Beruflich Dokumente

Kultur Dokumente

075 Oil Mist Application Manual PDF

Hochgeladen von

Adolfo EirasOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

075 Oil Mist Application Manual PDF

Hochgeladen von

Adolfo EirasCopyright:

Verfügbare Formate

Alemite Oil Mist

Application Manual

Oil Mist Application

Introduction

The Oil Mist principle was developed in the late 1930s by a

European bearing manufacturer. The problem that nurtured

this development was the inability to satisfactorily lubricate

high-speed spindle bearings on grinders and similar

equipment. The speeds of those bearings were too high for

grease lubrication, and the heat generated by fluid friction in

liquid oil necessitated the use of costly re-circulating

systems. Continuous thin-film lubrication with Oil Mist

provided a solution, and the purging of bearing housings that

accompanies this lubrication produced additional benefits.

Stewart-Warner Corporation purchased the rights to Oil Mist

in 1949. Since then, the Alemite Corporation has developed

a broad line of equipment and application techniques to

lubricate all kinds of machine elements, from the tiny, ultrahigh-speed parts of dentists drills to the huge gears and

bearings of steel rolling mills. With modern demands for

more and more complex machines running at higher and

higher speeds, and for greater reliability and economy, the

list of applications for Alemite Oil Mist Systems grows longer

and longer.

particles. This mist is then thrust against a baffle that collects

and drops larger particles back into the reservoir. The

lighter, airborne particles are then carried by the air stream

through the distribution system to the various points of

application.

The efficiency of an Oil Mist System is dependent upon

various designed lubrication fittings that serve as contact

points to the parts to be lubricated. These fittings serve two

functions. They maintain balanced pressure in the system

preventing over or under lubrication of a bearing. They

regulate the amount of mist through the fitting orifices into the

bearings being lubricated.

What it does

Oil Mist lubrication is an automatic, centralized system that

CONTINUOUSLY delivers fresh, clean oil to multiple, and

often widespread, machine elements. There are numerous

advantages to Oil Mist, in addition to the improvements in

safety, productivity, housekeeping, and lubrication that are

achieved by automatic centralized systems in general.

Continuous delivery, at rates closely approximating actual

bearing-surface needs, eliminates the overlubrication that is

necessary to insure adequate supply between periodic

applications. LUBRICANT CONSUMPTION can often be

reduced by as much as 80%.

In many cases, continuous lubricant delivery by Oil Mist

permits elimination of energy-wasting oil sumps. Reductions

in POWER consumption of more than 25% are common.

BEARING TEMPERATURES are often lowered dramatically,

not by actual cooling, but because most of the power

consumption reduction represents heat that is not generated

in churning excess lubricant.

Pressurization of housings, with continuous outward air flow,

extends MACHINE LIFE by helping to exclude dirt and

corrosive atmospheres. Oil Mist is even used to protect

equipment on standby and in storage.

How it does it

The heart of the system is the mist generator. Air from

normal factory air supply passes over a venturi inside the

generator, which accelerates the flow. This creates low

pressure and high velocity at the venturi discharge. As air

passes through the venturi it draws oil from the generator

reservoir into the high velocity air stream. The combination

of low pressure and high impact explodes the oil into tiny

How to apply it

BASIC STEPS TO DESIGN AN ALEMITE

OIL MIST SYSTEM

1. DESCRIBE each element to be lubricated and

CALCULATE its Oil Mist flow requirement in CUBIC FEET

PER MINUTE (CFM).

2. Select APPLICATION FITTING TYPES and determine

their PLACEMENT and VENTING provisions.

3. Select the DESIGN MANIFOLD PRESSURE (DMP).

4. Determine FITTINGS SIZES.

5. Select an appropriate Oil Mist GENERATOR.

6. ROUTE and SIZE air and mist distribution PIPING.

7. Select FITTNGS CONFIGURATIONS that will be most

convenient to install and connect to distribution system.

