Beruflich Dokumente

Kultur Dokumente

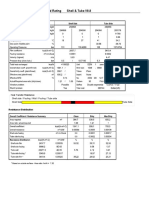

1st Cold Exchanger, 10-E-5005

Hochgeladen von

Hoàng Minh ÁiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

1st Cold Exchanger, 10-E-5005

Hochgeladen von

Hoàng Minh ÁiCopyright:

Verfügbare Formate

NO.

REV.

4238434

PETROVIETNAM

PAGE

1 of 1

Phu My Fertilizer Project

DOC.GRP.

DK-2800 Lyngby, Denmark

53

1350 MTPD Ammonia Plant

JOB NO.

DATE

1st Cold Exchanger

APPD.

22226

Duty

MTD

Corrected MTD

DED

17.8

8.09

8.09

DATE

25-09-01

1

1

DESCRIPTION

1

1

HUL

ITEM NO. 10-E-5005

552 m

628 m

1

Shell side

in

Fluids

Quantity: total

liquid

gas

Operating temperature

Operating pressure

Pressure drop, max. allowable/calculated

Liquid: density

viscosity

specific heat

thermal conductivity

boiling temperature

Gas:

molecular weight

density

viscosity

specific heat

thermal conductivity

dew point

Latent heat

Fouling resistance

Film coefficient, refers to outside surface

Overall heat transfer coefficient, clean/dirty

Tube side

out

Converter inlet

294958

294958

18

130

294958

37

0.32

1)

9.91

50.7

0.016

3.186

0.392

9.91

47.4

0.016

3.171

0.407

in

Units

out

Converter effluent

294958

11998

294958

282960

41

34.5

133

0.18

583

0.122

4.786

1.784

11.15

56.4

0.016

3.043

0.361

10.99

56.4

0.016

3.054

0.363

-5.1

39.6

0.000086

10154

5597

0.00017

14621

3994

kg/h

kg/h

kg/h

C

bar g

bar

kg/m

cP

kJ/kg C

kJ/m C h

C

kg/m

cP

kJ/kg C

kJ/m C h

C

kJ/kg

m C/ W

kJ/m C h

kJ/m C h

MECHANICAL DATA (one shell)

Design temperature

Design pressure

Test pressure

Number of passes

Corrosion allowance

Nozzle nominal diameter

THIS DOCUMENT CONTAINS TRADE SECRET AND PROPRIETARY INFORMATION, THE PROPERTY OF HALDOR TOPSE A/S, AND IS ISSUED ON CONDITION THAT IT IS RECEIVED AND

HELD IN CONFIDENCE. NEITHER IT NOR THE INFORMATION HEREIN SHALL BE REPRODUCED,

SOLD, LENT, DISCLOSED OR USED FOR ANY PURPOSE OTHER THAN THAT FOR WHICH IT HAS

BEEN ISSUED WITHOUT WRITTEN AUTHORITY OF HALDOR TOPSE A/S.

Rev.

Updated as per Rev. 1 flowsheets

APPD.

DER

OPERATING DATA (one unit)

DESCRIPTION

CHD.

ATJ

Calculated outside surface per unit

Installed outside surface per unit

Shells per unit

GJ/h

C

C

DRAWN

CHD.

DER

HEAT EXCHANGER SPECIFICATION SHEET

Rev.

1 Type

DRAWN

13-08-01

2)

in

out

-20/70

152

-20/70

152

1

1.6

2 x 14"

2 x 14"

1

1.6

18"

18"

Design mean metal temperature

Carbon steel

Carbon steel

Construction material

Shell id

1557 mm

4500

Tube no

od

12.7 mm

id

9.40

mm

length

3500 mm

pitch

Baffle type

Disc and doughnut

spacing

350 mm

cut oc/cc

Insulation

Cold

Free baffle hole area ow/iw

0.40/0.36

m2

Construction according to

ASME VIII Div. 1, TEMA Class R

Stress relieving

According to code

Length of tubes is excluding thickness of tube sheet

Remarks

1) Pressure loss at inlet and outlet nozzles included

2) Design differential pressure shell side/tube side: 20 bar

3) Mean shell metal temperature: 30 C

4) Mean tube metal temperature: 34 C

5) Design mean shell-tube metal temperature difference: 15 C

6) Ring chamber impingement protection at shell side inlet and outlet

7) Total tube length is to be 3660 mm (including tube sheets).

C

bar g

bar g

mm

19.05 mm

89.0/56.0 %

Mechanically identical to 10-E-5007.

