Beruflich Dokumente

Kultur Dokumente

Lean Implementation: Lean Implementation For Business Outcomes-Cost, Quality, and Process Improvement

Hochgeladen von

Raunaq SinghOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lean Implementation: Lean Implementation For Business Outcomes-Cost, Quality, and Process Improvement

Hochgeladen von

Raunaq SinghCopyright:

Verfügbare Formate

Lean IMPLEMENTATION

Lean Implementation for Business Outcomes- Cost, Quality, and Process Improvement

We will start with assessment for your organization to clearly identify where to start.

Post assessment, we will partner to implement a performance improvement model that will help you not

only achieve your financial and operational goals, but also implement a continuous improvement process.

Access powerful, post-assessment Lean expertise.

The Lean and Operational Excellence experts at Thought At Work work closely with your frontline staff and

leadership teams to outline an implementation model and plan to achieve your goals .Each recommendation is tailored to

your specific need, organization size, effort required for scope and the expertise and availability of internal resources to

support the initiative. Your solution will include all or some of the following core components:

Project Governance

Leadership Mentoring

Process Improvement Implementation

Project Team Coaching and Development

Multilevel Education

Benefits Realization and Validation

Count on a deployment based on best practices and deep experience.

Thought at Work is a distinguished expert, having implemented Lean

solutions in some of the most recognized organizations in the world. Your

solution will be based not only on industry best practices, but also on the best

practices and lessons learned by our team through decades of experience

applying Lean, learning, change management, and process excellence

methodologies. Deployments typically include:

Master Schedule Transformation Planning

Prototype Development and Trial Design

Measurement Systems Development

Lean Systems Implementation

Rapid Event Implementation

Pilot Process Implementation

Process Confirmation and Benefits Confirmation

Training Development and Deployment

Draw on a robust cache of tools and capabilities.

Continuous Improvement

While every engagement may have slightly

different goals and objectives, requiring different

tools and techniques to deliver maximum impact,

the core principles and methodologies are

common. The following are some of the

capabilities your implementation may draw on to

achieve your intended goals.

5S and Workplace Organization

Developing a culture and process of continuous improvement is

the ultimate goal of a Lean organization once the foundational

pieces are in place. This gives an organization the ability to

systematically identify waste and remove it to reduce costs and

meet the companys targets. Thought At Work works with you

to create and facilitate a learning organization equipped to

continuously challenge assumptions and develop new solutions.

Expect comprehensive service, built on thorough expertise.

5S and workplace organization build a foundation

for all subsequent activities, delivering the first

step in visual management and control by

highlighting abnormal situations.

Standardization

Implementations are led by Thought At Work, using the

show me, tell me, help me, let me methodology. Our role in

guiding you through the translation of strategy to execution

may take a variety of formatsdedicated or incremental

Thought At Work onsite transformation support, onsite

Thought At Work-led Kaikaku event support, focused-issue

onsite support, or virtual Thought At Work support.

Standardization is the breakdown of a process into

logical steps and elements that help identify waste

and build in safety and quality. Standardizing your

processes allows the staff to consistently provide a

quality service, on time and in a safe, predictable

manner.

Problem Solving

Problem solving is the systematic process of

grasping the actual situation and the facts leading

to identifying the root cause and developing a

permanent countermeasure to the problem.

Quick Changeover/Just In Time/Kanban

These methodologies help you develop an

operating structure in which material and

information flow is defined to achieve Just-InTime processing. Thought At Work will work

with designated participants to reduce changeover

time and procedure completion time, leading to

significant reductions in lead time and cycle time.

Thought At Work

B-401,Park View City1

Sector-48,Sohna Road

Gurgaon-122001(INDIA)

Regardless of the format, you can count on our full-service

capabilities for any required training, mentoring, guidance,

management communications, progress feedback, or other

agreed-on assistance to complete your implementation.

For more information call

91-8826216688 or email

lean@thoughtatwork.in

Contact us for end-to-end services for Lean implementation.

Contact Thought At Work for more information about cost,

quality, and process improvement results we can help you

achieve in the following phases of Lean implementation:

Initial Assessments

Pilot Implementation

Enterprise-wide Planning and Deployment

Supply Chain Rollout

thoughtatwork.in

+91-8826216688

info@thoughtatwork.in

2013 Thought At Work. All rights reserved. Thought At Work is a trademark of Vikas Gera . All other trademarks are trademarks or registered trademarks of their respective owners.