8. Select ACCESSORIES.

9. Plan ELECTRICAL CIRCUITRY.

Oil Mist Application

FITTING DISCHARGE DIRECTION

Details of basic steps General:

SPRAY and CONDENSING FITTINGS work most efficiently

when discharging downward. However, discharge may be in

any direction BETWEEN DOWNWARD AND HORIZONTAL.

For all Systems

SPRAY FITTINGS may also be installed to discharge

UPWARD, in which case the CALCULATED CFM used to

select fittings sizes should be DOUBLED.

1. The DESCRIPTIONS required to CALCULATE the mist

requirements of machine elements include type of element,

dimensions, and various details of installation and

operation. This information is used in simple formulas to

calculate cfm of mist required. The formulas are based on

the design standard oil/air ratio of 0.4 cubic inch (0.22

ounce) per hour per cfm. They assume that the elements

to be lubricated were properly selected for the intended

service and properly assembled and protected from

contamination. They also assume the use of an oil with the

proper misting and lubricating qualities for the intended

application. (FORMULAS and other considerations for

applying Oil Mist to SPECIFIC TYPES OF MACHINE

ELEMENTS are given in a later part of this manual:

PAGES 6-10.)

2.APPLICATION FITTING TYPES

FITTING SELECTIONS are primarily based on the types of

elements to be lubricated, but are often influenced by other

factors, such as machine configuration or speed. In

general, use SPRAY FITTINGS and SPRAY NOZZLES for

ROLLING MOTION elements, such as anti-friction

bearings, gears and chains. (SPRAY NOZZLES are just

multiples of the largest Alemite spray fitting.)

CONDENSING FITTINGS or SPRAY FITTINGS are used

for SLIDING MOTION elements, such as plain bearings,

slides, and ways. MIST FITTINGS are used only for rolling

element bearings operating in closed housings, under

particular types of loading, and above a minimum speed.

FITTINGS PLACEMENT

PLACE SPRAY FITTINGS to discharge close to the

lubricated elements, preferably less than one inch away.

REMOTE POSITIONING of spray fittings is permissible if

their outputs are ducted to and flow through the lubricated

elements because of relative positions of fittings and vents,

and if passages downstream from the fittings are horizontal

or sloped downward toward the elements.

TO SPRAY DIRECTLY on elements moving at speeds up

to about 1600 linear feet per minute, keep spacing between

spray fittings and moving surfaces under 1/20 inch per inch

water column manifold pressure. At higher speeds, install

spray fittings 1/8 to 1/4 inch from the moving surfaces and

use higher mist pressures-40 in. H20 above 2000 lfm and

up to 80 in. H20 at much higher speeds.

From CONDENSING FITTINGS the oil flows by gravity

directly to the grooves supplying the sliding surfaces. The

fitting location should be as close to the grooves as

possible.

MIST FITTINGS may be installed in any location, providing

the mist flow envelops or passes through the elements to

be lubricated.

Spray discharge should be approximately perpendicular to

the direction of motion of the sprayed surface.

MIST FITTINGS may be installed to discharge in any

direction.

VENTING

VENTING must be provided for the escape of carrier air from

closed housings.

MINIMUM VENT AREA is equal to twice the total flow area of

the application fittings supplying flow to that vent. Vent areas

of this size will produce housing back pressures equal to

about 20% of manifold pressure.

Wherever possible, relative POSITIONS of VENTS,

APPLICATION FITTINGS, and LUBRICATED ELEMENTS

should produce forced flow from application fittings to

lubricated surfaces.

VENTING can be by means of approximately located

DRILLED HOLES or, frequently, by existing ports in the

housing. LABYRINTH SEALS will usually provide adequate

venting, although a small one might have insufficient

clearances for this purpose, and require the addition of a

drilled hole. CONTACT SEALS can be notched to provide

venting, but this is not recommended because of the

likelihood that notching will not be provided when seals are

replaced.

