Beruflich Dokumente

Kultur Dokumente

Ers Ladwp

Hochgeladen von

LindseyusaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ers Ladwp

Hochgeladen von

LindseyusaCopyright:

Verfügbare Formate

SESSION PAPER 22-101

PARIS 2002

TRANSMISSION LINE EMERGENCY RESTORATION PHILOSOPHY

AT LOS ANGELES DEPARTMENT OF WATER AND POWER

by

R. J. SCHWEINER K. E. TWOMEY

Los Angeles Department of Water and Power

K. E. LINDSEY*

Lindsey Manufacturing Co.

(United States)

INTRODUCTION

An essential question for any utility is whether to

maintain their in-house emergency capability for line

restoration or whether to depend on subcontractors and

outside sources for this service.

Every utility should consciously address and decide

which plan is the most realistic for their particular

situation. In doing so a number of factors come into play

such as: the size of the utility, the availability of

subcontractors who can be depended upon during

emergency, whether there are other utilities willing to

enter into mutual assistance plans, and of course, costbenefit of the plan.

This paper describes how the Los Angeles Department of

Water and Power (LADWP) has chosen to maintain its

in-house capability as the solution to this concern,

including what they see as the critical success factors to

maintaining their in-house capability.

States. LADWP provides electricity to approximately 1.4

million electrical customers in a 1202-square-km area.

Business and industry consume about 70 percent of the

electricity in Los Angeles, but residences constitute the

largest number of customers. In addition to serving these

consumers, LADWP lights public streets and highways,

powers the city's water system and sells wholesale

electricity to other utilities.

LADWP supplies power from many sources, including its

own hydroelectric and fossil-fueled generating stations

and contracts for hydroelectric power from the Pacific

Northwest. Coal is the largest single source of power

supply in Los Angeles at 45 percent. Natural gas now

supplies about 20 percent of the city's energy;

hydroelectricity accounts for 12 percent; nuclear, 9

percent, and the remainder comes from purchased power,

including biomass, solar and cogeneration. LADWP has

a net dependable capacity of approximately 7000MW,

and an annual peak demand of approximately 6000MW.

1.1 LADWPS OVERHEAD TRANSMISSION GRID

Several incidents of overhead transmission line (OHTL)

failures and emergency restorations are presented

demonstrating these critical success factors.

KEYWORDS

Availability Economic Loss Emergency Restoration

Overhead Transmission Line

1.0 INTRODUCTION

The Los Angeles Department of Water and Power

(LADWP) established at the beginning of the 20th century

is the largest municipally owned utility in the United

* P.O. BOX 877, AZUSA, CA 91702

Publication Number 07T-001 LADWP 8-2002

The LADWP overhead transmission grid consists of

approximately 8,800 circuit km of 115, 138 and 230kV

transmission as well as both 500kV AC and DC

transmission lines. The Bulk Power Business Unit of

LADWP is responsible for all construction and

maintenance of these lines. Of approximately 15,000

transmission structures maintained by LADWP, over

90% of them are steel lattice type structures. Much of

the 8,800 circuit km of transmission is within the

metropolitan Los Angeles area; however, the LADWP

Bulk Power Business Unit also maintains 935km of

500kV DC transmission lines from Los Angeles to the

Nevada-Oregon border and 772 km from Los Angeles

to northern Utah. The major 230 and 500kV OHTLs

maintained by LADWP outside their service territory

are shown in figure 1.

+/-500kV HVDC

Celilo-Sylmar

NEVADA

CALIFORNIA

UTAH

+/-500kV

HVDC IPP

ARIZONA

LADWP

Service Area

500km

Figure 1

The service area and the 230 and 500kV OHTLs

maintained by LADWP

1.2 ECONOMIC IMPACT OF A TRANSMISSION

LINE FAILURE

In the current deregulated environment of California

electrical energy production, the loss of a critical

transmission line could be catastrophic.

LADWP currently has a typical peak native load of

approximately 5,500 MW (these are customers that

LADWP is committed to serve). LADWP has a peak

generating capacity of approximately 7,000 MW. Of

their large bulk 500kV AC and DC transmission system,

the 500kV lines range in capacity from 1,800 to 3,100

MW. The loss of one of these lines could require

purchasing 1,000 MW of power on the current

deregulated market during peak hours. At the time of the

writing of this paper, the current cost of electric energy on

the summer spot market in California is approximately

US$350/MW hour. The need to purchase 1,000 MW in

this market to prevent outages could cost

US$350,000/hour.

