Beruflich Dokumente

Kultur Dokumente

Condensate Treatment - Nuclear Applications

Hochgeladen von

ak_thimiriCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Condensate Treatment - Nuclear Applications

Hochgeladen von

ak_thimiriCopyright:

Verfügbare Formate

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

Via Pietro Nenni, 15 - 27058 VOGHERA ITALY

Tel. +39 0383 3371 Fax +39 0383 369052

E-mail: info@idreco.com

PRESENTATION OF NUCLEAR APPLICATIONS

OF CONDENSATE TREATMENT

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS OF CONDENSATE TREATMENT

0.

1.

2.

3.

4.

MAIN CONDENSATE TREATMENT

REACTOR WATER CLEAN-UP

FUEL POOL CLEAN-UP

LOW AND MEDIUM ACTIVITY WATER TREATMENT

OFF-GAS TREATMENT

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS OF CONDENSATE TREATMENT

0. MAIN CONDENSATE TREATMENT

Refere to presentation IDRECO

CONDENSATE TREATMENT

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS:

ONLY PRECOAT FILTER

FROM CONDENSATE

EXTRACTION PUMPS

PRECOAT

FILTER

DECOREX

TYPE

CONDENSATE POLISHING

PROCESSES

CLEAN CONDENSATE PRODUCT

TO PREHEATER

TYPICAL FLOW DIAGRAMS

CHECK

FILTER

PRECOAT

SYSTEM

ONLY MIXED BED

FROM CONDENSATE

EXTRACTION PUMPS

CLEAN CONDENSATE PRODUCT

TO PREHEATER

MIXED

BED

CHECK

FILTER

REGENERATION

SYSTEM

PRECOAT FILTER & MIXED BED

FROM CONDENSATE

EXTRACTION PUMPS

PRECOAT

FILTER

DECOREX

TYPE

PRECOAT

SYSTEM

CLEAN

CONDENSATE

PRODUCT

TO PREHEATER

MIXED

BED

CHECK

FILTER

CHECK

FILTER

REGENERATION

SYSTEM

CATIONIC UNIT & MIXED BED

FROM CONDENSATE

EXTRACTION PUMPS

CATIONIC

UNIT

MIXED

BED

RESIN TRAP

REGENERATION

SYSTEM

CLEAN

CONDENSATE

PRODUCT

TO PREHEATER

REGENERATION

SYSTEM

RESIN

TRAP

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS OF CONDENSATE TREATMENT

0.

1.

2.

3.

4.

MAIN CONDENSATE TREATMENT

REACTOR WATER CLEAN-UP

FUEL POOL CLEAN-UP

LOW AND MEDIUM ACTIVITY WATER TREATMENT

OFF-GAS TREATMENT

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS OF CONDENSATE TREATMENT

1. REACTOR WATER CLEAN-UP

Reactor water consists on the following:

-

in BWR (Boiling Water Reactors) the hot water in contact with

fuel elements

in PWR (Pressurized Water Reactors) the intermediate fluid

coming from the reactor and going to the steam generator

(secondary circuit)

Even if the operating and design condition are different, the two

technology of reactor water clean-up are similar.

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS OF CONDENSATE TREATMENT

1. REACTOR WATER CLEAN-UP

The reactor water clean-up, treating a radioactive liquid, consists on:

A) precoat filters

B) mixed beds without regeneration

C) both systems

The choice of the treating system depends from the type of reactors

and the power plant designer.

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS OF CONDENSATE TREATMENT

1. REACTOR WATER CLEAN-UP

A) Precoat Filter

This technology is the same as the one presented above in the main

condensate treatment section.

The filtering elements used for this application are always metal type,

in order to extend the element life.

The powdered resins used are in active form and very pure

(nuclear grade), avoiding the presence of residual compounds of

fabrication that could contaminate the effluent.

