Beruflich Dokumente

Kultur Dokumente

P1259 VTEC Malfunction

Hochgeladen von

mr_excelenciaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

P1259 VTEC Malfunction

Hochgeladen von

mr_excelenciaCopyright:

Verfügbare Formate

2000 Honda S2000

2000 ENGINE PERFORMANCE Self-Diagnostics - S2000

DTC P1259: VTEC SYSTEM MALFUNCTION

1. Perform PCM reset procedure using scan tool. See SELF-DIAGNOSTICS - INTRODUCTION

article. Ensure engine oil level is correct. Start engine and run at 3000 RPM with no loads and

transmission in Neutral until radiator fan comes on. Road test vehicle. Accelerate in 1st gear to an

engine speed over 6000 RPM and hold that engine speed for at least 2 seconds. If DTC P1259 is not

indicated during first road test, repeat road test 2 more times. If DTC P1259 is indicated, go to next

step. If DTC is not indicated, problem is intermittent. System is okay at this time. Check for poor

connections or loose wires at VTEC solenoid valve and PCM connectors. See appropriate wiring

diagram in WIRING DIAGRAMS article. Repair as necessary.

2. Turn ignition off. Disconnect VTEC pressure switch 2-pin connector, located at right front of engine.

Check for continuity between VTEC pressure switch connector terminals. If continuity exists, go to

next step. If continuity does not exist, replace VTEC pressure switch.

3. Turn ignition on. Measure voltage between ground and VTEC pressure switch harness connector

terminal No. 2 (Blue/Black wire). If battery voltage exist, go to next step. If battery voltage does not

exist, check for an open or short in Blue/Black wire between VTEC pressure switch and PCM 31-pin

connector "C" terminal No. 10. See Fig. 3. Repair as necessary. If wire is okay, substitute a knowngood PCM and recheck. See SUBSTITUTING PCM in SELF-DIAGNOSTICS INTRODUCTION article. If symptom or problem goes away, replace original PCM.

4. Measure voltage between VTEC pressure switch harness connector terminals. If battery voltage

exists, go to next step. If battery voltage does not exist, repair open in Brown/Yellow wire between

VTEC pressure switch and ground connector located behind valve cover. See appropriate wiring

diagram in WIRING DIAGRAMS article. If wire is okay, substitute a known-good PCM and

recheck. See SUBSTITUTING PCM in SELF-DIAGNOSTICS - INTRODUCTION article. If

symptom or problem goes away, replace original PCM.

5. Turn ignition off. Disconnect VTEC solenoid valve connector. Check resistance between ground and

VTEC solenoid valve connector. If resistance is 14-30 ohms, go to next step. If resistance is not 14-30

ohms, replace VTEC solenoid valve.

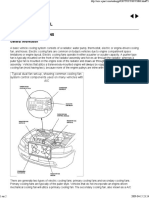

6. Turn ignition off. Remove VTEC pressure switch and install Pressure Gauge Adaptor (07NAJP07010A) and A/T Low Pressure Gauge (07406-0070300). Reinstall VTEC pressure switch into

adaptor. Connect tachometer. Start engine and run at 3000 RPM with no loads and transmission in

Neutral until radiator fan comes on. Because engine is running with no load, oil pressure must be

checked within one minute. Check oil pressure at engine speeds of 1000, 2000 and 5000 RPM. If oil

pressure is less than 7 psi (48 kPa), go to next step. If oil pressure is 7 psi (48 kPa) or more, check

VTEC solenoid valve. See SYSTEM & COMPONENT TESTING article.

7. Turn ignition off. Disconnect VTEC solenoid valve connector. Connect a fused jumper wire between

battery voltage and VTEC solenoid valve connector. Start engine. Check oil pressure at 5000 RPM. If

oil pressure is more than 57 psi (390 kPa), go to next step. If oil pressure is 57 psi (390 kPa) or less,

check VTEC solenoid valve. See SYSTEM & COMPONENT TESTING article.

