Beruflich Dokumente

Kultur Dokumente

Torque Motors v1.0

Hochgeladen von

ODG_290473Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Torque Motors v1.0

Hochgeladen von

ODG_290473Copyright:

Verfügbare Formate

Torque Motors

Innovative Motion Control

about etel torque motors

What is a torque motor?

Torque motors are a special class of brushless permanent-magnet synchronous motors. Since

the payload is directly connected to the rotor without the use of transmission elements, torque

motors are classified as direct drives.

Over the last 20 years, direct drive torque motors have provided significant performance

improvements in numerous applications covering a wide range of high-tech industries. Today,

direct drive technology is recognized as a leading solution towards meeting the requirements of

high productivity, improved accuracy, and increased dynamics of modern machinery.

Depending on your perspective, a torque motor is either a rolled-up linear motor or a classic

servodrive with a large number of poles. It is the large number of poles that enables conventional

torque motors to attain high torque at moderate speeds. Another attractive feature is their

compact design which includes a narrow lamination stack and a large hollow shaft or bore.

Direct drive essentially means the load and motor are directly connected; or in other words, the

motor directly drives the load. Significant improvement to stiffness and a more compact solution

are among the benefits of this technology. In addition to providing high dynamic performance,

torque motors reduce cost of ownership, simplify the design of the machine and eliminate wear

and maintenance.

As with linear motors, torque motors are a type of frameless motor. This means that the motor does

not include a housing, bearings, or feedback device. These components can be selected by the machine

builder and optimized according to the required performance, or purchased as part of an assembly.

Since its founding in 1974, ETEL has been exclusively dedicated to the development of direct

drive technology. Through numerous innovations and patented designs, ETEL continues to provide

unmatched torque efficiency for the most optimized designs.

Torque motors produce high torque at moderate speeds and even when stationary or stalled.

Contrary to traditional drives, the sizing and selection of a torque motor is purely based on

torque, not power. Fundamentally, the peak torque determines the maximum torque that the

motor physically produces and the continuous torque defines the amount of torque the motor

can continuously supply. The duty cycle of the application will define the dependency on peak or

continuous torque.

Torque motor advantages

Key benefits inherent to the adoption of torque motor technology include:

High dynamics

High accuracy

Optimal speed control

Very compact design

Outstanding MTBF

Low maintenance

Water cooling channel

Cables output

Rotor rings

Magnets

These advantages are further explained in the following pages.

Stator

Windings

O-ring sealings

INDUSTRY SECTORS

Below are some examples of industry sectors where torque motors are successfully used, providing our customers in these areas a distinct competitive advantage.

Machining

2 | Torque Motors

Finishing / grinding

Tables / milling heads

Stamping / laser cutting

Electronics

Semiconductor

Packaging

Printing / scanning

Telescopes

Robotics

Torque Motors | 3

Innovative Motion Control

why adopt torque motors?

why choose etel?

Reduced cost of ownership

Patented technology

Direct coupling of the payload to the rotor eliminates the need for mechanical transmission

elements such as gearboxes, timing belts, speed reducers and worm gear drives. And unlike

brushed rotary motors, there is no contact between rotor and stator; therefore there is no

mechanical wear resulting in excellent reliability and long lifetimes. Fewer mechanical parts also

minimizes maintenance and reduces the system cost. The direct drive technology intrinsic to a

torque motor system results in an efficient and effective gearless assembly.

ETELs patented ironcore design provides the industrys most efficient direct drive torque motors.

Direct drive

Unmatched performance

ETELs patented design is well known in the worldwide direct drive market as a high performance

product. For many years, the most high-end applications in the field have been driven by ETELs

motors. A continuous development effort is done to keep ETELs leading position in the market.

Easy integration

Direct drive expertise

ETELs torque motors are available in a wide range of sizes and can be easily adapted to

most applications. ETELs unmatched standard product offering includes motors with external

diameters from 140 mm to 1290 mm. The use of magnets and limited air gap results in a

large hollow shaft or bore for easy integration of cables, cooling tubes, or other application

related equipment. The ring-like configuration of a torque motor minimizes the volume required

for mounting. This gives the machine designer great flexibility in locating the motor to work with

bearings, feedback devices, and payload.

ETEL has been working strictly on direct drive technologies for more than 30 years. In addition

to the motor technology know-how, through the years, ETEL has developed valuable knowledge

about motion control by developing control electronics and fully integrated motion systems. Our

deep understanding of the overall motion system helps us find the appropriate solution for our

customers needs.

