Beruflich Dokumente

Kultur Dokumente

Artificial Lift Equipment Power Cables

Hochgeladen von

Michelle Valery0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

31 Ansichten22 SeitenPatent

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenPatent

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

31 Ansichten22 SeitenArtificial Lift Equipment Power Cables

Hochgeladen von

Michelle ValeryPatent

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 22

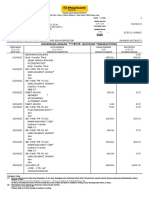

c2) Patent Application Publication

cu») United States

Holzmueller et al.

6,

(71) Applicant: Seht

Corporation,

sugat Land, TX (US)

(72) nventors: Jason Holemueller, Lawrence, KS (US)

Patriek Zhiyuan Ma, Laverence, KS

(US): Gregory H. Manke, Overland

k, KS (US); Mark A. Metzger,

Lawrence, KS (US); Melissa Ver Meer,

Shawnae, KS (US); Sayak Datta,

Lawrence, KS (US)

Schlumberger Technology

Corporation, Sugar Land, TX (US)

(13) Assignee:

21) Appl. No.

(22) Filed

137893,826

May 14,2013

Related US. Application Data

(60) Provisional application No, 61/648,826, filed on May

18,2012.

S00,

US 2013030634841

(10) Pub. No.: US 2013/0306348 Al

(43) Pub. Dat Nov. 21, 2013

Publication Classification

6) ea.

HOB 902 (2006.01)

(32) US.CL

cP Ho 902 (2013.01)

usp 174/105 R: 174/107; 427/118

(s) ABSTRACT

A power cable fr artical lift equipment can include one oF

more conductor assemblies, each including a copper conduc

tor, a conductor shield with resistivity less than about 5000

‘ohn surrounding the conductor, insulation, an station

Shield having a resistivity less than about 5000 ohm-m sur

rounding the insulation, « metallic shield surrounding the

insulation shicld, and a polymer barrier surrounding the

metallic shield, Such a eable may include a jacket molded

fhout the one or more conduetor assemblies and optionally

larmor sorronnding the ocket, Varios other apparatses, 88

tems, methods, et. are also disclose.

510 Conductor

so ogee

520 fsuston

4-5 ies

ceo 827

lays)

Patent Application Publication Nov.

Management Components 110

Other

Information

14

Seismic

Data

112

130

Analysis!

Visualization

142,

Attribute

21,2013 Sheet 1 of 9

system 100

' Framework 170

' Domain

' Objects

! Modules 175, 182

| Data

i Source

1 184

Model

! ‘Simulation 180

| Rendering

186

'

'

I Framework =

vices 1 t

| eee Interfaces

i 188

'

'

'

'

Geologic Environment

(eg., sensing, driling, injecting, extracting, etc.)

>

150

° lit

41000 i i ee

an Attica

3000

4000

5000

US 2013/0306348 A1

Patent Application Publication Nov. 21, 2013 Sheet 2 of 9 US 2013/0306348 A1

Geologic Environment 200

Patent Application Publication Nov. 21, 2013 Sheet 3 of 9 US 2013/0306348 A1

ay ESP System 300

controlier ‘Supply

Eo

ESP Motor VSD Unit

Controller | 320

‘Well

Sensor(s)

320

350

backspin

Gas

Handler

313

[sur |

tA;

‘Temperature

MTBFs

318

Sensor(s) Controller 330

26

UniConn 382 ECLIPSE 386

PIPESIM 384 PETREL 388

Patent Application Publication

I

Uphole/Surface

Downhole

|

WYE Point

425

Power Source 401

vsD/Step-up

Transformer(s)

470.

Power

Slate A: Normal

State B: Ground Fault

Nov. 21, 2013 Sheet 4 of 9

US 2013/0306348 A1

Data 402

Communication

430

oc

Circuitry | Power

4

Ea Data

Fig. 4

Sensor(s)

460

Patent Application Publication Nov. 21, 2013 Sheet 5 of 9 US 2013/0306348 A1

510 Conductor

J Conductor

AS 80 shield

) Insulation

5840

shield

Metallic

550 shield

Barrier

69 ayers)

570

Cable

jacket

580

‘Armor

590

‘Armor

Patent Application Publication Nov. 21, 2013 Sheet 6 of 9 US 2013/0306348 A1

610 Conductor

Conduetor

shield

630 Insulation

ao Msulation

Metallic

$0 shield

60 Barrier

layer(s)

670 Braid

Layer

Patent Application Publication Nov. 21, 2013 Sheet 7 of 9 US 2013/0306348 A1

m2 714 105

m1

710 |

2114 yor

m4 714

710

m2

na

1

m2

Patent Application Publication

Nov. 21, 2013 Sheet 8 of 9 US 2013/0306348 A1

Method 800

Select Materials 810

Construct Cable(s) 820

Deploy 830

Transmit Power 840

Fig. 8

Patent Application Publication Nov. 21, 2013 Sheet 9 of 9 US 2013/0306348 A1

‘System Components 200.