VENT PORTS can often serve as OIL OVERFLOW OR

DRAIN ports. In an oil-sump application the vent can be

placed just above the normal sump oil level to provide an

overflow path for any excess oil delivered by the Oil Mist

system. Such vents should be located so that liquid oil will

not splash out through the port. For a dry-sump application

the vent can be placed at the bottom of the housing to drain

all liquids.

VENTS should generally be PROTECTED from outside

contaminants. Holes in the sides of housings should slope

downward to the outside. Vent ports in the tops of housings

should have shielded vent fittings installed.

3. DESIGN MANIFOLD PRESSURE (DMP) is the pressure

drop across the application fittings at which the fittings sizes

are selected. It is the intended output pressure of the Oil Mist

generator. The ALEMITE STANDARD DMP IS 20 INCHES

WATER COLUMN. Occasionally, other pressures are

recommended to better meet specific application

requirements. In general, lower DMPs permit closer oil

output control. Higher DMPs are used to produce higher

output velocities from spray type application fittings to

penetrate air barriers around high-surface speed elements

(over 2000 linear feet per minute). Also, spray and

condensing fittings operate more efficiently with higher

pressure drops across them.

Oil Mist Application

4. Determine APPLICATION FITTING SIZES from the chart

on PAGE 28.

A. In the TYPE column, locate the fitting type selected

in Step 2.

B. In the section for that fitting type, go to the right to

the column under the DMP selected in Step 3.

C. In the PRESSURE DROP column and type section

find the mist flow equal to or nearest to and higher

than the requirement calculated in Step 1.

D. On that flow line, go to the left to the second

column, headed NO., and read the DASH

NUMBER that represents the fitting size.

E. The columns at the right side of the chart give the

minimum vent size for each fitting size. Actually,

the sizes given are those of standard drill bits

closest to calculated sizes and rounded to nearest

thousandth.

AN EXCEPTION to the above method of determining fitting

type, size and placement is for elements in a closed

housing that are lubricated from an oil sump by dipping into

the oil or by oil rings, flingers, etc. Gear boxes and pump

bearing housings are examples of such equipment to which

Oil Mist is often applied to provide purging and to make up

oil losses from the sump. In the Hydrocarbon Processing

Industries, this is referred to as PURGE-MIST application.

Since, in a Purge-Mist application, the Oil Mist system does

not actually lubricate the machine elements, and, since

sump losses cannot be calculated, there are no

calculations to determine application fitting size. Alemite

recommends simply starting with a -8 SPRAY FITTING (or

-1 spray nozzle) for each housing, and changing sizes as

indicated by housing oil levels and/or overflow rates. A 1/8

inch diameter hole at the top of the sump oil level can act

as VENT and as overflow to prevent raising sump level.

If a CONSTANT LEVEL OILER is used to control sump oil

level, it must be modified by drilling an approximately 3/16

inch diameter hole in the side of the surge chamber about

1/4 inch above the operating oil level. This is to provide an

overflow for any excess oil delivered by the mist system.

To prevent depressing of the sump oil level, the housing

must be VENTED to an internal pressure no greater than

1/10 inch water column. An Alemite 385608 vent fitting is

recommended to accomplish this.

5. Oil Mist GENERATOR selection is based on flow capacity

and air heater requirements and, in some cases, on

desired reservoir refill interval.

The required MIST GENERATING CAPACITY is

determined by adding together the flow ratings, at design

manifold pressure, of all of the APPLICATION FITTINGS

that are to be supplied from the mist generator. Select a

generator (see PAGES 11-12 ) for which this total is within

the operating range, preferably near the center of that

range. DO NOT plan to operate a system outside the

specified flow limits of the mist generator, especially at the

low end. Flows less than the minimum specified for a

generator will not reliably draw an adequate supply of oil

from the reservoir to the mist generating head. If it is

necessary to use a mist generator with a higher minimum

flow rating than the total of the flow ratings of the

application fittings, then that total must be increased. This

can be accomplished by using the same fittings at a higher

design manifold pressure or by using fittings with higher

flow ratings. In most cases, the greater lubricant delivery

will not even be noticeable. However, if this approach is

objectionable, application fittings can be added to the

system, either by lubricating points not included in the

original plan, or by discharging spray or condensing fittings

into a vented receptacle.