High quality

Dynamic performance

Dynamic performance is drastically improved by using direct drive due to the very high control

loop bandwidth that can be achieved on the overall system. The direct coupling of the load and

position feedback to the motor has the advantage of eliminating all phenomena that limit the

dynamic performance on non direct driven machines. Eliminating long-time drift, elasticity, and

backlash is a huge advantage for machine performance and lifetime.

Gear train

Compatibility of ETELs torque motors with a wide range of control electronics results in easy

integration of a direct drive solution.

Product range

Timing belt

With standard motors from 140 to 1290 mm in diameter and 38 to 31200 Nm of peak torque,

ETEL offers the largest s election of torque motors on the market.

Reducer

The majority of ETEL torque motors can be ordered with or without water cooling channels.

Furthermore, different winding types are available to best fit our customers applications.

Wide torque-speed range

Torque vs. speed for:

TMK0360-070-3UFS

1200

1000

800

Torque [Nm]

The torque motor is part of a complete direct drive solution which includes a position controller.

High-end digital controllers like the ETEL position controllers, which have been designed

specifically for direct drive applications provide excellent control loop quality ensuring optimum

stiffness, smooth motion, and excellent velocity control with low torque ripple.

Worm gear

Ease of integration

Torque motor applications have a wide range of dynamic performance requirements. Depending on

the specifics of a systems duty cycle, the peak torque, continuous torque, or both will drive the

selection of a motor. An application with a light duty cycle that requires high peak torque for a short

period of time will typically utilize an air cooled motor like ETELs TML series. As the continuous

torque requirement increases so will the temperature of the motor. The integrated liquid-cooling

capability of the ETEL TMB motor provides an efficient means of temperature control ensuring high

dynamic performance that can be maintained even for the most demanding applications.

Direct drive torque motors deliver high torque over a wide range of speed, from a stalled or low

speed condition to high angular velocities. While torque motors can achieve high velocities (up

to 5000 rpm), there is a trade-off in torque as the motor becomes limited by speed dependent

losses increase. The performance of a torque motor over its velocity range is illustrated in its

torque/speed curve. An example is shown opposite.

High product quality is guaranteed by ETELs use of modern development tools and thorough

qualification procedures. All ETEL motors are manufactured in Switzerland according to highest

quality standards.

600

400

200

0

0

300

Continuous torque at 600 V

Peak torque at 600 V

4 | Torque Motors

600

900

1200

1500

1800

Speed [rpm]

Torque Motors | 5

Innovative Motion Control

torque motors

Torque motors range

ETELs standard torque motors are available in a wide range of torque and sizes.

ETEL offers the most comprehensive standard torque motor range in the industry. With more

than 100 models to choose from, almost any requirement can be successfully fulfilled. ETEL also

excels in developing custom motors to meet a specific application need.

20 000

1221-150

0990-150

10 000

ETELs TM series are the industrys most popular ironcore frameless torque motors. Powerful

magnets are used to maximize torque and acceleration while minimizing the size of the motor.

The performance of ETELs torque motors have been further increased by the use of buried

magnet technology on the latest TMK family.

0990-150

0760-100

Continuous torque [Nm]

0760-100

The TMB motor series is todays industry preferred torque motor solution. This renowned family

is designed with a precision stator and has been optimized to achieve very high continuous

torque while minimizing the dissipated heat when liquid cooling is used. For more demanding

applications, the TMK family can achieve more torque and significantly faster speeds than

TMB motors thanks to its unique rotor design. In addition, the TML family can be used to reach high

performance at a lower price in less demanding applications. All families of torque motors benefit

from ETELs patented ironcore design that provides unmatched torque efficiency and low torque ripple.

0530-100

0530-100

0450-100

1 000

0360-070

0360-070

0291-050

0291-070

0175-100

0210-050

100

0175-050

0175-050

0140-030

10

40

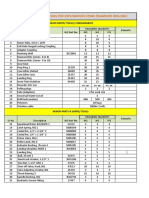

DESCRIPTION

TMB Series

APPLICATIONS

100

1 000

TMK Series

10 000

Maximum speed [rpm]