Memoryistorege

VO Device 206

Network System 910,

‘Component(s)

US 2013/0306348 Al

IAL LIFT EQUIPMENT POWER

‘CABLES

RELATED APPLICATIONS.

[0001] This pplication claims the benefit ofan priority 0

US, Provisional Application See. No, 61/648.326, fled 18

May 2012, which is incorporated by reference herein,

BACKGROUND,

10002} _Avttval it equipmentsuchaseletrie submersible

‘pumps (ESPs) may be deployed for any ofa variety of pam

dng purposes. For example, where a substance Jose not

realy flow responsive o existing natura forces, an ESP may

be iasplemeated wo arial Bi the substance. To receive

posse, an ESP is connected to a cable or cables. In some

stances, the length of sich cable o cables may be othe

coder of several filomcers. 4 cable may also ince one oF

‘more motor lad extensions (MIs) splice onto the cable

Forexanple, where the cable inches thre conductor cares

for powering a motor. a MLE may be splieeont each of the

conductor cores. Length of a MLE may be, For example, on

the onder of tens of meters ar mow (2, about 20 meters

bout 100 meters)

{0003} Some examples of available PSP cables include

those fated at about 3 KY, about 4 KV’ or about § KV. For

commercially avilable BSP cables, about 5 KV may be eon

Sider 2 peesent day Uppee ating limit forhigh temperature

dlownolseables (edo toa ack of electra ses li?

layers ete)

{0004} As may be appreciated, ESP configurations open.

Sons, ete. can depend on cable rating or integrity. Ax an

‘example, ibility data fran ESP cable may be primary in

‘stmatinga meantime between fire (MBE foranepen

tion. Fale of & cable ean increase non-productive ie

(NPT), rpairandreplacementcosts ete espa for doop

insalations (eq, whore over a kilometer af cable may be

deployed.

0005} Various technologies, techniques, te, described

Ihren pertain to cables, for example, to provide power to

cleetcally powered equipment positionable in a well

SUMMARY

10006] A power cable for artificial Kit equipment can

inchide one or more conductor assemblies where each con-

ductor assembly includes a copper conductor, a conductor

shield with resistivity fess than about $000 odm-m surround-

ing the conductor, insulation, an insulation shield having a

resistivity less than about $000 obm-m surrounding the inst

lation, metlli shield surrounding the insulation shield, and

‘polymer barrier surounding the metallic shield; «jacket

molded about the one oF more conductor assemblies: and

frmor surounding the jacket. A power eable for downhole

‘equipment can include a copper conductor; a conductor

shield with resistivity fess than about 5000 ofm-m surround-

ing the eonductor, insulation; an insulation shield having a

resistivity less than aboot $000 obim-m surrounding the insu

lation; a metal shield surrounding the insulation shiek

polymer barrier surrounding the metallic shield; a braided.

layer surrounding the metalic shield; and armor surrounding

the braided layer. method ean include providing a conduc

tor: providing a semiconductive material: providing an ins

lating material; extrading a portion of the semiconductive

‘material onto the conductor; extring the insulating material

Nov. 21, 2013

‘onto te semiconduetive material: and extruding another por:

tion of the semiconductive material onto the insulating mate-

al

[0007] Thissummary isprovidedto introduce selectionof

concepts that are further deseribed helow in the detailed

description. This summary is not intended to identity key oF

cssential features of the claimed subject matter, nor is it

intended to be used as an aid in limiting the scope of the

claimed subject mater,

BRIEF DESCRIPTION OF THE DRAWINGS

0008] Feotures and advantages of the described imple-

mmentations ean be more readily understood by reference 9

the following description taken in conjunction with the

accompanying drawings.

