Beruflich Dokumente

Kultur Dokumente

Marine A Nodes

Hochgeladen von

marieloneOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Marine A Nodes

Hochgeladen von

marieloneCopyright:

Verfügbare Formate

Cathodic Protection Technology Pte Ltd

Website: www.cptech.net Email: cptech@singnet.com.sg

Tel: +65-6862 3551 Fax: +65-6861 6436

SHIPS CATHODIC PROTECTION SYSTEM

ZINC & ALUMINIUM HULL & TANK ANODES

Corrosion causes frictional drag on the ships hull which in turn leads to higher operating cost. A high quality

coating provides a smooth hull and together with a well-engineered cathodic protection system, helps to ensure

that the surface is maintained in good condition.

Sacrificial anode systems are commonly used for external

hull cathodic protection as they are virtually maintenance

free.

Anodes for the external hull are designed to protect local

areas and are evenly spread to ensure a good distribution

of current.

Anodes located in the stern area are normally spaced

closer together because turbulence in this area increases

oxygen content in the water making it more corrosive and hence a higher current density is required to provide

cathodic protection.

Cathodic protection of ships cargo and ballast tanks is effected using sacrificial anodes. Zinc and/or aluminium

anodes are used and the material selection depends on the

compatibility of the alloy with the service of the tank.

Aluminium anodes are acceptable in cargo/ballast tanks

provided they are not located at a height (in metres) greater

than 27/W where W is the total mass of anode and core (in

kg).

Zinc presents no spark hazard and thus zinc anodes are

commonly used throughout. Magnesium anodes present a

spark hazard and are not allowed, except as ribbon for descaling.

CP TECH produces GALVALUM

Specification 18001K.

aluminium anodes as well as zinc anodes conforming to US Military

GALVALUM is CP TECHs proprietary aluminiumzinc-indium alloy and has been long-term tested by Det

Norske Veritas (DNV) and obtained its Type Approval

Certificate, complying with DNV's recommended

practice B401 and NORSOK Standard M-503 Cathodic

Protection Long-Term Testing. It has a high driving

voltage and capacity, allowing high current output and

reduced weight from anodes in all applications.

CHEMICAL

COMPOSITION

(%)

ALUMINIUM

CP TECH GALVALUM

ZINC

US MIL SPECS

18001K

Iron (Fe)

0.13 max

0.005 max

Silicon (Si)

0.20 max

Copper (Cu)

0.006 max

0.005 max

CP TECH operates from modern purpose built plants

and offices in Singapore and Malaysia. The companys

head office is in Singapore and is located together with

the manufacturing plant on a 4,400m site at Tuas,

Singapore's major industrial area and has a built up

area of 1,500m. In Malaysia, the facility is located in

the Senai Industrial Estate, Johor, about half an hour

drive from Singapore and has a land area of 4,000m

and built up area of 2,500m. The combined annual

capacity of both the plants is in excess of 10,000MT of

zinc and aluminium anodes.

Cadmium (Cd)

0.025 - 0.070

Indium (In)

0.01 - 0.02

Lead (Pb)

0.006 max

Aluminium (Al)

Remainder

0.10 - 0.50

Zinc (Zn)

2.00 - 6.00

Remainder

Others

0.02 max (each)

0.10 max (total)

CP TECH is committed to providing good quality products and services on time and at

competitive prices, as evidenced by the quality of its staff and accreditation of its Quality

Management System to ISO 9001 by Det Norske Veritas (DNV) for the design and manufacture

of cathodic protection systems since 1994.

