Beruflich Dokumente

Kultur Dokumente

3d Hall & Longmore 3 Layer Coating Brochure

Hochgeladen von

Yoga FirmansyahCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

3d Hall & Longmore 3 Layer Coating Brochure

Hochgeladen von

Yoga FirmansyahCopyright:

Verfügbare Formate

C

CM

MY

CY CMY

3-Layer Coatings: Technical Details

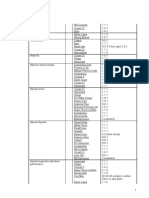

TYPICAL TECHNICAL SPECIFICATION FOR 3-LAYER COATINGS

System B1 : A coating that consists of a powdered epoxy primer (FBE) an extruded co-polymer adhesive

(cohesive) and an extruded polyethylene outer layer (HDPE)

Characteristic

Compound

Description

Test Criteria

Component Layers

Standard

Clause

Table

CSAZ245.20-02

N/A

FBE Layer

HDPE Layer

A thermosetting coating

material based on epoxy

resin.

Polyethylene based

adhesive

CSAZ245.21-02

N/A

Cure time

CSAZ245.20-02

12.1

Meets manufacturers

specification

Thickness

CSAZ245.21-20

N/A

Table 6

0.12mm minimum

Operating Temp

range

Manufacturers

specifications

Water Absorption

CSAZ245.20-02

12.3

CSAZ245.20-02

12.5

Density

Cohesive Layer

0.1mm minimum

3-Layer (Trilaminate)

Coatings

A black high density

natural resin polyethylene

with ultraviolet stabiliser

and colourant

Originally developed for the oil and gas industry, 3-layer coatings

have applications across the entire steel pipe corrosion protection

spectrum. 3-layer coatings provide a belt and braces solution to

steel pipe treatment by offering the enhanced corrosion protection

of the Fusion Bonded Epoxy (FBE) layer along with the robust,

impact and mechanical resistance of the polyethylene top coat.

0.45mm minimum

100C general

140C spikes

ASTM D 792

0.50% max

1400g/l

_ 1%

.915g/cm3 +

CSAZ245.21-20

Table 3

_ 1%

.950g/cm3 +

The long term benefits include:

High impact resistance

Impact Resistance

CSAZ245.20-02

12.12

1.5J

3J / mm of actual

thickness

Bond strength /

Adhesion

CSAZ245.20-02

12.14

Rating 1-3

Peel: 150N min.

Dialectric strength

ASTM D 149.95

Shore Hardness D

ASTM D 2240

Flow Rate

ASTM D 1238

CSAZ245.21-20

Table 2

Softening Point

ASTM D 1505

CSAZ245.21-20

Table 2

Tensile strength

at yield

ASTM D 638

Manufacturers

specifications

Elongation /

Ductility

ASTM D 638

Manufacturers

specifications

Environmental stress

cracking resistance

ASTM D 1693

Cathodic

Disbondment

CSAZ245.20-02

Flexibility

CSAZ245.21-20

Table 1

CSAZ245.21-20

Section 7.4.2

Highly impermeable to water penetration

/=60

1.5g/10min +

_ 20%

Superior adhesion to steel

0.4g/10min +

_ 20%

Good flexibility

85C

/= 18MPa

300% min.

CSAZ245.21-20

Table 3

1

Excellent resistance to soil stresses

10V / micron of thickness

up to 15000V max.

550v/mil

90

12.8

High corrosion resistance with cathodic protection

Excellent insulation properties with long term

resistance to stray current

17MPa min.

Can be customised to specific operating conditions

by varying the thickness of the coating in line with

specifications

300% min.

+

_ 1000hr

7mm max.

(24 hrs @ 3.5V; 65C

accelerate)

Bend of 2.5 - 3.0

(R=22.42t)

JULY 2008

Hall Longmore reserves the right to change or amend the contents of this document at anytime without any notice with this document intended

for general information only. Any specific information required about product specifications, applications, technical information, sales, conditions,

warranties and guarantees as required for any design or installation should be obtained from Hall Longmore.

