Beruflich Dokumente

Kultur Dokumente

Rupture Disk FUL-FLO Sampler: Halliburton

Hochgeladen von

saeed65Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Rupture Disk FUL-FLO Sampler: Halliburton

Hochgeladen von

saeed65Copyright:

Verfügbare Formate

HALLIBURTON

Rupture Disk FUL-FLO Sampler

Description

The rupture disk FUL-FLO sampler is a fullopen, full-bore sleeve sampler for use on

drillstem tests. The sampler is controlled by

a rupture disk that is operated by annulus

pressure.

Features and Benefits

Time-delay feature allows the sample to

be trapped after a preset time. Different

metering cartridges can be used to vary

the closing time.

Full-open capabilities are retained after

the tool has trapped its sample.

Several samplers can be run on a test to

allow sampling at different times.

Operation

The FUL-FLO sampler is controlled by a

pressure-operated rupture disk and has a

sample mandrel with a built-in differential

area. To catch a sample, annulus pressure is

increased to a predetermined level, the

rupture disk in the sampler breaks, and the

mandrel traps the sample.

When the rupture disk breaks, the differential

area of the sample mandrel is exposed to an

air chamber on one side and hydrostatic

pressure and applied annulus pressure on the

other. This results in the sample mandrel

moving up and trapping the sample. When

the sample mandrel reaches the top of its

stroke, it is locked in place by a set of locking

dogs.

The 1,200-cc sample chamber allows a

sufficient sample for two 500-cc PVT analyses

with additional volume for lines, valves, etc.

A piston in the sample chamber can be

pumped up to drain the sample without the

need to use mercury.

Rupture Disk

FUL-FLO Sampler

Tools, Testing and TCP

Rupture Disk Sampler Specifications

OD

in. (cm)

5.03

(12.78)

3.90

(9.91)

ID

in. (cm)

2.28

(5.79)

1.80

(4.57)

End Connections

3 1/2 IF

3 7/8 CAS

2 /8 CAS

Length*

in. (cm)

82.00

(208.28)

131.00

(332.74)

Tensile Rating**

lb (kg)

411,000

(186,000)

202,000

(91,000)

Burst Rating**

psi (kPa)

15,000

(103,000)

15,000

(103,000)

Collapse Rating**

psi (kPa)

15,000

(103,000)

15,000

(103,000)

Sample Volume

cc

1,200

1,200

Without time delay feature.

** The values of tensile, burst, and collapse strength are calculated

with new tool conditions, Lames formula for burst and collapse

strength, and stress area calculations for tensile strength.

Pressure rating is defined as differential pressure at the tool.

(Differential pressure is the difference in pressure between the

casing annulus and tool ID.)

These ratings are guidelines only. For more information, consult

your local Halliburton representative.

Halliburton warrants only title to the products, supplies and materials and that the same are free from defects in workmanship and materials. THERE ARE NO

WARRANTIES, EXPRESSED OR IMPLIED OF MERCHANTABILITY, FITNESS OR OTHERWISE WHICH EXTEND BEYOND THOSE STATED IN THE

IMMEDIATELY PRECEDING SENTENCE. Halliburton's liability and Customer's exclusive remedy in any cause of action (whether in contract, tort, breach of

warranty or otherwise) arising out of the sale or use of any products, supplies or materials is expressly limited to the replacement of such products, supplies or

materials on their return to Halliburton or, at Halliburton's option, to the allowance to the Customer of credit for the cost of such items. ACHIEVEMENT OF

PARTICULAR RESULTS FROM THE USE OF HALLIBURTON EQUIPMENT, PRODUCTS, MATERIALS OR SERVICES IS IN NO WAY GUARANTEED. In

no event shall Halliburton be liable for special, incidental, indirect, punitive or consequential damages.

TTT-TD94-036

1994 Halliburton Energy Services

Printed in USA

Das könnte Ihnen auch gefallen

- Drill Stem Testing RD Sampler: SmartstarDokument1 SeiteDrill Stem Testing RD Sampler: SmartstarDenier RubianoNoch keine Bewertungen

- Datasheet Downhole-Fluid-Sampler en ScreenDokument8 SeitenDatasheet Downhole-Fluid-Sampler en ScreenArash PourshoushtarNoch keine Bewertungen

- Bop1006 b73s33s-3r2l3l-35h-0Dokument1 SeiteBop1006 b73s33s-3r2l3l-35h-0api-513539506Noch keine Bewertungen

- "Ticfwg" By-Pass Blanking Plug: (Top No Go)Dokument1 Seite"Ticfwg" By-Pass Blanking Plug: (Top No Go)Edwin AbelloNoch keine Bewertungen

