Beruflich Dokumente

Kultur Dokumente

Rope Access Inspection Guidebook

Hochgeladen von

Shaik MohamedCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Rope Access Inspection Guidebook

Hochgeladen von

Shaik MohamedCopyright:

Verfügbare Formate

ROPE ACCESS GENERIC WORK GUIDANCE

ROPE ACCESS

GENERIC WORK

GUIDANCE

In accordance with

International Industrial

Rope Access Trade Association

ICOP & ISO Standard 22846 1-2

ROPE ACCESS GENERIC WORK GUIDANCE

THIS PERSONAL WORKBOOK BELONGS TO

First name

Lastname

Address

City

Mobile

IRATA No

CHANGES TO ABOVE

Country

ROPE ACCESS GENERIC WORK GUIDANCE

SUMMARY

Page

1.0

Introduction 4

2.0

Scope 5

3.0

Anchor requirements / Rigging / Limitations 6

4.0

Anchor line management and hierarchy of measures 13

5.0

Rigging for rescue 16

6.0

Retrievable sytems 15

7.0

Hauling / Pulley systems 17

8.0

Protection of third parties and anchor area 18

9.0

On-site communication 19

10. Buddy check 19

11.

Close monitoring supervision 20

12.

Toolbox talk briefing 20

13.

Rescue plan 21

14.

Small tools 22

15.

De-briefing 22

16. Incident reporting 23

17.

Daily diary for L3 safety supervisor 24

18.

Logging of hours worked 25

19.

Suspension trauma 27

20.

Work pack documentation 28

21.

About risk assessment 29

22.

Annex I 30

23.

Annex II 31

24.

Notes

32

ROPE ACCESS GENERIC WORK GUIDANCE

1.0 INTRODUCTION

Dacon Inspection Services has developed this generic method statement in

accordance with IRATA and ISO guidelines.

Industrial rope access methods used at height and in confined space shall

guarantee the highest possible level of protection for the technicians whilst

working.

This statement is to be considered as part of an overall statement covering all

access methods applicable at a site, not including those not relating to working

at height.

This generic statement is valid for most of the works to be undertaken, however

it should be regularly reviewed and amended by safety supervisors on site.

Should conditions of procedures change due to specific site conditions

encountered during the course or the work, the site supervisor may prepare

specific statements to encompass these conditions.

ROPE ACCESS GENERIC WORK GUIDANCE

2.0 SCOPE AND REFERENCES

2.1 Scope

This generic method statement should provide general information to

technicians engaged in rope access operations, in accordance with

IRATA International Code of Practice and ISO 22846 requirements.

2.2 Out-of-scope:

This generic statement doesnt replace the specific method statement done

according to site and access specifications.

2.3 References:

ISO

22846-1

ISO Personal Equipment for Protection Against

Falls - Rope Access Systems

Part 1: Fundamental Principles for a System of Work

ISO

22846-2

Personal Equipment for Protection Against Falls

- Rope Access Systems

Part 2: Code of Practice

ISO

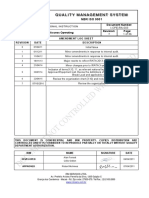

9001

Quality Management Systeme Standard

IRATA

ICOP

International Code of Practice

IRATA

TACS

Training, Assessment and Certification Scheme

ROPE ACCESS GENERIC WORK GUIDANCE

3.0 ANCHOR REQUIREMENTS / RIGGING / LIMITATIONS

3.1 Requirements

Statement:

Anchors should have a minimum breaking load

of 15kN and meet the EN 795-A requirements

EN 795-A

An unquestionable structural point should have

a minimum breaking strength of 2 x 15kN = 30kN

Eyebolts shall be torqued according to

manufacturers instructions

Testing (chemicals): Chemical anchors shall be pull tested at 5kN for

3 min with a calibrated device before first use,

and thereafter at regular intervals.

IRATA references:

ICOP 2.7.9, 2.11.2, 2.11.2.6,

Annex F / TACS 6.4.2, 7.7.25

ISO 22846-2 clauses: 7.7.3

3.2 Rigging of anchor lines

Statement:

Separate anchorages shall be used for working

and backup ropes

A minimum of 2 points of anchorage shall be used

to anchor both the working and the backup line

Each rope is fixed to both anchorages, via

basic anchor

bunny ears knot

Y-Hang (figure of 8 + alpine butterfly).