In addition, the loss of any

transmission line could prevent LADWP from selling

excess power to the neighboring utilities and again force

additional economic hardship on not only LADWP but

other utilities as well.

In recent years, LADWP has experienced several failures

of their critical transmission lines due to a variety of

causes. In each of these cases LADWP has been able to

respond quickly and effectively to restore these critical

lines. The next section will discuss what LADWP

believes are the critical success factors for this

performance.

Publication Number 07T-001 LADWP 8-2002

2.0 CRITICAL SUCCESS FACTORS FOR RAPID

RESTORATION OF A DAMAGED

TRANSMISSION LINE

2.1 MANAGEMENT SUPPORT

The Transmission Construction and Maintenance

Organization (TC&M) reports to the Director of the

Bulk Power Business Unit who in turn reports to the

power system Assistant General Manager of the Los

Angeles Department of Water and Power. The TC&M

Organization is responsible for all maintenance, capital

improvement jobs and emergency response when there

is a transmission line failure.

LADWP management has decided to have the in-house

line crews of TC&M perform capital improvement jobs

as opposed to using subcontractors. Conventional

wisdom views outside contractors as more economical

than in-house crews. However, LADWP management

has made a decision to stay with in-house transmission

construction and maintenance crews. This management

decision is one of the biggest success factors for rapid

restoration of a damaged overhead transmission line

(OHTL).

2.2 TRAINED IN-HOUSE PERSONNEL

The TC&M Organization consists of three

superintendents that share overall management duties.

One superintendent is responsible for fleet, secondary

land use and purchasing coordination, the other two are

field superintendents Under these two superintendents

are eight (8) line foremen and two (2) labor supervisors.

The line foremen direct 37 transmission patrolmen, 12

line maintenance assistants and two (2) heavy

equipment operators. In the mid 1980s, the size of the

transmission patrol staff was larger averaging

approximately 80 transmission patrolmen. Over the

years, this number has been reduced to its current

number. All transmission patrolmen are journeymen

linemen that were first trained in distribution work and

then advanced to the transmission department.

Transmission patrolmen get approximately 80 to 100

hours of classroom and field training per year at

TC&Ms training facility (see figure 2). However,

much of the training is on the job training, since TC&M

crews perform capital improvement jobs, such as,

transmission line modifications, fiber optic installations

as well as normal maintenance including live line

maintenance on all transmission lines voltages. The

TC&M line crews can and do build towers and string

conductor on a regular basis.

The 37 transmission patrolmen can work unsupervised

because of their extensive training and experience.

These transmission patrolmen can be dispatched from

their home, which can save considerable time since the

transmission patrolmen can proceed directly to a trouble

site. Transmission patrolmen are normally rotated

around the entire service territory of LADWP so that

they are familiar with the entire service territory.

they are used to locate the damaged site and find the

actual trouble location, weather permitting.

Because TC&M line crews do most of the capital

improvement jobs at LADWP, they are very familiar

with the equipment and tools that are available to them

because they use them on a normal, daily basis.

Without this normal use of the construction tools and

equipment, some material might not be operable when

required in emergencies. A free flow of ideas is

encouraged from the transmission patrolmen and

foremen on new tools and equipment. As a result, many

new tools are developed for a particular type of work

that is required by LADWP.

Figure 2

This LADWP training facility enables TC&M crews to

train in all phases of construction and maintenance.

Various DC, AC and temporary towers are erected.

One aspect of planning, crucial to the successful handling

of an emergency, is communication between the various

elements of the emergency response team. A single

point contact concept is used during emergency

situations to insure that all communication between each

department is direct and that the responsibilities are

clearly defined. Using this concept, a single individual

within each department is assigned to handle all intercompany contact in any major functional area. In

addition, once a task is assigned to an individual, it

becomes the obligation of that individual through

completionthus establishing a clearly defined path of

responsibility. This approach dramatically improved the

efficiency of the inter-company communications, an area

that, if not properly coordinated, can become a major

problem in the hectic environment of an emergency

situation.

Some specialized construction equipment; such as winch

trucks are strategically placed throughout the service

territory. However during emergencies local equipment,

such as backhoes and cranes, are typically rented from a

variety of sources in Los Angeles and outlying areas.

This equipment is readily available at this time.