[0009] FIG. 1 illustrates an example of «system that

includes various components for simblating and optionally

interacting with geological environment;

0010] FIG. 2itstrates an example of geologic environ-

‘meat that includes steam injection and artificial i

0011] FIG. 3 llustatesan example ofanclecticsubmers-

ible pump system:

[0012] FIG. 4 illustrates an example of a system that a

power cable and motor lad extensions:

[0013] FIG. 5 illustrates an example ofa power eable:

[0014] FIG. 6 illustrates an example of a motor lead exten-

[0015] FIG. 7 illustrates examples of methods and

‘examples of cables;

[0016] FIG. 8 illustrates an example ofa method; snd

[0017] FIG. 9ilustrates example components ofa system

and a networked system,

DETAILED DESCRIPTION

[0018] The following description includes the best mode

presently contemplated for practicing the described imple-

‘mealations. This deseripion is aot to be taken in a limiting

sense, but rather is made merely forthe purpose of describing

the general principles ofthe implementations. The seope of

the described implementations should be ascertained with

reference tothe issued claims

0019] _Artificiol Hit equipment suchas electric submersible

‘pumps (ESPs) may be deployed for any of variety of pammp-

ing purposes. For example, where a substance does not

reachlyflow responsive to existing natural forees, an SP may

be implemented to arficially it the substance. Commer-

cially available PSPs (suchas the REDA™ ESPs marketed by

‘Schlumberger Limited, Houston, Tex.) may find use in appli-

cations that require, for example, pump rates in excess of

about 4,000 barrels per day aud lft of about 12,000 feet or

0020] ESPs have associated costs, jnchuding equipment

costs, replacement costs, repair costs. and power consump-

tion costs. Selection of appropriate ESP specifications can be

anarcuous task especially yiven the fat that any factorsare

‘dynamic and even stochastic. For example, composition of a

‘pumped substance may vary over time, gost of eletrical

power may vary overtime, entrainment of solids may vary

‘overtime, ete, The ability o prect variations in such factors

‘with respect to time may spaina spectrum from poor to exeel-

lent (eg, depending on available dat, models, et). Punter,

adjusting operation of an ESP fora change in ane factor may

sive rise fo unintended consequences. For example, a change

US 2013/0306348 Al

in cost of power may pve rise toa need to operate a pump

‘motor with greater eificiency, which in turn, may alter inlet

‘presure othe pump, which, in ten, may cause & change in

‘phase composition of a substance being pumped, which, in

‘um, nay impact the ability of conteifgal pump slages 0 Kit

the substance, Where a chinge in phase includes an inerease

in free gas (eg, approaching 10% by volume), a condition

known as gas Tock may occur, form of cavitation that can

‘cause a pump to surge and fil prematurely.

[0021] To assist with selection of ESP specifications, a

rmanvfacturer may provide a plot witha pump perfoemance

‘cure that defiaes an optimal operating range for a given

‘pump speed and Muid viscosity. Such a plot may include a

hhead-capacity curve that shows amount of hit per pump stage

ata given flow rate, a horsepower requirements curve across

a range of flow capacities, and a pump efficiency curve, for

‘example, calculated from head, flow capacity, fui specific

‘enwily and horsepower. As an example, an ESP may be

specified as havinga best efficiency point (AEP) ofabot 77%

for a flow of about 7,900 barrels per day, ahead of about 49

fect anda horsepower of about 3.69 fora lid specific gravity

‘of approximately 1.0(e,REDA S38 Series, I stage at3.500

RPM at 60 Fz) An ESP may be specified witha it pr stage

such that number of stages may be selected Foran applica-

tion to moet ff requirements.

10022] Adjustments may be made to an ESP, for example,

Where the ESP is outlted witha variable-speed deve (VSD)

‘nit. A VSD unit can include an ESP controller sich a, for

‘example, the UniCona"™ coatroller marketed by Seblum-

‘berger Limited (Houston, Tex). In combination, a VSD unit

withan ESP controller alloss for variations in motor speed 0

pump optimal yates at variable frequencies, which ean bester

manage power, het, ee. As to hea generated by a motor, an

ESP may rely on low of pumped fd for eooling such thst a

change in motor speed ean change steady-siate operating

tomperature ofthe motor and, crrespondingl. efficieney of

the motor, Given such relationships, tade-ofls ean exist, for

‘example, between motor lifetime, power consumption and.

ow rate,

[0023] To improve PSP operations, an ESP may include

‘one of more sensors (e32, gages) that measure any of a

variety of phenomena (eg temperature, pressure, vib

te), A commercially avail

Sensor'™ marketed by Schlumberger Limited (Houston,

“Tex.)which monitors intake andl discharge pressures;

‘motor and discharge temperature; and vibration and current

leakage. An ESP monitoring system may include a supervi-

sory control anddata acquisition system (SCADA), Commer:

iaily’ available surveillance systems inchide the

‘espWatcher™ and the LiftWateher™ surveillance systems

marketed by Schlumberger Limited (Houston, Tex), which

provides for communication of data, for example, between a

production team and wellfild data (e.g, with oF without

SCADA installations). Such a system may isue instructions

'o, for example, stat, sop or contol ESP spoed via an ESP

controler.