With cage

TRADITIONAL FLUX

More than 50 models

External diameter from 160 to 1290 mm

Large hollow shaft from 60 to 1070 mm

Peak torque from 38 to 31200 Nm

Maximum rated speed up to 4500 rpm

Low torque ripple

TMB

Designed for the most demanding applications

Liquid cooling channels

600 VDC bus voltage

Very high continuous torque

Very high peak torque

Custom motors

Without cage

External diameter from 140 to 581 mm

Large hollow shaft from 60 to 420 mm

Peak torque from 38 to 4990 Nm

Maximum rated speed up to 4500 rpm

Low torque ripple

TML

TMM

TML: TMM motors with lugs

No liquid cooling option

600 VDC bus voltage

Very high peak torque

CONCENTRED FLUX

PERMANENT MAGNETS SYNCHRONOUS TORQUE MOTORS

MODEL

With cage

External diameter from 198 to 1050 mm

Large hollow shaft from 50 to 800 mm

Peak torque from 113 to 19900 Nm

Maximum rated speed up to 5170 rpm

Low torque ripple

TMK

6 | Torque Motors

Powerful high speed ironcore torque motor

TMK stator (up to 530 mm) compatible with

the mechanical interface of the TMB series

Liquid cooling channels

600 VDC bus voltage

Continuous torque increased by up to 30% vs TMB

Very high peak torque

Up to 8 times speed increase vs TMB

Field weakening compliant

High speed milling / turning tables

High precision machining centers

Grinding / finishing machines

Boring / drilling / tapping machines

Milling heads

Transfer lines

EDM

Laser / ultrasonic cutting machines

Stamping machines

Lathes

Indexing tables

Electronic chip testing equipment

Pick-and-place machinery

High-end printing / scanning machines

Packaging equipment

Handling equipment

Composite materials manufacturing

Telescopes

With over 30 years of direct drive innovation, ETEL has the expertise to quickly and efficiently

adapt existing products into custom solutions. The process is made simple due to the modular

and flexible design of our torque motors. ETEL can also develop a completely new motor design

to address a particularly demanding or unusual requirement.

ETELs experience also includes:

Ironcore and ironless motors

Integrated cooling

Transverse flux

Segmented motor

Combination with linear axis

High and low temperatures

Vacuum

Hazardous duty rating

UL certified

Aerospace motors

Torque Motors | 7

Innovative Motion Control

direct drive solution

Bearing

Bearing selection depends on system properties like dynamic load, accuracy... Applications that

require high stability, accuracy, and repeatability will typically use high stiffness bearings to meet

their performance needs. Mechanical bearings are often the only wear-prone components in a

direct drive based system. The most commonly used bearings are:

To achieve optimum performance from a direct drive motor it must be built to the necessary

standards of precision and stiffness as part of a complete direct drive solution. In addition to the

motor, the four key components of a direct drive system are the electronics, encoder, bearings and

machine structure. Each of the four components is briefly described in the following paragraphs.

Electronics

The best torque motor performance is achieved when integrated with a fully digital controller with

extremely high bandwidth capability like the ETEL AccurET position controllers family.

In a direct drive system, the controller can benefit from a very precise position feedback due to

the fact that there is no transmission in between the feedback device and the load. Because of

this high quality feedback signal, a high-end controller (such as ETELs AccurET) can compute

advanced control algorithms at a very high frequency. Ultimately, the precision and the dynamics

of the axis are drastically increased.

Some key factors to be taken into account when selecting a controller are listed below:

High frequency control loops (current, speed, and position loops).

High current and position loop bandwidths (typically >2 kHz and >100 Hz respectively).

High encoder interpolation factor to ensure adequate speed and position resolution.

Advanced control algorithms (PID with feed-forward, state space regulators, observers, notch

filters, etc).

Advanced features: ability to compensate for cogging torque, stick slip, and other system

repeatable phenomena.

Electronics

ETELs AccurET/UltimET controller

family is especially

designed

for a variety electronics and

semiconductor related applications,

where extremely high precision is

needed without any compromise on

throughput.

They can provide:

High position accuracy

Close to zero settling time

High dynamics

Multi-axis interpolation

Fast communication bus

And much more...

For more

information,

refer to our

Motion

Control

brochure.

ETELs torque motors have been successfully integrated with most major brands of servo

controllers and CNC including: Heidenhain, Siemens, Fanuc, Bosch, B&R, Kollmorgen, and Num.

Deep groove ball bearing

High speed capability, low cost

Angular contact ball bearing

High speed capability, suitable for combined loads

(axial & radial), high precision

Crossed roller bearing

Suitable for combined loads, high stiffness, low speed,

high precision, assembly with one single bearing

Axial-radial roller bearing

Very high stiffness, suitable for combined loads,

high precision

Axial-radial ball bearing

Very high stiffness, suitable for combined loads,

high precision

In addition to mechanical bearings, air and hydrostatic bearings are often used for ultra-precision

applications such as diamond turning/milling, silicon dicing, precision grinding and high accuracy

metrology axes.