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS OF CONDENSATE TREATMENT

ONLY PRECOAT FILTER

FROM REACTOR COOLING WATER

SYSTEM

RETURN TO

HEATING SYSTEM

BEFORE REACTOR

PRECOAT

FILTER

DECOREX

TYPE

CHECK

FILTER

PRECOAT

SYSTEM

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS OF CONDENSATE TREATMENT

1. REACTOR WATER CLEAN-UP

B) Mixed Beds Without Regeneration

This technology consists on ion exchange units containing strong

cationic and strong anionic resin mixed together in active form.

When exhausted, the resin is discharged and replaced with a new

charge.

The bead resins used are in active form and very pure (nuclear grade).

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS OF CONDENSATE TREATMENT

1. REACTOR WATER CLEAN-UP

B) Mixed Beds Without Regeneration

Exhausted Resin Treatment

Exhausted bead resins are discharged from filter units to a

phase separator using AIR and DEMI WATER.

In the phase separator: a settling of solid will take place and the two

phases are divided and sent to the final destination:

-

the liquid will reach the light radwaste tank (Medium Activity Water)

the solid will go to the solid radwaste treatment

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS OF CONDENSATE TREATMENT

ONLY MIXED BED (UNREGENERABLE)

FROM REACTOR COOLING WATER

SYSTEM

TO EXHAUSTED

RESINS PHASE

SEPARATOR

RETURN TO

HEATING SYSTEM

BEFORE REACTOR

MIXED

BED

CHECK

FILTER

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS OF CONDENSATE TREATMENT

1. REACTOR WATER CLEAN-UP

C) Precoat Filters + Mixed Bed

In this case, due to the presence of mixed bed as second treatment,

the precoat filters can use inert material instead of powdered resin.

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS OF CONDENSATE TREATMENT

PRECOAT FILTER & MIXED BED (UNREGENERABLE)

FROM REACTOR COOLING

WATER SYSTEM

PRECOAT

FILTER

DECOREX

TYPE

MIXED

BED

CHECK

FILTER

PRECOAT

SYSTEM

RETURN TO

HEATING SYSTEM

BEFORE REACTOR

CHECK

FILTER

TO EXHAUSTED

RESINS PHASE

SEPARATOR

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS OF CONDENSATE TREATMENT

0.

1.

2.

3.

4.

MAIN CONDENSATE TREATMENT

REACTOR WATER CLEAN-UP

FUEL POOL CLEAN-UP

LOW AND MEDIUM ACTIVITY WATER TREATMENT

OFF-GAS TREATMENT

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS OF CONDENSATE TREATMENT

2. FUEL POOL WATER CLEAN-UP

The spent fuel elements are normally stored in a pool filled with

demineralized water, that after needs to be decontaminated.

Decontamination means cleaning from soluble salts and also from the

suspended solid matter coming from the ambient.

This purpose is reached by means of precoat filtration using powdered

resins nuclear grade. The filtering elements used for this application are

always metal type, in order to extend the element life.

After cleaning, water is recycled in the fuel pool.

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS OF CONDENSATE TREATMENT

2. FUEL POOL WATER CLEAN-UP

This treatment can be continuous or discontinuous, depending on the

pool water characteristics.

Rarely this treatment is performed by means of mixed bed without

regeneration, as in the reactor water clean-up application above

described.

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS OF CONDENSATE TREATMENT

ONLY PRECOAT FILTER

FROM FUEL POOL BASIN

RETURN TO

FUEL POOL BASIN

PRECOAT

FILTER

DECOREX

TYPE

CHECK

FILTER

PRECOAT

SYSTEM

ONLY MIXED BED (UNREGENERABLE)

FROM FUEL POOL BASIN

TO EXHAUSTED

RESINS PHASE

SEPARATOR

RETURN TO

FUEL POOL BASIN

MIXED

BED

CHECK

FILTER

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS OF CONDENSATE TREATMENT

0.

1.

2.

3.

4.