0024] As an example, a commercially available surface

use cable rated for voltages higher than sbout $ KV may be

round and based on NEMA WC TV/ICEA $-96-659 and WC

TAICEAS.93-639. Such a cable may include the following:

‘copper conductor, a semiconductive conductor shicll layer,

an insulation layer, semiconductve insulation shield layer

‘conductive metallic shield layer (eg, metalic braid or tape

rap, with copper), a cable jacket (polyethylene), and amor

Nov. 21, 2013

(galvanized steel). However, in comparison to surface envi-

‘ronments, downhole environments may be bash in tems of

‘temperature, pressure and chemistry. Further, dow hole envi-

ronments may be harsh meehnically, For example, consider

Abrasion and mechanical stresses that may acche as a cable

‘raverses hundreds of mcters, especially where the cable ear

es the weight of equipment such as an ESP. Yer futher, a

downhole installation that may haves lengthofakilometer or

‘more may offer litle opportunity for filtering, ete. to handle

clerical issues suchas voltage spikes (¢g..dueto resonance,

‘t.). Additionally, information about downhole equipment

‘may be limited in comparison to a surface operation. For

‘example, where a surface mounted motor may be readily

fied with sensors, ef, and associated data transmission

lines, data transmission ine fora downhole motoemay beso

Jong that data bandwidth and data integrity become problem-

atic. Lack of information about operating conditions of a

‘downhole motar may increase risk oF issues that could detr-

‘mentally impact eable performance and reliability. Aecord-

ingly, downhole operations present Tactors not present in

surface operations (¢.,ornot present to the same extent asin

Surface operations)

0025] As 10 power cables suitable for downhole opera-

tions, asan example, ound ESP cable ated for operation up

to about $V can include one or mare copper conductors, oi

and heat resistant EPDM eubber insulation (eg, where The E

refers to ethylene, P to propylene, Dt diene and M refers to

4 classification in ASTM standard D-1418; eg, ethylene

‘copolymerized with propylene and a diene), a barrier layer

{©4 leadlforopolyine ornoneforlow cost cables}, a jacket

(eg, oll resistant EPDM or nitrile rubber) and anor (ex.

galvanized or stinlessstee! or MONEL® alloy marketed by

Inco Alloys Intemational, Inc, Huntington, W. Va.). As

another example, a at ESP cable for operation up w about S

KV can include one or more copper conductors, oi and heat

resistant EPDM rubber insulation, barrier layer (e.g, lead

fuoropolymer or none for low cost cables). jacket layer (il

resistant EPDM or nitrile rubber o none for low cost cables),

and armor (galvanized or stainless steel or MONELIE alloy

‘marketed by Inco Alloys Intemational, Ine., Huntington, W.

Vay

0026] As an example, an insulation material for @ cable

:nay be EPDM, EPDM compounds tend to have good dielee-

trie properties and heat resistance, but fend to be susceptible

to swelling whea exposed to hydrocarbons. In downhole oil

field applications, permeation of outer layers ofa eable by

‘uid may result in fuid contoeting the insulation. To mitigate

such risks, PSP cable manufacturers may use proprciary

EPDM compound formulations designed to limit the effecis

‘of hydrocarbons. Such formulations may be refered to as

Jow-swell EPDM or oil resistant EPDM,

0027] sto particular gas risks, as an example, considera

downhole envieonment at elevated pressures (e.., greater

than about 1,000 ps), which may cause gas intrusion into an

SP, an ESP cable ete In such an example, where hydrogen

sulfide (H,S) gas is present at elevated pressure it may per-

mate through elastomers and corrode copper conductors of |

insufficiently robust cables. Further, once downhole gases

have permeated a cable, a rapid change in well pressure can

cause explosive decompression damage, rendering a cable

inoperable

0028] Flastomer compounds that may be found in com-

‘mercially available ESP eable jacketing (eg. EPDM andor

nile) fend to be proprietary oilfield formulations. EPDM

US 2013/0306348 Al

based jacketing materials, as with EPDM insulation materi-

al, tend to be formulated for il and decompression resis

tance, Nitrile compounds have inherent oil resistance, how

‘ever, asan example, some oiled specific nitrile compounds

‘aim to combine oil resistane with brine nd water resistance

‘8 well ws decompression resistance and good heat aging.