Requirements for HEATERS are determined by referring to

the chart on PAGE 13. Use of the chart is explained on

that page. The lowest two curves indicate whether oil

(reservoir) and air heaters are REQUIRED. (Even though

they might not be required, these heaters are often used to

stabilize the oil/air ratio with widely varying ambient

temperatures.)

The two curves pertaining to application fittings indicate

limits necessitated by the tendency of oils to coat the bores

or passages of those fittings. As temperature falls, the

coating thickens. At FITTING TEMPERATURES above the

limits, the system maintains good balance and output by a

rise in manifold pressure, since, for a given input pressure,

the mist generator tends to act as a CONSTANT FLOW

device. However, at temperatures below the limits, the

restrictions become too great for the system to maintain

good distribution balance. Systems that are to operate

under such conditions should utilize mist generators with

Thermo-Aire. The temperature of the application fittings

can then usually be kept above the critical levels by

insulating the mist distribution system. Occasionally, it

might be necessary to provide some HEATING for the

FITTINGS.

If RESERVOIR REFILL INTERVAL is a matter of concern,

consult the chart on PAGE 14. The 0.6 cubic inches of oil

per hour per CFM of mist is the approximate maximum

oil/air ratio for Alemite Oil Mist generators operating without

heaters at normal plant ambient temperatures. Oil/air ratio

is a function of the setting of the oil flow adjustment screw

in the mist generating head, the type and viscosity of oil

used, as well as the air and oil temperatures. If all of these

were acting to maximize the oil/air ratio, the required refill

intervals could be as short as about one-half of those given

on the chart. With all factors combining to minimize oil/air

ratio, the intervals could be lengthened to five or six times

those shown. However, REMEMBER that changing oil/air

ratio also changes lubricant delivery. Reducing the ratio to

its minimum means reducing lubrication to about one-fourth

of the amount the system was designed to deliver, and

adds the danger of a complete loss of lubrication due to a

small drop in oil and/or air temperature, or to slightly

different misting characteristics of a new supply of oil. All

of which means: DO NOT plan to adjust system operating

conditions to achieve a desired refill interval. To the extent

possible, select a mist generator that will fit into the desired

schedule and, if necessary, adjust the schedule or consider

using an automatic refill system.

Oil Mist Application

6. PIPING refers to the systems used to supply air to the Oil

Mist generator and to distribute the Oil Mist from the

generator to the application fittings. It includes piping,

tubing, hose, and connectors.

In GENERAL, air and mist piping should be free of dirt,

scale, or other contaminants. Internal diameters should be

of sufficient size to avoid excessive pressure drop.

Materials should be compatible with internal fluids, and

resistant to external abuse, chemical attack and ambient

temperature.

For AIR PIPING, galvanized or copper pipe; copper,

stainless steel or anodized aluminum tubing; rubber hose

or synthetic tubing are recommended. The TABLE at the

TOP of the PAGE 15 gives pressure drops, at various air

flows, through 100 feet of pipe.

The plant main supply pipe must be larger than the branch

supplying air to the Oil Mist generator. The plant supply

pipe pressure, at the inlet to the branch, must be at least

equal to the sum of the generator regulated air pressure

and the pressure drop through the branch and the air

accessories, such as air solenoid valve, water separator,

and air pressure regulator. If the strainers in the water

separator and the air regulator become clogged, the

pressure drop will increase.