Das könnte Ihnen auch gefallen

- Wind TurbineDokument38 SeitenWind TurbineRaunaq Singh100% (1)

- UH-60A Blackhawk Eng. Simulation Program, Vol. 1, Math ModelDokument361 SeitenUH-60A Blackhawk Eng. Simulation Program, Vol. 1, Math Modelmanitheaerialfighter100% (1)

- LEAN Continuous Improvement KaizenDokument4 SeitenLEAN Continuous Improvement KaizenHafis BonterNoch keine Bewertungen

- Standard Operating Procedures (SOPs)Dokument19 SeitenStandard Operating Procedures (SOPs)Raunaq SinghNoch keine Bewertungen

- Estimation Software For Presure VesselDokument36 SeitenEstimation Software For Presure VesselKarthikeyan Shanmugavel0% (1)

- Just in Time System (2) 10000Dokument24 SeitenJust in Time System (2) 10000John GriffiesNoch keine Bewertungen

- CM 05 - Lean Management - Final PresentationDokument74 SeitenCM 05 - Lean Management - Final PresentationOmar RefaatNoch keine Bewertungen

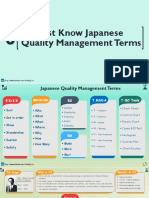

- 6 Must Know Japanese Quality Management Concepts 1664051048Dokument8 Seiten6 Must Know Japanese Quality Management Concepts 1664051048Shady Essam ElkilanyNoch keine Bewertungen

- Modern Guide Standard Work DozukiDokument30 SeitenModern Guide Standard Work Dozukisteved_43Noch keine Bewertungen

- Presentation On TPS - JIT KanbanDokument93 SeitenPresentation On TPS - JIT KanbanManish RajdevNoch keine Bewertungen

- Chapter 1 Introduction To Lean ManufacturingDokument37 SeitenChapter 1 Introduction To Lean Manufacturingelin chanNoch keine Bewertungen

- GBE KPO 2 001 00 Lean Basics 1Dokument75 SeitenGBE KPO 2 001 00 Lean Basics 1hondacarNoch keine Bewertungen

- Committing To A Lean Six-Sigma Roadmap: Merwan Mehta, PHD, Asq-CssbbDokument36 SeitenCommitting To A Lean Six-Sigma Roadmap: Merwan Mehta, PHD, Asq-CssbbCarlos Delgado NietoNoch keine Bewertungen

- Lean Management in Service Industry: TechnologiesDokument24 SeitenLean Management in Service Industry: TechnologiesRohit Bebarta80% (5)

- Laser Guidance Is A Technique of Guiding A Missile or Other Projectile or Vehicle To A TargetDokument22 SeitenLaser Guidance Is A Technique of Guiding A Missile or Other Projectile or Vehicle To A TargetRaunaq SinghNoch keine Bewertungen

- Implementing LeanDokument37 SeitenImplementing LeanVishnuNoch keine Bewertungen

- Becoming LeanDokument79 SeitenBecoming LeanItqan ArchiaNoch keine Bewertungen

- Workshop On Application of Lean Management: Gen-PromDokument102 SeitenWorkshop On Application of Lean Management: Gen-PromMudassar NawazNoch keine Bewertungen

- Reported By: Ms. Laarni P. LacandazoDokument36 SeitenReported By: Ms. Laarni P. Lacandazolpl_0124Noch keine Bewertungen

- Nissan's Global Strategy: March 1, 2007 Tadao Takahashi Executive Vice President Nissan Motor Co., LTDDokument16 SeitenNissan's Global Strategy: March 1, 2007 Tadao Takahashi Executive Vice President Nissan Motor Co., LTDazriffarisNoch keine Bewertungen

- Vertical Axis Wind TurbineDokument50 SeitenVertical Axis Wind TurbineRaunaq Singh100% (2)

- Oil & Gas Asset Integrity IssuesDokument15 SeitenOil & Gas Asset Integrity Issuesyogolain100% (2)

- Kaizen EventDokument22 SeitenKaizen EventRibmanNoch keine Bewertungen

- Lean Strategy Implementation MethodologyDokument48 SeitenLean Strategy Implementation MethodologyesilvarNoch keine Bewertungen

- Dual Clutch TransmissionDokument18 SeitenDual Clutch TransmissionRaunaq SinghNoch keine Bewertungen