- CamesaEMC Catalog 12-2013 7Dokument1 SeiteCamesaEMC Catalog 12-2013 7Gerardo LizardoNoch keine Bewertungen

- Jar Safety Clamps 2010Dokument21 SeitenJar Safety Clamps 2010Oswal Agusto Cabrera PantojaNoch keine Bewertungen

- Seal Lock HTDokument4 SeitenSeal Lock HTjustmenobleskNoch keine Bewertungen

- Camesa TechBulletin-022Dokument1 SeiteCamesa TechBulletin-022FauzanNoch keine Bewertungen

- Collect Accurate HP/HT Reservoir Samples: Production OptimizationDokument2 SeitenCollect Accurate HP/HT Reservoir Samples: Production OptimizationAngel GuamánNoch keine Bewertungen

- FSP 28"-2000 Psi Diverter/BOP: Diverters' Simplicity Maximizes ReliabilityDokument2 SeitenFSP 28"-2000 Psi Diverter/BOP: Diverters' Simplicity Maximizes Reliabilitymehmet sait öztürkNoch keine Bewertungen

- Camesa Cable SpecDokument1 SeiteCamesa Cable SpecShashank Anand MishraNoch keine Bewertungen

- CatalogDokument424 SeitenCatalogLuis David Concha CastilloNoch keine Bewertungen

- Kline General CatalogDokument30 SeitenKline General CatalogservicemenruNoch keine Bewertungen

- O 1 03 01Dokument2 SeitenO 1 03 01gplese0Noch keine Bewertungen

- LP15 Blow Out Preventer: Key Features Lp15 BopDokument2 SeitenLP15 Blow Out Preventer: Key Features Lp15 Bopjesf_2014Noch keine Bewertungen

- Brochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedDokument8 SeitenBrochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedNightNoch keine Bewertungen

- RTTS Forced Circulation Valve and RTTS Positive Circulating ValveDokument14 SeitenRTTS Forced Circulation Valve and RTTS Positive Circulating ValveMohamed ShafieNoch keine Bewertungen

- Lubricators and RisersDokument6 SeitenLubricators and RisersArielNoch keine Bewertungen

- DHSV TestDokument7 SeitenDHSV TestRonald Lucas Silva Lefundes OliveiraNoch keine Bewertungen

- Parker HTR ActuatorDokument22 SeitenParker HTR ActuatorYorkistNoch keine Bewertungen

- Venturetech XK 90 Power Swivel Spec SheetDokument1 SeiteVenturetech XK 90 Power Swivel Spec Sheetwilliam pinzonNoch keine Bewertungen

- 1PackerSystem PackerAccessories&tools PDFDokument21 Seiten1PackerSystem PackerAccessories&tools PDFAnand aashishNoch keine Bewertungen

- 2021 16.0 TST-2 Service PackerDokument15 Seiten2021 16.0 TST-2 Service PackerDhenny FarialNoch keine Bewertungen

- Caja de Cambio John DeereDokument52 SeitenCaja de Cambio John Deerenelson.oyanadel21Noch keine Bewertungen

- Te ValveDokument30 SeitenTe Valvecrni roko100% (2)

- Cameron EB 555 D Rev U2 - VBR Engineering InfoDokument6 SeitenCameron EB 555 D Rev U2 - VBR Engineering InfoCanrig Ramde100% (1)

- Packer Systems Technical Unit Model "M" Expansion Joint, Sizes 2-3/8, 2-7/8, 3-1/2, and 4-1/2Dokument4 SeitenPacker Systems Technical Unit Model "M" Expansion Joint, Sizes 2-3/8, 2-7/8, 3-1/2, and 4-1/2eberthson hernandezNoch keine Bewertungen

- D&L Double Grip Pkr-Asi-Xpacker1c PDFDokument2 SeitenD&L Double Grip Pkr-Asi-Xpacker1c PDFMoh Syamsul BahriNoch keine Bewertungen

- T-2 On/Off Tool Technical DatasheetDokument2 SeitenT-2 On/Off Tool Technical DatasheetEvolution Oil ToolsNoch keine Bewertungen

- 01 Bolt Tightening ToolDokument30 Seiten01 Bolt Tightening ToolabdulfetahNoch keine Bewertungen

- M60es54 Na549y QC Man 001Dokument29 SeitenM60es54 Na549y QC Man 001Riski Kurniawan67% (3)

- Abstract Awes Dig RPDokument4 SeitenAbstract Awes Dig RPabinadi1230% (1)

