Beruflich Dokumente

Kultur Dokumente

Thickening of Waste Activated Sludge by Biological Flotation

Hochgeladen von

Daniel Alejandro Jara PaineanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Thickening of Waste Activated Sludge by Biological Flotation

Hochgeladen von

Daniel Alejandro Jara PaineanCopyright:

Verfügbare Formate

;tat. Res. Vol. 26. No. 2. pp.

139-I,1-I, 1992

0043-1354,,92 $5.00 + 0.00

Pnnted in Great Britain. All rights r--~crvcd

Copyright ~ 1992 Pergamon Prt~..splc

THICKENING OF WASTE ACTIVATED SLUDGE BY

BIOLOGICAL FLOTATION

SIMON^ {~I~INSK~, i ViT M^T~J6, t CLAESW~E, z Y v o N r ~ KLASSON,z

JAKUB KREICi~and GUNNEL DALHAMMAR3

~lnstitute of Microbiology. Czechoslovak Academy of Sciences, Videnska 1083, 142 20 Prague 4,

Czechoslovakia. :Alfa Laval A. B., Department of Waste Streams. P.O.B 500. 147 80 Tumba and ~The

Royal Institute of Technology. Department of Biochemistry and Biotechnology,

100 4.1 Stockholm. Sweden

(First recen'ed JanuaO" 1991: accepted in recised form August 1991)

Abstract--Waste activated sludge was thickened by biological flotation without polymer flocculant

dosage. The BIOFLOT tt process utilizes the denitrifying ability of activated sludge bacteria. Gaseous

products of anaerobic nitrate reduction cause spontaneous flotation of the sludge suspended solids.

Laboratory tests confirmed the dependence of sludge thickening el~ciency on available nitrate concentration, flotation time and temperature. Full-scale experiments were performed in a fully automatized unit

for discontinuous sludge thickening from wastewater treatment plants with a capacity of up to 5000 I.E.

Waste activated sludge from wastewater treatment plants at Pisek, Milevsko and Bj6rnlunda was

thickened from 6.2, 10.7 and 3.5 g/I MLSS to 59.4. 59.7 and 66.7 g/I MLSS, respectively. Concentrations

of COD, ammonium and phosphate ions were decrea~d in sludge water. The average nitrate consumption

for bioflotation was 21.2 mg NOr per I g of MLSS of activated sludge. Flotation time ranged from 4 to

48 h.

Key wordy--waste activated sludge, thickening, dcnitrilication, flotation

IN'I'RODU('nON

Primary and waste activated sludgcs are formed

during the mcchanico-biological treatment of wastewater. Their treatment and handling account for up

to 50% of the total operating costs (Spinosa et al.,

1984). Waste activated sludge contains 99.0--99.5% of

water. If it is co-settled with the primary sludge it

contains 95.0-98.0% of water. However, at many

treatment plants activated sludges are thickened independently and are then combined with primary

sludges for further treatment (Eden, 1983).

It has often been assumed that handling costs can

be minimized by thickening or dewatering of sludge

at the treatment plant. Economic assessments show

that the installation of sludge thickening often represents considerable cost benefits, especially where

the sludge is finally transported in liquid form to its

disposal outlet (Bruce and Davis. 1989). The choice

of the ways of thickening or dewatcring depends on

properties and the quantity of the sludge but also on

the desired water content for its following treatment

or the best and environmentally most acceptable

disposal. Where liquid sludge is disposed of on land

or at sea it is often thickened to 4--6*/, solids to reduce

transport costs. When sludge is to be digested anaerobically there are advantages in thickening primary

or mixed sludges to as much as 10%. Incineration

requires a moisture content sufficiently low to permit

combustion of sludge to continue with little or no

auxiliary fuel (Eden. 1983)

Since simple scdimcntation is unable to remove

sufficient water from sludge some other treatment is

required. The use of thickening has been relatively

limited in the past. But now there is a surge of interest

in thickening and considerable numbers of new thickeners are being designed (Bruce and Davis, 1989).

Flotation is very often used for the thickening of the

sludge. Flotation methods can be divided according

to the operation and the way the bubbles are formed,

to the pressure, vacuum, chemical and electrolytic

flotation.

To enhance effects of thickening or dcwatering

chemical flocculants are usually added to the sludge.

They are one of the major cost factors (Bruce and

Davis, 1989) and they can have toxic and other

adverse influence on aquatic organisms (Biesinger

and Stokes, 1986).

The thickening of waste activated sludge only by

flotation is suitable especially for small wastewater

treatment plants for economic reasons. The costs and

dilliculties of sludge thickening and dewatering call

for optimization of these processes, especially with

regard to polymer dosage.

We developed a new thickening process using

biotechnologicai methods. The process involves two

steps--flocculation and flotation (Barta et al., 1983).

The new thickening process takes advantage of a

denitrifying capability of bacteria present in a mixed

population of activated sludge, in the activated

sludge process a wide variety of common facultative

bacteria such as Pseudomonas, Micrococcus, Achro139

SimoN^ ~t~sNsr~ et ~.

140

mobacter, Spirillum and Bacillus have been reported

to accomplish denitrification (Delwische, 1956).

In the bioflotation process it is necessary to enhance denitrifying activity by controlled addition of

B I O F L O T x reagent into the waste activated sludge.

In the first step of the process the physical structure

of the sludge floes is changed. When the zeta-potential decreases under a critical limit the flocculation

occurs and dewatering properties o f the sludge are

improved (Maixner, 1985). In the second step gaseous

products of dissimilatory denitrification are released

and flotation occurs. Suspended solids o f the sludge

are thickened considerably. Organic substances present in sludge water serve as a carbon source of

dissimilatory denitrification. It is not, therefore,

necessary to add an external source of organic carbon

(Mattjt3 and ~'i~insk:i, 1988).

After preliminary laboratory and pilot scale tests of

biological flotation at 25 biological wastewater treatment plants with the industrial pollution equivalents

in the range of 0 - 8 5 % , the B I O F L O T ~ unit for

batch biological thickening of waste activated sludge

from small wastewater treatment plants was designed.

MATERAI.N ANt) M E T I l O D S

Full-scale thickening of waste activated sludge by biologigill flotation using a BIOFLOT ~ unit was tested at three

wastcwalcr trcatmcnt plants. The wastewater treatment

plant at Pisck, Czechoslovakia treats wastewatcrs in a

two-stage system, approx. 60*/0 of which is of industrial

origin mainly from food and tcxtile industries. The treatment plant at Milevsko, Czechoslovakia treats wastewatcrs

in a one-stage system, where 36*/0 comes from engineering

works and a dairy. In a small wastewater treatment plant at

Bjtrnlunda, Sweden 850 i.E. are connected and no industrial wastewaters are treated there. A survey of other

technological data of tested plants is given in Table 1.