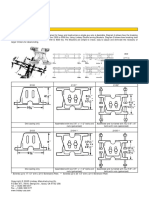

Most important, specialized transmission line

construction equipment such as: puller pilot winder, with

steel pulling line, all wheel drive tri bundle bull wheel

tensioners for both 2 and 3 bundle conductors (see

figure 3) and fiber optic bull wheel tensioners for

pulling overhead ground wire and fiber optic cable are

maintained by TC&M since they are not readily

available from other sources. This equipment must be

maintained in good working order for effective

emergency response. In addition, other specialized

equipment suitable for various terrains found along the

OHTL right-of-ways (such as: all terrain rubber track

vehicles for working in snow conditions, and all wheel

drive 2 ton trucks with front winches) are also

maintained by TC&M.

2.3 CONSTRUCTION EQUIPMENT

One of the most critical aspect of emergency restoration

is effective communication between all of the parties

involved.

One of the most important pieces of

equipment is communications equipment. The foremen

and supervisors have been equipped with new satellite

phones to improve communication between field and

TC&M headquarters where most of the materials and

equipment are kept. The satellite phones take care of

dead spots in LADWPs service territory that normal

cell phones and low band radio are unable to serve.

Another major piece of equipment for emergency

response is helicopters. LADWP has two Bell 206

Long Ranger helicopters that are primarily used by

TC&M for: transportation of men and materials to

remote job sites, staging materials in rough terrain, and

as safety standbys for construction personnel at job

sites. During transmission line emergency restoration,

Publication Number 07T-001 LADWP 8-2002

Figure 3

An all wheel drive tri bundle bull wheel tensioners for 2

bundle conductors is used to string 2312kcmil

conductor during restoration of the DC Intertie.

2.4 EMERGENCY MATERIALS

In order to perform any unplanned emergency work,

critical materials must be on hand and available.

LADWP typically carries standardized wire sizes in

appropriate quantities including all terminations and

splices. For example, LADWP stocks over 30km of

2312kcmil ACSR Thrasher conductor which is a

standard 500kV conductor.

Most of LADWPs 230kV transmission lines were built

between the 1950s and 1960s. In performing normal

maintenance or replacement during emergencies, it is

almost impossible to replace the older hardware from

this era; therefore, TC&M has standardized new

hardware and insulator assemblies for the 115, 138 and

230kV voltage classes.

This standardization has

resulted in considerable savings in time and money for

routine maintenance and for emergency restoration.

Since LADWP has a variety of different types of

transmission towers, extra permanent tower steel for

various types and classes of towers are stored close to

the transmission lines where they will be needed. The

majority of the transmission structures on the +/- 500kV

HVDC Celilo-Sylmar (DC Intertie) transmission line

are a guyed steel tower. Spare guyed steel towers are

located at various yards along this transmission line.

The majority of transmission towers for the 500kV DC

Intermountain Power Project are heavy self-supporting

steel towers and likewise these towers are located at

yards along the transmission line right of way.

In addition to this permanent tower steel available, a

quantity of light weight modular aluminum restoration

structures (ERS) made in accordance with IEEE

Standard 1070[1] are maintained at TC&M

headquarters. These lightweight structures are used

whenever permanent steel is not readily available. The

polymer insulators for emergency restoration and the

hardware and guying components are maintained in 20ft

storage containers for security and for easy of

transportation to job sites.

3.0 RECENT EXAMPLES OF OHTL EMERGENCY

RESTORATION BY LADWP

tensioner sites are sent to the site so that the work can be

started on placing anchors for the pullers and tensioners

Typically two foremen are sent to the jobsite to marshal

equipment and to communicate back to TC&M

headquarters.

One foreman is responsible for

mobilizing all required emergency materials to the

trouble locations. The second foreman is responsible

for mobilizing all equipment and other logistical support

such as hotels, food and lodging for the TC&M crews.

Next, all necessary critical emergency materials such as

conductors, splices, insulators, hardware and structures

are mobilized. If sufficient permanent steel is not

available or if there is foundation damage, the modular

lightweight IEEE Standard 1070 ERS structures are

brought to the jobsite along with the 20ft storage

container containing all the polymer insulators,

hardware and anchoring for these modular temporary

structures.

After the line is stabilized and the area around the line is

made safe for the general public and the workers, the

next priority is to restore the line either permanently or

temporarily considering the economic factors at that

time. In todays economic environment, the fastest

possible restoration scheme is usually the most

desirable.

