Beruflich Dokumente

Kultur Dokumente

TMCP Steels For Offshore Structures

Hochgeladen von

pandiangvOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

TMCP Steels For Offshore Structures

Hochgeladen von

pandiangvCopyright:

Verfügbare Formate

TMCP Steels for Offshore Structures: Part Two

Abstract:

The required material characteristics of TMCP steels are very specific and therefore fall into a small

yet extremely high-tech group of steels. What makes these materials unique is that they possess

very impressive mechanical properties and overall toughness which are in turn combined with

excellent cold-workability and weldability characteristics making it possible for them to perform in the

most demanding of conditions.

Generally, offshore structural steels require superior low temperature toughness for the base metal and the

welded joints in view of the need for prevention of brittle failure. Of particular importance are Charpy impact

properties, but also CTOD (crack tip opening displacement) properties subject to the local brittle zones

(hereinafter referred to as LBZ) are also of high importance. Therefore, the establishment of high toughness

and high strength through fining the microstructure of HAZ (heat affected zone), and the reduction of LBZ or the

suppression of its creation has been a one of the major issues of recent times.

Dillinger Htte GTS supplies heavy plate conforming to all widely used standards, including EN 10225, BS

7191, API and NORSOK. The range of grades available extends from normalized, via water-quenched and

tempered, up to and including TMCP steels. The outstanding mechanical strengths and associated toughness

of these materials meet even the most demanding specifications for offshore structures used in the North Sea.

But what makes these steels true high-tech materials is the combination of these properties with optimum

workability, and above all, cold-workability and weldability. Please see the table of materials.

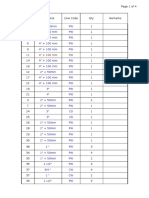

As an illustration in the tables below you will find a comparison of the steel grade 355 under delivery conditions

normalized (N) and thermo mechanically rolled (TMCP) comparing in detail, the tensile and yield strength and

toughness properties of each delivery condition.

* Rp0.2

Table 1: Grade 355N - comparison of tensile strength, yield strength and toughness

* Rp0.2

Table 2: Grade 355 TMCP comparison of tensile strength, yield strength and Toughness

Das könnte Ihnen auch gefallen

- CPHFD 011Dokument7 SeitenCPHFD 011Napoleon DasNoch keine Bewertungen

- NDT of Precipitation Hardened SteelsDokument12 SeitenNDT of Precipitation Hardened SteelsMahade Hasan DipuNoch keine Bewertungen

- Xylan Offshore FlierDokument2 SeitenXylan Offshore FlierpandiangvNoch keine Bewertungen

- WRC Input InstructionDokument2 SeitenWRC Input InstructionpandiangvNoch keine Bewertungen

- Aerospace MaterialsDokument28 SeitenAerospace MaterialsSebastian M. PajaroNoch keine Bewertungen

- Low Alloy Steels For Cryogenic ApplicationsDokument0 SeitenLow Alloy Steels For Cryogenic ApplicationsidienNoch keine Bewertungen

- Steel Plates With Excellent HAZ Toughness For Offshore StructuresDokument7 SeitenSteel Plates With Excellent HAZ Toughness For Offshore Structures구용찬Noch keine Bewertungen

- BSK 46 & Other Grade Material SpecificationDokument6 SeitenBSK 46 & Other Grade Material Specification4alamz100% (1)

- Technological Challenges in Manufacturing of Heavy Reactors Using New Generation 2.25Cr-1Mo-0.25V SteelDokument10 SeitenTechnological Challenges in Manufacturing of Heavy Reactors Using New Generation 2.25Cr-1Mo-0.25V Steelgovimano100% (1)

- Steels For Cryogenic and Low-Temperature Service - KEY To METALS ArticleDokument3 SeitenSteels For Cryogenic and Low-Temperature Service - KEY To METALS Articlekumarpankaj030Noch keine Bewertungen

- Metallurgical Benefits of Vanadium Microalloying in Producing High Strength Seismic Grade RebarDokument12 SeitenMetallurgical Benefits of Vanadium Microalloying in Producing High Strength Seismic Grade RebarUlises Quintana CarhuanchoNoch keine Bewertungen

- TMT Tor Steel Rebars PDFDokument10 SeitenTMT Tor Steel Rebars PDFNeha ChauhanNoch keine Bewertungen

- Propiedades AISI 410Dokument25 SeitenPropiedades AISI 410alvaroyepezNoch keine Bewertungen

- Materials QuestionsDokument30 SeitenMaterials QuestionsMatheus SouzaNoch keine Bewertungen

- AVESTA How To Weld Duplex SteelDokument20 SeitenAVESTA How To Weld Duplex SteelGMacella100% (1)

- Welding TMCP SteelsDokument7 SeitenWelding TMCP SteelsElias Kapa100% (1)

- Guidance Note Plate Bending No. 5.04: ScopeDokument3 SeitenGuidance Note Plate Bending No. 5.04: ScoperoldoguidoNoch keine Bewertungen