- (2012.04.28) Principles of Lean Six Sigma 2012Dokument88 Seiten(2012.04.28) Principles of Lean Six Sigma 2012JeanNoch keine Bewertungen

- Pazek K. Lean Manufacturing 2021Dokument223 SeitenPazek K. Lean Manufacturing 2021Mourad Ben OthmaneNoch keine Bewertungen

- The Toyota Way To Lean LeadershipDokument27 SeitenThe Toyota Way To Lean LeadershipalexminayaNoch keine Bewertungen

- SF6 Novec 4710Dokument4 SeitenSF6 Novec 4710Fidya Eka PrahestiNoch keine Bewertungen

- Engine Maintenance PartsDokument13 SeitenEngine Maintenance PartsSerkanAl100% (1)

- Continuous Improvement Toolkit PDCADokument42 SeitenContinuous Improvement Toolkit PDCAKhairuddin KhairuddinNoch keine Bewertungen

- Guided By: Prof P.K.Muley Presented By: Amit Chawla (Roll No: 17) Zankhana Chowhan (Roll No:18) Unnat Churi (Roll No:19) Vikas Dhende (Roll No:20)Dokument26 SeitenGuided By: Prof P.K.Muley Presented By: Amit Chawla (Roll No: 17) Zankhana Chowhan (Roll No:18) Unnat Churi (Roll No:19) Vikas Dhende (Roll No:20)Unnat ChuriNoch keine Bewertungen

- Developing Lean CultureDokument80 SeitenDeveloping Lean CultureJasper 郭森源Noch keine Bewertungen

- Process Manager WorkshopDokument58 SeitenProcess Manager WorkshopHamada AhmedNoch keine Bewertungen

- Basic Quality Tools, An Introduction To Problem SolvingDokument30 SeitenBasic Quality Tools, An Introduction To Problem Solvingobelix007Noch keine Bewertungen

- Green Belt Course ManualDokument34 SeitenGreen Belt Course ManualKaranShinde100% (1)

- Successful Implementation of DMAIC For Pizzeria RestaurantDokument1 SeiteSuccessful Implementation of DMAIC For Pizzeria RestaurantDIONISIOSALNoch keine Bewertungen

- Value Stream Mapping Training MaterialsDokument12 SeitenValue Stream Mapping Training Materialsgandi shrtnNoch keine Bewertungen

- 12 Pecb Whitepaper Iso 13053Dokument9 Seiten12 Pecb Whitepaper Iso 13053João Paulo Rolim SampaioNoch keine Bewertungen

- VSM 3 ToolsDokument102 SeitenVSM 3 ToolsElena Montero CarrascoNoch keine Bewertungen

- Hoshin Kanri Planning BookDokument30 SeitenHoshin Kanri Planning BookMarco Antonio Figueroa RamírezNoch keine Bewertungen

- TOYOTA (Guru)Dokument49 SeitenTOYOTA (Guru)Gurudatt BakaleNoch keine Bewertungen

- Total Quality ManagementDokument7 SeitenTotal Quality ManagementmansoorliveNoch keine Bewertungen

- Six SigmaDokument30 SeitenSix SigmaMaryjoy Benitez 12 ABM-4Noch keine Bewertungen

- Lean ClassDokument425 SeitenLean ClassElena Montero CarrascoNoch keine Bewertungen

- Learning Lms Through Understanding KaizenDokument58 SeitenLearning Lms Through Understanding Kaizenparamjeet yadavNoch keine Bewertungen

- Lean Managemnet FinalDokument72 SeitenLean Managemnet FinalmohamedNoch keine Bewertungen

- Plasma Propelled Rocket EnginesDokument24 SeitenPlasma Propelled Rocket EnginesRaunaq Singh100% (1)

- 001 3 Lean+Six+Sigma+Implementation+Manual V9 PDFDokument81 Seiten001 3 Lean+Six+Sigma+Implementation+Manual V9 PDFJuan Pablo Azcuña C.Noch keine Bewertungen

- Bazele Matematice Ale Calculatoarelor - Florian Mircea BoianDokument132 SeitenBazele Matematice Ale Calculatoarelor - Florian Mircea BoiannimsocNoch keine Bewertungen

- OTE Maintenance Inspection For Grinding Eng WebDokument2 SeitenOTE Maintenance Inspection For Grinding Eng WebjadetorresNoch keine Bewertungen