- Complete CatalogueDokument67 SeitenComplete Cataloguejarrod lyonNoch keine Bewertungen

- k10 GeothermalDokument1 Seitek10 GeothermalshegateNoch keine Bewertungen

- H00707Dokument2 SeitenH00707AQUILES CARRERANoch keine Bewertungen

- 616-35000 Assembly DrawingDokument1 Seite616-35000 Assembly DrawingAl KautsarNoch keine Bewertungen

- DSA6 15M SidedoorDokument14 SeitenDSA6 15M SidedoorДудла Станіслав100% (1)

- SB Drill Collar PDFDokument51 SeitenSB Drill Collar PDFSiva GanaNoch keine Bewertungen

- Oilfield UnionsDokument5 SeitenOilfield Unionslalberto96Noch keine Bewertungen

- Hydril Blowout Preventers Ram AssembliesDokument2 SeitenHydril Blowout Preventers Ram AssembliesJIN WANGNoch keine Bewertungen

- D392005428-MKT-001 6012 Bop PDFDokument2 SeitenD392005428-MKT-001 6012 Bop PDFMitul PatelNoch keine Bewertungen

- JU Pulling ToolDokument1 SeiteJU Pulling Toolazze bouzNoch keine Bewertungen

- DSQ4 10M SidedoorDokument15 SeitenDSQ4 10M SidedoorДудла СтаніславNoch keine Bewertungen

- PSC Ergodyne Range 2021Dokument45 SeitenPSC Ergodyne Range 2021Project Sales CorpNoch keine Bewertungen

- HP Auto Clave FittingsDokument1 SeiteHP Auto Clave FittingsRavi Chaitanya VelamarthyNoch keine Bewertungen

- Packard International Products - Drop-In Check ValvesDokument2 SeitenPackard International Products - Drop-In Check Valveskm1790Noch keine Bewertungen

- Product Information Bulletin: Date: Bulletin Number: 1000059437-PIB Revision: 01Dokument7 SeitenProduct Information Bulletin: Date: Bulletin Number: 1000059437-PIB Revision: 01carlosorizabaNoch keine Bewertungen

- Adjustable Ckoke (Not Cortec) SOPDokument10 SeitenAdjustable Ckoke (Not Cortec) SOPAmer RehanNoch keine Bewertungen

- Packer Cup Testing - 9-5-8 Packer Cup LineDokument2 SeitenPacker Cup Testing - 9-5-8 Packer Cup LineFerney FonsecaNoch keine Bewertungen

- 2023 10.75 TST-2 Service PackerDokument15 Seiten2023 10.75 TST-2 Service PackerDhenny FarialNoch keine Bewertungen

- Pumptools - BOP CanDokument1 SeitePumptools - BOP Cancasda73Noch keine Bewertungen

- CTT CatalogDokument18 SeitenCTT Catalogdineshmehta2013Noch keine Bewertungen

- TopTools Catalog 20170906Dokument49 SeitenTopTools Catalog 20170906JoséManuelOvandoNoch keine Bewertungen

- Oil States Swab Cups PDFDokument2 SeitenOil States Swab Cups PDFramudo ZNoch keine Bewertungen

- Packer HP 6 Technical LiteratureDokument7 SeitenPacker HP 6 Technical LiteratureRaul Diaz100% (1)

- Case Study VR Lubricator ToolDokument2 SeitenCase Study VR Lubricator ToolVictorNoch keine Bewertungen

- Fail Safe or TR RegulatorDokument2 SeitenFail Safe or TR RegulatorYeit HauNoch keine Bewertungen

- TRSV SP-ENH 5.5 20 Vamtop - 4.562in Sealbore MN 102951596Dokument3 SeitenTRSV SP-ENH 5.5 20 Vamtop - 4.562in Sealbore MN 102951596alejandromarinch7Noch keine Bewertungen

- LPR N TesterValveH09381Dokument2 SeitenLPR N TesterValveH09381JerrydawangNoch keine Bewertungen

- Halliburton: Rtts PackerDokument2 SeitenHalliburton: Rtts PackermehrdadNoch keine Bewertungen

- API 6A Gate ValvesDokument12 SeitenAPI 6A Gate ValvesLee Sweningson100% (1)

- Api 16A 3 Edition: Api 16A Chairman: John Busby Co-Chair: Jim MccabeDokument11 SeitenApi 16A 3 Edition: Api 16A Chairman: John Busby Co-Chair: Jim Mccabesaeed65Noch keine Bewertungen

- Well Head Sealing Guide PDFDokument4 SeitenWell Head Sealing Guide PDFQaiser Hafeez100% (1)