Structure

Encoders

Structure

High precision, high resolution feedback is

essential for achieving optimum performance

using direct drive. Direct coupling of the load

to the drive improves accuracy but the best

performance can only be achieved with the

appropriate feedback device. This requires

an absolute or incremental optical encoder

with a high line count. When combined with

the interpolation capability of the electronics,

resolutions of less than 1 arcsec can be achieved.

Rotor

Stator

Bearings

Encoder

Special attention must be paid to the

machine's structural stiffness. In most

applications the structure should be

designed with a natural frequency

above 200 Hz. Finite element

analysis is typically used as a

design validation tool. Below

is an example of typical FEM

simulation of radial load stiffness

on an ETEL rotary table design.

Picture courtesy of Dr J. Heidenhain GmbH

8 | Torque Motors

Torque Motors | 9

Innovative Motion Control

torque motor selection

Motor constant

The motor constant, Km, is one of the key parameters for comparing permanent magnets

synchronous motors. It shows the relationship between torque produced and resulting power

losses. A motor with a higher value of Km is a more efficient generator of torque.

Many factors must be taken into consideration when choosing a torque motor to ensure

outstanding system performance. This brochure provides a basic overview of some of the key

selection factors that should be taken into account when choosing a torque motor. For detailed

calculation and sizing information, please refer to the ETEL torque motors handbook, or ask an

ETEL application and support engineer for assistance.

Km is determined by the design and construction of the motor. This parameter is related to the

internal design of the motor (copper filling factor, electromagnetic design, etc). Therefore, it is

a better indicator of motor performance than the torque constant, Kt (Nm/Arms), which relates

torque output to the supplied current. In ETEL motors, Kt can be easily adjusted by changing

the winding type. Kt is useful for matching a motor to a servo amplifier, but it does not provide

information about the motors efficiency.

Motor sizing

The first step in a torque motor sizing is to define the torque and speed requirements for the

application. The torque required for each move within the cycle can then be used to determine

the continuous torque. When calculating the continuous torque it is important to include all

sources of torque such as friction, machining torque, static force due to an offset load, and

external perturbations.

Thermal considerations

Like all servo motors, torque motors generate heat in operation. In order to reduce thermal

expansion of the machine, this heat has to be removed as efficiently as possible. ETEL TMBs

and TMKs torque motors provide optimized cooling channel design to ensure a maximum heat

evacuation through the coolant. Keeping the machine structure cold is mandatory to reach high

precision and repeatability levels.

Power dissipation of the motor is estimated calculating the continuous torque. The amount

of heat produced by motor power dissipation will determine the temperature increase of the

structure and if liquid cooling is required.

Torque motors can be cooled either by free air convection or with a coolant. Liquid cooling is

recommended for demanding applications where a coolant is available. Due to their optimized

electromagnetic design, ETELs torque motors produce much more torque for the same input

power than competitive products.

Under static conditions with an applied load, one motor phase can get disproportionately hot,

because the power dissipation is not shared equally among all three phases. To ensure safe

operation under these conditions a stall torque calculation should be performed.

ETELs motors are available in several winding configurations. The winding should be chosen to

match the speed requirements of the application and the voltage and current specifications of

the electronics. Note that the torque/speed characteristics of a motor change with the winding.

On any direct drive application, the thermal management is of major importance and closely

related to the final machine performance. In fact, in a direct drive axis, the motor is located very

close to the working point. This is a big advantage in terms of mechanical stiffness and leads

to unmatched machine performance. However, the fact that the motor is highly integrated also

means that the heat generation is closer to the critical area than in a conventional worm gear

system for example.

Detent effects

Thanks to a patented design, ETEL has the expertise to manufacture ironcore torque motors

with very low detent effects. The patented design uses an innovative combination of open slots,

orthocyclic windings and fractional pole pitch. This solution significantly reduces detent effects

without any skewing of laminations or magnets which would result in lower torque density.

ETEL has a long experience in torque motor integration and heat management. Do not hesitate

to contact your ETELs representative to get support during machine design.

Torque motors - Data sheets

Torque motors - Handbook

ETEL Website

ETEL Sizing Tool

ETEL torque motor specifications

are available in the ETEL torque

motors data sheets.

For more information on motor

selection and integration, ask for

the ETEL torque motors handbook

from our website.

For more information

about the torque motors

or to download the data

sheets booklet, refer to

our website: www.etel.ch

ETEL has developed a powerful

sizing tool that can simulate the

customers machine operation.

This tool will help you getting the

very best performance/price

ratio that can be obtained on your

specific application. Do not hesitate

to contact your local ETEL sales

office to get technical support

during the machine design phase.

