitenLabrie Optimizer Maintenance Manual PDFstainless31620039126100% (1)

- P01-E12 Rev 1 Sep 2015 Dynamic Effects On Piping SystemsDokument11 SeitenP01-E12 Rev 1 Sep 2015 Dynamic Effects On Piping Systems234ahmedNoch keine Bewertungen

- 555 Audio Alarm ChartDokument4 Seiten555 Audio Alarm Chartnasty_beerNoch keine Bewertungen

- Effect of Temperature On Wind Forces On Tall Building Using Numerical Approach - Computational Fluid Dynamics (CFD)Dokument6 SeitenEffect of Temperature On Wind Forces On Tall Building Using Numerical Approach - Computational Fluid Dynamics (CFD)Jay KasodariyaNoch keine Bewertungen

- Bebin Mech TechnicianDokument3 SeitenBebin Mech TechnicianDIJUNoch keine Bewertungen

- Tutorial 3Dokument4 SeitenTutorial 3Ngudo Ewart NephaweNoch keine Bewertungen

- B.1.1 Spur Gears With Gearwheels-10Dokument34 SeitenB.1.1 Spur Gears With Gearwheels-10Ganapathy Subramaniam100% (1)

- Design of Pressed Steel Tank PDFDokument8 SeitenDesign of Pressed Steel Tank PDFEr Harsh Mahajan89% (19)

- MIG and TIG WeldingDokument2 SeitenMIG and TIG WeldingshahzafNoch keine Bewertungen

- Auxiliary climate control wiring diagrams for 2006.50 Transit vanDokument10 SeitenAuxiliary climate control wiring diagrams for 2006.50 Transit vanTuan TranNoch keine Bewertungen

- Air Compressor 1 PDFDokument48 SeitenAir Compressor 1 PDFDanielNoch keine Bewertungen

- Anchor Block DesignDokument3 SeitenAnchor Block Designrameshb308100% (1)

- 46-47RHE VacTestGuideDokument4 Seiten46-47RHE VacTestGuideMauricio Exequiel ChavezNoch keine Bewertungen