CM

MY

CY CMY

3-Layer Coating

3-Layer Coating is the generic term for a pipe outer coating comprised of FBE

base or primer coat, an extruded co-polymer adhesive intermediate layer and an

extruded polyethylene top coat, as described by System B1 of the Canadian

Specification Z245.21-02.

Hall Longmore offers the following tests on all 3-layer coatings:

1. Cathodic Disbondment (CD)

Cathodic disbondment

2. Peel Adhesion

Application of 3-layer coatings follow the same typical process. Pipes are shot

blast to Sa21/2 to remove rust, debris and to provide a suitable profile for adhesion

of the FBE layer.

3. Elongation

4. Impact

Pipes are then fed through induction heaters to bring the pipes up to a temperature

required for the FBE to bond. The FBE is applied through a number of electrostatic

spray nozzles.

5. Dust and Debris

Peel Adhesion

6. EID (Holiday testing)

The co-polymer adhesive - which provides a chemical bond between the FBE

and top coat - and the polyethylene top coat are then applied through extruders

on to the rotating pipe. Cure is affected within 90 seconds of application

which allows the pipes to be cooled quickly by means of water quenching.

Shot Blasted Pipe

The above tests are generally performed in accordance with CSA

Z245.20/21-02. Additional or enhanced testing as required by

Institutional / Client based Particular Specifications must be

verified by Hall Longmores Quality-Assurance/Control department.

Once fully cooled, pipes are subjected to Electric Insulation Detection (EID)

to check for pinholes before having the ends dressed and prepared.

Elongation Test

Pipe inspections are performed at each stage to ensure compliance

and minimize the risk of defects.

3-Layer Polyethylene Coatings (3LPE) can be used in operating

conditions of up to 80C, making them suitable in most steel pipe

applications from water to gas transfer. However, for pipelines with

operating temperatures in excess of 80C, polypropylene and the

associated high temperature FBE and co-polymer adhesives are

required 3LPP.

Extruded Material

Impact Test

Please contact Hall Longmore for further information in this regard.

PRE-HEATING

EXTERNAL

BLASTING

INDUCTION HEATING

POWDER EPOXY

COATING

ADHESIVE & PE COATING

QUENCHING

Dust and Debris Inspection

FINAL INSPECTION

ELECTRIC

INSULATION

DETECTION

SHIPPING

END PREPARATION

Sample Cut

INTERNAL BLASTING

INTERNAL COATING

FINAL INSPECTION

SHIPPING

The 3-Layer Manufacturing Process

Electric Insulation Detection (EID)

CM

MY

CY CMY

3-Layer Coating

3-Layer Coating is the generic term for a pipe outer coating comprised of FBE

base or primer coat, an extruded co-polymer adhesive intermediate layer and an

extruded polyethylene top coat, as described by System B1 of the Canadian

Specification Z245.21-02.

Hall Longmore offers the following tests on all 3-layer coatings:

1. Cathodic Disbondment (CD)

Cathodic disbondment

2. Peel Adhesion

Application of 3-layer coatings follow the same typical process. Pipes are shot

blast to Sa21/2 to remove rust, debris and to provide a suitable profile for adhesion

of the FBE layer.

3. Elongation

4. Impact

Pipes are then fed through induction heaters to bring the pipes up to a temperature

required for the FBE to bond. The FBE is applied through a number of electrostatic

spray nozzles.

5. Dust and Debris

Peel Adhesion

6. EID (Holiday testing)

The co-polymer adhesive - which provides a chemical bond between the FBE

and top coat - and the polyethylene top coat are then applied through extruders

on to the rotating pipe. Cure is affected within 90 seconds of application

which allows the pipes to be cooled quickly by means of water quenching.

Shot Blasted Pipe

The above tests are generally performed in accordance with CSA

Z245.20/21-02. Additional or enhanced testing as required by

Institutional / Client based Particular Specifications must be

verified by Hall Longmores Quality-Assurance/Control department.

Once fully cooled, pipes are subjected to Electric Insulation Detection (EID)

to check for pinholes before having the ends dressed and prepared.

Elongation Test

Pipe inspections are performed at each stage to ensure compliance

and minimize the risk of defects.