1

Design case: Case 2, GPP Gas, ex. HRU

831515

Calcno

FORM NO. 4-1125/E (Ex)

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Aspen Exchanger Design and Rating Shell & Tube V8.8: Overall PerformanceDokument1 SeiteAspen Exchanger Design and Rating Shell & Tube V8.8: Overall PerformanceHoàng Minh ÁiNoch keine Bewertungen

- Aspen Exchanger Design and Rating Shell & Tube V8.8: Overall PerformanceDokument1 SeiteAspen Exchanger Design and Rating Shell & Tube V8.8: Overall PerformanceHoàng Minh ÁiNoch keine Bewertungen

- 20/01/2018 17:43 MATLAB Command Window 1 of 1Dokument1 Seite20/01/2018 17:43 MATLAB Command Window 1 of 1Hoàng Minh ÁiNoch keine Bewertungen

- E5006 ModelDokument1 SeiteE5006 ModelHoàng Minh ÁiNoch keine Bewertungen

- CLCDokument3 SeitenCLCHoàng Minh ÁiNoch keine Bewertungen

- HFHFDokument37 SeitenHFHFHoàng Minh ÁiNoch keine Bewertungen

- FLooding FactorDokument20 SeitenFLooding FactorHoàng Minh ÁiNoch keine Bewertungen

- 4.1 16163070-BOM - 01 CommentedDokument3 Seiten4.1 16163070-BOM - 01 CommentedHoàng Minh ÁiNoch keine Bewertungen

- Script File To Calculate The Fugacity of A Mixture Based On TheDokument5 SeitenScript File To Calculate The Fugacity of A Mixture Based On TheHoàng Minh ÁiNoch keine Bewertungen

- FLoodingDokument17 SeitenFLoodingHoàng Minh ÁiNoch keine Bewertungen

- FLoodingDokument4 SeitenFLoodingHoàng Minh ÁiNoch keine Bewertungen

- Info RASCHIG Super Ring 250Dokument24 SeitenInfo RASCHIG Super Ring 250Hoàng Minh ÁiNoch keine Bewertungen

- NCNCDokument2 SeitenNCNCHoàng Minh ÁiNoch keine Bewertungen

- BVBVDokument67 SeitenBVBVHoàng Minh ÁiNoch keine Bewertungen

- GDGDFDokument8 SeitenGDGDFHoàng Minh ÁiNoch keine Bewertungen

- Dresser Italia S.R.L.: MasoneilanDokument1 SeiteDresser Italia S.R.L.: MasoneilanHoàng Minh ÁiNoch keine Bewertungen

- EML PumpDokument6 SeitenEML PumpJordan Alejandro CoronaNoch keine Bewertungen

- Dresser Italia S.R.L.: MasoneilanDokument1 SeiteDresser Italia S.R.L.: MasoneilanHoàng Minh ÁiNoch keine Bewertungen

- READMEDokument4 SeitenREADMEHoàng Minh ÁiNoch keine Bewertungen

- GPSADokument13 SeitenGPSAMuhammadNoch keine Bewertungen

- 03RMPCODokument58 Seiten03RMPCOHoàng Minh ÁiNoch keine Bewertungen

- Optimized Gas Treating, Inc PDFDokument1 SeiteOptimized Gas Treating, Inc PDFHoàng Minh ÁiNoch keine Bewertungen

- Find The Best Licensing Option For Your Business - WangDokument36 SeitenFind The Best Licensing Option For Your Business - WangHoàng Minh ÁiNoch keine Bewertungen

- Optimized Gas Treating, IncDokument1 SeiteOptimized Gas Treating, IncHoàng Minh ÁiNoch keine Bewertungen

- 02APCOVDokument48 Seiten02APCOVHoàng Minh ÁiNoch keine Bewertungen

- Seal 1Dokument6 SeitenSeal 1Hoàng Minh ÁiNoch keine Bewertungen

- Profit Controller Design Considerations: Process SolutionsDokument41 SeitenProfit Controller Design Considerations: Process SolutionsHoàng Minh ÁiNoch keine Bewertungen

- Profit Controller - Implementation Course 4516: Process SolutionsDokument5 SeitenProfit Controller - Implementation Course 4516: Process SolutionsHoàng Minh ÁiNoch keine Bewertungen

- Ese 00528 enDokument36 SeitenEse 00528 enHoàng Minh ÁiNoch keine Bewertungen

- Api ListDokument2 SeitenApi ListHoàng Minh Ái50% (2)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- En 360ES HandbookDokument75 SeitenEn 360ES Handbookyashiro732Noch keine Bewertungen

- MTC Building Structures MTC 1Dokument48 SeitenMTC Building Structures MTC 1Syach FirmNoch keine Bewertungen