ROPE ACCESS GENERIC WORK GUIDANCE

The load should be equally shared between

both anchorages

Y-hang

< 90

Basic anchor

Bunny ears anchor

Y-hang

Considering load sharing, the maximum angle

created by the ropes shall not exceed 120

At the work site, a maximum of 90 can be used

as an easy reference point to ensure the loading

at each of the anchor points remains less than

the load in suspension

2 slings or 2 wire strops may be used on the same

unquestionable structural point (e.g. H-beam)

to build a 2-rope anchor (basic anchor)

IRATA references:

ICOP 1.4.2.5.3, 2.11.1.3, 1.4.2.5.1 2.11.1.2, 2.11.2.2

/ TACS 7.7.35

ISO 22846-2 clauses: 6.4.1.4 (d) (i), 7.6

ROPE ACCESS GENERIC WORK GUIDANCE

3.3 Limitations

Statement:

While using Y-hangs to anchor the ropes,

the following angles should be considered

(cf. 3.3.1):

very good loading of anchors

< 60

60 < < 90 good loading of anchors

90 < < 120 acceptable loading of anchors

(each anchor will now bear the

equivalent force of the load in

suspension)

> 120

NOT ACCEPTABLE

The maximum practicable angle should not exceed 90

If, for some reason, it is not possible to keep

the angle < 120, the risk assessment shall define

whether a system is still safe or not, and/or where

it has to be re-enforced.

3.3.1 Tensioned lines:

Statement:

For horizontal tensioned lines, the maximu

angle created by the ropes loaded in the middle

should not exceed 160

Fa,b =

m/[cos(a/2)]

2

ROPE ACCESS GENERIC WORK GUIDANCE

For a weight M of 100 kg and an angle of...

= 60

= 90

= 120

= 130

= 150

= 160

= 170

= 178

IRATA references:

TACS 6.4.12

ISO 22846-2 clauses: Annex D

Fa,b = 57 daN (force applied to a and b)

Fa,b = 70 daN

Fa,b = 100 daN

Fa,b = 118 daN

Fa,b = 193 daN

Fa,b = 288 daN

Fa,b = 574 daN

Fa,b = 2865 daN

10

ROPE ACCESS GENERIC WORK GUIDANCE

3.3.2 Deviation limitations:

The maximum angle for a single-anchor deviation

shall not exceed 20

In any case, the consequences of a potential swing

should be risk assessed

Statement:

A single-anchor deviation should only be rigged if,

and in case of unique anchor failure:

no rope friction, shock nor contact with

an edge is possible

a potential swing is not dangerous for the

technician nor third parties

the structure cannot be damaged by

the resulting swing

A double-anchor deviation should be considered

if the the system doesnt meet the safety requiments

applied to a single-anchor deviation

Use a double-anchor deviation if an anchor failure

could lead to a hazardous edge contact

Do NOT rig at the edge level

and keep clearance distance

IRATA references:

ICOP 2.7.8.3 2, 2.11.2.10 / 11/ 19 / 21, 2.11.3.1.5,

2.11.4 / TACS 6.4.8

ISO 22846-2 clauses: Annex D

ROPE ACCESS GENERIC WORK GUIDANCE

3.4 Connection to the harness

The connecting central ring of the harness is

located below the centre of gravity and used for:

devices connected to the working line

cows tails

positioning lanyards

The sternal ring of the harness- sometimes

marked A- is located above the centre of gravity,

and shall be used for:

backup devices (EN 353-2)

fall arrest lanyards (EN 355)

The dorsal D-ring sometimes marked A- shall

exclusively be used to connect:

fall arrest lanyards (EN 355)

The central lower D-ring of the harness

is considered an unquestionable point

11

12

ROPE ACCESS GENERIC WORK GUIDANCE

If the top part of the harness (EN-361)

is connected to the sit via a single Delta maillon,

following should be done before considering the

sternal D-ring as an unquestionable point:

The maillon should have a MBS of at least 15kN

and always be positioned in order to offer this MBS

A mechanical unscrewing of the maillon by hand

shall not be possible

The maillon shall be torqued according to manu

facturers recommendation

The screw should be sealed with Loctite 243

and the plastic cover sealed with silicone in

order to avoid any accidental removal

Source: Petzl

IRATA references:

TACS 6.3.5.2.3

ROPE ACCESS GENERIC WORK GUIDANCE

4.0 ANCHOR LINE MANAGEMENT AND HIERARCHY

OF MEASURES

4.1 Hierarchy of measures

Statement:

Rigging hierarchy:

Avoid the hazard

Prevent the hazard

Mitigate the hazard

Protect the rope

Fabric rope protections should be considered as

last choice, and best manufactured in Aramid

/ Kevlar or equivalent

EDGE MANAGEMENT

& ROPE PROTECTION

HIERARCHY OF

MEASURES

13

14

ROPE ACCESS GENERIC WORK GUIDANCE

4.2 Mechanical protection devices

Statement:

Rope protection devices should be selected

according to risk assessment

Where rigging to avoid or prevent edge is not

possible, pads, mats or specific construction should

be used to mitigate the consequences

4.3 Rope protectors

Statement:

Source: Beal

For hot works, aramid/kevlar protection on each

rope should be used.