10029] As an example of a commercially available power

cables suitable for downhole use, consider the the

RedaMAXT™ Hotline™ ESP power cables (eg a8 well as

‘motor lead extensions “MLES"), which are marketed by

Schlumberger Limited (Houston, Tex.). As an example, a

RedaMAX™ Fotline™ ESP power cable can include com-

binations of polyimide tape, lead, EPDM, and polyether ether

ketone (PEEK, ez, oranother poly aryl ether ketone (PEK)

type of polymer) to provide insulation and a jacket. Lead

walls can provide for compatibility with high gasil ratio

(GOR) and highly corrosive conditions. Armor can mechani-

cally protect the cable and may be galvanized steel, heavy

‘galvanized steel, sianless steel, or MONEL® alloy. As an

‘example, a pothead, an electrical connector between a cable

and an ESP motor, may be constructed with metal-to-metal

seals or elastomer seals, A pothead ean provide mechanical

bracrer to fui entry in high-temperature applications.

[0030] ‘The RedaMAX™ Hoaline™ ESP power eables may

‘be suitable for we in wells with high botfombole tempers:

tures, steamflooding and thermal recovery applications, go0-

‘themnal applications, gassy wells, wells with corrosive ius,

inchuding 14S. CO,, and chemical treatments

[0031] As an example of a RedaMAX™ Hotline™ ESP

power cable, a 5 kV round ELBE GSR can include solid

‘conductor sizes of about #1 AWG (e.g. 1 AWG), bout #2

‘AWG (eg.,2AWG/I) and about #4 AWG (eg. 4 AWG). AS

tp conversion to metric, #1, #2 and #4 AWG correspond to

approximately 42.4 min?, 38.6 mm and 21.1 mim’, respec

tively. As another example, 2 5 KV flat EHLTB GSF ean

inchide ssolidconductorsize of 4 AWG (e.8,4AWGII).A8

an example, dimensions may be, for round configurations,

About 110 2 inches in diameter and, for Mat configurations,

about half an inch by about 1 inch to about 2 inches. As an

‘example, weights may range from about I Thnvi to about 3

Ibm

10032] Various examples of power cables and various

‘examples of method for making a power eable (eg, or a

portion thereof) are described herein. Such power cables can

include atleast one ayer formed ofa semiconduetive mate-

tal, For example, a cable may include a semiconductive

‘conductor shield and a semiconduetive insulation shield. In

sch an example, semicondctive material may be fed via an

‘exinkler orextniders for deposition onto another ayer (ea

conductor and an insulation layer, respectively). As an

‘example, insulation or an insulation layer may be deposited.

Via extrision onto a conductor shield via an extrusion pro=

‘ess, optionally a co-extrusion process that deposits both the

‘conductor shield and the insulation (eg. Which may allow for

crosslinking at an interface therebetween), As an example,

‘an insulation shield may be deposited onto insulation in a

‘manper tha fclitates stripping ofthe insulation shield from

‘the insulation, for example, for purposes of spicing a eon-

«ductor about which the insulation is deposited (esx, with an

intermediate conductor shield)

10033] As an example, a cable suitable for downhole use

tay be constrocted with materials having properties resistant

to conditions associated with a corrosive willeld environ

Nov. 21, 2013

ment, resistant hydrocarbons, resistant to high pressure

tpises, andlor capable of operating at temperatures above

about 180 degrees C.