3-Layer Polyethylene Coatings (3LPE) can be used in operating

conditions of up to 80C, making them suitable in most steel pipe

applications from water to gas transfer. However, for pipelines with

operating temperatures in excess of 80C, polypropylene and the

associated high temperature FBE and co-polymer adhesives are

required 3LPP.

Extruded Material

Impact Test

Please contact Hall Longmore for further information in this regard.

PRE-HEATING

EXTERNAL

BLASTING

INDUCTION HEATING

POWDER EPOXY

COATING

ADHESIVE & PE COATING

QUENCHING

Dust and Debris Inspection

FINAL INSPECTION

ELECTRIC

INSULATION

DETECTION

SHIPPING

END PREPARATION

Sample Cut

INTERNAL BLASTING

INTERNAL COATING

FINAL INSPECTION

SHIPPING

The 3-Layer Manufacturing Process

Electric Insulation Detection (EID)

CM

MY

CY CMY

3-Layer Coatings: Technical Details

TYPICAL TECHNICAL SPECIFICATION FOR 3-LAYER COATINGS

System B1 : A coating that consists of a powdered epoxy primer (FBE) an extruded co-polymer adhesive

(cohesive) and an extruded polyethylene outer layer (HDPE)

Characteristic

Compound

Description

Test Criteria

Component Layers

Standard

Clause

Table

CSAZ245.20-02

N/A

FBE Layer

HDPE Layer

A thermosetting coating

material based on epoxy

resin.

Polyethylene based

adhesive

CSAZ245.21-02

N/A

Cure time

CSAZ245.20-02

12.1

Meets manufacturers

specification

Thickness

CSAZ245.21-20

N/A

Table 6

0.12mm minimum

Operating Temp

range

Manufacturers

specifications

Water Absorption

CSAZ245.20-02

12.3

CSAZ245.20-02

12.5

Density

Cohesive Layer

0.1mm minimum

3-Layer (Trilaminate)

Coatings

A black high density

natural resin polyethylene

with ultraviolet stabiliser

and colourant

Originally developed for the oil and gas industry, 3-layer coatings

have applications across the entire steel pipe corrosion protection

spectrum. 3-layer coatings provide a belt and braces solution to

steel pipe treatment by offering the enhanced corrosion protection

of the Fusion Bonded Epoxy (FBE) layer along with the robust,

impact and mechanical resistance of the polyethylene top coat.

0.45mm minimum

100C general

140C spikes

ASTM D 792

0.50% max

1400g/l

_ 1%

.915g/cm3 +

CSAZ245.21-20

Table 3

_ 1%

.950g/cm3 +

The long term benefits include:

High impact resistance

Impact Resistance

CSAZ245.20-02

12.12

1.5J

3J / mm of actual

thickness

Bond strength /

Adhesion

CSAZ245.20-02

12.14

Rating 1-3

Peel: 150N min.

Dialectric strength

ASTM D 149.95

Shore Hardness D

ASTM D 2240

Flow Rate

ASTM D 1238

CSAZ245.21-20

Table 2

Softening Point

ASTM D 1505

CSAZ245.21-20

Table 2

Tensile strength

at yield

ASTM D 638

Manufacturers

specifications

Elongation /

Ductility

ASTM D 638

Manufacturers

specifications

Environmental stress

cracking resistance

ASTM D 1693

Cathodic

Disbondment

CSAZ245.20-02

Flexibility

CSAZ245.21-20

Table 1

CSAZ245.21-20

Section 7.4.2

Highly impermeable to water penetration

/=60

1.5g/10min +

_ 20%

Superior adhesion to steel

0.4g/10min +

_ 20%

Good flexibility

85C

/= 18MPa

300% min.

CSAZ245.21-20

Table 3

1

Excellent resistance to soil stresses

10V / micron of thickness

up to 15000V max.

550v/mil

90

12.8

High corrosion resistance with cathodic protection

Excellent insulation properties with long term

resistance to stray current

17MPa min.

Can be customised to specific operating conditions

by varying the thickness of the coating in line with

specifications

300% min.

+

_ 1000hr

7mm max.