In addition, ropes should be backed up

with wire strops

ROPE ACCESS GENERIC WORK GUIDANCE

No fabric rope protection shall be used if the

edge radius is < 5 mm

Where rope protectors (eg mid-rope protection)

have to be used, a thorough assessment should

define whether:

one protector for both ropes

protector per rope

should be used. The stretch of the ropes should

also be considered

Source: Beal

IRATA references:

ICOP Annex P, 2.7.10, 2.11.3.1 2.11.3.2

TACS 6.4.1(d), 6.4.6

ISO 22846-2 clauses: 6.4.2.6

15

16

ROPE ACCESS GENERIC WORK GUIDANCE

5.0 RIGGING FOR RESCUE

Statement:

As far as technically possible, ropes should be

anchored on releasable anchors to simplify

a potential emergency lowering / hauling

Best practice is to use 2 descenders of the same type

The manufacturers instructions for releasable

devices should be followed at all times

Rigging for rescue

shall be a priority

IRATA references:

ICOP 2.2.3 (e), 2.2.5.2, 2.2.6 (h & i), 2.7.9.7, 2.11.2.22,

2.11.4 (i)(ii), 2.11.11.3

ISO 22846-2 clauses: 7.2.4 (c)

6.0 RELEASABLE AND RETRIEVABLE ACHORS

Statement:

Retrievablea anchors should only be used when

classical method using fix and certified anchorages

are not applicable

Rope shall always be protected, even if the structure

appear to be clean and not abrasive

Releasable anchors should only be used under

exceptional circumstances and under close supervision

While rigging a pull through,

ropes shall always be

protected

IRATA references:

TACS 6.4.9

ROPE ACCESS GENERIC WORK GUIDANCE

7.0 HAULING / PULLEY SYSTEMS

17

18

ROPE ACCESS GENERIC WORK GUIDANCE

8.0 PROTECTION OF THIRD PARTIES AND ANCHORS

3.1 Third party

Statement:

Dacon Inspection Services is responsible to restrict

the access to the work sites / training area and

to avoid any damages to third persons

Always ensure that In any case, an exclusion area should be defined

and marked in order to avoid any access to

the exclusion area

is under controlled

unauthorized personnel, this includes following

possible protective measures:

Signals (exclusion zone) at groud level

(barriers, cones, etc)

Pictograms (mandatory PPE when entering site

/ venue, etc)

No access for unauthorized persons

IRATA references:

ISO 22846-2 clauses:

ICOP 1.4.1.1 (f), (ii) & (iv), 1.4.2.6, 2.2.4.3 (b), 2.2.6 (j),

2.11.8.2, Annex M

TACS 6.1.3.13f, 6.2.7, 7.7.11, 7.7.27

4.7(o), 7.7.2

8.2 Anchor protection

Statement:

According to risk assessment, anchors should be

protected from interference

A sentry should be posted to restrict the access

to the anchor area

IRATA references:

ICOP 2.11.8.1.2, 2.11.8.2.3, 2.11.8.3

ISO 22846-2 clauses: 7.7.2.2(e)

ROPE ACCESS GENERIC WORK GUIDANCE

9.0 ON-SITE COMMUNICATION

Statement:

As far as possible, vocal communication

should be used

Emergency signs should be practiced

and understood

If communication devices have to be used,

Communicaion

a functional check shall be carried out before

devices checked

and connected to

beginning the task

the harness

Communication devices shall be securely

connected to the harness to avoid

a potential dropping

IRATA references:

ICOP 1.4.2.5.6, 2.11.9 / TACS 6.2.8.1f, 6.5.2.1b, 9.2.2

ISO 22846-2 clauses: 4.13

10. PRE-USE INSPECTION OF EQUIPMENT

AND BUDDY CHECK

Statement:

Buddy check and check of all suspension

equipment is part of the safety and control

measures of the risk assessment

Buddy check

The buddy check should be carried out exclusively

to be done each

under L3 supervision

time before going

on ropes

Buddy checks should be recorded during

the toolbox talk briefing

IRATA references:

ICOP 2.11.7.4, 2.11.7.5 / TACS 6.3.3, 6.3.4, 6.3.5

ISO 22846-2 clauses: 4.12.3 (c)

19

20

ROPE ACCESS GENERIC WORK GUIDANCE

11. CLOSE MONITORING SUPERVISION

Statement:

Newly qualified operatives shall

initially work under direct supervision of the rope

access supervisor

gradually be allowed to progress to working

under the close supervision of an experienced

operative, at the rope access supervisors

discretion

The limits of the technical knowledge, as defined

in the IRATA syllabus, as well as the experience of

the technicians, should be considered at any time

IRATA references:

ICOP 2.5.2.3, 2.5.2.4

ISO 22846-2 clauses: 5.1, 5.3 (d), 5.4.2, 5.5.2, 5.5.3.4 (g), 5.6.2

12. TOOLBOX TALK BRIEFING

12.1 Project briefing

Statement:

The project briefing should be carried out by

project engineer

12.2 On-site daily briefing (toolbox talk)

Statement:

The toolbox talk briefing shall be carried out

by L3 supervisor

The briefing by L3 supervisor is addressed

to all technicians engaged

Mandatory toolbox talk A toolbox talk briefing should be carried out at

every new shift, but latest every morning

briefing at every new

shift and recorded

All briefings shall be recorded

Briefings should include sharp edge management,

rescue plan and rigging for rescue

Cf. form reference No in section 23.0

ROPE ACCESS GENERIC WORK GUIDANCE

A toolbox talk record is only valid if signed by all attendees

IRATA references:

ISO 22846-2 clauses:

ISO 9001 clauses:

ICOP 1.4.2.7, 2.2.2 (e), 2.2.4.5, 2.2.6, 2.6.2.8,

2.11.6.6, 2.11.7.2

4.14

7.5.1

13. RESCUE PLAN

Statement:

The rescue plan shall ALWAYS be part of

the work statement

Every rope access technician engaged on ropes

should be evacuated within a maximum of

20 minutes (to a suitable place for first aid,

stretcher, medical assistance, etc)

A special rescue bag shoud be used wherever

rigging for rescue is not possible

The L3 supervisor shall ensure that:

All team members understand the rescue

scenarios

The rescue task remains within technician

level of competence

No work should be carried out without or prior to

rescue plan briefing

Cf. form reference No in section 23.0

IRATA references:

ISO 22846-2 clauses:

ICOP 1.4.1.1 (i), 1.4.2.7, 1.4.3.11, 2.2. 5.2, 2.2.6

(h & i), 2.11.11, 2.11.11.6, Annex B, TACS 6.2.5.1,

6.2.6, 6.2.8, 6.2.9.2, 6.5.1.2.4 6.5.1.1, 7.7.17, 9.2.2

4.3.2 (k), 4.6, 7.2.4 (c), 8.1.3, 8.1.5 (a) (b)

21

22

ROPE ACCESS GENERIC WORK GUIDANCE

14. SMALL TOOLS

Statement:

Small tools shall be connected to the harness,

to avoid being dropped to the ground.

If not possible, they should be stored in a closable

Small tools SHALL

bag attached to the harness.

be connected to the

harness or bagged

The small tool management should also deal with

instructions related to the use of mobile phone

/ camera on site

IRATA references:

ICOP 2.11.8.2.2, Annex M / TACS 6.1.3.13(f), 6.2.7

ISO 22846-2 clauses: 4.11.4

15. DE-BRIEFING

Statement:

The de-briefing shall be carried out at the end

of each shift

The de-briefing shall be recorded in the toolbox

talk form in the according section

ISO 22846-2 clauses: 4.15

ROPE ACCESS GENERIC WORK GUIDANCE

16. INCIDENT MANAGEMENT

Statement:

Following events shall be recorded as incident,

investigated and treated as nonconformity:

Incident

Not working according to procedure

Working out-of-scope

Accident

Near miss

Equipment misuse

Incidents shall be communicated without delay

to the line management

Incidents shall be recorded and investigated

according to Dacon Inspection Services procedure

Investigation results and proposal of corrective

action shall be communicated to the line

management

IRATA Form 021R shall be completed

and sent to IRATA admin

Cf. form reference No in section 23.0

IRATA references:

ICOP 2.26(f), 2.10.1.6, 2.11.12

ISO 22846-2 clauses: 4.7(f)

23

24

ROPE ACCESS GENERIC WORK GUIDANCE

17. DAILY DIARY FOR L3 SAFETY SUPERVISOR

SIRATA references:

ICOP 2.2.2 (f), 2.2.4.5, 2.2.6 (h & i), 2.6.2.8, 2.11.6.6,

2.11.7.2 / TACS 7.7.18

ROPE ACCESS GENERIC WORK GUIDANCE

18. LOGGING OF HOURS WORKED

Statement:

Working on ropes includes:

on-site work such as

rigging

de-rigging

gaining access

protection installation

rescue equipment installation and preparation

supervision (harnessed up) on-site

all workers directly in support of

rope access teams

trials carried out on site such as

rescue practice

trial procedure testing

Working off ropes on-site includes:

site survey and inspection

waiting for permits

preparations prior to and post site working

direct on-site supervision

on-site job-related meetings such as tool box talks

preparatory work on site

any directly related work associated with

the work or job on site.

pre-use and post-use equipment inspections

down time because of weather

use of IRATA qualified personnel working

where rope use is not the primary support element

(e.g. working offcradlesand scaffolds)

where IRATA qualified personnel are in attendance

at the work site in support roles (winch operators,

communications etc) but who are not harnessed

(for rescue duty).

Excludes unqualified support workers/supervisors who have no control or direct

involvement in rope access.