[0034] _Asanexample, a power cable may incite multiple

‘conductors where each conductor has an associated condic-

tor shield, insulation, insulation shield, metallic shield, and

barrier layer. For each conductor, such a layered assembly

may be referred to as a single conductor cable. Fora power

‘cable that includes maltiple conductors, configured as mul-

tiple single conductor cables, a cable jacket may be provided

‘that jackets the multiple single conductor cables, Further, one

‘or more armor layers may surround the eable jacket

0035] Asan example, a motor lead extension (MLE) may

hea single conductor cable. Such # single conductor cable

‘may include a conductor, 2 conductor shield, insulation, an

insulation shicld, a metalic shield, « bariet layer, « braid

layer, and armor. Where conductor has eyindcal shape,

the variouscomponents may besnnularin shape of inereasing

liameter where thickness of each annular component is

selected, for example, according to function to provide suit-

able physical characteristics for purposes of withstanding

‘operational conditions, including electwomagnetic andl envi-

ronmental conditions. Such an arrangement of components

‘may be coaxial, for example, various components may be

arranged couxilly about a coudector, which may bea solid

‘conductor, a braided conductor, et

[0036] As an example, (ez, fo lower cost, ease spooling,

cle.) MLEs may be consolidated into an N-across flat cable

(eg, where N equals a number of conductors). In sueh an

‘example, each conductor may haven individual armor jacket

‘where a overall additional armor layer helps ote the indi

‘vidual armor jacketed conductors together. Asan altemative

‘example, consolidated! MLEs may include an overall armor

layer (eo jacket). In the foregoing MLE examples, an

‘outer jacket may be individual, consolidated, or skipped

‘entirely.

0037] Ast conductors, for example, a cable may include

conductors of high purity copper, which may be solid,

‘runded oF compacted stranded. Stranded and compacted

Stranded conductors can offer improved flexibility, which

may be an advantage in some installations. Conductors may

also be coated with a corrosion resistant coating to prevent

‘conduetordepradation from the hydrogen sulfide gas Whieh s

‘comimioniy present in dovinhole environments. Fxamples of

such a coating would inelude tin, lead, nickel, silver, or other

‘corrosion resistant alloy of meta

0038] Ast conductors, compacted strands provideacom-

bination of fexibilty and reduced cross section. A costing

may be applied toa conductor, for example, to prevenslans

corrosion of eopper by downhole gases. Such a coating may

bbe compatible with a subsequent process (eg., conductor

shiold extrsion, etc.) As an example, a coneosion resistant

coating may be provided in an effort to prevent conductor

degradation front 5 gas. Sich a coating may include, for

‘example, tn, lead, nickel, iver, or another corrosion res

tant alloy or metal

0039] "As an example, a gas-blocking coating may he

applied toa conductor, for example, an Amalloy™Tead-based

‘metal alloy may be applied to one or more conductors (4.10

Ine block gas such as gas that includes H,8)-

[0040] As to conductor shields, conductor shield may be

asemiconductve layer around the conductor (eg. optionally

inchuding a costing) that ats to contol electrical stress in a

cable to minimize discharge. Such a layer may include a

US 2013/0306348 Al

thickness of about 0,002" to about 0,020", Such a layer may

be bonded tothe conductor (2. optionaly including a coat

ing) and insulation to prevent was migration or it may be

strippable to allow for easy cable repair. splicing, ete. As an

‘example, a strippable conductor shield ean assist with easy

‘cablerepairand splicing. Whether or nota conductor shields

‘bonded may depend on the application,

10041} Asan example, a conductor shield may bea semi

‘conductive tape wrap or an extruded semiconductive polymer

‘composition. Such & layer may be an elastomer or themo-

plastic eo-extruded with insulation. As an example, €0-ex-

tmuded elastomer inslation shield and inslation may allow

for crosslinking the insulation shield and insulation matei-

als. Covextnided thermoplastics may provide for intimate

bonding (¢., optionally without cross-linking). Such manu-

facturing processes can help eliminate voide a the condactor

shield/instlation interface

[0042] As mentioned, material used for the conductor

Shield may be semiconductive, for example, defined as has=

ing resistivity les than about 000 chi-m. As an example,

an elastomer (e.g, FPDM) compound loaded with vondue:

tive fillers may be used. Asan example, for high temperature

‘and reliability improvement, « PEEK compound (or related

high temperature polymer) containing conductive or semi

conductive fillersmay beused, Selection of the optimum filler

type and filer quantity can help achieve an optiaum level of |

‘volume resistivity inthe compound. The insulation shield and

the insulation may include the same or similar material,

‘which ean facilitate processing,

[0043] _Astoa conductor shield, jt may have someadhesion

toaconductorto provides void-free interfue. Adhesion toa

‘conductor ean also help prevent downlole gases from migra

ing along a cable. Extrusion can provide a relatively smooth

surface (e.g. compared to tape) and tend tallow for penetra

lion of material into spaces between strands of « conductor,

‘Noting that, fora conductor shield regularities nits surface

‘may cause volage stress points. conductor shield may bean

clastomer or thermoplastic eo-extruded or tandem extruded

With insulation allowing the layers to cross-link together

(€., elastomer) or intimately “bond” (e, thermoplastic)

Which may help to eliminate voids atthe interface of these

layers. Such an approach can provide for discharge esistance

(eq. for EPDMand PAEK insulation materals).A conductor

shield may include several different elastomers. A condctor

shield may inelude nanoscale fillers (eto provide a com-

bination of low resistivity and good mechanical properties).