Bioflotation is initiated by the addition of BIOFLOT ~

reagent in the form of 10% aqueous solution which contains

nitrate ions with a small portion of ammonium ions or, if

need be. trace elements and bases. The addition of trace

elements, bases and ammonium ions is usually not a

condition for bioflotation and they can only increase the

elticiency of the process. The composition of the

BIOFLOT ~ reagent is recommended according to the laboratory tests for each locality separately. The choice of the

nitrate used depends on the price and its availability. It is

enough to use nitrate of technical grade.

Laboratory tests of sedimentation and bioflotation were

carried out in 2-1. graduated cylinders of 8 cm in diameter

and 50cm high. BIOFLOT ~ reagent was added to the

sludge suspension at time zero in order that the initial nitrate

Table I. Technological parameters of wastewater treatment plants

t~t~

soo

Plant

BOD~.

(kg/m |)

B,

(kg/m Id)

B,

(kg/kgd)

SRT

(d)

Pisek

0.170

1.67

0.67

6-6

92

Milcvsko

Bjtrnlunda

0.310

0.153

0.34

--

0.08

0.28

8-10

6

94

91

BOD~ - influen[ total BODs concentration.

B, ,- volumetric loading rate.

B, - sludge loading rate.

SRT - solids retention time.

K~on ~ efficiency of gOD s removal.

(%)

content could reach concentrations ranging from 100 to

300 m&11NOr. At chosen time intervals the course of sludge

thickening was visually evaluated. The residual concentrations of nitrates and nitrites in sludge water were simultaneously measured and a specific denitrifying rate (qo) was

then calculated. This rate expresses the amount of reduced

nitrate and/or nitrite nitrogen to gaseous dinitrogen per I g

of MLSS of activated sludge per hour as follows:

qo

(NOr - N + NOr - N)0 (mg/gh)

2" M LSS" t0.~

where

(NO/ - N + NO.,- - N)0 = initial nitrate and nitrite nitrogen concentrations (mg/I)

t0.~ = time when half of the initial

nitrate and nitrite nitrogen concentrations are reduced (h).

Full-scale tests were made in a BIOFLOT s prototype unit

which was produced by cooperation between the Swedish

firm Alfa Laval and ZVU Hradec Kralove. Czechoslovakia

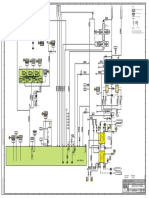

(Fig. I). The direction of suspension flow is controlled by

three three-way valves. The filling and emptying of the

bioreactor are automatically controlled by level probes.

When the bioflotation is over the sludge water is pumped

from the bottom of the flotation tank into the inlet of the

wastewater treatment plant. When the layer of the thickened

sludge reaches the optical measuring device the sludge is

pumped into the sludge storage tank. Outside dimensions of

the BIOFLOT ~" unit 3500x 1856 x 2400mm follow the

Europallet standard. The weight of the unit is 1400 kg.

The unit was filled up to 50% at the wastewater treatment

plant Bjtrnlunda because of low production of waste activated sludge. Flotation time w:ls changed in a broad

interval, i.e. at Pi.~k from 4 to 12 h, at Milevsko from 8 to

19 h and at Bj6rnlunda from 20 to 48 h.

Testing and analysis were carried out in general accordance with Standard Method~ (APIIA, 1980). Total nitrogen

was determined using a CiIN analyzer (LECO CIIN-600).

RESULTS

The tests were performed at three wastewater

treatment plants with different treatment technologies and wastewater qualities.

Laboratory tests

The dependence o f both the thickening o f waste

activated sludge and specific denitrifying rate upon

initial nitrate concentration, temperature and

flotation time was investigated. At the same time

thickening of the sludge by bioflotation and simple

sedimentation, i.e. without B I O F L O T ~ reagent

dosage, were compared. The results are summarized

in Tables 2 and 3 as average values.

The efficiency of sludge thickening increased with

increased initial nitrate concentration. There was no

apparent influence o f initial nitrate concentration

upon the specific denitrifying rate. Increasing sludge

suspension temperature accelerated the start of

bioflotation, however, the final concentration o f

M L S S in flotated sludge cake was not influenced

considerably. The rising o f the enzymic reaction rate

with increasing temperature can be expressed by the

Q,0 quotient. The specific denitrifying rate o f the

sludge increased by a factor 1.74-2.00 per 10C

temperature increase. Denitrification proceeded even

Thickening of waste activated sludge

141

Fig. I. BIOFLOT ~ unit dsesign. I, Flotation bioreactor; 2, frame; 3, armatures; 4, BIOFLOT ~ additive

dissolving tank; 5, control panel; 6 platform.

at 5~'C at the Bj6rnlunda wastewater treatment plant.

Prolonged flotation time from 4 to 24 h increased the

MLSS concentration in flotated sludge cake by

49.3% on average. The MLSS concentration in

flotated sludge cake was as much as 150% higher if

compared with the MLSS concentration achieved by

sedimentation. The optimum nitrate dose and

Table 2. The effect of temperattire and flotation lime on sludge

thickening

flotation time for full-scale tests were determined

according to the laboratory test results.

Full-scale tests

The parameters of full-scale biological flotation tests

as well as their results are summarized in Table 4

Table 3. The effect of initial nitrate concentration and flotation time

on sludge thickening

M LSS~.~,

Place

Pisek

Milevsko

M LSS T

(&~l) ("C)

(NO~" }e

(rag/I)

t

(h)

I0

15

20

I00

I00

100

0.85

0.50

0.25

4 1 . 0 6 4 . 5 2.74

4 9 . 0 6 7 . 8 3.87

51.0 6 8 . 2 5.08

10.136 10

10.06 15

10.06 20

200

200

200

3.00

2.00

1.50

230

230

230

3.50

2.50

2.00

5.92

5.92

5.92

Bj6rnlunda 23.10

23.10

23.10

Im

26z 2-8

5

10

15

MLSS~

4h

24 h

qn

(g/I)

(mg/g h)

MLSS

(g/II)

(NOj')o

(mg/l)

4h

Pisek

3.22

3.22

3.22

100

200

0

32.2

46.0

23.0

59.4

65.8

29.0

3.95

3.85

--

38.0 51.0 1.15

4 1 . 5 53.0 1.44

44.5 5 4 . 2 2.00

Milevsko

9.55

9.55

9.55

150

300

0

31.2

35.4

21.0

61.3

63.4

25.5

1.50

1.62

--

31.5

35.0

38.5

Bj6rnlunda

22.50

22.50

22.50

190

300

0

39.5

41.4

28.9

63.0

68.5

41.9

2.51

2.48

--

64.5 1.10

65.5 1.64

6 5 . 7 2.21

24 h

(g/l)

qo

(mg/g h)

142

StMO~:A (~I21NSKA et al.