This booklet includes the performance

specifications, torque/speed curves

and mechanical dimensions of each

standard ETEL motor. In addition,

an overview of the ETEL torque

motor product range and a motor

comparison chart is provided.

10 | Torque Motors

Torque Motors | 11

Innovative Motion Control

case studies

Small TMKs in high-end printing

Large TMKs enable milling / turning feature

ETEL has been active and present for many years in the machine tool industry, particulary with

high-end machines using the TMB motor range. Nowadays, the TMK motor range strongly contributes to

customers success and uniqueness by providing substantial adding value to their products. In this case,

the integration of TMK motors in a CNC 5-axis machining

center made the Milling/Turning option possible on these

large high-end machines. For instance, using

a large TMK motor size made the milling and

rotational machining at 500 rpm of parts

that could weigh up to 1000 kg in a single clamping possible. This specific

Milling/Turning feature drastically increases the machine productivity without

any comprise on precision and performance.

In addition, the upgrade of an existing TMB based machine to a

high speed TMK based machine is made easy thanks to the fact

that TMB and TMK motors are nearly pin-to-pin compatible. The

TMK series is available in a very wide range of sizes to fit any

applications (see pages 6 and 7).

In high-end printing machines, smooth and accurate motion is a key factor to success. On machines

targeting 8000 dpi and more with a precision down to 50 nanometers, the choice of the motor is

crucial. Speed stability has to be perfect

to ensure good printing quality while

maximizing machine throughput

which, like in many other applications,

is a key specification to be successful

in the market. In this case, the use of

a TMK high speed motor allows both a stable high speed operation and very

short acceleration/deceleration times. In addition to that, in this specific

application, the TMK motor has been slightly customized to reach optimal

machine performance in forced air cooling mode (see picture). Finally, the

very high torque density of the TMK motor contributes to the overall compact

size of the machine to best fit the industry standards.

ETEL linear motors are also integrated in the presented machine. ETELs LMG

motors are used for the linear motion of the exposing drum. To reach outstanding

performance, the full motion system has been designed based on direct drive technology.

The combination of ETEL motors and optimized control and mechanical design makes

this machine very successful in its industry.

Picture courtesy of

Lscher AG Maschinenbau

Pictures courtesy of

Maschinenfabrik Berthold Hermle AG

TMBs in high-end machine tool

ETELs longstanding and renowned TMB motor range is still widely

used and valued in the machine tool industry. The well known

advantages of direct drive technology associated to

the outstanding performance and reliability of ETEL

products contributes to our customers success.

In some fields of applications like aerospace or

power generation, precision and quality are a must

in component machining. For instance, in these

5- or 6-axis machines, the key criteria for productivity

are stability, dynamics, and agile contouring

capabilities. Meeting the specifications of the machine

becomes even more challenging when materials to

be machined are difficult-to-cut materials such as

titanium or super-alloys. In this case, direct drive

technology and more precisely ETELs TMB motors

play a major role in the overall machine performance.

12 | Torque Motors

The limited production related to this specific high-end market naturally

defines some key factors such as: flexibility, optimal performing and low

cost of ownership. With 10 different motor diameters (from 140 mm to

1290 mm) the very wide TMB range perfectly fits these kinds of applications

where flexibility on standard products is needed with absolutely no

trade-off on performance and quality.

Pictures courtesy of

Liechti Engineering AG

Torque Motors | 13

Innovative Motion Control

case studies

ETEL torque motors in 5-axis machines

About twenty years ago, ETEL started to develop direct drive motors to serve the industry. It took a

few years to convince the machine tool industry that direct drive torque motors were the solution for

their future needs. ETEL being the first supplier of torque

motors, had the chance to set what became the standards

in terms of dimensions and performances. At that time,

this very fast evolution of machine tool toward direct

drive was lead by the most renowned European

machine tool makers.

ETEL torque motors in rotary tables

In addition to ETELs long-lasting collaboration with high-end market-leading

machine tool manufacturers, ETEL also closely collaborates with

sub-components makers such as rotary table builders. These

companies concentrate their effort to build a highly-optimize single

axis product to reach outstanding performance. The wide range of

standard torque motors offered by ETEL is a key element in helping

table makers meet the needs of the most demanding customers.

ETEL provides the widest range of standard torque motors on the

market with diameters from 140 mm up to 1290 mm. As such, table

designs can be made flexible to fit with different standard TMB sizes

as well as with the new high speed TMK motors. This flexibility provides

Picture

the final customer with a dedicated solution based on a proven and stable

courtesy of Weiss GmbH

design. The optimal selection of bearings, encoders, and torque motors finally

results in one of the most advanced rotary tables with undeniable advantages. These are mainly linked to the absence of mechanical elements

and gears. The result is high speed, high stiffness and zero backlash table that is more compact than conventional tables.