- High School Earth Science 14-26Dokument529 SeitenHigh School Earth Science 14-26Andrei PopaNoch keine Bewertungen

- Newsletter DT 1204 PDFDokument20 SeitenNewsletter DT 1204 PDFBelen TapiaNoch keine Bewertungen

- Refrigeration & Air Conditioning by W.F. Stoecker & J.W JhonesDokument440 SeitenRefrigeration & Air Conditioning by W.F. Stoecker & J.W JhonesJuniel CalixtroNoch keine Bewertungen

- Polyester SynthesisDokument8 SeitenPolyester SynthesisTrangNoch keine Bewertungen

- FI01 2008 en Kap04 PDFDokument388 SeitenFI01 2008 en Kap04 PDFRandy LangleyNoch keine Bewertungen

- KERN BalancesDokument194 SeitenKERN Balancessava88Noch keine Bewertungen

- Measure Density Lab DOCUMENTDokument3 SeitenMeasure Density Lab DOCUMENTAthira NairNoch keine Bewertungen

- Thermodynamics 1 Basic Principles, Concepts and DefinitionDokument8 SeitenThermodynamics 1 Basic Principles, Concepts and DefinitionHENRICK IGLENoch keine Bewertungen

- 03 Post-Print PDFDokument24 Seiten03 Post-Print PDFMaruf BillahNoch keine Bewertungen

- FinalDokument50 SeitenFinalPeter MotoNoch keine Bewertungen

- Forces, Density, and PressureDokument21 SeitenForces, Density, and PressureYossef AmrNoch keine Bewertungen

- Final Product 7 Learning Cycles - 6th Grade MatterDokument46 SeitenFinal Product 7 Learning Cycles - 6th Grade Matterapi-310725472Noch keine Bewertungen

- Understanding Pressure: Units, Measurements, and CalculationsDokument2 SeitenUnderstanding Pressure: Units, Measurements, and Calculationsirma elNoch keine Bewertungen

- Formulation and Evaluation of Enteric Coated Pellets of Omeprazole PDFDokument8 SeitenFormulation and Evaluation of Enteric Coated Pellets of Omeprazole PDFYuppie RajNoch keine Bewertungen

- Material Spec SheetsDokument21 SeitenMaterial Spec SheetsAdityaDeshmukhNoch keine Bewertungen

- STD XI AKTUTORIAL Multiple Choice Questions on Dimensional AnalysisDokument4 SeitenSTD XI AKTUTORIAL Multiple Choice Questions on Dimensional AnalysisAnoushka NagNoch keine Bewertungen

- Smoke Control: Section 4/chapter 12Dokument12 SeitenSmoke Control: Section 4/chapter 12Ramyaa LakshmiNoch keine Bewertungen

- STP24222S Effect of Aggregate Size and Other Factors On Refusal Density of Asphalt Concrete by Vibratory CompactionDokument13 SeitenSTP24222S Effect of Aggregate Size and Other Factors On Refusal Density of Asphalt Concrete by Vibratory Compactionanant11235Noch keine Bewertungen

- Sand Cushion: 1. IntroductionDokument2 SeitenSand Cushion: 1. Introductionlokesh nandinaNoch keine Bewertungen

- 4 Reservoir Geomechanics PDFDokument130 Seiten4 Reservoir Geomechanics PDFMahardika Aji Kurniawan100% (2)

- Astm 1188 PDFDokument4 SeitenAstm 1188 PDFrajeshji_000100% (1)

- DPWH Standard Specification on:COMPACTION AND STABILIZATIONDokument7 SeitenDPWH Standard Specification on:COMPACTION AND STABILIZATIONAldever BretanaNoch keine Bewertungen

- Measurement and Matter Notes for Honors ChemistryDokument15 SeitenMeasurement and Matter Notes for Honors ChemistryLuis Enrique Cabrera TapiaNoch keine Bewertungen

- Mix Design Report For M-30 Grade of Concrete: M/s Aegis Logistics LTDDokument5 SeitenMix Design Report For M-30 Grade of Concrete: M/s Aegis Logistics LTD123shripadNoch keine Bewertungen

- Geotechnical Engineering: Lab ManualDokument78 SeitenGeotechnical Engineering: Lab ManualajaykumarNoch keine Bewertungen

- Physics Grade 8Dokument5 SeitenPhysics Grade 8AshaNoch keine Bewertungen

- STD 8 Physical Quantities WorksheetDokument2 SeitenSTD 8 Physical Quantities WorksheetSid SinhaNoch keine Bewertungen

- A Different Approach To Estimate Air MoistureDokument7 SeitenA Different Approach To Estimate Air MoistureVal MosNoch keine Bewertungen