- A Conceptual and Strategy Map For Lean Process TransformationDokument12 SeitenA Conceptual and Strategy Map For Lean Process Transformationivan platiniNoch keine Bewertungen

- Kaizen Approach - Lean Methodology On Continuous ImprovementDokument32 SeitenKaizen Approach - Lean Methodology On Continuous ImprovementMuthupandiNoch keine Bewertungen

- 2014 Lean Management Enterprise Compendium With LinksDokument164 Seiten2014 Lean Management Enterprise Compendium With LinksSajid AliNoch keine Bewertungen

- Lean Project Management A Complete Guide - 2020 EditionVon EverandLean Project Management A Complete Guide - 2020 EditionNoch keine Bewertungen

- Lean Six Sigma White Belt Autor University of California San DiegoDokument31 SeitenLean Six Sigma White Belt Autor University of California San DiegoGoran SpasićNoch keine Bewertungen

- Lean ImplementationDokument28 SeitenLean ImplementationJacob EdwardsNoch keine Bewertungen

- Overview of Lean: Lean Management Program Sept 2012Dokument36 SeitenOverview of Lean: Lean Management Program Sept 2012Monindika WarshakoonNoch keine Bewertungen

- Accenture Process and Innovation Performance Solving Retail Problems Using Lean Six SigmaDokument12 SeitenAccenture Process and Innovation Performance Solving Retail Problems Using Lean Six SigmaGermán Huarte ZubiateNoch keine Bewertungen

- Senior Leadership Lean Transformation PDFDokument48 SeitenSenior Leadership Lean Transformation PDFMario Alejandro Charlin SteinNoch keine Bewertungen

- Apply Lean ThinkingDokument12 SeitenApply Lean ThinkingArifaniRakhmaPutriNoch keine Bewertungen

- Initial Plan For Sonoco Improvement Basic Notes: Example of A Matrix To Prioritise The Line For Performance ImprovementDokument5 SeitenInitial Plan For Sonoco Improvement Basic Notes: Example of A Matrix To Prioritise The Line For Performance ImprovementDamianNoch keine Bewertungen

- Lean EN 2018Dokument48 SeitenLean EN 2018Karan KarnikNoch keine Bewertungen

- Basic Concepts On 5s Kaizen TQMDokument19 SeitenBasic Concepts On 5s Kaizen TQMRodj Eli Mikael Viernes-IncognitoNoch keine Bewertungen

- Opex VSM Training Module 100711001122 Phpapp02Dokument53 SeitenOpex VSM Training Module 100711001122 Phpapp02Jesus Jose Hernandez GuerreroNoch keine Bewertungen

- Lean Six Sigma CrosswordDokument1 SeiteLean Six Sigma CrosswordexamplecgNoch keine Bewertungen

- Total Productive Maintenance (TPM) : Prevent Inefficiencies and Enhance Safety Through The Power of The TPM SystemDokument16 SeitenTotal Productive Maintenance (TPM) : Prevent Inefficiencies and Enhance Safety Through The Power of The TPM SystemjjfmedNoch keine Bewertungen

- Seminar On Optimisation of Process Parameters For Lean Manufacturing in Medium and Large Industries - An Indian PerspectiveDokument42 SeitenSeminar On Optimisation of Process Parameters For Lean Manufacturing in Medium and Large Industries - An Indian PerspectivesataooNoch keine Bewertungen

- Value Stream MappingDokument40 SeitenValue Stream Mappingjinyue7302Noch keine Bewertungen

- Lean and Green: Profit for Your Workplace and the EnvironmentVon EverandLean and Green: Profit for Your Workplace and the EnvironmentBewertung: 3 von 5 Sternen3/5 (1)

- SMED single minute exchange of die A Complete Guide - 2019 EditionVon EverandSMED single minute exchange of die A Complete Guide - 2019 EditionNoch keine Bewertungen

- Quality Management System Process A Complete Guide - 2020 EditionVon EverandQuality Management System Process A Complete Guide - 2020 EditionNoch keine Bewertungen

- Science and Technology Literature Survey of Wind Power Integration With Hydroelectric EnergyDokument8 SeitenScience and Technology Literature Survey of Wind Power Integration With Hydroelectric EnergyRaunaq SinghNoch keine Bewertungen

- Security For WindowDokument48 SeitenSecurity For WindowRaunaq SinghNoch keine Bewertungen