At later dates during power plant

maintenance, temporary towers can be taken down and

permanent structures are rebuilt and the line restored to

its original permanent condition.

Since the mid 1980s TC&M crews have had to restore

several major OHTL failures. Most of these failures have

been on the +/- 500kV HVDC Celilo-Sylmar (DC

Intertie) transmission line. Other failures on 230kV

transmission lines have been due to a variety of causes

such as earthquakes and lightning strikes on wood poles.

The next section will briefly discuss some of the failures

on the DC Intertie and failures due to the 1994

Northridge earthquake.

3.1 GENERAL RESTORATION PROCEDURES

3.2 FAILURES ON THE DC INTERTIE

When an overhead transmission line failure occurs the

first job is to find the trouble location. Weather

permitting, helicopters are sent to find the trouble

location and to report back. When the helicopter is sent,

either a transmission patrolmen or a foreman from

TC&M is sent along with the helicopter in order to

report back.

The first priority is to ensure the safety of the general

public and the workers at the jobsite and to prevent

further damage and/or cascading of the transmission

line. Transmission patrolmen are sent directly to the

jobsite in order to ground any conductors and to start

snubbing operations of the downed conductors.

Snubbing equipment consists of a variety of anchoring

equipment, winch trucks, conductor splices and grips.

In addition preplanned layouts of conductor puller and

Publication Number 07T-001 LADWP 8-2002

Between 1984 and 1986 the DC Intertie was uprated with

several of the guyed suspension towers raised 2.1 to

6.4m. This was done by adding mast sections and

lengthening guy wires without moving guy footings. On

three different occasions sabotage has brought down

these guyed towers. But the most extensive failures

began in January 1988 when sixteen guyed and one self

supporting tower collapsed due to high winds and

cascading. Both of these incidences have been discussed

previously and will not be discussed here [2], [3].

In February 1989 eight more guyed and two self

supporting towers collapsed again due to high winds and

cascading. From 1990 to 1992 the DC Intertie line was

upgraded by reguying, moving footings and replacing

defective hardware.

This upgrade has effectively

prevented any further cascade type failures. However,

isolated failures have still occurred. All of these failures

were quickly restored by TC&M crews. The following is

a brief summary of each failure and their restoration.

Indian Wells site and assembled the tower for erection,

completing the restoration (see figure 4).

3.2.1 1989 STORM DAMAGE

At 1:20 p.m. on Saturday, February 4, 1989, high winds

again damaged the DC Intertie. Eight guyed towers, one

self-supporting angle and one self-supporting suspension

tower were destroyed. The 2312 kcmil conductor and

static wires in those 11 spans were too damaged to be

reused, requiring the installation of approximately 16 km

of 2312 kcmil conductor and 8 km of static wire.

The Owens Gorge transmission line encountered

structural damage to six towers. The 954 kcmil

conductor was down on seven spans and required

replacement of approximately 5 km of 954 kcmil

conductor. The damage to the Owens Gorge line was

caused primarily by the falling of the DC Intertie

structures and conductors.

TC&M personnel immediately activated their emergency

response plan. After the initial single point contacts for

the support functions were established, the Supervisors

started the transporting of material and equipment to the

soon-to-be established marshalling yard at Indian Wells.

A remote command post was set up at Indian Wells to

control: material and equipment delivered from Los

Angeles; supply and personnel needs; lodging; meals;

crew assignments; timekeeping; and progress logs.

By 3:30 p.m. on February 4, the available on-duty

Transmission Section personnel in Valley, Victorville and

Los Angeles were to report to TC&M for instruction.

The Transmission personnel were into the first day of the

scheduled days off, and approximately 50 percent of the

transmission line series personnel were off shift.

However, by 9:00 p.m. of that day, all Transmission offduty supervisors were called out to travel and report to

the Indian Wells damage site.

The major tasks were divided into two areas: the Owens

Gorge line restoration and the DC Intertie restoration

which included the assembling and erection of eight instock guyed suspension towers, as well as anchor

installation, pad development, and erection of three IEEE

Standard 1070 ERS structures to replace the two selfsupporting towers.

The Owens Gorge- transmission line was Okayed for

service on the evening of Sunday, February 11, and the

DC Intertie on the following Thursday, February 16.