- پدیده های مخرب در شیرهای کنترل و راه کارهای مقابله با انهاDokument25 Seitenپدیده های مخرب در شیرهای کنترل و راه کارهای مقابله با انهاsaeed65Noch keine Bewertungen

- Hydra Jar ProceduresDokument3 SeitenHydra Jar Proceduresice_PLNoch keine Bewertungen

- Comparison of Analytical and Numerical Models On Torque and Hookload CalculationDokument7 SeitenComparison of Analytical and Numerical Models On Torque and Hookload Calculationsaeed65Noch keine Bewertungen

- 4th 120316074120 Phpapp02Dokument27 Seiten4th 120316074120 Phpapp02Ahmed ghNoch keine Bewertungen

- Difference Between PSL1 and PSL2Dokument1 SeiteDifference Between PSL1 and PSL2samkarthik47100% (1)

- Quantum Shear Type Anchor LatchDokument1 SeiteQuantum Shear Type Anchor Latchsaeed65Noch keine Bewertungen

- Study of The Interaction Model of PDC Cutters With RockDokument5 SeitenStudy of The Interaction Model of PDC Cutters With Rocksaeed65Noch keine Bewertungen

- Basic Equation of DrillingDokument4 SeitenBasic Equation of Drillingsaeed65Noch keine Bewertungen

- Multivariate Probability DistributionDokument55 SeitenMultivariate Probability Distributionrnjan321Noch keine Bewertungen

- Blanking PlugsDokument21 SeitenBlanking Plugsu2006262918Noch keine Bewertungen

- Arma 10 407 PDFDokument7 SeitenArma 10 407 PDFsaeed65Noch keine Bewertungen

- Article1379511666 - Kutasov and Eppelbaum PDFDokument8 SeitenArticle1379511666 - Kutasov and Eppelbaum PDFsaeed65Noch keine Bewertungen

- Casing-Running Challenges For Extended-Reach WellsDokument2 SeitenCasing-Running Challenges For Extended-Reach Wellssaeed65Noch keine Bewertungen

- Liner Equipment: Class Code: 1539Dokument1 SeiteLiner Equipment: Class Code: 1539saeed65Noch keine Bewertungen

- Sulphide Scavengers in Oil and Gas Industry - A ReviewDokument8 SeitenSulphide Scavengers in Oil and Gas Industry - A ReviewMartín Diego MastandreaNoch keine Bewertungen

- Fann Model 35Dokument4 SeitenFann Model 35Mahardhyka PrakashaNoch keine Bewertungen

- Drilling EquationDokument1 SeiteDrilling Equationsaeed65Noch keine Bewertungen

- Drilling ProblemsDokument7 SeitenDrilling ProblemsMEUBRONoch keine Bewertungen

- Manual For ConductingDokument1 SeiteManual For Conductingsaeed65Noch keine Bewertungen

- Subject:: TKC Mms 8 Round Ancillary SpecificationsDokument2 SeitenSubject:: TKC Mms 8 Round Ancillary Specificationssaeed65Noch keine Bewertungen

- Spe 5906 MSDokument13 SeitenSpe 5906 MSsaeed65Noch keine Bewertungen

- Spwla 1961 JDokument15 SeitenSpwla 1961 Jsaeed65Noch keine Bewertungen

- Tools Diagram Run 2 PDFDokument2 SeitenTools Diagram Run 2 PDFsaeed65Noch keine Bewertungen

- Positive Displacement Motor (PDM)Dokument2 SeitenPositive Displacement Motor (PDM)RFVNoch keine Bewertungen

- 3.5, 13.3 - G Grade NC38 5-2.438 PDFDokument1 Seite3.5, 13.3 - G Grade NC38 5-2.438 PDFsaeed65Noch keine Bewertungen

- Aade 22 PDFDokument8 SeitenAade 22 PDFsaeed65Noch keine Bewertungen

- Petroleum Transactions: Spectral Gamma-Ray LoggingDokument6 SeitenPetroleum Transactions: Spectral Gamma-Ray Loggingsaeed65Noch keine Bewertungen

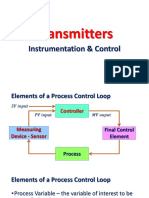

- TransmittersDokument40 SeitenTransmittersSka dooshNoch keine Bewertungen

- AeroJet Manual NewDokument18 SeitenAeroJet Manual NewRoselle GarciaNoch keine Bewertungen

- Chm1 Gasses 1004 FDDokument13 SeitenChm1 Gasses 1004 FDaerkn skjksNoch keine Bewertungen