8. Ensure fused jumper wire is still connected to VTEC solenoid valve connector. Start engine and allow

it to idle. Set engine speed to more than 5000 RPM and using backprobe set, measure voltage between

ground and PCM 31-pin connector "C" terminal No. 10 (Blue/Black wire). See Fig. 3. See appropriate

wiring diagram in WIRING DIAGRAMS article. If battery voltage exists, go to next step. If battery

voltage does not exist, replace VTEC pressure switch.

9. Turn ignition off. Disconnect fused jumper wire from VTEC solenoid valve connector. Using

backprobe set, check for continuity in Green/Yellow wire between VTEC solenoid valve harness

connector and PCM 25-pin connector "B" terminal No. 12. See appropriate wiring diagram in

AUTOTRONICA Y ELECTRONICA PORTUGAL

sbado, 26 de marzo de 2011 18:38:25

Page 1

2004 Mitchell Repair Information Company, LLC.

2000 Honda S2000

2000 ENGINE PERFORMANCE Self-Diagnostics - S2000

WIRING DIAGRAMS article. If continuity exists, go to next step. If continuity does not exist, repair

open in Green/Yellow wire between VTEC solenoid valve connector and PCM 25-pin connector "B"

terminal No. 12. See appropriate wiring diagram in WIRING DIAGRAMS article. Repair as

necessary.

10. Check for continuity between ground and VTEC solenoid valve harness connector. See appropriate

wiring diagram in WIRING DIAGRAMS article. If continuity exists, repair short in Green/Yellow

wire between VTEC solenoid valve connector and PCM 25-pin connector "B" terminal No. 12. If

continuity does not exist, substitute a known-good PCM and recheck. See SUBSTITUTING PCM in

SELF-DIAGNOSTICS - INTRODUCTION article. If symptom or problem goes away, replace

original PCM.

AUTOTRONICA Y ELECTRONICA PORTUGAL

sbado, 26 de marzo de 2011 18:38:25

Page 2

2004 Mitchell Repair Information Company, LLC.

Das könnte Ihnen auch gefallen

- EW160 AlarmsDokument12 SeitenEW160 AlarmsIgor MaricNoch keine Bewertungen

- Capsule Research ProposalDokument4 SeitenCapsule Research ProposalAilyn Ursal80% (5)

- 1999 E320 Owners Manual Pt1Dokument20 Seiten1999 E320 Owners Manual Pt1Sarah BryanNoch keine Bewertungen

- Jaguar XF Service PDFDokument1 SeiteJaguar XF Service PDFtheprof55Noch keine Bewertungen

- Wotbox Instructions 2010mustangDokument14 SeitenWotbox Instructions 2010mustangAlejandro Da CostaNoch keine Bewertungen

- Most Complete List For Chevy Check Engine Light CodesDokument14 SeitenMost Complete List For Chevy Check Engine Light CodesMassango J JuniorNoch keine Bewertungen

- 1996 S320 S420 S500 Owner's ManualDokument153 Seiten1996 S320 S420 S500 Owner's ManualHameleo1000Noch keine Bewertungen

- Honda B16A ECU Error CodesDokument2 SeitenHonda B16A ECU Error CodesAzim Sani67% (3)

- Mazda RX 8 Series II Workshop Manual (Preview)Dokument6 SeitenMazda RX 8 Series II Workshop Manual (Preview)Amip FolkNoch keine Bewertungen

- The GM Documents, Part 3Dokument198 SeitenThe GM Documents, Part 3ballaban8685Noch keine Bewertungen

- C (2) CosengDokument32 SeitenC (2) CosengCristhian RiosNoch keine Bewertungen

- BOSCH D JETRONIC Fuel Injection of Renault 17 TSDokument18 SeitenBOSCH D JETRONIC Fuel Injection of Renault 17 TSRaul Quispe Ramirez60% (5)

- ENG Connecting DEC To MErcedes m102Dokument3 SeitenENG Connecting DEC To MErcedes m102Vincent RenaNoch keine Bewertungen