25

26

ROPE ACCESS GENERIC WORK GUIDANCE

Other includes:

any time spent not covered by any other category

such as

travel time

relevant admin support hours from head office

which is directly related to rope access such as

risk assessment

method statement preparation

equipment procurement and inspection

Cf. form reference No in section 23.0

LOGBOOK ENTRIES (Hours worked)

Should be an accurate reflection of the time spend carrying out

rope access, including normal requirements such as pre-work

requirements (toobox talk briefing), pre-work equipment inspection,

rigging, de-rigging and training. Working with fall arrest methods

is of relevance only if used in combination with rope access

IRATA references: TACS 4.13, 4.14

ISO 22846-2 clauses: 4.17

ROPE ACCESS GENERIC WORK GUIDANCE

19. SUSPENSION INTOLERANCE ( SUSPENSION TRAUMA )

Statement:

The suspension trauma is a breakdown of the

normal blood circulation caused by the free,

immobile suspension in a harness

The leg loops can squeeze the veins together

and thus prevent the blood circulation back

to the heart

As the resistance below the feet is missing the

so-called muscle pump can no longer be effective

for the delivery of the venous reverse flow.

Thus big amounts of blood can remain in the veins

of the legs and the blood circulation is not provided

with enough blood. Vital organs as brain, heart and

lungs are not sufficiently supplied.

The injured person should be removed as fast as

possible from the hanging position

The most frequent complication after a long

hanging period is the right heart part failure,

also called rescue death, and caused by the

classic shock positioning

IRATA references:

ICOP Annex G

ISO 22846-2 clauses: 8.2, Annex E

27

28

ROPE ACCESS GENERIC WORK GUIDANCE

20. WORKPACK DOCUMENTATION

Statement:

The outgoing work pack should at least contain:

IRATA L3 On-Site Obligation Flowchart

Rope access procedure

Personnel files

Equipment manifest

Equipment technical notices

Clients details

Project information

Risk assessment (generic & specific)

Method statement (generic & specific)

Specific work instruction

Blank forms:

Toolbox talk briefing

Daily report

Rescue plan

Hour log

Incident report

The returning work pack should at least contain:

Rope access procedure

Personnel files

Equipment manifest

Equipment technical notices

Clients details

Project information

Risk assessment (generic & specific), amended if required

Method statement (generic & specific), amended if required

Specific work instruction

Records:

Toolbox talk briefings

Daily reports

Rescue plans

Hour logs

Incident reports

Work permits (if applicable)

IRATA references: ICOP Annex N

ISO 22846-2 clauses: 4.18

ROPE ACCESS GENERIC WORK GUIDANCE

21. ABOUT RISK ASSESSMENT

Potential hazard ....

Hazardous situation (a person and a potential hazard

are brought together) ...

. ... Consequence (result of incident)

.... Incident (occurence) ....

Follow the 5 steps while amending a risk assessment:

Step 1: Identify the hazards

Step 2: Decide who might be harmed and how

Step 3: Evaluate the risks and decide on precautions

Step 4: Record your findings and implement them

Step 5: Review your assessment and update if necessary

IRATA references: ICOP 1.4.1.1 (i),1.4.2.1, 1.4.2.7, 2.2, 2.11.11, 2.11.11.5,

Annex A, Annex B, TACS 4.4.2, 6.2.3, 6.2.4, 6.2.5, 6.2.8,

6.5.1.1, 7.7.13/14/17 9.2.1

ISO 22846-2 clauses: 4.3.2(f), 4.4, 4.5

29

30

ROPE ACCESS GENERIC WORK GUIDANCE

22. ANNEX I

22.1 Correct use of connectors

Source: Petzl

22.2 Correct coiling of rope

22.3 Lark head

Source: Petzl

Example for a 22 kN sling:

- 30%

15 kN

- 60% + 100%

8.8 kN 44 kN

ROPE ACCESS GENERIC WORK GUIDANCE

23. ANNEX II: REFERRED DOCUMENTS AND FORMS

Document

Reference

Rope access procedure

Rope access rescue procedure

Quality and procedure manual

Incident management procedure

Document

Toolbox talk

Rope access rescue procedure

Risk assessment

Nonconformity report

Request for improvement

Reference

31

32

ROPE ACCESS GENERIC WORK GUIDANCE

NOTES

ROPE ACCESS GENERIC WORK GUIDANCE

NOTES

33

34

ROPE ACCESS GENERIC WORK GUIDANCE

NOTES

ROPE ACCESS GENERIC WORK GUIDANCE

NOTES

35

36

ROPE ACCESS GENERIC WORK GUIDANCE

NOTES

ROPE ACCESS GENERIC WORK GUIDANCE

NOTES

37

38

ROPE ACCESS GENERIC WORK GUIDANCE

NOTES

ROPE ACCESS GENERIC WORK GUIDANCE

NOTES

39

40

ROPE ACCESS GENERIC WORK GUIDANCE

NOTES

ROPE ACCESS GENERIC WORK GUIDANCE

NOTES

41

42

ROPE ACCESS GENERIC WORK GUIDANCE

NOTES

ROPE ACCESS GENERIC WORK GUIDANCE

NOTES

43

44

ROPE ACCESS GENERIC WORK GUIDANCE

DACON INSPECTION SERVICES CO.,LTD.