[0043] As to insulation, it may include a material sueh 2s,

Tor example, EPDM or, for example, for improved tempers

‘ureane reliability, PEEK may beused(¢ 2, oranotherPAEK

material) For FPDM-based insulation, 3 compound formu

Iation forol and decompression resistance may be selected.

As to PEEK, it ay provide improved mechanical properties

that allow for improved damage resistance during cable

installation and cable operation, Thehigher silliness of PEEK

nay also allow for greater ease in sealing over cable members

at cable termination points (motor potbead, well connectors,

feedthroughs, et.) Such eonstretion can improve relia

ity ofthe cable and of systems,

[0045] Insulation (ean insulation layer) may adhere to

‘or bo bonded to-8 conductor shield. Iasuation may be eon:

tinuous with an insolation shield, optionally completely or

partially bonded. As an example, a continuous defect-tree

Interface may be formed between instlation ands condactor

shield (eq, with some amount of adhesion). Cable connee-

Nov. 21, 2013

be considered weak points ofa system. AS

isulation can improve seal reliability

high temperature and improve sealing through thermal

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Baixar A Guide To The Project Management Body of Knowledge (PMBOK® Guide) - Seventh Edition and The Standard For Project Management (ENGLISH) PDF GrátDokument2 SeitenBaixar A Guide To The Project Management Body of Knowledge (PMBOK® Guide) - Seventh Edition and The Standard For Project Management (ENGLISH) PDF Gráteduelis0% (17)

- LG 23MT77V LW50A Schematic Diagram and Service ManualDokument34 SeitenLG 23MT77V LW50A Schematic Diagram and Service Manualaze1959Noch keine Bewertungen

- 3144Dokument16 Seiten3144Michelle ValeryNoch keine Bewertungen

- Mean Metal TempsDokument1 SeiteMean Metal TempsThiruppathi RajanNoch keine Bewertungen

- Lift PDFDokument15 SeitenLift PDFGuillermo LedezmaNoch keine Bewertungen

- Pupu Con Pipi LicuadoDokument2 SeitenPupu Con Pipi LicuadoMichelle ValeryNoch keine Bewertungen

- Us 20130193034Dokument10 SeitenUs 20130193034Michelle ValeryNoch keine Bewertungen

- ISA S5.1 - 2009 - SummaryDokument36 SeitenISA S5.1 - 2009 - SummaryMichelle Valery100% (1)

- 3 Additives: 3.1 AntioxidantsDokument16 Seiten3 Additives: 3.1 AntioxidantsMichelle ValeryNoch keine Bewertungen

- Guo2007 PDFDokument17 SeitenGuo2007 PDFMichelle Valery100% (1)

- Pupu Con Pipi LicuadoDokument2 SeitenPupu Con Pipi LicuadoMichelle ValeryNoch keine Bewertungen

- SPE 21691 Evaluating and Establishing Safety Ratings For Submersible CablesDokument6 SeitenSPE 21691 Evaluating and Establishing Safety Ratings For Submersible CablesMichelle ValeryNoch keine Bewertungen

- Cross EPDM PeroxDokument14 SeitenCross EPDM PeroxMichelle ValeryNoch keine Bewertungen

- Part 1Dokument24 SeitenPart 1Michelle ValeryNoch keine Bewertungen

- Area (%) Muestra 1 Muestra 2 Muestra 3 Molécula PM TR Eto H Tol Ed Eto H Tol Ed Eto H Tol EdDokument2 SeitenArea (%) Muestra 1 Muestra 2 Muestra 3 Molécula PM TR Eto H Tol Ed Eto H Tol Ed Eto H Tol EdMichelle ValeryNoch keine Bewertungen

- Ravi Shankar 2012Dokument23 SeitenRavi Shankar 2012Michelle ValeryNoch keine Bewertungen

- 2 Days Berlin Top AttractionsDokument16 Seiten2 Days Berlin Top AttractionsMichelle ValeryNoch keine Bewertungen

- Describe YourselfDokument1 SeiteDescribe YourselfMichelle ValeryNoch keine Bewertungen

- Ibs Kota Bharu 1 30/06/22Dokument7 SeitenIbs Kota Bharu 1 30/06/22Nik Suraya IbrahimNoch keine Bewertungen