- Bentley Mbc0 New - Product.announcement 2Dokument1 SeiteBentley Mbc0 New - Product.announcement 2master masNoch keine Bewertungen

- A Winning Formula: Debrief For The Asda Case (Chapter 14, Shaping Implementation Strategies) The Asda CaseDokument6 SeitenA Winning Formula: Debrief For The Asda Case (Chapter 14, Shaping Implementation Strategies) The Asda CaseSpend ThriftNoch keine Bewertungen

- Starter Chevrolet S10Dokument22 SeitenStarter Chevrolet S10Maxi SardiNoch keine Bewertungen

- Motorcycle, Solo (Harley-Davidson Model WLA)Von EverandMotorcycle, Solo (Harley-Davidson Model WLA)Noch keine Bewertungen

- Ignition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.Von EverandIgnition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.Bewertung: 3 von 5 Sternen3/5 (4)

- 9913 Ap 34Dokument108 Seiten9913 Ap 34احمدميدوNoch keine Bewertungen

- 1998 E320 Owners Manual pt1Dokument15 Seiten1998 E320 Owners Manual pt1Itzel ardilla de gomezNoch keine Bewertungen

- 2012 ENGINE PERFORMANCE Electronic Throttle Control System - TL PDFDokument64 Seiten2012 ENGINE PERFORMANCE Electronic Throttle Control System - TL PDFsoftallNoch keine Bewertungen

- 18672622-2PPSRMS-2010 Porsche Panamera Service Repair Manual Software-1 PDFDokument1 Seite18672622-2PPSRMS-2010 Porsche Panamera Service Repair Manual Software-1 PDFTodor NakovNoch keine Bewertungen

- Kia Code RetrievalDokument2 SeitenKia Code Retrievalandreisim80100% (1)

- Useful Info For Acura Legend 1993Dokument3 SeitenUseful Info For Acura Legend 1993jcalaqNoch keine Bewertungen

- DSM Tuning Sheet v2.1Dokument15 SeitenDSM Tuning Sheet v2.1Ultraman NexusNoch keine Bewertungen

- Intermittent Transmission Clutch Shudder Dps6 Automatic Transmission And/Or Transmission Fluid Leak TSB 14-0047Dokument6 SeitenIntermittent Transmission Clutch Shudder Dps6 Automatic Transmission And/Or Transmission Fluid Leak TSB 14-0047peter064Noch keine Bewertungen

- 1997 BlazerDokument402 Seiten1997 Blazermaster838Noch keine Bewertungen

- Map Sensor Drivability SymptomsDokument15 SeitenMap Sensor Drivability SymptomsmichaelsilvaNoch keine Bewertungen

- Pioneer Gm-A6604 Crt5455Dokument31 SeitenPioneer Gm-A6604 Crt5455boroda2410Noch keine Bewertungen

- Corolla 2006 ToyotaDokument19 SeitenCorolla 2006 ToyotabrauliojimenezNoch keine Bewertungen

- Charging 2001-04 PDFDokument19 SeitenCharging 2001-04 PDFoz23Noch keine Bewertungen

- Fuel InjectionDokument18 SeitenFuel InjectionAshutoshSharmaNoch keine Bewertungen

- ZD Racing 1 - 10 ZMT-10 User-Manual-3576507Dokument19 SeitenZD Racing 1 - 10 ZMT-10 User-Manual-3576507ruup2010 AlexNoch keine Bewertungen

- Honda OBD I Vehicles (1985 - 1995) Supported by Actron's Honda/Nissan/Toyota Code Scanner CP9025Dokument8 SeitenHonda OBD I Vehicles (1985 - 1995) Supported by Actron's Honda/Nissan/Toyota Code Scanner CP9025izalirunk100% (1)

- 1000 Manual 0407Dokument60 Seiten1000 Manual 0407Dharmesh patelNoch keine Bewertungen

- BMW E23 24 28 OdogearDokument9 SeitenBMW E23 24 28 OdogearporkfaceNoch keine Bewertungen