78/4 Moo 6, Sukhumvit Road, Ban Chang

Rayong, 21130, THAILAND

Phone: +66 38 880788

Fax: +66 38 880727

Email: info@dacon-inspection.com

www. dacon-inspection.com

Das könnte Ihnen auch gefallen

- RA Risk Window Cleaning by Using Rope AccessDokument11 SeitenRA Risk Window Cleaning by Using Rope AccessADIL FAZALNoch keine Bewertungen

- 303 Rope Rescue Operational LevelDokument13 Seiten303 Rope Rescue Operational LevelUirapuru Florêncio100% (2)

- Rope Access Training ManualDokument128 SeitenRope Access Training ManualRoberto TeekersinghNoch keine Bewertungen

- Fall Protection EquipmentDokument24 SeitenFall Protection Equipmentmdsartaj7428100% (1)

- Safety Moment Personal Protective EquipmentDokument1 SeiteSafety Moment Personal Protective EquipmentEvert W. VanderBerg100% (1)

- CMS F R4 435 Rope Access Training Record Under Review 2018Dokument58 SeitenCMS F R4 435 Rope Access Training Record Under Review 2018panjiNoch keine Bewertungen

- Technical Rescue: Introduction To Technical Rescue, Core Qualifications, and Rope TechniquesDokument341 SeitenTechnical Rescue: Introduction To Technical Rescue, Core Qualifications, and Rope TechniquesForum Pompierii100% (1)

- JSA For Rope Access Services (24-Sep-14)Dokument8 SeitenJSA For Rope Access Services (24-Sep-14)TomasPavlovic100% (1)

- Confined Space GuidebookDokument32 SeitenConfined Space GuidebookPcEng100% (4)

- Rope Rescue EquipmentDokument23 SeitenRope Rescue EquipmentCarletonRescueNoch keine Bewertungen

- Confined Space Rescue Plan-Fb EngineeringDokument17 SeitenConfined Space Rescue Plan-Fb EngineeringPatrick Ruwona100% (1)

- Vortex Laser Reiki 1Dokument17 SeitenVortex Laser Reiki 1Volkan VVolkan100% (3)

- Rope Access-Method Statement RoughDokument22 SeitenRope Access-Method Statement RoughSean Kalu Onuoha80% (5)

- case study حنانDokument35 Seitencase study حنانMera Abo ElhassanNoch keine Bewertungen

- Abseil HandbookDokument24 SeitenAbseil HandbookRowan BirchNoch keine Bewertungen

- Blood Transfusion Policy 6.3Dokument90 SeitenBlood Transfusion Policy 6.3raNoch keine Bewertungen

- Basic Rigging For Rope RescueDokument8 SeitenBasic Rigging For Rope RescueLogan RodgersNoch keine Bewertungen

- MPT NeurologyDokument22 SeitenMPT NeurologyDevasyaNoch keine Bewertungen

- Rope RescueDokument8 SeitenRope RescueMarinescuPaul1100% (1)

- Oral Physiology ReviewerDokument20 SeitenOral Physiology ReviewerCamille Baybay100% (1)

- ITS LEEA 036 Practical Training Courses L14Dokument19 SeitenITS LEEA 036 Practical Training Courses L14doan8057% (7)

- WTM-053 Safety Procedure in Radiographic WorkDokument15 SeitenWTM-053 Safety Procedure in Radiographic WorkWisüttisäk PeäröönNoch keine Bewertungen

- Rope Access Guide Book Vertical SpecialistDokument23 SeitenRope Access Guide Book Vertical Specialistpkannan100% (1)

- Job Hazard Analysis Rope AccessDokument6 SeitenJob Hazard Analysis Rope AccessSean Kalu Onuoha100% (1)

- Emergency Rescue Plan For Operatives Working at HeightDokument9 SeitenEmergency Rescue Plan For Operatives Working at Heightloveson709Noch keine Bewertungen

- Standard Manual Machine Guard en Tryb ZgodnosciDokument31 SeitenStandard Manual Machine Guard en Tryb Zgodnoscicomputacion100% (1)

- LCC DOCS-11568884-V1-HS-PRO-013 Working in On Over or Adjacent To WaterDokument13 SeitenLCC DOCS-11568884-V1-HS-PRO-013 Working in On Over or Adjacent To WaterabogadieNoch keine Bewertungen

- Manual Life On A LineDokument182 SeitenManual Life On A Lineasphenaut100% (1)

- Colin Ross BluebirdDokument40 SeitenColin Ross Bluebirdplan2222Noch keine Bewertungen

- Rope Access LEVEL 1 InTR0Dokument74 SeitenRope Access LEVEL 1 InTR0Wan RozaidiNoch keine Bewertungen

- OSH Safety Harness Inspection ChecklistDokument1 SeiteOSH Safety Harness Inspection ChecklistXozan100% (1)