Table 4. Parameters and results of full-zcal tests of biological

flotation

Parameter

Pisek

Mtkwsko

8j6rnlunda

Number of flotation cycles

13

26

Flotation time (h)

8

14

Waste actirated sludge + BIO FLO T It additir

MLSS (g:l)

6.2

10.7

SS {g/l)

5.6

10.2

Ash (%)

19.5

26.5

Total nitrogen (%)

8.4

6.8

COD (rng, I)

I 12.5

74.2

3.5

3.3

39.0

4.5

225.0

NO~- (mg,r'l)

NO~- (rag,l)

N H ; (mg/I)

POI- (re&l)

T CC)

Thickened sludge

MLSS (g/I)

M L S S , , (g/I)

M L.SSm, (g/l)

Ash (%)

Total nitrogen (%)

Sludge water after flotation

MLSS (g/I)

SS (g/l)

COD (mg/I)

NOr (rag/I)

NO z (mg,,I)

N H ; (rag/I)

PO~ - (mg/I)

22

24

151.1

0.9

188.1

2.4

147.7

1.2

56.6

21.2

23.3

27.2

25.4

14.6

47.1

65.2

9.8

59,4

53.0

74.0

19. I

8.3

59.7

55.2

64.9

31.4

6.7

66.7

42.7

87.4

36.9

--

0.9

1.0

0,8

0.3

0.4

0.2

104.0

35.4

0.6

36.1

20.9

63.7

21.5

1.0

26.2

20. I

25.0

30.5

5.9

44.0

6.3

as average values from all flotation cycles performed.

Waste activated sludge from the wastewater treatment plant at Pisek reached the highest specific

dcnitrifying rates and therefore the shortest flotation

time was chosen. On the other hand short flotation

time in the broad range mentioned in the Materials

and Methods influenced the efficiency of sludge

thickening and consequently the average and minimum values of MLSS at all wastewater treatment

plants.

During the biological flotation the concentration of

organic substances (COD), ammonium and phosphate ions in sludge water were, however, reduced at

each locality to various extents.

The activated sludge was thickened at the wastewater treatment plants at Pisek, Milevsko and Bjfrnlunda by 9.5, 5.6 and 19.1 times, respectively. In

sludge water, concentrations of organic substances as

COD were decreased by 7.5 to 88.9%, ammonium

ions by about 3.7 to 36.2% and phosphates by about

10.3 to 90.3%.

The nitrate consumption per l g of MLSS for

bioflotation was calculated from all flotation cycles.

This consumption was 17.2, 16.7 and 29.7mg NOr

per I g of MLSS at the treatment plants of Pisek,

Milevsko and Bj6rnlunda, respectively.

DISCUSSION

Wastewater treatment plants at Pisek, Milevsko

and Bjfrnlunda operate with high, low and median

loading rates of the aeration tank. Since treatment

technology and the quality of treated wastewater

differ, the diverse microbial community was selected

there.

The highest specific denitrifying rates of waste

activated sludge were achieved at Pisek, which was

supported by a two-stage treatment system with a

middle sedimentation tank, appropriate sludge age,

sludge loading rate and low content of ash.

At Milevsko, waste activated sludge partly settled

in the flotation bioreactor (11% of total volume on

the average). It was affected by both low sludge

loading rate and breakdowns in the operation of the

wastewater treatment plant. Settled sludge of lower

MLSS concentration decreased resulting MLSS content of thickened sludge in the storage tank.

The relationship between the specific denitrifying

rate and consequently the efficiency of bioflotation

versus the initial nitrate concentration and temperature is fully in accordance with the theory of denitrification (Juszczak and Domka, 1988; Dawson and

Murphy, 1972; Lewandowski, 1982).

The time period for the starting of sludge flocs

flotation fluctuated between 0.25 and 3.50 h due to

the type and temperature of the sludge. After sludge

is flotated appropriate sludge thickening or compression phase occurs. The desired sludge concentration could be achieved with thc flotation time in

the range of 4-48 h.

Biological flotation resulted in 1.8-2.5 times higher

MLSS concentration of thickened sludge in comparison with gravity thickening of the same sludge.

In full-scale tests the reliability of equipment and

bioflotation technology were verified. Waste activated sludge from wastewater treatment plants at

Pisek, Milcvsko and Bj6rnlunda was thickened from

6.2, 10.7 and 3.5 g/I MLSS to 59.4, 59.7 and 66.7 g/I

MLSS, respectively. Reduction in concentration of

COD, ammonium and phosphate ions is connected

with the biochemistry of denitrification and sorption

properties of the sludge (Payne, 1973; Verstraete and

van Vaerenberg, 1986).

The presence of calcium ions supports phosphate

removal and sludge flocculation (Diamadopoulos,

1984; Kakii et aL, 1985) and therefore calcium nitrate

was used as a constituent of the BIOFLOT z reagent.

Because of the high suspended solids concentration

in sludge water after flotation it is returned to the

wastewater treatment plant inlet.

The possibility of the influence of the BIOFLOT ~

process on the wastewater treatment was studied only

at Bj0rnlunda because at Pisek and Milevsko only

part of the waste activated sludge production was

thickened in the BIOFLOT ~ unit.

It has to be taken into consideration that the sludge

water from the BIOFLOT ~ unit, which is returned to

the treatment plant inlet, is diluted by the influent

wastewater. The influent had an average flow of

314 m~/d. This means that the sludge water volume

amounted to (3/317) x 100 = 0.95% of the total water

amount.

Concerning the sludge water, nitrates, nitrites and

suspended solids are the most important factors.

With a nitrate dose of 100--200 mg/I N O r for the

Thickening of waste activated sludge

bioflotation and at retention time of about 24 h it was

possible to achieve concentrations < 50 mg/I NO/and <8 mg/I NO.,- in the sludge water leaving the

BIOFLOT ~t unit. This means that there is a nitrate

and nitrite increase of 0.0095.50 - 0.47 rag/! NOr

and 0.0095.8 = 0.076 mg/l NOr in the influent to the

treatment plant. These values did not influence wastewater treatment. The nitrate and nitrite concentrations in the effluent from the wastewater treatment

plant were determined during the test period and 2

months after the last running of the BIOFLOT ~ unit.

By comparing these values it can be concluded that

the sludge water does not affect the outlet of nitrogen

into the water recipient at all (Klasson, 1990).

The average value of suspended solids in the sludge

water was 0.2 g/i. The influent wastewater had an

average SS concentration of 0.370g/I and it was

decreased by the BIOFLOT a sludge water to

0.368 g/I. Suspended solids in the sludge water did not

influence the wastewater treatment plant in any way,

i.e. settling properties of mixed liquor passing to final

clarifiers and SS concentration in final effluent. The

same results were obtained in continuous sludge

thickening by bioflotation at the wastewater treatment plant in Pisek during a year test period

(Maixner, 1985).