The permanent restoration of the DC Intertie was

contingent on delivery of self-supporting tower steel, and

the availability of DC Intertie. During the week of March

27, the northern crew transported the tower steel to the

Publication Number 07T-001 LADWP 8-2002

Figure 4

Permanent restoration of a self-supporting DC Intertie

tower. The de-energized conductors are supported in the

ERS, and the Owens line is shown at the right.

3.2.2 1995 STORM DAMAGE

On December 12, 1995, at 7:53 a.m., a guyed suspension

tower of the DC Intertie collapsed under heavy wind.

This tower had a height of 36m from the base to the

crossarm elevation and was one of the towers that

collapsed in 1988 as part of the wind cascade failure that

took down seventeen other towers.

The tower was permanently replaced using spare guyed

tower components stored in the Mojave Yard.

Approximately 100m of subconductor were replaced, and

the remaining conductor was repaired by sanding and

adding sleeves. The replacement tower was assembled,

erected, and secured by the night of December 13. On

December 14, all other restoration work was completed,

and the line was available for service by 4:00 p.m.

3.2.3 1998 AIRCRAFT COLLISION WITH TOWER

On September 20, 1998, at 4:38 p.m., a twin-engine

Cessna sliced through conductors and hit and destroyed a

self-supporting tower on the DC Intertie. The aircraft

burst into flames along the right-of-way just 20m from a

housing development.

LADWP crews immediately responded. They grounded

and snubbed the conductor to prevent further damage (see

figure 5), and a roadway under the line was barricaded for

public safety. As a similar self-supporting tower was not

available, LADWP crews installed a temporary IEEE

Standard 1070 ERS structure. Due to the close proximity

of residential houses, a steep down guy angle was

required. This was quickly analyzed using the emergency

restoration structure structural analysis computer

programs.

Crews work around the clock using night lights.

Conductor hardware and insulators were replaced on the

adjacent tension tower and new conductor was spliced in

and sagged. Spacers were installed and the line energized

within 36 hours after the start of the outage.

responsibility given to the staff and crews of TC&M has

promoted an esprit de corps in that organization which

fosters cooperation among the personnel of the TC&M

Group.

Granted, this type of capability will not be feasible for

every utility. However, every utility and transmission

line asset owner should address its own needs by a

careful review of emergency service contracts, available

emergency equipment and stocks of emergency

materials, and most importantly their plans for dealing

with emergency situations.

Figure 5

Snubbing the twin bundle 2312kcmil conductor with

conductor grips and a winch truck. Note the residential

area to the left of the damaged tower.

3.3 THE 1994 NORTHRIDGE EARTHQUAKE.

At 4:31 a.m. on January 17, 1994, the 6.6 magnitude

Northridge earthquake hit Los Angeles. For the first time

in the history of LADWP the entire city of Los Angeles

went black. Only one transmission line was operational.

A four circuit 230kV transmission tower, that normally

brings 1500MW of power from the Castaic pump storage

generating station north of the city, was completely

destroyed, and several other towers were severely

damaged. It was vital to restore one circuit of this line to

support the black start procedures for the fossil fuel

generating stations. Adding to the difficulty was the

damage to several roadways leading to the site.

Within eight hours after the earthquake, TC&M Crews

were able to bring in a crane and assemble a vertical

string of polymeric insulators and conductor travelers to

lift one circuit and allow it to be energized (see figure6).

In order to support the load that was being brought back

on line, two more circuits of this critical 230kV line

needed to be restored. In order to accomplish this a

special double circuit narrow right-of-way ERS structure

made from the same IEEE Standard 1070 components

was erected next to the energized circuit in the crane (see

figure 6). By the morning of January 19, all three circuits

were energized.

4.0 CONCLUSION

The ability to quickly react to any transmission line

emergency at LADWP is due in large part to

managements decision to maintain a skilled, trained inhouse workforce and to provide them the necessary

equipment and materials to perform the job. The

Publication Number 07T-001 LADWP 8-2002

Figure 6

One circuit at the left is supported by the crane; two other

circuits are supported by an IEEE Standard 1070 ERS.

5.0

REFERENCES

[1] IEEE Guide for the Design and Testing of

Transmission Modular Restoration Structure

Components, IEEE Std 1070-1995, ISBN 1-55937592-2.

[2] J. C. Pohlman, K. E. Lindsey, L. N. Agrawal, A. K.

