Beruflich Dokumente

Kultur Dokumente

Equivalent Pipe Length Method

Hochgeladen von

Lê Đình HoàngCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Equivalent Pipe Length Method

Hochgeladen von

Lê Đình HoàngCopyright:

Verfügbare Formate

Equivalent Pipe Length Method Calculating Pressure Loss in Piping

Systems

Calculating pressure loss in piping systems with the

Equivalent Pipe Length Method

An efficient and simple way to calculate the pressure loss in a piping system is the "Equivalent Pipe

Length Method".

1. Make a Diagram of the Piping System

Make a diagram where the system is structured with nodes as shown below.

In the very simply circulating system used in this example the first node (0) is the pump. The next node

is the tees (2) where the piping system splits up. The other nodes are the heating radiators.

In many systems the structure can be simplified as above since the piping in both directions are of

same size. If a more fine grained approach is required, additional nodes can be added in both

directions as shown below.

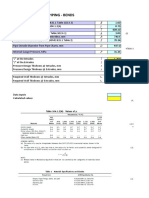

2. Make a calculation table

With the most simplified nodes structure above a calculation table can be made as shown below. Each

section from node to node is calculated by supplying length, volume flow, pipe size, pressure loss from

diagrams or tables for the actual pipes and components in the sections and their individual equivalent

length substituting the the minor loss.

An excel template with the table above can be downloaded here:

Equivalent Pipe Length Method - Excel Template

Note! The flow and pressure units must be adjusted to the data available for your piping system.

3. Add Volume flow, Pipe Size and Pressure Loss for each Section

Add actual pipe size and in each section. Use tabulated data or a diagrams.

The pressure loss may alternatively be calculated with the Hazen-Williams Equation or the DarcyWeisbach Formula.

Pressure loss for many types of pipes can be found here.

4. Add Equivalent Length of all Valves, Fittings and Straight Pipes

Add the equivalent length of all valves, components, fittings and straight pipes in the sections.

5. Summarize the Pressure Loss in each Section

Calculate and summarize the pressure loss in each section.

6. Summarize the Pressure Loss in all Paths

Finally, add up the pressure loss in all sections that form unique paths. In the example above there are

two unique paths - one is section 0 - 2 - 3, the other is section 0 - 2 - 4. Add extra columns for

additional paths in more complicated systems.

The highest pressure loss determines the pump head.

7. Add Balancing Valves

Add valves where it is necessary to balance the system. In the example above a balancing valve is

added in section 2-4.

Note! The Equivalent Pipe Length Method can be adapted to most piping systems - like water supply

systems, gravity heating systems and similar.

Das könnte Ihnen auch gefallen

- Part 1 Answer Below Here: Calculate The Head Loss in A Pipe With FittingsDokument1 SeitePart 1 Answer Below Here: Calculate The Head Loss in A Pipe With FittingsRafael ReyesNoch keine Bewertungen

- Electrical Thumb RuleDokument3 SeitenElectrical Thumb RuleSrinivasNoch keine Bewertungen

- Flowrate Calculation For A Draining TankDokument2 SeitenFlowrate Calculation For A Draining TankAnonymous bHh1L1Noch keine Bewertungen

- 5 - Pressure Drop CalculationsDokument64 Seiten5 - Pressure Drop CalculationsPradyumna DhamangaonkarNoch keine Bewertungen

- Chiller Types and Application Guide - The Engineering MindsetDokument7 SeitenChiller Types and Application Guide - The Engineering MindsetFaizanKhanNoch keine Bewertungen

- Sizing of Power Cables For Circuit Breaker Controlled Feeders Part 3Dokument8 SeitenSizing of Power Cables For Circuit Breaker Controlled Feeders Part 3Parikh Hardik DNoch keine Bewertungen

- Heat Transfer Excel Calculations 1Dokument48 SeitenHeat Transfer Excel Calculations 1Felix100% (1)

- PL 3900 Battery Room Ventilation SystemDokument2 SeitenPL 3900 Battery Room Ventilation SystemcandratrikusumaNoch keine Bewertungen

- Case 2 - Tank Heat LossDokument86 SeitenCase 2 - Tank Heat Lossahmad santosoNoch keine Bewertungen