- Brgy. Kimalok Page Final VersionDokument55 SeitenBrgy. Kimalok Page Final VersionRichard EyanaNoch keine Bewertungen

- TRENDS AND CRITICAL THINKINGExamDokument4 SeitenTRENDS AND CRITICAL THINKINGExamRyan TamelinNoch keine Bewertungen

- Research Paper Latex ExampleDokument8 SeitenResearch Paper Latex Exampleafnkjdhxlewftq100% (1)

- AE 321 - Module 07 - FinalDokument14 SeitenAE 321 - Module 07 - FinalJohn Client Aclan RanisNoch keine Bewertungen

- Cambridge International AS and A Level Economics Coursebook CD ROMDokument5 SeitenCambridge International AS and A Level Economics Coursebook CD ROMNana Budu Kofi HAYFORDNoch keine Bewertungen

- BT-FPFF - Read To Find Questions For Asynchronous LearningDokument2 SeitenBT-FPFF - Read To Find Questions For Asynchronous Learningjaredlimson1129Noch keine Bewertungen

- DC BASIC GAS at Ravi Ranjan KumarDokument1 SeiteDC BASIC GAS at Ravi Ranjan KumarRAVI RANJAN KUMARNoch keine Bewertungen

- Re Cri Retd de JagerDokument23 SeitenRe Cri Retd de JagerMaitheNoch keine Bewertungen

- Satellite Communication - An IntroductionDokument19 SeitenSatellite Communication - An IntroductionThembelanienkosini ChikhambiNoch keine Bewertungen

- CAVLC ExampleDokument12 SeitenCAVLC ExampleboujmiliNoch keine Bewertungen

- Top 20 Customer Service Manager Interview Questions & Answers 2022Dokument21 SeitenTop 20 Customer Service Manager Interview Questions & Answers 2022IsyhomerNoch keine Bewertungen

- Ocr GttsDokument49 SeitenOcr GttsKshitij NishantNoch keine Bewertungen

- 2013-03 CBTA OverviewDokument19 Seiten2013-03 CBTA OverviewRahul Thandani100% (1)

- Final Project Template V2 1Dokument46 SeitenFinal Project Template V2 1HUY NGUYEN QUOCNoch keine Bewertungen

- Penawaran Harga ACCOR Vacation Club-1Dokument4 SeitenPenawaran Harga ACCOR Vacation Club-1Sedana HartaNoch keine Bewertungen

- Yellampalli S. Wireless Sensor Networks - Design, Deployment..2021Dokument314 SeitenYellampalli S. Wireless Sensor Networks - Design, Deployment..2021Myster SceneNoch keine Bewertungen

- IsoMetrix Case Study OmniaDokument9 SeitenIsoMetrix Case Study OmniaOvaisNoch keine Bewertungen

- Seminar3 enDokument7 SeitenSeminar3 enandreiNoch keine Bewertungen

- Guide Wire Installation: MaintenanceDokument26 SeitenGuide Wire Installation: MaintenanceMichael HunterNoch keine Bewertungen

- PolyBrick+3 0Dokument16 SeitenPolyBrick+3 0Sachal AbdullahNoch keine Bewertungen

- The Students Allotted With The Is Available at The End of The DocumentDokument4 SeitenThe Students Allotted With The Is Available at The End of The DocumentShivaNoch keine Bewertungen

- Perilaku Masyarakat Terhadap Kesehatan Lingkungan (Studi Di Pantai Desa Ketong Kecamatan Balaesang Tanjung Kabupaten Donggala)Dokument11 SeitenPerilaku Masyarakat Terhadap Kesehatan Lingkungan (Studi Di Pantai Desa Ketong Kecamatan Balaesang Tanjung Kabupaten Donggala)Ali BaktiNoch keine Bewertungen

- Discrete Mathematics - Propositional LogicDokument8 SeitenDiscrete Mathematics - Propositional LogicAldrich PanioNoch keine Bewertungen

- NetworksDokument6 SeitenNetworksscribdNoch keine Bewertungen

- ProjectDokument14 SeitenProjectNavneet singh50% (2)

- Ab 521 Requirements For Engineered Pressure EnclosuresDokument39 SeitenAb 521 Requirements For Engineered Pressure EnclosuresCarlos Maldonado SalazarNoch keine Bewertungen

- Seminar Topic On Compuetr ForensicsDokument11 SeitenSeminar Topic On Compuetr ForensicsS17IT1207Hindu Madhavi100% (1)