MAIN CONDENSATE TREATMENT

REACTOR WATER CLEAN-UP

FUEL POOL CLEAN-UP

LOW AND MEDIUM ACTIVITY WATER TREATMENT

OFF-GAS TREATMENT

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS OF CONDENSATE TREATMENT

3. LOW AND MEDIUM ACTIVITY WATER TREATMENT

LOW ACTIVITY WATER: comes from phase separator of exhausted

precoat waste and from the resin final washing in main condensate

mixed bed

MEDIUM ACTIVITY WATER: comes from phase separator of

exhausted bead resins and from the floor drain cleaning activity.

Sometimes comprises some water coming from laundry and from

laboratories

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS OF CONDENSATE TREATMENT

3. LOW AND MEDIUM ACTIVITY WATER TREATMENT

Low activity water

Are usually treated with precoat filters plus mixed bed as previously

described. The treated water is recycled as demi water make-up.

The exhausted resins are conveyed to the relevant phase separator

and the liquid phase comes back to low activity water tank while the

resin are fed to the solid radwaste system.

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS OF CONDENSATE TREATMENT

A) LOW ACTIVITY WATER

FROM LOW ACTIVITY

TANK

PRECOAT

SYSTEM

PRECOAT

FILTER

DECOREX

TYPE

RETURN TO

MAKE UP

WATER

MIXED

BED

CHECK

FILTER

TO EXHAUSTED

RESINS PHASE

SEPARATOR

CHECK

FILTER

OR RECYCLE

TO LOW ACTIVITY

TANK

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS OF CONDENSATE TREATMENT

3. LOW AND MEDIUM ACTIVITY WATER TREATMENT

Medium Activity Water

Are usually treated with precoat filters and after testing recycled to

the low activity water.

The exhausted precoat is treated as above described.

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS OF CONDENSATE TREATMENT

B) MEDIUM ACTIVITY WATER

FROM MEDIUM ACTIVITY TANK

PRECOAT

SYSTEM

PRECOAT

FILTER

DECOREX

TYPE

RECYCLE TO LOW ACTIVITY WATER

OR RECYCLED TO MEDIUM ACTIVITY TANK

CHECK

FILTER

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS OF CONDENSATE TREATMENT

0.

1.

2.

3.

4.

MAIN CONDENSATE TREATMENT

REACTOR WATER CLEAN-UP

FUEL POOL CLEAN-UP

LOW AND MEDIUM ACTIVITY WATER TREATMENT

OFF-GAS TREATMENT

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS OF CONDENSATE TREATMENT

4) OFF GAS TREATMENT

OFF GAS is the nuclear plant ambient air, which must be cleaned to

eliminate radioactive content due to contact with fuel during operations.

OFF GAS consists also in:

-

free hydrogen

traces of radioactive substances such as:

- rare gas deriving from radioactive atoms scission

- radioactive elements

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS OF CONDENSATE TREATMENT

4) OFF GAS TREATMENT

Hydrogen elimination

Performed by means of catalytic recombination:

-

Catalyst contained in its own reactor consisting of palladium on a

metallic support, generally stainless steel

Catalyst effectively operates at high temperatures so off gas to be

treated is preheated

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS OF CONDENSATE TREATMENT

Step 1) HYDROGEN ELIMINATION

HYDROGEN RECOMBINATION

TO MOLECULAR SIEVE

FROM EXHAUST FAN

HYDROGEN

RECOMBINER

CHECK

FILTER

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS OF CONDENSATE TREATMENT

4) OFF GAS TREATMENT

Radioactive Substances Elimination

1) Rare gas and radioactive elements are eliminated by means of

molecular sieve beds

2) Radioactive elements are eliminated by active carbon adsorption

Both molecular sieves and active carbon are included in dedicated

filters supported by filtering plates threatening the media.

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS OF CONDENSATE TREATMENT

Step 2) RADIOACTIVE SUBSTANCES ELIMINATION

MOLECULAR SIEVE & ACTIVATED CARBON ADSORPTION

TO ATMOSPHERE

FROM HYDROGEN

ELIMINATION

PRECOAT

SYSTEM

MOLECULAR

SIEVE

CHECK

FILTER

CHECK

FILTER

ACTIVATED CARBON

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

NUCLEAR APPLICATIONS OF CONDENSATE TREATMENT

4) OFF GAS TREATMENT

Off gas treating plants doesnt traditionally need any important

maintenance service and are characterised by the same nuclear

power plant life.