Kapur, Practical Steps for Increasing Availability of

Existing Overhead Lines, (CIGRE Paper 22-105,

Paris 2000).

[3] S. A. Rutty, et. al., Planning Ahead Proves

Invaluable to the Rapid Restoration of the Pacific

DC Intertie and Owens Gorge Transmission Lines,

(11th IEEE/PES Transmission and Distribution

Conference, New Orleans, Louisiana, April 2-7,

1989).

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Fail Safe Insulator BasesDokument7 SeitenFail Safe Insulator BasesLindseyusaNoch keine Bewertungen

- Distributed Horizontal Dumping RollerDokument2 SeitenDistributed Horizontal Dumping RollerLindseyusaNoch keine Bewertungen

- Distribution Rollers Multi ConductorDokument2 SeitenDistribution Rollers Multi ConductorLindseyusaNoch keine Bewertungen

- Distributed String Roller Lindsey Manufacturing CoDokument1 SeiteDistributed String Roller Lindsey Manufacturing CoLindseyusaNoch keine Bewertungen

- Distributed Speciality String RollerDokument1 SeiteDistributed Speciality String RollerLindseyusaNoch keine Bewertungen

- 07t 003 Colombia RestorationDokument15 Seiten07t 003 Colombia RestorationLindseyusaNoch keine Bewertungen

- Distributed String Roller Lindsey ManufacturingDokument1 SeiteDistributed String Roller Lindsey ManufacturingLindseyusaNoch keine Bewertungen

- Philippine ExperienceDokument10 SeitenPhilippine ExperienceLindseyusaNoch keine Bewertungen

- Ferc1000 MarchDokument2 SeitenFerc1000 MarchLindseyusaNoch keine Bewertungen

- LINDSEY ERS Questionnaire 1Dokument8 SeitenLINDSEY ERS Questionnaire 1LindseyusaNoch keine Bewertungen

- Emergency Restoration SystemDokument15 SeitenEmergency Restoration SystemmhergonzalesNoch keine Bewertungen

- Pole Line Hardware Horizontal Clamp Adapter PDFDokument2 SeitenPole Line Hardware Horizontal Clamp Adapter PDFLindseyusaNoch keine Bewertungen

- Pole Line Hardware Fail Safe BasesDokument5 SeitenPole Line Hardware Fail Safe BasesLindseyusaNoch keine Bewertungen

- Pole Line Hardware Double Arming BracketsDokument1 SeitePole Line Hardware Double Arming BracketsLindseyusaNoch keine Bewertungen

- Dynamic Line Rating SystemDokument2 SeitenDynamic Line Rating SystemLindseyusaNoch keine Bewertungen

- Tie Top Vertical Clamps 10 2015 PDFDokument1 SeiteTie Top Vertical Clamps 10 2015 PDFLindseyusaNoch keine Bewertungen

- Pole Line HardwareDokument2 SeitenPole Line HardwareLindseyusaNoch keine Bewertungen

- Pole Line Hardware Dead End AdapterDokument2 SeitenPole Line Hardware Dead End AdapterLindseyusaNoch keine Bewertungen

- Dynamic Line Rating As A Means To Enhance Transmission Grid ResilienceDokument7 SeitenDynamic Line Rating As A Means To Enhance Transmission Grid ResilienceLindseyusaNoch keine Bewertungen

- Canductors Clamps, Lindsey Manufacturing Co.Dokument1 SeiteCanductors Clamps, Lindsey Manufacturing Co.LindseyusaNoch keine Bewertungen

- Real Time Transmission Line Conductor MonitorDokument2 SeitenReal Time Transmission Line Conductor MonitorLindseyusaNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- State Common Entrance Test Cell: 3001 Jamnalal Bajaj Institute of Management Studies, MumbaiDokument9 SeitenState Common Entrance Test Cell: 3001 Jamnalal Bajaj Institute of Management Studies, MumbaiSalman AnwarNoch keine Bewertungen

- Nodal Analysis Collection 2Dokument21 SeitenNodal Analysis Collection 2Manoj ManmathanNoch keine Bewertungen

- SSC 211 ED Activity 4.1Dokument4 SeitenSSC 211 ED Activity 4.1bernard bulloNoch keine Bewertungen

- Kpolovie and Obilor PDFDokument26 SeitenKpolovie and Obilor PDFMandalikaNoch keine Bewertungen