Today, machine tool makers are present all over the globe and

are becoming stronger in some Asian countries like Taiwan for

instance. ETEL followed this trend by opening offices in five key

Asian countries to provide the best possible local support starting

collaboration in the very early phases of new machine development.

The use of high-end core components like TMB motors and NC

Controllers allowed Asian companies to develop award winning

5-axis machines. These machines meet the most demanding

specifications in diverse applications including die and mold, energy,

and automotive markets. By using direct drive TMB motors in both

A and C axes, parts up to 1000 kg can be machined with the highest

level of precision and surface qualities. In addition, the machine reliability

benefits from the quality of ETEL products and can proudly compete with the

most advanced European 5-axis machines.

Pictures courtesy of WELE Mechatronics Co., Ltd.

ETEL is part of pioneering challenges

In addition to supplying high technology products to our main markets, we are also proud to improve our

existing competencies by addressing new technological challenges that push back the limits of the impossible.

ETEL torque motor technology, for instance, is being used in many challenging scientific undertakings to

do just that. The ultra-lightweight revolutionary airplane from Solar Impulse, capable of flying days and

nights without fuel, is fascinating case study. This airplane is combining the most advanced scientific

knowledge in terms of aeronautics,

materials, photovoltaic energy, and

electrical motors.

For this unique aircraft; reliability is not just a nice-to-have, it is vital!

The quality of the ETEL torque motors operating in the most extreme

environmental conditions is a key success factor. The performance has to

be maintained optimal and constant during non-stop flights for multiple

tens of hours for which failure is not an option. In addition, the motor

efficiency must reach extremely high values to maximize the use of the

precious solar energy. By using the same base technology ETEL is using

in standard TMB and TMK motors, an efficiency of 96% can be reached.

Finally, in such a project, the weight reduction is a continuous effort.

14 | Torque Motors

Solar Impulse / Jean Revillard

All components down to the smallest screw are

designed to have the best performance-per-weight

ratio. This weight optimization was also applied

to the torque motors to get the very best

mechanical power out of the smallest possible

space. Once again, the ETEL technology was

perfectly suited to serve these needs as well.

Finally, it is a combination of ETEL torque motor

technology together with the most advanced

technologies from other fields that allowed

this airplane to successfully fly days and nights

across Europe. The next step will be a round

trip of the globe, and ETEL is proud to be part

of this new challenge.

Picutres courtesy of

Solar Impulse SA

www.solarimpulse.com

Solar Impulse / Jean Revillard

Torque Motors | 15

GROUP SUBSIDIARIES AND SALES OFFICES

info@etelusa.com

sales@heidenhain.com.cn

FRANCE etel@etel.fr

GERMANY etel@etelgmbh.de

GREAT BRITAIN sales@heidenhain.co.uk

HONG KONG sales@heidenhain.com.hk

ITALY etel@etelsa.it

KOREA info@heidenhain.co.kr

SINGAPORE info@etel.sg

SWITZERLAND sales@etelsa.ch

TAIWAN info@heidenhain.tw

THE NETHERLANDS etel@etelbv.nl

AMERICAS

CHINA

OTHER COUNTRIES

ETEL S.A.

Zone Industrielle

CH - 2112 Mtiers

Switzerland

T +41 (0)32 862 01 00

F +41 (0)32 862 01 01

etel@etel.ch

www.etel.ch

internationalsales@etel.ch

REPRESENTATIVES

b.hoerburger@iul-elektronik.at

ISRAL comotech@medital.co.il

SPAIN farresa@farresa.es

AUSTRIA

version 1.0 - 12/12 - subject to modifications without previous notice

HEADQUARTERS

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- CWI TEST FlashcardsDokument30 SeitenCWI TEST FlashcardsLuis Jaramillo100% (3)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Project Management ProcessDokument23 SeitenProject Management ProcessMuhammad Sajid Saeed100% (2)

- HAZOPDokument47 SeitenHAZOPMiftakhul Nurdianto100% (4)

- Operations and Maintenance Manual MAN-10000946 Elmar Grease Injection Equipment AssemblyDokument56 SeitenOperations and Maintenance Manual MAN-10000946 Elmar Grease Injection Equipment AssemblyAbhinav KumarNoch keine Bewertungen

- Jared Diamond. Guns Germs and Steel 1999 PDFDokument3 SeitenJared Diamond. Guns Germs and Steel 1999 PDFSabah MushtaqNoch keine Bewertungen