Seldom they suffer only from catalyst poisoning, solvable simply by

catalyst media substitution.

Certified ISO9001

THE SCIENCE OF A PURE ENVIRONMENT

Via Pietro Nenni, 15 - 27058 VOGHERA ITALY

Tel. +39 0383 3371 Fax +39 0383 369052

E-mail: info@idreco.com

Thank you !

STATE OF THE ART TECHNOLOGIES FOR

NUCLEAR ENERGY APPLICATIONS

Das könnte Ihnen auch gefallen

- Is.1448.16.1990 Density or API Gravity by Hydrometer Petroleum Produect PDFDokument10 SeitenIs.1448.16.1990 Density or API Gravity by Hydrometer Petroleum Produect PDFak_thimiriNoch keine Bewertungen

- Chemical Cleaning Procedure BdEU UNIT & AU Dahej SiteDokument24 SeitenChemical Cleaning Procedure BdEU UNIT & AU Dahej Siteak_thimiriNoch keine Bewertungen

- AinDokument6 SeitenAinak_thimiriNoch keine Bewertungen

- APPENDIX B: Short Cut Key FunctionsDokument2 SeitenAPPENDIX B: Short Cut Key Functionsak_thimiriNoch keine Bewertungen

- About ELGIDokument1 SeiteAbout ELGIak_thimiriNoch keine Bewertungen

- HRSG High Pressure Evaporator Sampling For Internal DepositDokument26 SeitenHRSG High Pressure Evaporator Sampling For Internal Depositak_thimiriNoch keine Bewertungen

- SAMSONType 3730 2 Electropneumatic Positioner & Type 3730 3 With HART Communication t83842Dokument8 SeitenSAMSONType 3730 2 Electropneumatic Positioner & Type 3730 3 With HART Communication t83842ak_thimiriNoch keine Bewertungen

- 10HCB20AT160 LRSB While Retracting Power Cable and Cable Chain Link Damaged Due To Cable Chain JammedDokument4 Seiten10HCB20AT160 LRSB While Retracting Power Cable and Cable Chain Link Damaged Due To Cable Chain Jammedak_thimiriNoch keine Bewertungen

- Spray-Type Deaerator: Installation and Operating Service ManualDokument19 SeitenSpray-Type Deaerator: Installation and Operating Service Manualak_thimiriNoch keine Bewertungen

- High Pressure Boiler Water TreatmentDokument90 SeitenHigh Pressure Boiler Water Treatmentak_thimiri100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Copper-Brazed Steel Tubing: Standard Specification ForDokument4 SeitenCopper-Brazed Steel Tubing: Standard Specification ForSofiaJabadanEspulgar100% (1)

- Grout CatalogDokument36 SeitenGrout CatalogJohneey DeepNoch keine Bewertungen

- Geochemical Characteristics of Igneous Rocks As Petrogenetic IndicatorsDokument2 SeitenGeochemical Characteristics of Igneous Rocks As Petrogenetic IndicatorsFrank Hoyos CubasNoch keine Bewertungen

- 1-Polo - MSDSDokument5 Seiten1-Polo - MSDSSaad IqbalNoch keine Bewertungen

- 21 - Suitability of Shredded Tires For Use in Landfill Leachate Collection SystemsDokument13 Seiten21 - Suitability of Shredded Tires For Use in Landfill Leachate Collection SystemsbelavelosoNoch keine Bewertungen

- ASCO Series 307 Solenoid Valves No Voltage ReleaseDokument6 SeitenASCO Series 307 Solenoid Valves No Voltage Releasehacene omarNoch keine Bewertungen

- The Passivated Emitter and Rear Cell (PERC) PDFDokument8 SeitenThe Passivated Emitter and Rear Cell (PERC) PDFShadab AhmedNoch keine Bewertungen