- M C S E P A S S: Aterials For Ryogenic Ervice: Ngineering Roperties of Ustenitic Tainless TeelsDokument50 SeitenM C S E P A S S: Aterials For Ryogenic Ervice: Ngineering Roperties of Ustenitic Tainless TeelswholenumberNoch keine Bewertungen

- Maraging SteelDokument4 SeitenMaraging SteelJayanthiANoch keine Bewertungen

- Microstructure, Properties and Welding of T24 Steel - Critical ReviewDokument9 SeitenMicrostructure, Properties and Welding of T24 Steel - Critical Reviewahmed saiedNoch keine Bewertungen

- Balancing Wear, StrengthDokument4 SeitenBalancing Wear, StrengthStephen MontelepreNoch keine Bewertungen

- Application of Stainless SteelDokument13 SeitenApplication of Stainless Steelsweety1188Noch keine Bewertungen

- Offshore Structural Plate Fabrication GuideDokument8 SeitenOffshore Structural Plate Fabrication Guidedaniel_c_popa3357Noch keine Bewertungen

- 13 - Q+T Steels & Welding Q+T SteelsDokument22 Seiten13 - Q+T Steels & Welding Q+T SteelsbbqarNoch keine Bewertungen

- Advanced Ceramics Excel in High-SpeedDokument4 SeitenAdvanced Ceramics Excel in High-SpeedgzmyldsNoch keine Bewertungen

- 6.1.3. Dillimax Tech InfoDokument52 Seiten6.1.3. Dillimax Tech Infosohanlal29Noch keine Bewertungen

- Sadique Pro If SteelDokument12 SeitenSadique Pro If Steelsatish_trivediNoch keine Bewertungen

- Section2 04Dokument16 SeitenSection2 04swainpiyush123Noch keine Bewertungen

- Chapter Five Materials and Fabrication SelectionDokument11 SeitenChapter Five Materials and Fabrication SelectionKom MieNoch keine Bewertungen

- Cu Ni FabricationDokument28 SeitenCu Ni FabricationAli Varmazyar100% (1)

- Recent Development of High-Strength and Tough Welding Consumables For Offshore StructuresDokument8 SeitenRecent Development of High-Strength and Tough Welding Consumables For Offshore StructuresDiNoch keine Bewertungen

- High Strength SteelDokument19 SeitenHigh Strength SteelBHARANINoch keine Bewertungen

- Weldability of Structural SteelsDokument48 SeitenWeldability of Structural SteelsAytuğ KarameşeNoch keine Bewertungen

- Welding of Offshore Structure 2012Dokument17 SeitenWelding of Offshore Structure 2012ABDELOUAHEB HAMIDINoch keine Bewertungen

- Steels For Oil - Gas - ExplorationDokument16 SeitenSteels For Oil - Gas - Explorationدكتور مهندس جمال الشربينىNoch keine Bewertungen

- Weldability Investigation of Fine-Grained S1100Ql Steel: I. Samardžić, A. Ćorić, M. DunđerDokument4 SeitenWeldability Investigation of Fine-Grained S1100Ql Steel: I. Samardžić, A. Ćorić, M. DunđerInaamNoch keine Bewertungen

- Cryogenics: Qinyan Pan, Chuanjun Huang, Laifeng LiDokument7 SeitenCryogenics: Qinyan Pan, Chuanjun Huang, Laifeng LipurnashisNoch keine Bewertungen

- 38 - Liquid Metal Assisted Cracking of Galvanized Structural Steel SectionsDokument7 Seiten38 - Liquid Metal Assisted Cracking of Galvanized Structural Steel SectionsMarjan SubanNoch keine Bewertungen

- Designing With Ductile IronDokument4 SeitenDesigning With Ductile IronCarlos LaoNoch keine Bewertungen

- Arc Welding of Specific Steels and Cast Irons: Fourth EditionDokument170 SeitenArc Welding of Specific Steels and Cast Irons: Fourth EditionDiNoch keine Bewertungen

- Double Aust. AssgnmntDokument15 SeitenDouble Aust. Assgnmntmaurya21Noch keine Bewertungen

- The Effects of Niobium Microalloying in Second Generation Advanced High Strength SteelsDokument12 SeitenThe Effects of Niobium Microalloying in Second Generation Advanced High Strength SteelsemregnesNoch keine Bewertungen

- PWHTDokument2 SeitenPWHTvsajuNoch keine Bewertungen

- Cladding & Overlay - Ni InstituteDokument24 SeitenCladding & Overlay - Ni Institutesajid aslamNoch keine Bewertungen

- Welding CoatingDokument69 SeitenWelding CoatingphillipskincaidNoch keine Bewertungen

- Hsla SteelDokument22 SeitenHsla SteelriteshbarmanNoch keine Bewertungen

- Wear Resistance of High C High Si Steel With Low RDokument11 SeitenWear Resistance of High C High Si Steel With Low RChristina Christina ChristinaNoch keine Bewertungen