- LEEA Passing CriteriaDokument1 SeiteLEEA Passing CriteriaKhurram S. Muzammil50% (2)

- Rope Access TechnicssDokument6 SeitenRope Access TechnicssNizar MohamedNoch keine Bewertungen

- Anaesthesiology NAGY TESZTKÖNYVDokument1.064 SeitenAnaesthesiology NAGY TESZTKÖNYVoroszgabor100% (10)

- Authorised Gas Tester Competence Training PackageDokument158 SeitenAuthorised Gas Tester Competence Training Packageina23aj93% (14)

- Heightworksiratatrainingmanualversion2 140911074418 Phpapp02 PDFDokument128 SeitenHeightworksiratatrainingmanualversion2 140911074418 Phpapp02 PDFRoberto Benavente100% (4)

- Fire Watch TrainingDokument26 SeitenFire Watch TrainingSaeed Malik100% (2)

- Rope Access Rescue PlanDokument4 SeitenRope Access Rescue Planpatvindewr89% (9)

- Rope AccessDokument120 SeitenRope AccesslovesakiNoch keine Bewertungen

- EHS Monthly MeetingDokument31 SeitenEHS Monthly MeetingShaik MohamedNoch keine Bewertungen

- IRATA Rope Access Training and Qualification Requirements R1Dokument9 SeitenIRATA Rope Access Training and Qualification Requirements R1Trinh Dung100% (1)

- Industrial Rope AccessDokument166 SeitenIndustrial Rope Accessrevers0100% (3)

- Rope Rescue - Colorado Tech RescueDokument53 SeitenRope Rescue - Colorado Tech RescueJairus Sumineg100% (2)

- Uts-Eng-pro-081 - c2 Air Diving System Lars Operational and Emergency Proc...Dokument21 SeitenUts-Eng-pro-081 - c2 Air Diving System Lars Operational and Emergency Proc...Siva KumarNoch keine Bewertungen

- Electric Part-Turn Actuators: SG 03.3 - SG 04.3 Auma NormDokument28 SeitenElectric Part-Turn Actuators: SG 03.3 - SG 04.3 Auma Normابزار دقیق100% (1)

- Standard Scaffold CatalogueDokument10 SeitenStandard Scaffold Cataloguelwin_oo2435100% (6)

- Banksman and Slinger Training Stages 1 and 2Dokument56 SeitenBanksman and Slinger Training Stages 1 and 2Mohammed Rizwan AhmedNoch keine Bewertungen

- Guidelines For Good Clinical Practice in Clinical Trials (1998)Dokument49 SeitenGuidelines For Good Clinical Practice in Clinical Trials (1998)analyn123Noch keine Bewertungen

- Roto Fix 32 Service ManualDokument31 SeitenRoto Fix 32 Service Manualperla_canto_150% (2)

- Industrial Industrial Rope Access Division Method Statement Method StatementDokument22 SeitenIndustrial Industrial Rope Access Division Method Statement Method StatementAli SadiqinNoch keine Bewertungen

- Industrial Rope Access MethodDokument38 SeitenIndustrial Rope Access MethodUllas Krishnan0% (1)

- An Overview of Confined Space RescueDokument50 SeitenAn Overview of Confined Space RescueHtin Lin Aung100% (5)

- DM-PHSD-P7-A-TG - (Guidelines For Rope Access Work) English PDFDokument11 SeitenDM-PHSD-P7-A-TG - (Guidelines For Rope Access Work) English PDFdemie figueroaNoch keine Bewertungen

- Rope Access TechniqueDokument14 SeitenRope Access TechniqueSai FujiwaraNoch keine Bewertungen

- Banksman Slinger Stages 3-4 Dec 2010Dokument43 SeitenBanksman Slinger Stages 3-4 Dec 2010Matthew Kennedy100% (3)

- Volume 2 Safe Working Near WaterDokument51 SeitenVolume 2 Safe Working Near WaterVijay SharmaNoch keine Bewertungen

- Rescue Plan Sample (Derrick)Dokument4 SeitenRescue Plan Sample (Derrick)Anil CNoch keine Bewertungen

- Restraint CompetencyDokument6 SeitenRestraint CompetencyFrederick RyanNoch keine Bewertungen

- Confined SpaceDokument45 SeitenConfined SpaceDeepu Ravikumar100% (1)

- Bacterial Fungal Parasitic Overgrowth PDFDokument104 SeitenBacterial Fungal Parasitic Overgrowth PDFportosinNoch keine Bewertungen

- Manual SpoolerDokument118 SeitenManual Spooleryubelly gómezNoch keine Bewertungen

- Operator Manual AXIOM Artis: ListsDokument606 SeitenOperator Manual AXIOM Artis: ListsHelen Cid Acevedo100% (2)

- Alpaccess: Wind Turbine Maintenance & RepairsDokument7 SeitenAlpaccess: Wind Turbine Maintenance & RepairsDragos StateNoch keine Bewertungen