- Tech SharmitDokument16 SeitenTech SharmitRishu SinhaNoch keine Bewertungen

- Discrete Random Variables: 4.1 Definition, Mean and VarianceDokument15 SeitenDiscrete Random Variables: 4.1 Definition, Mean and VariancejordyswannNoch keine Bewertungen

- Sip Poblacion 2019 2021 Revised Latest UpdatedDokument17 SeitenSip Poblacion 2019 2021 Revised Latest UpdatedANNALLENE MARIELLE FARISCALNoch keine Bewertungen

- Flange CheckDokument6 SeitenFlange CheckMohd. Fadhil JamirinNoch keine Bewertungen

- Grade 7 Hazards and RisksDokument27 SeitenGrade 7 Hazards and RisksPEMAR ACOSTA75% (4)

- How Should We Allocate Scarce Resources Over Our Business Portfolio?Dokument20 SeitenHow Should We Allocate Scarce Resources Over Our Business Portfolio?Vivek AryaNoch keine Bewertungen

- Week 1-2 Module 1 Chapter 1 Action RseearchDokument18 SeitenWeek 1-2 Module 1 Chapter 1 Action RseearchJustine Kyle BasilanNoch keine Bewertungen

- 7540 Physics Question Paper 1 Jan 2011Dokument20 Seiten7540 Physics Question Paper 1 Jan 2011abdulhadii0% (1)

- Mastering American EnglishDokument120 SeitenMastering American Englishmarharnwe80% (10)

- Paper:Introduction To Economics and Finance: Functions of Economic SystemDokument10 SeitenPaper:Introduction To Economics and Finance: Functions of Economic SystemQadirNoch keine Bewertungen

- Service Manual: NISSAN Automobile Genuine AM/FM Radio 6-Disc CD Changer/ Cassette DeckDokument26 SeitenService Manual: NISSAN Automobile Genuine AM/FM Radio 6-Disc CD Changer/ Cassette DeckEduardo Reis100% (1)

- Electromyostimulation StudyDokument22 SeitenElectromyostimulation StudyAgnes Sophia PenuliarNoch keine Bewertungen

- Fabric DefectsDokument30 SeitenFabric Defectsaparna_ftNoch keine Bewertungen

- Astm C119-16Dokument8 SeitenAstm C119-16Manuel Antonio Santos Vargas100% (2)

- Basics of Petroleum GeologyDokument23 SeitenBasics of Petroleum GeologyShahnawaz MustafaNoch keine Bewertungen

- Brochure - Actiwhite PWLS 9860.02012013Dokument12 SeitenBrochure - Actiwhite PWLS 9860.02012013J C Torres FormalabNoch keine Bewertungen

- Cognitive Coaching AdelaideDokument3 SeitenCognitive Coaching AdelaideBusiness-Edu100% (2)

- AnkitKumar InternshalaResume PDFDokument2 SeitenAnkitKumar InternshalaResume PDFkusha010Noch keine Bewertungen

- Matrix CPP CombineDokument14 SeitenMatrix CPP CombineAbhinav PipalNoch keine Bewertungen

- Diagnostic Test Everybody Up 5, 2020Dokument2 SeitenDiagnostic Test Everybody Up 5, 2020George Paz0% (1)

- Annotated Bibliography 2Dokument3 SeitenAnnotated Bibliography 2api-458997989Noch keine Bewertungen

- Libel Arraignment Pre Trial TranscriptDokument13 SeitenLibel Arraignment Pre Trial TranscriptAnne Laraga LuansingNoch keine Bewertungen

- Vicente BSC2-4 WhoamiDokument3 SeitenVicente BSC2-4 WhoamiVethinaVirayNoch keine Bewertungen

- List of Practicals Class Xii 2022 23Dokument1 SeiteList of Practicals Class Xii 2022 23Night FuryNoch keine Bewertungen

- Catalog de Aparatura Si Instrumentar Veterinar Eikemeyer-GermaniaDokument336 SeitenCatalog de Aparatura Si Instrumentar Veterinar Eikemeyer-GermaniaDr. Dragos CobzariuNoch keine Bewertungen

- 1000 Base - T Magnetics Modules P/N: Gst5009 LF Data Sheet: Bothhand USA Tel: 978-887-8050Dokument2 Seiten1000 Base - T Magnetics Modules P/N: Gst5009 LF Data Sheet: Bothhand USA Tel: 978-887-8050DennisSendoyaNoch keine Bewertungen