(24 hrs @ 3.5V; 65C

accelerate)

Bend of 2.5 - 3.0

(R=22.42t)

JULY 2008

Hall Longmore reserves the right to change or amend the contents of this document at anytime without any notice with this document intended

for general information only. Any specific information required about product specifications, applications, technical information, sales, conditions,

warranties and guarantees as required for any design or installation should be obtained from Hall Longmore.

Das könnte Ihnen auch gefallen

- Lower PumpDokument1 SeiteLower PumpYoga FirmansyahNoch keine Bewertungen

- Marketing Action PlanDokument76 SeitenMarketing Action PlanYoga FirmansyahNoch keine Bewertungen

- E-501S Data SheetDokument2 SeitenE-501S Data SheetYoga FirmansyahNoch keine Bewertungen

- Walmart StoriesDokument2 SeitenWalmart StoriesYoga FirmansyahNoch keine Bewertungen

- Corrosion Protection PT Tosanda Dwi SapurwaDokument18 SeitenCorrosion Protection PT Tosanda Dwi SapurwaYoga FirmansyahNoch keine Bewertungen

- Company Profile PT Indosafe Jaya Perkasa New 2016Dokument16 SeitenCompany Profile PT Indosafe Jaya Perkasa New 2016Yoga FirmansyahNoch keine Bewertungen

- 3a2495en DDokument68 Seiten3a2495en DYoga FirmansyahNoch keine Bewertungen

- Corrosion Protection PT Tosanda Dwi SapurwaDokument18 SeitenCorrosion Protection PT Tosanda Dwi SapurwaYoga FirmansyahNoch keine Bewertungen

- Corrosion Protection PT Tosanda Dwi SapurwaDokument18 SeitenCorrosion Protection PT Tosanda Dwi SapurwaYoga FirmansyahNoch keine Bewertungen

- 01 JP 13 (2) 2012 Afgani, Implementasi Strategi Pembelajaran KK, JArnawi, Irul 65-76Dokument12 Seiten01 JP 13 (2) 2012 Afgani, Implementasi Strategi Pembelajaran KK, JArnawi, Irul 65-76Mya SumitraNoch keine Bewertungen

- Moving AverageDokument4 SeitenMoving AverageYoga FirmansyahNoch keine Bewertungen

- 3M Engineering Repair PDFDokument1 Seite3M Engineering Repair PDFYoga FirmansyahNoch keine Bewertungen

- Remote TLR 300Dokument19 SeitenRemote TLR 300Yoga FirmansyahNoch keine Bewertungen

- 3M Dynatel Locating & Marking SystemDokument16 Seiten3M Dynatel Locating & Marking SystemYoga FirmansyahNoch keine Bewertungen

- 300578I - Xtreme Airless SprayersDokument7 Seiten300578I - Xtreme Airless SprayersEngTamerNoch keine Bewertungen

- List Price ResellerDokument2 SeitenList Price ResellerYoga FirmansyahNoch keine Bewertungen

- List Price ResellerDokument2 SeitenList Price ResellerYoga FirmansyahNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- What's The Use of Neuroticism?: G. Claridge, C. DavisDokument18 SeitenWhat's The Use of Neuroticism?: G. Claridge, C. DavisNimic NimicNoch keine Bewertungen

- Homophones WorksheetDokument3 SeitenHomophones WorksheetAmes100% (1)

- Julie RiesenweberDokument14 SeitenJulie RiesenweberisidorabilbaoNoch keine Bewertungen

- Iloilo City Regulation Ordinance 2006-010Dokument4 SeitenIloilo City Regulation Ordinance 2006-010Iloilo City CouncilNoch keine Bewertungen

- Good Stuff Courage, Resilience, Gratitude, Generosity, Forgiveness, and Sacrifice (Akhtar, Salman)Dokument221 SeitenGood Stuff Courage, Resilience, Gratitude, Generosity, Forgiveness, and Sacrifice (Akhtar, Salman)madhugaggar999Noch keine Bewertungen

- Group Collaborative Activity TaskonomyDokument2 SeitenGroup Collaborative Activity TaskonomyTweeky SaureNoch keine Bewertungen