- Escape 2008Dokument628 SeitenEscape 2008kuya batokNoch keine Bewertungen

- VTECDokument13 SeitenVTECNarendra ChavdaNoch keine Bewertungen

- Reverse Camera Installation Guide: Tools and Supplies NeededDokument9 SeitenReverse Camera Installation Guide: Tools and Supplies Neededaxell AxelzonNoch keine Bewertungen

- General Information: Section 0Dokument12 SeitenGeneral Information: Section 0Jeremy WaldnerNoch keine Bewertungen

- Service ManualDokument115 SeitenService Manualcarlos maradiagaNoch keine Bewertungen

- Under-Dash Fuse/Relay Box (2001-2005 1.7L Honda Civic)Dokument4 SeitenUnder-Dash Fuse/Relay Box (2001-2005 1.7L Honda Civic)Rolando Alfaro NuñezNoch keine Bewertungen

- Rpocodes (HTC Holden)Dokument412 SeitenRpocodes (HTC Holden)Jhovany LMNoch keine Bewertungen

- 1991 Wire DiagramDokument30 Seiten1991 Wire DiagramJim SmithNoch keine Bewertungen

- 00-02-001, Systems OverviewDokument21 Seiten00-02-001, Systems OverviewВалентин СелищевNoch keine Bewertungen

- ME 87 enDokument295 SeitenME 87 enUserfabian215Noch keine Bewertungen

- 2005 9-5 EnginesDokument2 Seiten2005 9-5 Enginessnappydressedotter100% (1)

- Ignition, Engine Control (b4204t2 CVVT 2000)Dokument319 SeitenIgnition, Engine Control (b4204t2 CVVT 2000)Jose PichinteNoch keine Bewertungen

- 07 - Chassis ElectricalDokument52 Seiten07 - Chassis ElectricalEdgardo Rivas100% (1)

- 1维修手册 Section Index - Chapter 1Dokument19 Seiten1维修手册 Section Index - Chapter 1Frank Ch CcaicoNoch keine Bewertungen

- Translator DSM 1GDokument5 SeitenTranslator DSM 1Gtcbikerguy6100% (1)

- Re4F04A and Re4F04V Automatic Transmission (A/T) - Solenoid Valve Replacement ProceduresDokument3 SeitenRe4F04A and Re4F04V Automatic Transmission (A/T) - Solenoid Valve Replacement ProceduresfulltransmissionNoch keine Bewertungen

- Banshee ElectricalDokument23 SeitenBanshee ElectricalBrett SonnierNoch keine Bewertungen

- Fiat PuntoDokument17 SeitenFiat PuntoKavya M BhatNoch keine Bewertungen

- VW Passat B5 1.8T Timing Belt Replacement DIYDokument26 SeitenVW Passat B5 1.8T Timing Belt Replacement DIYaweed100% (1)

- Alh Wiring HarnessDokument18 SeitenAlh Wiring HarnessAlex DavidNoch keine Bewertungen

- Transmission and Transfer CaseDokument6 SeitenTransmission and Transfer CaseawemetalNoch keine Bewertungen

- SRS Cheat CodesDokument9 SeitenSRS Cheat CodesnurhayatiNoch keine Bewertungen

- A Report On Industrial Work ExperienceDokument20 SeitenA Report On Industrial Work ExperienceAgusiobo Anthony ChukwudiNoch keine Bewertungen

- 2021 Kia Sorento 116225Dokument700 Seiten2021 Kia Sorento 116225Tien Nguyen TatNoch keine Bewertungen

- (ACYFAR2) Toribio Critique Paper K36.editedDokument12 Seiten(ACYFAR2) Toribio Critique Paper K36.editedHannah Jane ToribioNoch keine Bewertungen

- IP Based Fingerprint Access Control & Time Attendance: FeatureDokument2 SeitenIP Based Fingerprint Access Control & Time Attendance: FeaturenammarisNoch keine Bewertungen