- I-OPE-RA-003 - Rope Access Operating - Rev.7 (Em Revisao)Dokument36 SeitenI-OPE-RA-003 - Rope Access Operating - Rev.7 (Em Revisao)Rael Zorzo MichelsNoch keine Bewertungen

- Rescue Plan For Maintenance Building Using Rope Access MethodDokument4 SeitenRescue Plan For Maintenance Building Using Rope Access MethodCristlee TombokanNoch keine Bewertungen

- Project Proposal Wind MillDokument8 SeitenProject Proposal Wind MillAbdul BasitNoch keine Bewertungen

- Hs Module 5A: Height SafetyDokument2 SeitenHs Module 5A: Height SafetyDeepu RavikumarNoch keine Bewertungen

- JJ22543-K3 Mast User ManualDokument23 SeitenJJ22543-K3 Mast User ManualJohn SimancaNoch keine Bewertungen

- Eps Mma Tig en PDFDokument18 SeitenEps Mma Tig en PDFAdrian EftimieNoch keine Bewertungen

- Inst IFM RMS001Dokument11 SeitenInst IFM RMS001Alonso BarreraNoch keine Bewertungen

- 319-6424 Alt LL6100 - EnglishDokument20 Seiten319-6424 Alt LL6100 - EnglishEbied Yousif AlyNoch keine Bewertungen

- ValveDokument86 SeitenValvephanindraNoch keine Bewertungen

- Ve Pua315 1997Dokument10 SeitenVe Pua315 1997Shaik MohamedNoch keine Bewertungen

- PR & PO For Safety ShoesDokument5 SeitenPR & PO For Safety ShoesShaik MohamedNoch keine Bewertungen

- Tagging Sample Board LFDokument3 SeitenTagging Sample Board LFShaik MohamedNoch keine Bewertungen

- Internal Accident & Incident Escalation Process - VESBDokument1 SeiteInternal Accident & Incident Escalation Process - VESBShaik MohamedNoch keine Bewertungen

- Fire Extinguisher ChartDokument2 SeitenFire Extinguisher ChartShaik MohamedNoch keine Bewertungen

- Heartbeat Times 2013Dokument7 SeitenHeartbeat Times 2013heartbeatLBNoch keine Bewertungen

- TetrabenazinaDokument23 SeitenTetrabenazinanieve2010Noch keine Bewertungen

- Ee BD ManualDokument37 SeitenEe BD Manualsergey62Noch keine Bewertungen

- Homeo MedicinesDokument31 SeitenHomeo MedicinesSaleem RazaNoch keine Bewertungen

- Stress ManagementDokument19 SeitenStress ManagementMarites Laroco CincoNoch keine Bewertungen

- Article 1525968342 PDFDokument10 SeitenArticle 1525968342 PDFanindhitha thandapaniNoch keine Bewertungen

- Current Scenario: Knowledge of Basic Life Support in Medical CollegeDokument3 SeitenCurrent Scenario: Knowledge of Basic Life Support in Medical CollegeaminNoch keine Bewertungen

- Cefdinir Capsules PIJan07Dokument12 SeitenCefdinir Capsules PIJan07Ali AlhajNoch keine Bewertungen

- Triclosan USP..Dokument2 SeitenTriclosan USP..Arun Kumar PandeyNoch keine Bewertungen

- Intensive Revision Course in Paediatrics (Poster)Dokument2 SeitenIntensive Revision Course in Paediatrics (Poster)Chris Jardine LiNoch keine Bewertungen

- Factors Influencing Customer Satisfaction in Healthcare ServicesDokument47 SeitenFactors Influencing Customer Satisfaction in Healthcare ServicesRaman ChandelNoch keine Bewertungen

- Magnesium ReplacementDokument4 SeitenMagnesium ReplacementArvenaa SubramaniamNoch keine Bewertungen

- Qi Presentation VapDokument19 SeitenQi Presentation Vapapi-383799988Noch keine Bewertungen

- Medical Malpractice (DR Jarcia Vs People)Dokument8 SeitenMedical Malpractice (DR Jarcia Vs People)Francesco Celestial BritanicoNoch keine Bewertungen

- Concept Map Chap7 General Survey Vital SignsDokument1 SeiteConcept Map Chap7 General Survey Vital SignsEvelyn MoatsNoch keine Bewertungen

- Jurnal Pijat 1Dokument4 SeitenJurnal Pijat 1Herli SahputriNoch keine Bewertungen

- Pain and Pain Gate Control MechanismDokument17 SeitenPain and Pain Gate Control MechanismKapil LakhwaraNoch keine Bewertungen

- Antipsychotics Pharm 3 Year 2Dokument19 SeitenAntipsychotics Pharm 3 Year 2Dua'a Al-HamdanNoch keine Bewertungen

- New Microsoft Office PowerPoint PresentationDokument33 SeitenNew Microsoft Office PowerPoint PresentationVasuda Devi MalepatiNoch keine Bewertungen