- Ocean Power Conversion For Electricity Generation and Desalinated Water ProductionDokument8 SeitenOcean Power Conversion For Electricity Generation and Desalinated Water ProductionODG_290473Noch keine Bewertungen

- Wave Final ReportDokument60 SeitenWave Final ReportODG_290473Noch keine Bewertungen

- 35.renewable Energy From The Ocean PDFDokument9 Seiten35.renewable Energy From The Ocean PDFODG_290473Noch keine Bewertungen

- Material Sound VelocitiesDokument10 SeitenMaterial Sound VelocitiesODG_290473Noch keine Bewertungen

- Optimum Probe Frequency and Sampling Rates REV ACPDokument3 SeitenOptimum Probe Frequency and Sampling Rates REV ACPODG_290473Noch keine Bewertungen

- 356A01Dokument16 Seiten356A01ODG_290473Noch keine Bewertungen

- Ultrasonic Properties of A New Low Attenuation Dry Couplant Elastomer PDFDokument10 SeitenUltrasonic Properties of A New Low Attenuation Dry Couplant Elastomer PDFODG_290473Noch keine Bewertungen

- 3d ImagingDokument3 Seiten3d ImagingODG_290473Noch keine Bewertungen

- 3 Assessment of Wave Energy Resource PDFDokument42 Seiten3 Assessment of Wave Energy Resource PDFODG_290473Noch keine Bewertungen

- Principles For Capture of Energy From Ocean Waves.Dokument8 SeitenPrinciples For Capture of Energy From Ocean Waves.Nicholas Michael James EntwistleNoch keine Bewertungen

- Material Property OverviewDokument2 SeitenMaterial Property OverviewODG_290473Noch keine Bewertungen

- How To Calculate + - DB As A Percentage of The Source SignalDokument5 SeitenHow To Calculate + - DB As A Percentage of The Source SignalODG_290473Noch keine Bewertungen

- Worm Gears & Worms - 48 Pitch: MaterialDokument1 SeiteWorm Gears & Worms - 48 Pitch: MaterialODG_290473Noch keine Bewertungen

- Combate EspiritualDokument338 SeitenCombate EspiritualOfelia Trejo67% (3)

- HX324C11SRK2/16: 16GB (8GB 1G X 64-Bit X 2 PCS.) DDR3-2400 CL11 240-Pin DIMMDokument2 SeitenHX324C11SRK2/16: 16GB (8GB 1G X 64-Bit X 2 PCS.) DDR3-2400 CL11 240-Pin DIMMODG_290473Noch keine Bewertungen

- 7434 23145 1 PBDokument5 Seiten7434 23145 1 PBODG_290473Noch keine Bewertungen

- L SeriesSPDokument2 SeitenL SeriesSPscribdheinzNoch keine Bewertungen

- Parish Book of Chant PDFDokument341 SeitenParish Book of Chant PDFmike04lesNoch keine Bewertungen

- ISCE - ThrmAC - 800BTU - Broch - 120611 - OK PDFDokument2 SeitenISCE - ThrmAC - 800BTU - Broch - 120611 - OK PDFODG_290473Noch keine Bewertungen

- En A 523 LbearingDokument30 SeitenEn A 523 LbearingODG_290473Noch keine Bewertungen

- NG360 e PDFDokument6 SeitenNG360 e PDFODG_290473Noch keine Bewertungen

- en Y-Bearing and Y-B UnitsDokument262 Seitenen Y-Bearing and Y-B UnitsJosé Del Orbe GarcíaNoch keine Bewertungen

- ThermoTECTM 141 Series 800 BTU Air ConditionerDokument2 SeitenThermoTECTM 141 Series 800 BTU Air ConditionerODG_290473Noch keine Bewertungen

- Photo Indication Dimension Diagram: H.264 Megapixel Ip D/N Poe Box CameraDokument2 SeitenPhoto Indication Dimension Diagram: H.264 Megapixel Ip D/N Poe Box CameraODG_290473Noch keine Bewertungen

- CP-200HT Peltier-Thermoelectric Cold Plate Cooler: Technology, IncDokument3 SeitenCP-200HT Peltier-Thermoelectric Cold Plate Cooler: Technology, IncODG_290473Noch keine Bewertungen

- 12 - Right Angle Drives: Catalog Series Material Pages RatiosDokument16 Seiten12 - Right Angle Drives: Catalog Series Material Pages RatiosODG_290473Noch keine Bewertungen

- Encoder HEDL-5540-A13 PDFDokument5 SeitenEncoder HEDL-5540-A13 PDFODG_290473Noch keine Bewertungen