The specific energy consumption for the

BIOFLOT ~" unit is 0.2 kW per I m' of sludge, thc

installed power input is 4 kW max.

The comparison of bioflotation with the dissolved

air flotation (DAF) indicates that a similar degree of

sludge thickening is achieved, however, bioflotation

requires lower operating costs. When DAF works

without polymer dosage the lower thickening effects

are usually reached. Furthermore, the BIOFLOT s

process is ecologically advantageous because it utilizes only natural properties of sludge microorganisms and it works without polymer dosages. Polymer

use could be helpful only in cases of bad bioflocculation properties of the sludge, which were rarely

observed, but it is not necessary. Because of their high

costs and negative environmental effects (Biesinger

and Stokes, 1986) we cannot recommend their use.

Another advantage of bioflotation is suitable size and

distribution of gas bubbles released during denitrification and also their formation inside sludge flocs.

This enhances adhesion of bubbles and flotating flocs.

According to van Vuuren and Merwe (1989) a solid

concentration of 6-7% was achieved by dissolved air

flotation after 24.--48 h aging time. Leineninger et al.

(1980) reported that waste activated sludge was

thickened by flotation only to 3.0% without polymer

dose and up to 4.0% with polymer dose.

Based on the experimental results obtained and our

experience, some technological parameters of biological wastewater treatment, with positive or negative

influence on the BIOFLOT x process, can be distinguished and some process conditions can be defined.

The BIOFLOT ~ process is positively influenced by

using activated sludge produced in partly or com-

143

pletely treated mixed wastcwaters, however, without

substantial aerobic mineralization, with the sludge

age up to 8 days and with a minimum BOD sludge

loading rate of 0.4 kg/kg d. The absence of primary

sedimentation did not influence the bioflotation. The

BIOFLOT s process is negatively affected by extended aeration with sludge age higher than 15 days.

The presence of denitrifiers, sufficient nitrate and

organic carbon concentrations, appropriate temperature and oxygen conditions are some of the most

important parameters for high efficiency of the

BIOFLOT s process:

--Denitrifiers can be found in nearly all activated sludges, however, in various amounts

and with different denitrifying activities (AIlievi and Ferrari, 1985). Their properties determine flotation time which can fluctuate in the

I and 24 h intervals, 7 h on average. Flotation

time is to be determined for each locality

separately.

--Nitrate consumption for sludge thickening by

bioflotation is about .5-30 mg NOr per I g of

MLSS. The process can be controlled in such

a way that nitrate concentration in sludge

water after flotation will not exceed 20mg/I

NOr.

--Waste activated sludge usually contains sufficient amounts of biodegradable compounds

for dissimilatory dcnitrification or endogenous

respiration takes place (Sutton et al., 1979).

Therefore it is not necessary to add an external

substrate.

--The BIOFLOT ~ unit is designed for discontinuous sludge thickening even when the

sludge temperature could drop below 5C.

That is why it is proposed the device should be

placed in a hall with thermal insulation.

--Dissimilatory denitrification is inhibited by

the presence of dissolved oxygen (Najakima et

al., 1985). The anoxic condition in the

flotation bioreactor is accomplished within a

few minutes.

Discontinuous activated sludge thickening is suitable for small wastewatcr treatment plants. The

BIOFLOT ~ unit is automatically operated and

requires very simple maintenance. The operator only

has to prepare BIOFLOT ~ reagent approximately

once a week.

The BIOFLOT ~ process can be followed by dewatering in centrifuges (Maixner, 1985).

CONCLUSIONS

(i) The BIOFLOT ~ process utilizes the denitrifying capability of bacteria present in the mixed population of activated sludge.

(2) The efficiency of the BIOFLOT ~ process is

influenced, above all, by the technology of treatment,

wastewater quality, nitrate concentration, C : N ratio

S|MONA CI~INSKA et

144

and by temperature. The nitrate consumption for

bioflotation ranged from 16.7 to 29.7 mg N O ; per 1 g

of MLSS.

(3) A fully automated compact unit was designed

for discontinuous biological thickening of waste activated sludge from wastewater treatment plants up to

50OO I.E.

(4) During full-scale tests at the wastewater treatment plants in Pisek, Milevsko and Bj6rnlunda,

waste activated sludge was thickened to 59.4, 59.7

and 66.6 g/! MLSS which means a volume reduction

to 10.4, 17.9 and 1.9%, respectively. Simultaneously

COD, ammonium and phosphate ion concentrations

were partly removed in the sludge water.

(5) The BIOFLOT jt process can ix applied either

independently or in connection with centrifugation.

(6) The BIOFLOT jt process has low energy consumption, small space requirements, very simple

maintenance and does not require polyelectrolyte

flocculants, which may represent an environmental

hazard.

REFERENCES

Allievi L. and Ferrari A. (1985) Microbiological characterization of some wastewatcr sludges. Agricult. Wastes 12,

137-145.

API IA (1980) Standard Methodv fiJr Examination of Water

and Wa,tewater, 15th edition. American Public tlcalth

Association. Washington, D.C.

Barta J., Vcrncr M., Pardus l., Vcsel~, D. and Aronsson G.

(1983) Method for thickening of biological activated

sludgcs. Czechoslovakian Patent No. 228 403, concordant

with Swedish Patent 13.3016.

Bicsingcr K. E. and Stokes G. N. (1986) Effects of synthetic

polyclcctrolytcs on selected aquatic organisms. J. War.

Pollut. Control Fed..qg, 207-213.

Bruce A. M. and Davis R. D. (1989) Sewage sludge disposal:

current and future options. War. Sci. Technol. 21,

1113-1128.

Dawson R. N. and Murphy K. L. (1972) Factors affecting

biologicaldenitrification of waste water. Adv. War. Pollut.

Res. 6, 671-683.

Delwische C. C. (1956) Dcnitrification. In Symposium on

Inorganic Nitrogen Metabolism (Edited by McEIroy A. B.

and Glass C. D). pp. 233-256. Johns Hopkins University

Press, Baltimore, Md.

aL

Diamadopoulos E. and Benedek A. (1984) The precipitation

of phosphorus from wastewater through pH variation in

the presence and absence of coagulants. War. Res. 18,

I 175--! 179.

Eden G. E. (1983) Modem trends in sludge management:

sludge conditioning. War. Sci. Technol. 15, 37-48.

Juszczak A. and Domka F. 0988) The effect of initial

concentrations of nitrates and nitrites on the denitrification by the bacteria of Pseudomonas genus. Z. Wass.Abwass. Forsch. 21, 199-202.

Kakii K., Kitamura S., Shirakashi T. and Kuriyama M.

(1985) Effect of calcium ion on sludge characteristics. J.