- The Role of Niobium in Austenitic and Duplex Stainless SteelsDokument25 SeitenThe Role of Niobium in Austenitic and Duplex Stainless SteelsZoe SideriNoch keine Bewertungen

- Latest Shipbuilding MaterialsDokument9 SeitenLatest Shipbuilding MaterialsAnonymous e3ceN15Noch keine Bewertungen

- Barreto 2020Dokument11 SeitenBarreto 2020Daniyar MaukenovNoch keine Bewertungen

- Weldability of Thermo-Mechanically Rolled Steels Used in Oil and Gas Offshore StructuresDokument8 SeitenWeldability of Thermo-Mechanically Rolled Steels Used in Oil and Gas Offshore StructurestheijesNoch keine Bewertungen

- Vol-7 (No1) 9Cr FluageDokument10 SeitenVol-7 (No1) 9Cr FluageClaude BouillotNoch keine Bewertungen

- Aluminium and Its AlloysDokument14 SeitenAluminium and Its Alloysrif87100% (1)

- Module-2 - Materials and Manufacturing & SystemsDokument43 SeitenModule-2 - Materials and Manufacturing & SystemsVijay KumarNoch keine Bewertungen

- Welding Metallurgy of Stainless Steels During Resistance Spot Welding Part I - Fusion Zone PDFDokument11 SeitenWelding Metallurgy of Stainless Steels During Resistance Spot Welding Part I - Fusion Zone PDFKhalid HafezNoch keine Bewertungen

- PART 02 (Steel Sections)Dokument23 SeitenPART 02 (Steel Sections)MohamedMostafaNoch keine Bewertungen

- Structural Steel Design L 03A-19.11.2021Dokument74 SeitenStructural Steel Design L 03A-19.11.2021LUGHANO NGAJILONoch keine Bewertungen

- Thermomechanical Processing of High-Strength Low-Alloy SteelsVon EverandThermomechanical Processing of High-Strength Low-Alloy SteelsNoch keine Bewertungen

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonVon EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNoch keine Bewertungen

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkVon EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNoch keine Bewertungen

- Ultra-High Temperature Ceramics: Materials for Extreme Environment ApplicationsVon EverandUltra-High Temperature Ceramics: Materials for Extreme Environment ApplicationsWilliam G. FahrenholtzNoch keine Bewertungen

- Crosby Eye Bolt G 291Dokument1 SeiteCrosby Eye Bolt G 291pandiangvNoch keine Bewertungen

- Studding Outlet DimensionDokument2 SeitenStudding Outlet DimensionpandiangvNoch keine Bewertungen

- As Me Certificate Holder ReportDokument5 SeitenAs Me Certificate Holder ReportpandiangvNoch keine Bewertungen

- Peppers Catalogue Approved AccessoriesDokument16 SeitenPeppers Catalogue Approved AccessoriespandiangvNoch keine Bewertungen

- Wind Load SheetDokument2 SeitenWind Load SheetpandiangvNoch keine Bewertungen

- UBC DIVISION-III (Wind Design) : Ce Combined Height, Exposure & Gust Factor CoeffDokument4 SeitenUBC DIVISION-III (Wind Design) : Ce Combined Height, Exposure & Gust Factor CoeffpandiangvNoch keine Bewertungen

- Guidance Notes RevisionDokument8 SeitenGuidance Notes RevisionpandiangvNoch keine Bewertungen

- Design and Development PlanningDokument6 SeitenDesign and Development PlanningpandiangvNoch keine Bewertungen

- S2 - Jaw and Jaw-136Dokument1 SeiteS2 - Jaw and Jaw-136pandiangvNoch keine Bewertungen

- ASME Section II C 2015 ChangesDokument3 SeitenASME Section II C 2015 Changespandiangv0% (1)

- Input:-: Design of Base Plate Length of Base Plate (MM) W 0.11 Width of Base Plate (MM) A (MM) B (MM) Axil Load (M.T)Dokument6 SeitenInput:-: Design of Base Plate Length of Base Plate (MM) W 0.11 Width of Base Plate (MM) A (MM) B (MM) Axil Load (M.T)pandiangvNoch keine Bewertungen

- Load-Carrying Capacity Analysis On Derrick of Offshore Module Drilling RigDokument12 SeitenLoad-Carrying Capacity Analysis On Derrick of Offshore Module Drilling RigpandiangvNoch keine Bewertungen

- N1192-ST - Colour CoadingDokument4 SeitenN1192-ST - Colour CoadingpandiangvNoch keine Bewertungen

- Level Gauge, Level Switch ModelDokument8 SeitenLevel Gauge, Level Switch ModelpandiangvNoch keine Bewertungen

- Graphite PSM AsDokument2 SeitenGraphite PSM AspandiangvNoch keine Bewertungen

- WRC Input InstructionDokument1 SeiteWRC Input InstructionpandiangvNoch keine Bewertungen

- Api2000rev.6 02-13Dokument33 SeitenApi2000rev.6 02-13pandiangvNoch keine Bewertungen

- Heat TreatmentDokument13 SeitenHeat TreatmentpandiangvNoch keine Bewertungen