- Thumb Rules For PumpsDokument6 SeitenThumb Rules For PumpsSarjit ChoksiNoch keine Bewertungen

- Thermal Conductivity of FRP CompositesDokument69 SeitenThermal Conductivity of FRP Compositesjppmj100% (1)

- FTFS Chap20 P032Dokument23 SeitenFTFS Chap20 P032AbdulAbdulNoch keine Bewertungen

- Equivalent Length of Pipe PDFDokument3 SeitenEquivalent Length of Pipe PDFSSudhakarNoch keine Bewertungen

- BoilBal SpreadsheetDokument16 SeitenBoilBal SpreadsheetZulkarnain NasrullahNoch keine Bewertungen

- Power Factor Correction - EEPDokument10 SeitenPower Factor Correction - EEPjanarthananNoch keine Bewertungen

- Compressed Air System Guideline FinalDokument38 SeitenCompressed Air System Guideline FinalRafael MeloNoch keine Bewertungen

- FormulasDokument9 SeitenFormulasShankar JhaNoch keine Bewertungen

- 3-Phase AC Calculations Revisited: AN110 Dataforth Corporation Page 1 of 6Dokument6 Seiten3-Phase AC Calculations Revisited: AN110 Dataforth Corporation Page 1 of 6arunmozhiNoch keine Bewertungen

- Sizing Duct Work SheetDokument4 SeitenSizing Duct Work SheetMaulana MaftuhiNoch keine Bewertungen

- Fluid Engineering Flow in P.Dokument6 SeitenFluid Engineering Flow in P.sunilkumar2685Noch keine Bewertungen

- Water - Dynamic and Kinematic ViscosityDokument3 SeitenWater - Dynamic and Kinematic ViscosityManik KandanNoch keine Bewertungen

- PSYCH v10Dokument9 SeitenPSYCH v10Daniel Puello RodeloNoch keine Bewertungen

- Dokumen - Tips Pipe Insulation THK Calculation 55846188ba816Dokument9 SeitenDokumen - Tips Pipe Insulation THK Calculation 55846188ba816Diksha surekaNoch keine Bewertungen

- Centrifugal Pump System TutorialDokument45 SeitenCentrifugal Pump System Tutorialrecep1Noch keine Bewertungen

- Gases and Vapors (Part 1)Dokument2 SeitenGases and Vapors (Part 1)Khristel PenoliarNoch keine Bewertungen

- Pipe Stiffness CalculationDokument1 SeitePipe Stiffness Calculationข้าวเม่า ทอดNoch keine Bewertungen

- Hydraulic Grade LineDokument0 SeitenHydraulic Grade LinemuazeemKNoch keine Bewertungen

- ABB Circuit Breaker GuideDokument56 SeitenABB Circuit Breaker GuideAhmed Sami El SharkawiNoch keine Bewertungen

- Calculated Motor Pump SizeDokument6 SeitenCalculated Motor Pump SizeRicky Ocktavi RizkyNoch keine Bewertungen

- ME 257 Composite MaterialsDokument30 SeitenME 257 Composite Materialsarun_premnathNoch keine Bewertungen

- PipeFlow PracticeProblemsDokument23 SeitenPipeFlow PracticeProblemsFawaz PartoNoch keine Bewertungen

- Piping & Bending and Straight Pipe - Required Minumum Wall Thickness Calculations (ASME B31.1 Power Piping 2010)Dokument40 SeitenPiping & Bending and Straight Pipe - Required Minumum Wall Thickness Calculations (ASME B31.1 Power Piping 2010)Ahmet OVENNoch keine Bewertungen

- Heat Exchangers of PolypropyleneDokument2 SeitenHeat Exchangers of PolypropyleneTan So100% (1)

- Fitting Loss CalculationDokument6 SeitenFitting Loss CalculationSvetla NikolovaNoch keine Bewertungen

- Causes and Effects of LighteningDokument7 SeitenCauses and Effects of LighteningLAMIA LATANoch keine Bewertungen