- Article JAS Cyclone Revised R2 PDFDokument24 SeitenArticle JAS Cyclone Revised R2 PDFAinaNoch keine Bewertungen

- Precision Medical Air-Oxy BlenderDokument34 SeitenPrecision Medical Air-Oxy BlenderBong Kek Chiew100% (1)

- Gases and The Structure of MatterDokument20 SeitenGases and The Structure of MatterJaimeNoch keine Bewertungen

- q4 Quiz 2Dokument2 Seitenq4 Quiz 2Daniella CernaNoch keine Bewertungen

- Pneumatic Test - CalculationDokument3 SeitenPneumatic Test - CalculationSubbarayan Saravanakumar57% (7)

- Biofluidodinamica Lecture NotesDokument356 SeitenBiofluidodinamica Lecture NotesverbicarNoch keine Bewertungen

- Dynamic Behavior of Flexible Rectangular Liquid Storage TanksDokument10 SeitenDynamic Behavior of Flexible Rectangular Liquid Storage Tanksy_fakoriNoch keine Bewertungen

- STD 132Dokument31 SeitenSTD 132Valesh MonisNoch keine Bewertungen

- Aurora 2500 GPM 913 SERIES: Diesel Engine DriveDokument1 SeiteAurora 2500 GPM 913 SERIES: Diesel Engine DriveJuan Víctor JiménezNoch keine Bewertungen

- R. H. Barnard - Road Vehicle Aerodynamic Design - 2nd EdDokument290 SeitenR. H. Barnard - Road Vehicle Aerodynamic Design - 2nd EdRodrigo CastroNoch keine Bewertungen

- Heat Capacity of GasesDokument9 SeitenHeat Capacity of Gasesismail100% (1)

- On-Line Manual: Important InformationDokument66 SeitenOn-Line Manual: Important InformationMilan GašićNoch keine Bewertungen

- Thermodynamic Steam TrapDokument8 SeitenThermodynamic Steam TrapMallela Sampath KumarNoch keine Bewertungen

- Assignment DocumentationDokument9 SeitenAssignment DocumentationMiras Muratbekov0% (1)

- Trampa Termo-Dinamica TD 52 PDFDokument12 SeitenTrampa Termo-Dinamica TD 52 PDFjose david CardozoNoch keine Bewertungen

- Title of Report or Project: Team Name Course Name / Department / Organisation Date of SubmissionDokument16 SeitenTitle of Report or Project: Team Name Course Name / Department / Organisation Date of SubmissionEric HeNoch keine Bewertungen

- MAN LIFT ML-001 TB42manual-OperatorDokument68 SeitenMAN LIFT ML-001 TB42manual-OperatorRoxana Elizabeth Valencia NavarrteNoch keine Bewertungen

- Centrifugal Pump ExperimentsDokument18 SeitenCentrifugal Pump ExperimentssamadonyNoch keine Bewertungen

- Reduce Hazards-Vaccum SystemDokument7 SeitenReduce Hazards-Vaccum SystemChem.EnggNoch keine Bewertungen

- Phase Behavior 2023Dokument17 SeitenPhase Behavior 2023ig.hader55Noch keine Bewertungen

- Thermodynamics (TKJ3302) Lecture Notes - 3 Properties of Pure SubstancesDokument34 SeitenThermodynamics (TKJ3302) Lecture Notes - 3 Properties of Pure Substancesmamat8889% (9)

- Semiconductor Technical Data: 0 To 100 Kpa (0 To 14.5 Psi) 40 MV Full Scale Span (Typical)Dokument8 SeitenSemiconductor Technical Data: 0 To 100 Kpa (0 To 14.5 Psi) 40 MV Full Scale Span (Typical)jugybocaNoch keine Bewertungen

- 4th Periodical ExaminationDokument20 Seiten4th Periodical ExaminationNikko CarilloNoch keine Bewertungen

- Mano StarDokument3 SeitenMano StarImam Syafi'iNoch keine Bewertungen

- Astm F645Dokument8 SeitenAstm F645Hernando Andrés Ramírez Gil0% (1)

- 0893 Lower Secondary Science Stage 8 Scheme of Work - tcm143-595696Dokument90 Seiten0893 Lower Secondary Science Stage 8 Scheme of Work - tcm143-595696manojNoch keine Bewertungen

- NR 13 - Pressure Vessels (: Review) Notions of Applied Physics PressureDokument12 SeitenNR 13 - Pressure Vessels (: Review) Notions of Applied Physics PressureDaniel BeckNoch keine Bewertungen