For MIST PIPING, any manifold material meeting the

GENERAL requirements above can be used. Black pipe

and plain steel tubing can be used if protected from

external corrosion by paint. The bore of black pipe should

be coated with preservative oil to prevent corrosion prior to

the introduction of Oil Mist. Mist piping should permit mist

flow with minimum wetting out of oil, and provide for

drainage of any oil that is deposited, without creating

obstructions to the mist flow. Since the mist system

operates at very low pressure, the use of pipe dope or

other thread sealants is not necessary and not

recommended. Improperly used, these sealants can

contaminate the mist piping. Flushing of the manifold is

recommended during installation to eliminate scale and dirt

which can plug the small bores of the application fittings.

MIST PIPING SIZES are selected primarily to limit mist

flow velocity. The TABLE at the BOTTOM of PAGE 15

shows the CFM that a given pipe, tube, or hose size

carries at various flow velocities. The MAXIMUM

VELOCITY of mist in the distribution system should be 24

fps (feet per second). Higher velocities will cause

excessive wetting out of oil from the mist. The GENERAL

RECOMMENDATION is to select distribution piping sizes

to limit flow velocity to 18-20 fps. This will keep wetting out

of oil to an acceptable minimum and will permit some

increase in system flow, if required, without exceeding the

maximum rate. For ROLLING MILL application, 15 fps

should be the maximum flow velocity. For systems

designed to operate at manifold pressures between 16

inches and 6 inches water column, use 12 fps as design

velocity. The use of OVERSIZE mist lines is

PERMISSIBLE but UNDERSIZE piping should NOT BE

USED.

In some installations, drain lines are provided to carry

reclassified oil away from housings. If such lines are also

acting as vents, they should follow the same criteria as

mist distribution piping, regarding flow velocity and

avoidance of traps.

In ROUTING MIST PIPING, the main consideration is

AVOIDANCE OF TRAPS - low spots in which oil could

collect. All parts of the distribution systems MUST DRAIN

by gravity. The main manifold should be sloped downward

toward the Oil Mist generator wherever possible. It is

especially important to slope the first part of the main

manifold toward the generator for a distance equal to 300

times the pipe ID, since most of the oil wetting-out occurs

within that distance. The TABLE at the TOP of PAGE 16

shows the RECOMMENDED SLOPE of manifold for proper

drainage back toward the generator.

Branch lines, if sloped toward the main manifold, should be

connected to the top or sides of the manifold, to avoid liquid

oil traps.

Where drainage provisions allow liquid oil and mist to flow

in the same direction, horizontal runs do not require any

slope. Horizontal runs which are not sloped should have

drainage points not farther apart than 300 times the

manifold ID. The drainage may be to points of lubrication,

or to a standpipe or sump having provision for periodic

dumping of collected oil.

Where oil traps are unavoidable, a 3/64 inch diameter hole

or a -3 spray fitting should be provided at the lowest point

of the trap to drain oil. If dripping is objectionable, run a

drain tube to a suitable receptable, vented with a 1/16 inch

diameter hole.

7. Select APPLICATION FITTINGS CONFIGURATIONS

that will be most convenient to install. Refer to types and

sizes previously determined (Step 4), and select from

fittings described on PAGES 17-21, and in Oil Mist

Catalog.

The complete fitting part number consists of a six-digit

number, designating type and style, followed by the dash

number, indicating size.

8. ACCESSORIES

The basic Oil Mist system components are:

a. An air line filter/water separator to assure a clean air

supply to the Oil Mist generator. (INCLUDED with some

models of Alemite Oil Mist generators, purchased

separately for others).

b. An air pressure regulator to control the atomizing air

pressure to the generator - the BASIC SYSTEM

ADJUSTMENT. (INCLUDED with some models of

Alemite Oil Mist generators, purchased separately for

others).

c. An Oil Mist generator which includes a venturi nozzle, oil

life tube, reservoir, and oil flow adjusting screw.

d. Mist distribution system to convey the Oil Mist to the

application fittings.

Oil Mist Application

e. Mist, spray or condensing application fittings to meter

and reclassify the Oil Mist at each lubrication point.