- Heatloss in Industrial Plants Part 1 PDFDokument10 SeitenHeatloss in Industrial Plants Part 1 PDFMuhammad HarisNoch keine Bewertungen

- Darcy Weisbatch Calculation PDFDokument2 SeitenDarcy Weisbatch Calculation PDFSaputraNoch keine Bewertungen

- CABLE SIZING CALCULATION REv1Dokument4 SeitenCABLE SIZING CALCULATION REv1jack jala0% (1)

- Lecture 1-2 Vacuum SystemDokument113 SeitenLecture 1-2 Vacuum SystemMehreen AkmalNoch keine Bewertungen

- Library WebDokument128 SeitenLibrary WebVikash AgarwalNoch keine Bewertungen

- Pump Calc ExampleDokument4 SeitenPump Calc ExampleshahqazwsxNoch keine Bewertungen

- Cooler CatalogueDokument53 SeitenCooler CatalogueCărunta-Crista CristinaNoch keine Bewertungen

- Capacity Charts For The Hydraulic Design of Highway CulvertsDokument95 SeitenCapacity Charts For The Hydraulic Design of Highway CulvertsphisitlaiNoch keine Bewertungen

- Water Distribution ManualDokument20 SeitenWater Distribution ManualOxfamNoch keine Bewertungen

- Design Cal IndoramaDokument13 SeitenDesign Cal IndoramaKUNALJAYNoch keine Bewertungen

- General Hydraulic CalDokument9 SeitenGeneral Hydraulic CalFerdian Ali RahmanNoch keine Bewertungen

- Two Phase Flow Pattern and Flow PatternDokument45 SeitenTwo Phase Flow Pattern and Flow Patternfoad-7100% (1)

- Motor Engineering FormulasDokument1 SeiteMotor Engineering FormulasDede SadiNoch keine Bewertungen

- 00000-UDS-001 (Chemical Injection Unit) Rev 0Dokument2 Seiten00000-UDS-001 (Chemical Injection Unit) Rev 0sithulibraNoch keine Bewertungen

- Calculation of Orifice DiameterDokument4 SeitenCalculation of Orifice DiameterNaseer HydenNoch keine Bewertungen

- Pressure Loss in A Piping SystemDokument2 SeitenPressure Loss in A Piping SystemAli AimranNoch keine Bewertungen

- Equivalent Pipe Length Method - 1Dokument2 SeitenEquivalent Pipe Length Method - 1Aziz Khan KakarNoch keine Bewertungen

- Calculating Pump HeadDokument8 SeitenCalculating Pump HeadPascal SayahNoch keine Bewertungen

- Liquid Pressure Drop CalculationDokument9 SeitenLiquid Pressure Drop CalculationMichaelMahonyNoch keine Bewertungen

- Gas Line Sizing Rev1Dokument11 SeitenGas Line Sizing Rev1Sermsak LimpadapunNoch keine Bewertungen

- Liquid Line SizingDokument12 SeitenLiquid Line Sizinglolofm25Noch keine Bewertungen

- Pump Head CalculationDokument15 SeitenPump Head CalculationYashapuja100% (1)

- 3.3.4 System DesignDokument3 Seiten3.3.4 System DesignJan Marvin TamseNoch keine Bewertungen

- Air Duct System, DesignDokument9 SeitenAir Duct System, DesignkktayNoch keine Bewertungen

- Dimensionamiento de Lineas de GasDokument10 SeitenDimensionamiento de Lineas de GasHugo Narvaez FuentesNoch keine Bewertungen

- DepEd Learner Information System (LIS) PDFDokument36 SeitenDepEd Learner Information System (LIS) PDFshasagailNoch keine Bewertungen

- Security Officer/GuardDokument2 SeitenSecurity Officer/Guardapi-121358674Noch keine Bewertungen

- CMP Tutorial PDFDokument83 SeitenCMP Tutorial PDFMax HaroutunianNoch keine Bewertungen

- MSDS Argon Compressed GasDokument6 SeitenMSDS Argon Compressed Gassajid aliNoch keine Bewertungen

- Rubric For Case StudyDokument1 SeiteRubric For Case StudyCj NavarroNoch keine Bewertungen