- Storage Incoming Process Flow: F U N C T I O N SDokument1 SeiteStorage Incoming Process Flow: F U N C T I O N SRaunaq SinghNoch keine Bewertungen

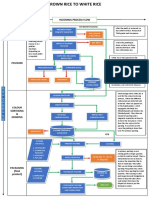

- Rice To Rice Flow Diagram 1Dokument1 SeiteRice To Rice Flow Diagram 1Raunaq SinghNoch keine Bewertungen

- Internship Report May 2016Dokument11 SeitenInternship Report May 2016Rupini RagaviahNoch keine Bewertungen

- Mega PostDokument5 SeitenMega PostandreyfgNoch keine Bewertungen

- MILL Series GB-1007 01Dokument20 SeitenMILL Series GB-1007 01Ady IonutNoch keine Bewertungen

- 701.ssvseat 1.04Dokument2 Seiten701.ssvseat 1.04Cosmin MuscaluNoch keine Bewertungen

- Pioneer XDP - 30R ManualDokument213 SeitenPioneer XDP - 30R Manualmugurel_stanescuNoch keine Bewertungen

- Ex-Cell XR2750 Pressure Washer Operation ManualDokument16 SeitenEx-Cell XR2750 Pressure Washer Operation Manualj_wilson85Noch keine Bewertungen

- Kinematics-03-Subjective SolvedDokument11 SeitenKinematics-03-Subjective SolvedRaju SinghNoch keine Bewertungen

- An 80-Mg Railroad Engine A Coasting at 6.5 KM - H Strikes A 20Dokument4 SeitenAn 80-Mg Railroad Engine A Coasting at 6.5 KM - H Strikes A 20Aura Milena Martinez ChavarroNoch keine Bewertungen

- 1998-10 The Computer Paper - Ontario EditionDokument156 Seiten1998-10 The Computer Paper - Ontario Editionthecomputerpaper100% (1)

- 4.10) Arch Shaped Self Supporting Trussless Roof SpecificationsDokument11 Seiten4.10) Arch Shaped Self Supporting Trussless Roof Specificationshebh123100% (1)

- Ultra Petronne Interior Supply Corp.: Manufacturer of Light Metal FramesDokument1 SeiteUltra Petronne Interior Supply Corp.: Manufacturer of Light Metal Framesjun vincint geleraNoch keine Bewertungen

- Teaching Finite Element Analysis For Design Engineers: August 2011Dokument7 SeitenTeaching Finite Element Analysis For Design Engineers: August 2011Nelu CheluNoch keine Bewertungen

- FL-02-01 PM SheetDokument12 SeitenFL-02-01 PM SheetBikas SahaNoch keine Bewertungen

- 007-013558-001 SAS PCE SPE With Support For HSM PSE2 Integration Feature Documentation RevCDokument43 Seiten007-013558-001 SAS PCE SPE With Support For HSM PSE2 Integration Feature Documentation RevCpietoeNoch keine Bewertungen

- Tube Well Design Project SolutionDokument5 SeitenTube Well Design Project SolutionEng Ahmed abdilahi IsmailNoch keine Bewertungen

- Steel Top Hats Battens Capacitytables Product Technical ManualDokument16 SeitenSteel Top Hats Battens Capacitytables Product Technical ManualbhukthaNoch keine Bewertungen

- Oracle Jrockit Mission Control Lab GuideDokument17 SeitenOracle Jrockit Mission Control Lab GuideashuhegdeNoch keine Bewertungen

- Sec VlanaclsDokument10 SeitenSec VlanaclsTry FajarmanNoch keine Bewertungen

- Riscv SpecDokument32 SeitenRiscv SpeckartimidNoch keine Bewertungen

- Transmisor HarrisDokument195 SeitenTransmisor HarrisJose Juan Gutierrez Sanchez100% (1)

- Schematic Lenovo ThinkPad T410 NOZOMI-1Dokument99 SeitenSchematic Lenovo ThinkPad T410 NOZOMI-1borneocampNoch keine Bewertungen

- Manual CRM-91H 93H 9SDokument2 SeitenManual CRM-91H 93H 9SFilip FilipovicNoch keine Bewertungen

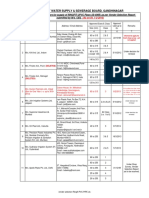

- GWSSB Vendor List 19.11.2013Dokument18 SeitenGWSSB Vendor List 19.11.2013sivesh_rathiNoch keine Bewertungen