ACCESSORY Oil Mist system components include:

a. An air supply on-off valve. A solenoid valve is often used

and is INCLUDED with some models of Alemite Oil Mist

generators. The use of a solenoid valve permits remote

control or the interlocking of mist system operation with

that of the lubricated machine.

b. An oil heater to maintain the oil in the generator reservoir

at the proper viscosity for good mist generation

(INCLUDED with all generators supplied with air heater

and with some sales models of most other generators.)

c. An air heater (Thermo-Aire) to stabilize oil/air ratio, at

varying ambient temperature, or to mist heavy oils which

will not properly atomize at the prevailing ambient

temperature.

INCLUDED with some sales models of all generators for

which available. NOT AVAILABLE for 12 ounce or one

gallon generators).

d. An oil level switch to signal low oil level in the reservoir

and/or to control automatic reservoir refill.

e. A mist manifold pressure gauge (manometer) for visual

indication of manifold pressure. Although not necessary

for system operation, it is STRONGLY RECOMMENDED

that a mist pressure gauge be included in every Oil Mist

system. It simplifies and improves the accuracy of

system adjustment and provides valuable information on

system operation, especially during start-up and if trouble

shooting is required.

f. A mist manifold pressure switch to signal high or low

manifold pressure. SHOULD BE INCLUDED IN

THERMO-AIRE SYSTEMS, wired to shut off air heater

under alarm conditions, to protect heater element. See

circuit diagrams in section 9.

g. An Oil Mist detection unit (Mist Monitor) to signal high

or low density of oil particles in the mist. With reservoir

oil level, manifold pressure, and air temperature all within

normal limits, it is still possible that a mist generator will

not produce mist, due to improper oil in the reservoir or

to blockage of oil flow to the mist head. The Mist Monitor

continuously monitors mist density, photoelectrically, and

signals any serious deviation from the calibration level.

9. Some suggested ELECTRICAL CIRCUITS are shown on

PAGES 23-26. Terminal or wire numbers for electrical

components are given on PAGE 22. Of course, the user

may use these components as desired, within their ratings.

NOTE that circuits involving Thermo-Aire (air heaters)interlock

the heater with the mist pressure switch. This is to protect the

heater by preventing application of power without air flow

through the unit.

Oil Mist Application

Applying Oil Mist to specific

types of machine elements

ROLLING ELEMENT BEARINGS

location is used advantageously on single row, moderate

service, ball bearings on shafts under four inches in diameter,

operating over 200 lfm. Bearings in this category, mounted in

the wall of a machine housing containing a mist atmosphere,

can be mist lubricated if BOTH SIDES of the bearing are freely

exposed to the mist. A drilled hole or undercut with a minimum

area of 0.049 square inches in the outer race support is used to

expose the outboard side of a bearing in a blind wall mounting

to the mist in the housing. The windage created by the rotating

parts of the bearing assembly will create sufficient flow of mist

through the rolling elements. The cfm requirement for each

such bearing should be included in the calculated mist input for

the housing.

For radially mounted bearings designed to carry THRUST

LOADS (Heavy Service), such as angular contact ball or

tapered roller bearings, spray fittings and vents should be

located so the flow through the bearing is opposite to the

direction of thrust from the shaft. This is not necessary if an oil

sump or bath is maintained.

MODERATE SERVICE

CFM = 2x1/40=0.05

CFM CALCULATIONS

Moderate Service

cfm=DR/40

Heavy Service

cfm=DR/20

Rolling Mill Service

cfm=DR/14

Where

D = Shaft diameter in inches

R = Number of rows of rolling elements

The HEAVY SERVICE formula is used for:

All constantly thrust loaded bearings.

All preloaded bearings

All bearings on shafts transmitting more than 40 horsepower.

All bearings subjected to high inertial loads, either by

frequent hard starting and stopping or by unbalanced shaft

designs.

The ROLLING MILL SERVICE formula is used for work roll and

backup roll bearings in ferrous and non-ferrous rolling mills.

MODERATE SERVICE is any not included in the other service

definitions.