Ferment. Technoi. 63, 263-270.

Klasson Y. (1990) Evaluation of the Bioflot process, a

biotechnological sludge thickening method. Examination

work, Royal Institute of Technology, Stockholm.

Leininger K. V., Nehm P. H. and SchellpfefferJ. W. (1980)

Trade-offs in sludge thickening and transport/reuse

systems. J. Wat. Pollut. Control Fed. 52, 2771-2779.

Lewandowski Z. (1982) Temperature dependency of biological denitrification with organic material addition.

War. Res. 16, 19-22.

Maixner J. (1985) Biologicaldenitrification fotation. Ph.D.

thesis, Institute of Microbiology of Czechoslovak

Academy of Sciences, Prague.

Mat~j6 V. and ~'i~.insk:i S. (1988) Sludge thickening: a

biotechnological approach. In Agricultural Derelopment

and Environmental Research: American and C=echoMovak

Perspecth,es (Edited by Phillips A. S. and Schweitzer G.

E.). NRC, National Academy Press, Washington, D.C.

Mat~j6 V., Vit P., ~i~.insk~i S., Paikert M.. Barta J.,

Mclichar J., Wast C., Widlund T. and Aronsson G.

(1989) New arrangement ofequlpmcnt for sludge thickening. Czechoslovak Industrial Sample 22573/89.

Najakima M., tlayanizu T. and Nishimura H. (1984) Inhibitory effcct of oxygen on dcnitrilication in sludge from an

oxidation ditch. Wat. Res. 18, 339-343.

Payne W. J. (1973) Reduction of nitrogenous oxides by

microorganisms. Boer. Rev. 37, 409--452.

Spinosa L., Mininni G. and Misiti A. (1984) Sludge mechanical dcwatering, ingegn, sanit. 34-42.

Sutton P. M., Murphy K. L., Jank B. E. and Monaghan B.

A. (1979) Single sludge nitrogen removal system. Canada

Ontario Agreement Research Report No. 88., Wastewater

Technology Centre, Burlington, Ontario.

Verstraete W. and van Vaerenbergh E. (1986) Aerobic

activated sludge. In Biotechnology (Edited by Rehm H. J.

and Reed G.)0 Vol. 8. VCH, Weinheim.

van Vuuren L. R. J. and van der Merwe P. J. (1989)

Thickening of sludges by dissolved air flotation. War. Sci.

Technol. 21, 1771-1774.

Das könnte Ihnen auch gefallen

- Demonstration of A Treatment For Purification and Reuse of Laundry Waste WaterDokument9 SeitenDemonstration of A Treatment For Purification and Reuse of Laundry Waste Waterprag314Noch keine Bewertungen

- 2009 Micropollutant Removal During Biological Wastewater Treatment and A SubsequentDokument6 Seiten2009 Micropollutant Removal During Biological Wastewater Treatment and A Subsequentsirilak1726Noch keine Bewertungen

- WORLD'S LARGEST RETRIEVABLE FINE BUBBLE AERATION SYSTEMDokument15 SeitenWORLD'S LARGEST RETRIEVABLE FINE BUBBLE AERATION SYSTEMLye YpNoch keine Bewertungen

- Trickling Filter For HighDokument3 SeitenTrickling Filter For HighepebeNoch keine Bewertungen

- 25.000 M3 AAT de Çamurun Ozonla Azaltımı-Fabiyi2008Dokument11 Seiten25.000 M3 AAT de Çamurun Ozonla Azaltımı-Fabiyi2008yusuf yeniceNoch keine Bewertungen

- Odegaard 1998Dokument11 SeitenOdegaard 1998star warsNoch keine Bewertungen

- 1 s2.0 S0011916400900018 MainDokument16 Seiten1 s2.0 S0011916400900018 MainAnita YunusNoch keine Bewertungen

- Organics and Nitrogen Removal From Textile Auxiliaries Wastewater With A2O-MBR in A Pilot ScaleDokument9 SeitenOrganics and Nitrogen Removal From Textile Auxiliaries Wastewater With A2O-MBR in A Pilot ScaleHuong ZamNoch keine Bewertungen

- Minimization of Excess Sludge Production For Biological Wastewater TreatmentDokument15 SeitenMinimization of Excess Sludge Production For Biological Wastewater Treatmentashoori79Noch keine Bewertungen

- Gonze, Environmental TechnologyDokument19 SeitenGonze, Environmental TechnologyMarwen EsselmiNoch keine Bewertungen

- Application of Bioremediation Process For Textile Wastewater Treatment Using Pilot PlantDokument7 SeitenApplication of Bioremediation Process For Textile Wastewater Treatment Using Pilot PlantGovind ManglaniNoch keine Bewertungen

- USE Water Hyacinth (Eichhornia Crassipes Solmsi IN Treatment Systems For Textile Mill Effluents A Case StudyDokument13 SeitenUSE Water Hyacinth (Eichhornia Crassipes Solmsi IN Treatment Systems For Textile Mill Effluents A Case StudydarshworldNoch keine Bewertungen

- Methanol Removal From Methanol-Water Mixture Using Municipal Activated SludgeDokument10 SeitenMethanol Removal From Methanol-Water Mixture Using Municipal Activated SludgeRickyWisaksonoNoch keine Bewertungen

- Charmot Charbonnel1999Dokument7 SeitenCharmot Charbonnel1999jairoNoch keine Bewertungen

- Fecal Coliform Removal in Wastewater Treatment Plants Studied Byplate Counts and Enzymatic MethodsDokument11 SeitenFecal Coliform Removal in Wastewater Treatment Plants Studied Byplate Counts and Enzymatic MethodsJamina CaliganNoch keine Bewertungen

- Treatment of Tunnel Construction Wastewater Using Chitosan CoagulantDokument9 SeitenTreatment of Tunnel Construction Wastewater Using Chitosan CoagulantepebeNoch keine Bewertungen

- Optimisation and Assessment of Different PDFDokument8 SeitenOptimisation and Assessment of Different PDFMonico DeytiquezNoch keine Bewertungen

- 24 05 2016 EvaluationDokument7 Seiten24 05 2016 EvaluationChristeenaJoyNoch keine Bewertungen

- Treating Textile Dye Wastewater Using Moroccan Clay AdsorptionDokument18 SeitenTreating Textile Dye Wastewater Using Moroccan Clay AdsorptionibrahimNoch keine Bewertungen

- Treatment and Reuse of Wastewater From The Textile Wet-Processing Industry Review of Emerging TechnologiesDokument14 SeitenTreatment and Reuse of Wastewater From The Textile Wet-Processing Industry Review of Emerging Technologiesdumitrescu viorelNoch keine Bewertungen

- Integrated biological and ozone treatment of printing textile wastewaterDokument9 SeitenIntegrated biological and ozone treatment of printing textile wastewaterTcnghe TuấnNoch keine Bewertungen