- Danh Sach Khach Hang VIP Diamond PlazaDokument9 SeitenDanh Sach Khach Hang VIP Diamond PlazaHiệu chuẩn Hiệu chuẩnNoch keine Bewertungen

- CNG Fabrication Certificate16217Dokument1 SeiteCNG Fabrication Certificate16217pune2019officeNoch keine Bewertungen

- VISCOROL Series - Magnetic Level Indicators: DescriptionDokument4 SeitenVISCOROL Series - Magnetic Level Indicators: DescriptionRaduNoch keine Bewertungen

- Projects: Term ProjectDokument2 SeitenProjects: Term ProjectCoursePinNoch keine Bewertungen

- Quantum Hopfield NetworksDokument83 SeitenQuantum Hopfield NetworksSiddharth SharmaNoch keine Bewertungen

- GATE General Aptitude GA Syllabus Common To AllDokument2 SeitenGATE General Aptitude GA Syllabus Common To AllAbiramiAbiNoch keine Bewertungen

- Residential BuildingDokument5 SeitenResidential Buildingkamaldeep singhNoch keine Bewertungen

- Simavi - Project Officer PROPOPIDokument4 SeitenSimavi - Project Officer PROPOPIAgus NugrahaNoch keine Bewertungen

- Minor Ailments Services: A Starting Point For PharmacistsDokument49 SeitenMinor Ailments Services: A Starting Point For PharmacistsacvavNoch keine Bewertungen

- V Series: Three Wheel, Counterbalanced Lift TruckDokument126 SeitenV Series: Three Wheel, Counterbalanced Lift TruckВиктор МушкинNoch keine Bewertungen

- COGELSA Food Industry Catalogue LDDokument9 SeitenCOGELSA Food Industry Catalogue LDandriyanto.wisnuNoch keine Bewertungen

- Rs 422Dokument1 SeiteRs 422rezakaihaniNoch keine Bewertungen

- Algorithm - WikipediaDokument34 SeitenAlgorithm - WikipediaGilbertNoch keine Bewertungen

- DR-2100P Manual EspDokument86 SeitenDR-2100P Manual EspGustavo HolikNoch keine Bewertungen

- Bank of AmericaDokument1 SeiteBank of AmericaBethany MangahasNoch keine Bewertungen

- Purchases + Carriage Inwards + Other Expenses Incurred On Purchase of Materials - Closing Inventory of MaterialsDokument4 SeitenPurchases + Carriage Inwards + Other Expenses Incurred On Purchase of Materials - Closing Inventory of MaterialsSiva SankariNoch keine Bewertungen

- Reference: Digital Image Processing Rafael C. Gonzalez Richard E. WoodsDokument43 SeitenReference: Digital Image Processing Rafael C. Gonzalez Richard E. WoodsNisha JosephNoch keine Bewertungen

- Random Variable N N Mean or Expected Value: Number of Ducks Type of Duck AmountDokument2 SeitenRandom Variable N N Mean or Expected Value: Number of Ducks Type of Duck AmountAngie PastorNoch keine Bewertungen

- KrauseDokument3 SeitenKrauseVasile CuprianNoch keine Bewertungen

- Health, Safety & Environment: Refer NumberDokument2 SeitenHealth, Safety & Environment: Refer NumbergilNoch keine Bewertungen

- Customer Satisfaction-ICICI Bank-Priyanka DhamijaDokument85 SeitenCustomer Satisfaction-ICICI Bank-Priyanka DhamijaVarun GuptaNoch keine Bewertungen

- ACM2002D (Display 20x2)Dokument12 SeitenACM2002D (Display 20x2)Marcelo ArtolaNoch keine Bewertungen

- Aluminium Extrusion Industry in IndiaDokument3 SeitenAluminium Extrusion Industry in Indiakalan45Noch keine Bewertungen

- PHP IntroductionDokument113 SeitenPHP Introductionds0909@gmailNoch keine Bewertungen

- Fundamental RightsDokument55 SeitenFundamental RightsDivanshuSharmaNoch keine Bewertungen