Cathodic Protection Technology Pte Ltd

Website: www.cptech.net

Tel: +65-6862 3551

E-mail: cptech@singnet.com.sg

Fax: +65-6861 6436

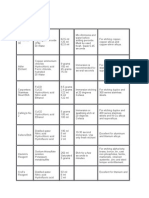

CP TECH / WILSON WALTON

MARINE ANODES

Aluminium Hull Anodes

Type

W131

W130

W111

W114

W117

W119

W118

W124

W126

W128

A

340

350

530

650

650

650

650

1015

1015

1015

B

200

270

395

550

550

550

550

915

915

920

C

95

150

150

127

130

130

130

130

130

130

D

30

30

30

50

65

75

96

50

75

104

Gross Wt

1.4

3.2

5.2

9.8

11.6

14.1

18.0

16.0

24.0

33.0

B

305

305

305

305

305

305

456

C

75

75

90

152

152

152

102

D

38

40

45

32

35

38

53

Gross Wt

4.5

5.0

6.8

8.5

9.7

10.0

15.0

B

585

585

585

C

134

142

149

D

37

53

69

Gross Wt

18.3

26.3

36.3

B

270

400

550

550

550

550

915

C

150

150

130

130

130

130

130

D

32

32

50

65

75

96

50

Gross Wt

7.1

12.0

22.5

27.0

34.7

44.9

36.5

B

220

290

280

C

75

100

150

D

38

50

75

Gross Wt

2.6

5.0

10.7

Zinc Hull Anodes

Type

Z41

Z50

Z64

Z81

Z93

Z100

Z140

A

425

425

425

425

425

425

625

Zinc Hull Anodes

Type

Z170

Z250

Z350

A

750

750

750

Zinc Hull Anodes

Type

W6Z

W11Z

W14Z

W17Z

W19Z

W18Z

W24Z

A

370

530

650

650

650

650

1015

Zinc Hull Anodes

Type

WP2

WP5

W10Z

A

300

370

370

All dimensions in mm & weight in kg

Cathodic Protection Technology Pte Ltd

Website: www.cptech.net

Tel: +65-6862 3551

E-mail: cptech@singnet.com.sg

Fax: +65-6861 6436

CP TECH / WILSON WALTON

MARINE ANODES

Welded Hull Anode

Type

S2

S3

S4

S4E

Type

S6

S8

S9

S9E

S9F

A

238

350

350

350

A

300

300

300

300

300

Type

S18

B

150

200

200

200

C

75

100

100

100

B

150

150

150

150

150

A

800

C

270

270

270

270

270

B

75

D

25

20

30

40

D

20

25

30

40

50

C

50

Zinc

Aluminium

Gross Wt

1.7

3.0

4.2

6.3

Gross Wt

0.7

1.4

1.7

2.7

Zinc

Aluminium

Gross Wt

6.5

8.0

9.5

12.0

14.6

Gross Wt

3.0

3.5

4.1

5.0

6.0

Zinc

Aluminium

Gross Wt

19.0

Gross Wt

7.5

Aluminium Bolted Hull Anodes

Type

A36B

A45B

A84B

A114B

RF80

MF93

RF96

RF118

RF155

A

305

305

300

456

540

400

540

460

540

B

76

80

150

102

130

150

140

200

200

C

36

38

30

53

53

60

64

64

65

D

205

205

200

230

340

180

340

260

340

E

19

17

18

23

26

26

26

26

26

F

50

50

32

60

60

60

60

60

60

Gross Wt

1.9

2.0

3.6

5.0

8.0

9.3

9.6

11.8

15.4

D

205

205

200

230

340

340

180

260

340

E

19

17

18

23

26

26

26

26

26

F

50

50

32

60

60

60

60

60

60

Gross Wt

4.1

4.5

8.4

12.1

19.7

23.7

23.0

30.8

40.0

Zinc Bolted Hull Anodes

Type

Z36B

Z45B

Z84B

Z114B

20RB

24RB

23MB

30RB

40RB

A

305

305

300

456

540

540

400

460

540

B

76

80

150

102

130

140

150

200

200

C

36

38

30

53

53

64

60

64

65

All dimensions in mm & weight in kg

Cathodic Protection Technology Pte Ltd

Website: www.cptech.net

Tel: +65-6862 3551

E-mail: cptech@singnet.com.sg

Fax: +65-6861 6436

CP TECH / WILSON WALTON

MARINE ANODES

Bolted Hull Anode

Zinc

Aluminium

Type

B2

B3

B4

B4E

B6

B8

B9

B9E

B9F

B9G

B12

B12D

B12E

A

150

200

200

200

300

300

300

300

300

300

300

300

300

B

75

100

100

100

150

150

150

150

150

150

200

200

200

C

25

20

30

40

20

25

30

40

50

75

40

50

65

D

75

110

110

110

160

160

160

160

160

160

160

160

160

E

14

14

14

14

26

26

26

26

26

26

26

26

26

F

33

38

38

38

50

50

50

50

50

50

50

50

50

Gross Wt

1.5

2.5

3.6

4.2

5.9

7.3

8.3

11.0

13.8

22.0

15.2

18.8

26.8

Gross Wt

0.7

1.1

1.5

1.8

2.7

2.9

3.3

4.6

5.5

8.0

6.0

7.4

10.7

B18

800

75

50

400

26

50

15.8

6.3

Aluminium Tank Anode

Type

W110

W151

W152

W153

W154

W155

W156

W191

W192

W193

W194

W195

W196

A

1225

1985

1730

1475

1225

1070

765

1985

1720

1465

1210

1060

765

B

765

1525

1270

1015

765

610

305

1525

1260

1005

750

600

305

C

50

75

75

75

75

75

75

95

95

95

95

95

95

D

40

50

50

50

50

50

50

75

75

75

75

75

75

E

50

65

65

65

65

65

65

85

85

85

85

85

85

F

14

14

14

14

14

14

14

14

14

14

14

14

14

Gross Wt

5.4

19.3

16.3

13.1

10.0

8.1

3.8

32.9

27.2

21.7

16.3

13.2

6.3

C

57

69

79

57

69

79

91

D

64

77

83

64

77

83

94

E

14

14

14

14

14

14

14

F

19

23

25

19

23

25

32

Gross Wt

11.3

15.9

21.1

22.6

31.8

42.2

53.8

Zinc Tank Anode