- Anaerobic USB Reactor Concept for Biological Wastewater TreatmentDokument36 SeitenAnaerobic USB Reactor Concept for Biological Wastewater TreatmentinscNoch keine Bewertungen

- Biological Treatment and Nanofiltration of Denim Textile Wastewater For ReuseDokument7 SeitenBiological Treatment and Nanofiltration of Denim Textile Wastewater For ReuseOmaya TariqNoch keine Bewertungen

- Activated Carbon VS Anthracite As Primary Dual Media Filters - A Pilot Plant StudyDokument7 SeitenActivated Carbon VS Anthracite As Primary Dual Media Filters - A Pilot Plant StudyWendyNoch keine Bewertungen

- Urban Wastewater Treatment Using Vermi-Biofiltration SystemDokument9 SeitenUrban Wastewater Treatment Using Vermi-Biofiltration Systemsalvador_kuzNoch keine Bewertungen

- Anoxic TankDokument12 SeitenAnoxic TankpragatheeskNoch keine Bewertungen

- Bio Cos 03 enDokument63 SeitenBio Cos 03 enDeveshDharDwivediNoch keine Bewertungen

- Landfill LeachateDokument7 SeitenLandfill LeachateChristian Mihai GNoch keine Bewertungen

- Treatment and Remediation of A Wastewater Lagoon Using Microelectrolysis and Modified DAT /IAT MethodsDokument8 SeitenTreatment and Remediation of A Wastewater Lagoon Using Microelectrolysis and Modified DAT /IAT MethodsIna ElenaNoch keine Bewertungen

- Biofiltration of BTEX Contaminated Air Streams Using Compost-Activated Carbon Filter MediaDokument16 SeitenBiofiltration of BTEX Contaminated Air Streams Using Compost-Activated Carbon Filter Mediaaldian wahidNoch keine Bewertungen

- RBC in Doua TrepteDokument15 SeitenRBC in Doua TrepteRoxana AvramNoch keine Bewertungen

- Effect of Gravel-Sand Substrate On Sub-Surface Flow Constructed Wetland For Palm Oil Mill Effluent TreatmentDokument7 SeitenEffect of Gravel-Sand Substrate On Sub-Surface Flow Constructed Wetland For Palm Oil Mill Effluent TreatmentCt Kamariah Md SaatNoch keine Bewertungen

- Combination of Physico-Chemical Treatment and Nanofiltration To Reuse Wastewater of A Printing, Dyeing and Finishing Textile IndustryDokument8 SeitenCombination of Physico-Chemical Treatment and Nanofiltration To Reuse Wastewater of A Printing, Dyeing and Finishing Textile IndustryChittaranjan SahooNoch keine Bewertungen

- Pilot Scale Study of Horizontal Anaerobic Digester For Biogas Production Using Food WasteDokument4 SeitenPilot Scale Study of Horizontal Anaerobic Digester For Biogas Production Using Food WasteAl AkilNoch keine Bewertungen

- Quality Water Drinking Irrigation Contaminants: Chapters 21 IntroductionDokument10 SeitenQuality Water Drinking Irrigation Contaminants: Chapters 21 IntroductionMohd ShakoorNoch keine Bewertungen

- About ORGANIC and INORGANIC CoagulantDokument12 SeitenAbout ORGANIC and INORGANIC Coagulantlipi8Noch keine Bewertungen

- Treatment of MedicalDokument6 SeitenTreatment of MedicalalexNoch keine Bewertungen

- Art:10.1007/s10529 015 1864 7Dokument9 SeitenArt:10.1007/s10529 015 1864 7Amal ..Noch keine Bewertungen

- Removal of AmmoniacalDokument26 SeitenRemoval of AmmoniacalKaterine Giomara Soto CasoNoch keine Bewertungen

- Bioretention Case Studies Demonstrate Pollutant Removal and Volume ReductionDokument3 SeitenBioretention Case Studies Demonstrate Pollutant Removal and Volume Reductionstings_ary1556Noch keine Bewertungen

- Journal of Water Process Engineering: SciencedirectDokument10 SeitenJournal of Water Process Engineering: SciencedirectLaura Ximena Huertas RodriguezNoch keine Bewertungen

- Fount Ou Lakis 2016Dokument6 SeitenFount Ou Lakis 2016CutNuruddiniyahNoch keine Bewertungen

- Water Purification Do It YourselfDokument4 SeitenWater Purification Do It YourselfvthiseasNoch keine Bewertungen

- Laundry Wastewater Treatment Using Coagulation and Membrane FiltrationDokument20 SeitenLaundry Wastewater Treatment Using Coagulation and Membrane FiltrationAnggy de Rincon100% (1)

- Water Research: M. Pronk, M.K. de Kreuk, B. de Bruin, P. Kamminga, R. Kleerebezem, M.C.M. Van LoosdrechtDokument11 SeitenWater Research: M. Pronk, M.K. de Kreuk, B. de Bruin, P. Kamminga, R. Kleerebezem, M.C.M. Van LoosdrechtirpansejatiNoch keine Bewertungen

- Treatment of Textile Industry Waste Water Using Solar Photo CatalysisDokument14 SeitenTreatment of Textile Industry Waste Water Using Solar Photo CatalysisnurwahidaNoch keine Bewertungen

- Jurnal Ekologi UmumDokument10 SeitenJurnal Ekologi Umumrr josephineNoch keine Bewertungen

- Anaerobic Digestion of Sewage Sludge in An Anaerobic Fixed Bed DigesterDokument3 SeitenAnaerobic Digestion of Sewage Sludge in An Anaerobic Fixed Bed DigesterNurul RazakNoch keine Bewertungen

- Decoloration System Using Rotating Membrane Up Module: Makoto Ohnishi . Yutaka Okuno and Naoki OhkumaDokument9 SeitenDecoloration System Using Rotating Membrane Up Module: Makoto Ohnishi . Yutaka Okuno and Naoki OhkumaRohan ChauguleNoch keine Bewertungen

- Dictionary of Water and Waste ManagementVon EverandDictionary of Water and Waste ManagementBewertung: 4.5 von 5 Sternen4.5/5 (3)

- 1.9 SBRDokument11 Seiten1.9 SBRAbdul rahmanNoch keine Bewertungen

- July 20, 1971, R. C. Carlson 3,594,316: Filed April 13, 1970Dokument5 SeitenJuly 20, 1971, R. C. Carlson 3,594,316: Filed April 13, 1970Marcelo Alejandro PalaciosNoch keine Bewertungen

- Leachate Treatment-Km-Impart-Km5Dokument53 SeitenLeachate Treatment-Km-Impart-Km5manoj kumar GNoch keine Bewertungen