- Shailendra - Yadav - R.F Design and Optimization Engineer - 5.10 - Yrs ExpDokument7 SeitenShailendra - Yadav - R.F Design and Optimization Engineer - 5.10 - Yrs ExpGaurav TiwariNoch keine Bewertungen

- 2 - Way Ball ValvesDokument6 Seiten2 - Way Ball ValvesFitra VertikalNoch keine Bewertungen

- Corrective MaintenanceDokument12 SeitenCorrective MaintenanceMohammed Nerissa100% (1)

- Cembrit Patina Design Line - LowresDokument11 SeitenCembrit Patina Design Line - LowresRaul AntonieNoch keine Bewertungen

- Reciprocating Compressor Discharge TemperatureDokument6 SeitenReciprocating Compressor Discharge TemperaturesalleyNoch keine Bewertungen

- Advance Java Sem 5Dokument18 SeitenAdvance Java Sem 5Gunjan Pratim JadhavNoch keine Bewertungen

- CNC Grinding Notching and Marking Machine: AT 710 ENDokument2 SeitenCNC Grinding Notching and Marking Machine: AT 710 ENsmarjanNoch keine Bewertungen

- Ethods For Mitigation of Voltage Fluctuation Effects: Publication No Cu0208 Issue Date: November 2014Dokument5 SeitenEthods For Mitigation of Voltage Fluctuation Effects: Publication No Cu0208 Issue Date: November 2014Camilo CortesNoch keine Bewertungen

- Homework 1Dokument3 SeitenHomework 1Bukhosi MsimangaNoch keine Bewertungen

- XMEye Android User ManualDokument32 SeitenXMEye Android User Manualaxelkal ck50% (2)

- FacebookDokument13 SeitenFacebookDivya SharmaNoch keine Bewertungen

- DIN 3900 1984 04 Compression CouplingsDokument3 SeitenDIN 3900 1984 04 Compression Couplingsjangaswathi0% (1)

- Maintenance ManualDokument6 SeitenMaintenance ManualHuda LestraNoch keine Bewertungen

- Pavilion Design Workshop + Competition: Uni - Xyz/competitionsDokument14 SeitenPavilion Design Workshop + Competition: Uni - Xyz/competitionsNikunj DwivediNoch keine Bewertungen

- How02 - Z11 - Mec503 - C01 - Oss Piping Matr Class SpecDokument31 SeitenHow02 - Z11 - Mec503 - C01 - Oss Piping Matr Class Speckristian100% (1)

- Your Profile 16personalitiesDokument3 SeitenYour Profile 16personalitiesapi-583293897Noch keine Bewertungen

- CEN ISO TR 17844 (2004) (E) CodifiedDokument7 SeitenCEN ISO TR 17844 (2004) (E) CodifiedOerroc Oohay0% (1)

- Electrical Design Checklist v1.2Dokument39 SeitenElectrical Design Checklist v1.2huangjlNoch keine Bewertungen

- Clearcase Branching and Labeling Best Practices For Parallel DevelopmentDokument50 SeitenClearcase Branching and Labeling Best Practices For Parallel DevelopmentakkachotuNoch keine Bewertungen

- Philips HeartStart MRX EMS BrochureDokument12 SeitenPhilips HeartStart MRX EMS BrochureEnerspect Medical Solutions100% (1)

- Service Manual MIH Series Condensing Units Heat Pump: 1.5 Tons To 5 TonsDokument30 SeitenService Manual MIH Series Condensing Units Heat Pump: 1.5 Tons To 5 TonsHenry Javier RíosNoch keine Bewertungen

- CE ThesisDokument210 SeitenCE ThesisKristin ArgosinoNoch keine Bewertungen

- Characteristics of Logic Gates: A. ObjectivesDokument10 SeitenCharacteristics of Logic Gates: A. ObjectivesManish KumarNoch keine Bewertungen

- Edtpa 2nd Lesson PlanDokument5 SeitenEdtpa 2nd Lesson Planapi-297045693Noch keine Bewertungen

- Masonry - Block Joint Mortar 15bDokument1 SeiteMasonry - Block Joint Mortar 15bmanish260320Noch keine Bewertungen