- God Is My Refuge PDFDokument1 SeiteGod Is My Refuge PDFODG_290473Noch keine Bewertungen

- 10 Pentagramas en A4Dokument1 Seite10 Pentagramas en A4Mariaherva67Noch keine Bewertungen

- Agilent 700 Series ICP-OESDokument52 SeitenAgilent 700 Series ICP-OESRoger ManzanarezNoch keine Bewertungen

- Fluid Mechanics & Machines IES2009 GATE2009Dokument451 SeitenFluid Mechanics & Machines IES2009 GATE2009paragmishra1986Noch keine Bewertungen

- 15 Step Guide to Build Simple Electric GeneratorDokument13 Seiten15 Step Guide to Build Simple Electric GeneratorSeindahNyaNoch keine Bewertungen

- Consistent Engineering Units in FEADokument6 SeitenConsistent Engineering Units in FEAAntonis AlexiadisNoch keine Bewertungen

- Catalog CabluriDokument7 SeitenCatalog CabluriAdrian OprisanNoch keine Bewertungen

- D 2320 - 98 R03 RdizmjaDokument3 SeitenD 2320 - 98 R03 RdizmjaEliKax!Noch keine Bewertungen

- Endress KatalogDokument72 SeitenEndress KatalogpnsanatNoch keine Bewertungen

- Minimum drilling supplies stockDokument3 SeitenMinimum drilling supplies stockAsif KhanzadaNoch keine Bewertungen

- Recruitment Brochure: National University of Study and Research in Law RanchiDokument15 SeitenRecruitment Brochure: National University of Study and Research in Law RanchiSiddharth SinghNoch keine Bewertungen

- "The Land of Plenty?": Student's Name: Bárbara Milla. Semester: Third Semester. Professor: Miss Patricia TapiaDokument11 Seiten"The Land of Plenty?": Student's Name: Bárbara Milla. Semester: Third Semester. Professor: Miss Patricia TapiaAndrea José Milla OrtizNoch keine Bewertungen

- Fly by WireDokument2 SeitenFly by WireAmit VarmaNoch keine Bewertungen

- Shahzeb Hassan: Career ObjectiveDokument2 SeitenShahzeb Hassan: Career ObjectiveomairNoch keine Bewertungen

- TH3122 004 PDFDokument14 SeitenTH3122 004 PDFSasa MitrovicNoch keine Bewertungen

- Ramon Magsaysay Memorial College-Marbel INC Bachelor of Science in Tourism ManagementDokument7 SeitenRamon Magsaysay Memorial College-Marbel INC Bachelor of Science in Tourism ManagementRam G. MorteraNoch keine Bewertungen

- As 61800.3-2005 Adjustable Speed Electrical Power Drive Systems EMC Requirements and Specific Test MethodsDokument11 SeitenAs 61800.3-2005 Adjustable Speed Electrical Power Drive Systems EMC Requirements and Specific Test MethodsSAI Global - APAC0% (1)

- Huarui Technologies Co.,Ltd VipDokument19 SeitenHuarui Technologies Co.,Ltd Vipdrfaizal01Noch keine Bewertungen

- Revision Sex Death and EpicsDokument77 SeitenRevision Sex Death and EpicsAshli KingfisherNoch keine Bewertungen

- UnlversDokument55 SeitenUnlversCan AcarNoch keine Bewertungen

- Neurodiagnostic TechnologyDokument3 SeitenNeurodiagnostic TechnologyJeyarajasekar TtrNoch keine Bewertungen

- D5 Novtek Premium Tile Adhesive TDSDokument2 SeitenD5 Novtek Premium Tile Adhesive TDSJILBERT DORIANoch keine Bewertungen

- Safety Bulletin 35 HOT WORKDokument3 SeitenSafety Bulletin 35 HOT WORKTrebor SantosNoch keine Bewertungen

- Manual Solis-RSD-1G - V1.0 9 0621 - 27 V6Dokument9 SeitenManual Solis-RSD-1G - V1.0 9 0621 - 27 V6Long ComtechNoch keine Bewertungen

- User Manual SR 9797HDDokument47 SeitenUser Manual SR 9797HDnavamivbNoch keine Bewertungen

- Product Overview - COMFORT OVERVIEWDokument16 SeitenProduct Overview - COMFORT OVERVIEWDam Ngoc KienNoch keine Bewertungen

- AART To Revitalize Aarhus Port District With TerracedDokument4 SeitenAART To Revitalize Aarhus Port District With TerracedaditamatyasNoch keine Bewertungen