- Analysis of Treatment Plant For Dyeing IDokument9 SeitenAnalysis of Treatment Plant For Dyeing ISaravanaKumarNoch keine Bewertungen

- Anarebic PondsDokument5 SeitenAnarebic Pondsunitechwater6517100% (2)

- Ijaret: ©iaemeDokument11 SeitenIjaret: ©iaemeIAEME PublicationNoch keine Bewertungen

- Waste-Water Treatment Removes Over 99% of Detergent SurfactantsDokument2 SeitenWaste-Water Treatment Removes Over 99% of Detergent SurfactantsSamWatchNoch keine Bewertungen

- Vietnam Septic Tank and Wetland PaperDokument17 SeitenVietnam Septic Tank and Wetland PaperuserabcdNoch keine Bewertungen

- Sustainable Environment Research: Reyhaneh Zeynali, Mehdi Khojastehpour, Mohammadali Ebrahimi-NikDokument6 SeitenSustainable Environment Research: Reyhaneh Zeynali, Mehdi Khojastehpour, Mohammadali Ebrahimi-NikJhosselyn Solano MezaNoch keine Bewertungen

- XXIVth International Congress of Pure and Applied Chemistry: Main Section Lectures Presented at Two Joint Symposia Held During the Above Congress at Hamburg, Federal Republic of Germany, 2–8 September 1973Von EverandXXIVth International Congress of Pure and Applied Chemistry: Main Section Lectures Presented at Two Joint Symposia Held During the Above Congress at Hamburg, Federal Republic of Germany, 2–8 September 1973Noch keine Bewertungen

- 1997, Wilf, Design consequences of recent improvements in membrane performanceDokument7 Seiten1997, Wilf, Design consequences of recent improvements in membrane performanceDaniel Alejandro Jara PaineanNoch keine Bewertungen

- 1995, Malley, The Use of Selective and Direct DAF For Removal of Particulate Contaminants in Drinking Water TreatmentDokument9 Seiten1995, Malley, The Use of Selective and Direct DAF For Removal of Particulate Contaminants in Drinking Water TreatmentDaniel Alejandro Jara PaineanNoch keine Bewertungen

- 2009, Joon, Site-specific raw seawater quality impact study on SWRO process for optimizing operation of the pressurized stepDokument18 Seiten2009, Joon, Site-specific raw seawater quality impact study on SWRO process for optimizing operation of the pressurized stepDaniel Alejandro Jara PaineanNoch keine Bewertungen

- 10 Reverse OsmosisDokument15 Seiten10 Reverse OsmosisDaniel Alejandro Jara PaineanNoch keine Bewertungen

- Corrosion Guide - Stainless Internation NickelDokument20 SeitenCorrosion Guide - Stainless Internation NickelJohn BurkeNoch keine Bewertungen

- Eliminacion de SolidosDokument47 SeitenEliminacion de SolidosIgnacNoch keine Bewertungen

- Paidar2016, MembraneDokument69 SeitenPaidar2016, MembraneDaniel Alejandro Jara PaineanNoch keine Bewertungen

- 1995, Edzwald, Principles and Applications of Dissolved Air Flotation PDFDokument23 Seiten1995, Edzwald, Principles and Applications of Dissolved Air Flotation PDFDaniel Alejandro Jara PaineanNoch keine Bewertungen

- Optimization of Seawater RO Systems Design: DesalinationDokument8 SeitenOptimization of Seawater RO Systems Design: DesalinationRavi PrasadNoch keine Bewertungen

- 1986, Adin, Pretreatment of Seawater by Flocculation and Settling For Particulates Removal PDFDokument16 Seiten1986, Adin, Pretreatment of Seawater by Flocculation and Settling For Particulates Removal PDFDaniel Alejandro Jara PaineanNoch keine Bewertungen

- Role of Heat Treatment On The Performance of Polymers As Iron Oxide DispersantsDokument9 SeitenRole of Heat Treatment On The Performance of Polymers As Iron Oxide DispersantsLuis RebolledoNoch keine Bewertungen

- 1995, Edzwald, Principles and Applications of Dissolved Air Flotation PDFDokument23 Seiten1995, Edzwald, Principles and Applications of Dissolved Air Flotation PDFDaniel Alejandro Jara PaineanNoch keine Bewertungen

- Detection of Escherichia Coli in Biofilms From Pipe Samples and Coupons in Drinking Water Distribution NetworksDokument9 SeitenDetection of Escherichia Coli in Biofilms From Pipe Samples and Coupons in Drinking Water Distribution NetworksDaniel Alejandro Jara PaineanNoch keine Bewertungen

- 2018, Fane, A Grand Challenge For Membrane Desalination More Water, Less CarbonDokument9 Seiten2018, Fane, A Grand Challenge For Membrane Desalination More Water, Less CarbonDaniel Alejandro Jara PaineanNoch keine Bewertungen

- 2018, Sanches, Microbial Diversity in Biofilms From Reverse Osmosis Membranes A Short Review of PDFDokument10 Seiten2018, Sanches, Microbial Diversity in Biofilms From Reverse Osmosis Membranes A Short Review of PDFDaniel Alejandro Jara PaineanNoch keine Bewertungen

- Mod 4lect 2Dokument34 SeitenMod 4lect 2Daniel Alejandro Jara PaineanNoch keine Bewertungen

- 1986, Adin, Pretreatment of Seawater by Flocculation and Settling For Particulates Removal PDFDokument16 Seiten1986, Adin, Pretreatment of Seawater by Flocculation and Settling For Particulates Removal PDFDaniel Alejandro Jara PaineanNoch keine Bewertungen

- 2018, Fane, A Grand Challenge For Membrane Desalination More Water, Less CarbonDokument9 Seiten2018, Fane, A Grand Challenge For Membrane Desalination More Water, Less CarbonDaniel Alejandro Jara PaineanNoch keine Bewertungen

- Chloride Contamination of The Water Steam Power Plant PDFDokument15 SeitenChloride Contamination of The Water Steam Power Plant PDFDiniNoch keine Bewertungen

- Chloride Contamination of The Water Steam Power Plant PDFDokument15 SeitenChloride Contamination of The Water Steam Power Plant PDFDiniNoch keine Bewertungen

- Paidar2016, MembraneDokument69 SeitenPaidar2016, MembraneDaniel Alejandro Jara PaineanNoch keine Bewertungen

- 1987, Alrqobah, Optimization of Chemical Pretreatment For Reverse Osmosis (RO) Seawater DesalinationDokument8 Seiten1987, Alrqobah, Optimization of Chemical Pretreatment For Reverse Osmosis (RO) Seawater DesalinationDaniel Alejandro Jara PaineanNoch keine Bewertungen

- Duan 2009Dokument12 SeitenDuan 2009Daniel Alejandro Jara PaineanNoch keine Bewertungen