Type

WT25Z

WT35Z

WT45Z

WT50Z

WT70Z

WT90Z

WT110Z

A

1066

1066

1066

1676

1676

1676

1676

B

610

610

610

1220

1220

1220

1220

Pit-Guard Tank Anode

Type

AT 2235

AT 2235/1

AT 2235/2

AT 2237

ZT 2247

ZT 2252

Material

Aluminium

Aluminium

Aluminium

Aluminium

Zinc

Zinc

A

200

400

356

395

332

342

B

70

70

70

76

70

76

C

76

76

76

63

76

63

Nett Wt

2.3

4.7

4.2

4.5

10.0

10.0

All dimensions in mm & weight in kg

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- List of Etchant For MetallographyDokument3 SeitenList of Etchant For Metallographyniraj_hwbNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- YG-1 Americas - 2021 - Indexable Grade Overview FastenalDokument5 SeitenYG-1 Americas - 2021 - Indexable Grade Overview FastenalferNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Interpreting Cement Science Since 2005: Understanding Cement Book/ebookDokument14 SeitenInterpreting Cement Science Since 2005: Understanding Cement Book/ebookVirat ChintuNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Chlorine and Its Compounds QuestionsDokument2 SeitenChlorine and Its Compounds QuestionsMARK DEFREITAS100% (1)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Stainless Steel Components Heat Treatment PDFDokument45 SeitenStainless Steel Components Heat Treatment PDFsmani170Noch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Magnesium AlloyDokument22 SeitenMagnesium AlloyPrethevNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Chemistry Paper 2 November 2009Dokument14 SeitenChemistry Paper 2 November 2009deanNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Alkali & Sulphur RatioDokument2 SeitenAlkali & Sulphur RatioManish KumarNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- IS4736.1986 - Galvanizing On Tubes PDFDokument15 SeitenIS4736.1986 - Galvanizing On Tubes PDFdombipin100% (1)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Cable Gland Exhibitor List MEEDokument23 SeitenCable Gland Exhibitor List MEESaurabh DangariaNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Chapter 1 (A) Corrosion SlideDokument26 SeitenChapter 1 (A) Corrosion SlideNasyitah TarmiziNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Classified Chem U5 AnswersDokument105 SeitenClassified Chem U5 AnswersAzeem iftikharNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Aquacheck Instruction SheetDokument56 SeitenAquacheck Instruction SheetAdem YildirimNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Half-Life and Mean LifeDokument10 SeitenHalf-Life and Mean LifeIsaac KandaNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Coordination Compounds Assertion and ReasonDokument2 SeitenCoordination Compounds Assertion and Reasonkrishna kumar bhardwaj100% (1)

- Chemistry SPM Potential Questions-Form5chap1 2Dokument15 SeitenChemistry SPM Potential Questions-Form5chap1 2EloiseCalaisNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Color Code ChartDokument15 SeitenColor Code ChartYel DG0% (1)

- Asme Sec - Ii D (Sa 193 GR.B7)Dokument3 SeitenAsme Sec - Ii D (Sa 193 GR.B7)AARTICKNoch keine Bewertungen

- Chapter 2Dokument8 SeitenChapter 2Megan SchmidtNoch keine Bewertungen

- Exer 10Dokument2 SeitenExer 10Mariel TrinidadNoch keine Bewertungen

- 2nd Puc Chemistry Model Question Paper 2023Dokument7 Seiten2nd Puc Chemistry Model Question Paper 2023Shadow KingNoch keine Bewertungen

- Behind The Glass Screen: A Homeopathic Survey of OzoneDokument2 SeitenBehind The Glass Screen: A Homeopathic Survey of OzoneRita SkarbaNoch keine Bewertungen

- Tata Metal: LestariDokument2 SeitenTata Metal: Lestariyoanda adimas putraNoch keine Bewertungen

- Activity No. 27: Constituents of UrineDokument50 SeitenActivity No. 27: Constituents of Urinemhai requilmanNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Jee ChemistryDokument24 SeitenJee ChemistrySumit KumarNoch keine Bewertungen

- C13 Enthalpy ChangeDokument19 SeitenC13 Enthalpy ChangeKris DookharanNoch keine Bewertungen

- 316L-SS-annealed Bar and Cold DrawnDokument2 Seiten316L-SS-annealed Bar and Cold DrawnARUNKANNANNoch keine Bewertungen

- ENVMicro - N - Aurellia Nur Islami PutriDokument7 SeitenENVMicro - N - Aurellia Nur Islami PutriaurelliaputryNoch keine Bewertungen

- TC WC W 37 Sept 23 7 Days.Dokument1 SeiteTC WC W 37 Sept 23 7 Days.Sabyasachi BangalNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Salt Analysis-Ferric ChlorideDokument3 SeitenSalt Analysis-Ferric ChlorideVandana0% (1)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)