- B 524 - B 524M - 99 - Qjuync9cnti0tqDokument11 SeitenB 524 - B 524M - 99 - Qjuync9cnti0tqCarlos Luis Oyuela GomezNoch keine Bewertungen

- Assignment: Submitted by R.Deepa 116011001503 Ii Yr / Iv SemDokument6 SeitenAssignment: Submitted by R.Deepa 116011001503 Ii Yr / Iv SemR. Deepa - ANoch keine Bewertungen

- Failure Analysis Question BankDokument29 SeitenFailure Analysis Question BankAbd-Elaleem Abdallah SosaNoch keine Bewertungen

- Earth Pressures CoulombDokument15 SeitenEarth Pressures CoulombDhananjay ShahNoch keine Bewertungen

- Sulfate AttackDokument1 SeiteSulfate AttackbozarromegustaNoch keine Bewertungen

- CHAPTER - 2 - Acids, Bases and SaltsDokument2 SeitenCHAPTER - 2 - Acids, Bases and Saltsshuchi guptaNoch keine Bewertungen

- Business ProfileDokument6 SeitenBusiness Profilerajesh kothariNoch keine Bewertungen

- BERKLEY - Catalogo Caà As 2011Dokument8 SeitenBERKLEY - Catalogo Caà As 2011dondepescasNoch keine Bewertungen

- For EntingDokument5 SeitenFor EntingVicente TanNoch keine Bewertungen

- Gunstone 61 eDokument0 SeitenGunstone 61 esusu222000Noch keine Bewertungen

- Heat Intake LabDokument3 SeitenHeat Intake LabTajay BillingsNoch keine Bewertungen

- Basic of Soil-Soil Formation (DR - Khalid Farooq)Dokument26 SeitenBasic of Soil-Soil Formation (DR - Khalid Farooq)Haseeb Rehman100% (1)

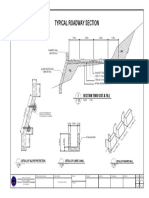

- Typical Roadway SectionDokument1 SeiteTypical Roadway SectionCarmela Ayessa PiguerraNoch keine Bewertungen

- Physical Science DLP Q1W3Dokument7 SeitenPhysical Science DLP Q1W3junar asentistaNoch keine Bewertungen

- Processing of Oil SeedsDokument20 SeitenProcessing of Oil SeedsRohit Ramesh KaleNoch keine Bewertungen

- FinalExam B AnsKeyDokument12 SeitenFinalExam B AnsKeyDVRaoNoch keine Bewertungen

- Weld Repairs:: Weld Repairs Can Be Divided Into Two Specific Areas: 1) Production Repairs 2) in Service RepairsDokument59 SeitenWeld Repairs:: Weld Repairs Can Be Divided Into Two Specific Areas: 1) Production Repairs 2) in Service RepairsThe Engineers EDGE, CoimbatoreNoch keine Bewertungen

- Electrical Discharge Through GasesDokument4 SeitenElectrical Discharge Through GasessambhuNoch keine Bewertungen

- PFM920I-6U-U Datasheet 20221020Dokument2 SeitenPFM920I-6U-U Datasheet 20221020GgopNoch keine Bewertungen

- Uhde Dual-Pressure Process For Large-Scale Ammonia Plants: - Saskferco Ammonia-Urea Complex, CanadaDokument6 SeitenUhde Dual-Pressure Process For Large-Scale Ammonia Plants: - Saskferco Ammonia-Urea Complex, CanadaMUHAMMAD USMAN0% (1)

- Graphical Methods For Phase Equilibrium: Class 21Dokument3 SeitenGraphical Methods For Phase Equilibrium: Class 21Aruna KumarasiriNoch keine Bewertungen

- Adiabatic Dryers PresentationDokument27 SeitenAdiabatic Dryers PresentationJunaid IqbalNoch keine Bewertungen

- Endalkachew AbrhameDokument93 SeitenEndalkachew Abrhamelibanhaji25Noch keine Bewertungen