- BTL Info CNC ProgrammDokument132 SeitenBTL Info CNC ProgrammdieulafaitNoch keine Bewertungen

- 2.4 Assembly ManualDokument139 Seiten2.4 Assembly Manualgustavo dlsNoch keine Bewertungen

- Sermo 13 de Tempore (2 Feb in Praes)Dokument1 SeiteSermo 13 de Tempore (2 Feb in Praes)GeorgesEdouardNoch keine Bewertungen

- Welding Research Council: BulletinDokument28 SeitenWelding Research Council: BulletinRogerio Tropia GranjaNoch keine Bewertungen

- Glacial Lakes of Himachal PradeshDokument4 SeitenGlacial Lakes of Himachal PradeshMonidipa DeyNoch keine Bewertungen

- Smart Watch User Manual: Please Read The Manual Before UseDokument9 SeitenSmart Watch User Manual: Please Read The Manual Before Useeliaszarmi100% (3)

- CFD - Basement Car ParkDokument43 SeitenCFD - Basement Car ParkTanveer HasanNoch keine Bewertungen

- General Anaesthesia MCQsDokument5 SeitenGeneral Anaesthesia MCQsWasi Khan100% (3)

- Scuba Diving - Technical Terms MK IDokument107 SeitenScuba Diving - Technical Terms MK IJoachim MikkelsenNoch keine Bewertungen

- Stress Management PPT FinalDokument7 SeitenStress Management PPT FinalAdarsh Meher100% (1)

- Magneto-Convective Non-Newtonian Nanofluid With Momentum and Temperature Dependent Slip Flow From A Permeable Stretching Sheet With Porous Medium and Chemical ReactionDokument18 SeitenMagneto-Convective Non-Newtonian Nanofluid With Momentum and Temperature Dependent Slip Flow From A Permeable Stretching Sheet With Porous Medium and Chemical ReactionIOSRjournalNoch keine Bewertungen

- Afectiuni Si SimptomeDokument22 SeitenAfectiuni Si SimptomeIOANA_ROX_DRNoch keine Bewertungen

- KZPOWER Perkins Stamford Genset Range CatalogueDokument2 SeitenKZPOWER Perkins Stamford Genset Range CatalogueWiratama TambunanNoch keine Bewertungen

- Celly BoostbkDokument15 SeitenCelly BoostbknomikabNoch keine Bewertungen

- Timer Relay ERV-09Dokument1 SeiteTimer Relay ERV-09wal idNoch keine Bewertungen

- Technical Methods and Requirements For Gas Meter CalibrationDokument8 SeitenTechnical Methods and Requirements For Gas Meter CalibrationIrfan RazaNoch keine Bewertungen

- PalmistryDokument116 SeitenPalmistrymarinoyogaNoch keine Bewertungen

- Asyb 2020 2Dokument295 SeitenAsyb 2020 2KhangNoch keine Bewertungen

- The World S Finest Ideas in Cooling!: A Division ofDokument4 SeitenThe World S Finest Ideas in Cooling!: A Division ofChiragNoch keine Bewertungen

- Airbus A319-A320-A321 - Quick Reference HandbookDokument113 SeitenAirbus A319-A320-A321 - Quick Reference Handbookrafaelldalpra100% (9)

- Kiss Forex How To Trade Ichimoku PDFDokument72 SeitenKiss Forex How To Trade Ichimoku PDFSastryassociates Chartered100% (3)

- CAT25256 EEPROM Serial 256-Kb SPI: DescriptionDokument22 SeitenCAT25256 EEPROM Serial 256-Kb SPI: DescriptionPolinho DonacimentoNoch keine Bewertungen

- Electric Bike Monitoring and Controlling System Based On Internet of ThingsDokument8 SeitenElectric Bike Monitoring and Controlling System Based On Internet of ThingsEarl PhamtonhiveNoch keine Bewertungen

- Food - Forage - Potential - and - Carrying - Capacity - Rusa Kemampo - MedKonDokument9 SeitenFood - Forage - Potential - and - Carrying - Capacity - Rusa Kemampo - MedKonRotten AnarchistNoch keine Bewertungen