- 1980, Brunelle, Colloidal Fouling of Reverse Osmosis MembranesDokument9 Seiten1980, Brunelle, Colloidal Fouling of Reverse Osmosis MembranesDaniel Alejandro Jara PaineanNoch keine Bewertungen

- 2016, Sarai, An Operational and Economic Study of A Reverse Osmosis Desalination System For Potable Water and Land IrrigationDokument11 Seiten2016, Sarai, An Operational and Economic Study of A Reverse Osmosis Desalination System For Potable Water and Land IrrigationDaniel Alejandro Jara PaineanNoch keine Bewertungen

- 1999, Vilgritter, Removal of Natural Organic Matter by Coagulation-Flocculation A Pyrolysis-GC-MS StudyDokument6 Seiten1999, Vilgritter, Removal of Natural Organic Matter by Coagulation-Flocculation A Pyrolysis-GC-MS StudyDaniel Alejandro Jara PaineanNoch keine Bewertungen

- Yoon 2013Dokument7 SeitenYoon 2013Daniel Alejandro Jara PaineanNoch keine Bewertungen

- Ebrahim 2001Dokument13 SeitenEbrahim 2001Daniel Alejandro Jara Painean100% (1)

- Hardness Test Kit InstructionsDokument2 SeitenHardness Test Kit InstructionsDaniel Alejandro Jara PaineanNoch keine Bewertungen

- 0 06400 77813 01 - 0Dokument1 Seite0 06400 77813 01 - 0Daniel Alejandro Jara PaineanNoch keine Bewertungen

- Wastewater Treatment Process OverviewDokument148 SeitenWastewater Treatment Process OverviewAilan TenGkuNoch keine Bewertungen

- Environmental Quality (Sewage) Regulations 2009Dokument29 SeitenEnvironmental Quality (Sewage) Regulations 2009YudhisthiraNoch keine Bewertungen

- Design of A Sewage Treatment PLANT (4.5 MLD) : Project PresentationDokument20 SeitenDesign of A Sewage Treatment PLANT (4.5 MLD) : Project Presentationchandan pandey100% (1)

- What Is Fukuoka Method ?: BackgroundDokument5 SeitenWhat Is Fukuoka Method ?: BackgroundJah knowNoch keine Bewertungen

- Mewar University Advanced Waste Water Treatment Question BankDokument4 SeitenMewar University Advanced Waste Water Treatment Question BankEr Govind Singh ChauhanNoch keine Bewertungen

- SEPTAGE COLLECTION CALCULATION and SEPTAGE TREATMENT PLANT DESIGN CONCEPTDokument31 SeitenSEPTAGE COLLECTION CALCULATION and SEPTAGE TREATMENT PLANT DESIGN CONCEPTKladees WorldNoch keine Bewertungen

- SWTP Operation ManualDokument131 SeitenSWTP Operation ManualKASHIFNoch keine Bewertungen

- Sewage Treatment Plant Operations ManualDokument2 SeitenSewage Treatment Plant Operations ManualCharles MayoNoch keine Bewertungen

- 100 Years of Activated Sludge: A History and Overview of Its DevelopmentDokument13 Seiten100 Years of Activated Sludge: A History and Overview of Its Developmentnguyen anNoch keine Bewertungen

- Activated Sludge Process: Nelson Pynadathu Rumjit (13MEE0006)Dokument22 SeitenActivated Sludge Process: Nelson Pynadathu Rumjit (13MEE0006)dhanushNoch keine Bewertungen

- Flush With SuccessDokument1 SeiteFlush With SuccessfredwineNoch keine Bewertungen

- Sewagetreatmentplant Designcalculation 130528150104 Phpapp01Dokument8 SeitenSewagetreatmentplant Designcalculation 130528150104 Phpapp01Muhammad IdrisNoch keine Bewertungen

- ELMITVALLI 2005 Treatment of Municipal Wastewater in Upflow Anaerobic Sludge Blanket UASB ReactorDokument32 SeitenELMITVALLI 2005 Treatment of Municipal Wastewater in Upflow Anaerobic Sludge Blanket UASB ReactorKuswandi AndiNoch keine Bewertungen

- Designing a Sewage Treatment Plant for a Growing TownDokument24 SeitenDesigning a Sewage Treatment Plant for a Growing TownanushkaNoch keine Bewertungen

- Decentralized WTF For Liloan Cebu Public MarketDokument7 SeitenDecentralized WTF For Liloan Cebu Public MarketN.a. M. TandayagNoch keine Bewertungen

- Dialysis of Sewage Water PDFDokument7 SeitenDialysis of Sewage Water PDFGaley wangchuk80% (5)

- JRMS Engineering Works STP maintenance estimateDokument1 SeiteJRMS Engineering Works STP maintenance estimateaminur rahamanNoch keine Bewertungen

- FlyerDokument3 SeitenFlyerAlex SmithNoch keine Bewertungen

- Sewerage in TokyoDokument62 SeitenSewerage in TokyoSyed Yasir AliNoch keine Bewertungen

- CVL723PS1Dokument5 SeitenCVL723PS1Ronald Ewa100% (1)

- A Review On Full-Scale Decentralized Wastewater Treatment Systems: Techno-Economical ApproachDokument12 SeitenA Review On Full-Scale Decentralized Wastewater Treatment Systems: Techno-Economical ApproachDavid CahyaNoch keine Bewertungen

- Public Health Engineering MicroprojectDokument7 SeitenPublic Health Engineering MicroprojectsoumyasonawaneNoch keine Bewertungen

- LESSON 5 Wastewater Treatment and DisposalDokument24 SeitenLESSON 5 Wastewater Treatment and Disposalfuchima07Noch keine Bewertungen

- Decanting System - Decanting - Water Discharge - Sequencing Batch Reactor1Dokument1 SeiteDecanting System - Decanting - Water Discharge - Sequencing Batch Reactor1Anonymous qRe192Noch keine Bewertungen

- Sanitary Engineering (Qwa)Dokument13 SeitenSanitary Engineering (Qwa)Arun KumarNoch keine Bewertungen

- 03 Biological Treatment PDFDokument22 Seiten03 Biological Treatment PDFAlvaro HueteNoch keine Bewertungen

- Sedimentation Basins ExplainedDokument12 SeitenSedimentation Basins ExplainedShane RodriguezNoch keine Bewertungen

- Oxidation Ditch: Technical Elective Ii - Sanitary EngineeringDokument7 SeitenOxidation Ditch: Technical Elective Ii - Sanitary EngineeringLyka Isabel TanNoch keine Bewertungen

- Technical ComparisonDokument25 SeitenTechnical ComparisonVijay KumarNoch keine Bewertungen

- Different Types of ToiletsDokument2 SeitenDifferent Types of ToiletsAngelica Charisse Buligan100% (1)