SPRAY FITTINGS OR NOZZLES are preferred for rolling

element bearings.

MIST FITTINGS are used for moderate service rolling element

bearings in closed housings where it is not practical to place a

spray fitting close to each bearing. Because most of the output

of a mist fitting will remain air-borne until carried into the

turbulent region of a bearing, mist fittings can be installed

remotely from the bearings they are to lubricate. Several

bearings in a housing can be served by one mist fitting. To

utilize the output from mist fittings, bearings must be operating

at speeds no lower than 200 linear feet per minute and

preferably above 1000 lfm, at the mean diameter of the bearing.

VENTS must be positioned and sized to proportion positive mist

flow through each bearing.

AN EXCEPTION to the forced flow principle of inlet and vent

TAPERED ROLLER BEARINGS, operating with light preloads,

are best lubricated from the small end of the rollers. On

HEAVILY PRELOADED tapered roller bearings, two spray

fittings per row can be used to advantage, especially in critical

applications such as precision machine tool spindles. For these

installations use the HEAVY SERVICE or even the MILL

SERVICE formula. On the upstream side of the bearing use a

spray fitting sized to deliver about one-third of the calculated

requirement, and on the vent side use a spray fitting that will

deliver about two-thirds of the calculated value. On the vent

side, place the fitting as close as possible to the bearing and try

to direct its output toward the bearing and away from the vent.

VENTS and APPLICATION FITTINGS should generally be

located so the calculated cfm for each row of rolling elements in

HEAVY SERVICE flows through that row before exhausting

through the vent. For bearings in MODERATE SERVICE, such

forced flow can be through two consecutive rows, if necessary.

With the EXCEPTION noted previously, forced flow through

bearings is necessary when using mist fittings. In direct spray

applications, with spray fittings discharging close to lubricated

elements, the vents and fittings need not be on opposite sides

of the bearings.

OIL SUMPS are recommended for ALL HEAVY SERVICE

BEARINGS and for all moderate service bearings mounted on

shafts four inches or larger in diameter. A DEPTH of oil

sufficient to cover the inside diameter of the bearing cup is

recommended for tapered roller bearings. For other bearing

types the depth of oil should be to the mid-height of the rolling

element at the bottom of the bearing. Vent locations can be

used to maintain the proper oil level. For high speed bearings,

vents used to control the sump level should be located so the

churning effect of the rolling elements does not throw sump oil

out of the vent ports.

Bearing housings with DOUBLE LIP SEALS require spray inlets

and vents located to maintain an oil sump in the area between

the contacting lips. The CFM seal requirement is equal to a

row of elements on the same shaft in moderate service

(cfm=D/40).

Means of sighting sump oil level are recommended.

Oil Mist Application

Oil Mist Application

PLAIN BEARINGS

CFM CALCULATIONS

Moderate Service

cfm=LD/100

Heavy Service

cfm=LD/60

Heavy Service, High Loss

cfm=LD/30

Where D = Shaft Diameter in Inches

L = Sleeve Length in Inches

MODERATE SERVICE BEARINGS are:

Rotating bearings on horizontal shafts where the load zone

is always in the lower half of the bearing.

Bearings mounted in any position where the oil is retained

in the bearing by contact type seals.

Bearings with porous bushings or synthetic frictionless

sleeves.

HEAVY SERVICE BEARINGS are:

Oscillating bearings on horizontal shafts where the load

zone is always in the lower half of the bearing.

Unsealed bearings subjected to shock loading where the

load zone constantly shifts, but boundary lubrication is

permissible, such as king pins and spring pins on trucks.

Small rotating bearings not mounted on horizontal shafts.

HEAVY SERVICE, HIGH OIL LOSS BEARINGS are:

Rotating bearings or bearings oscillating rapidly where the

load zone shifts more than 180, such as crankshaft and

crankarm bearings. Applications where these bearings

operate over 600 lfm should be referred to the factory.

Large bearings without seals that are not mounted on

horizontal shafts.

CONDENSING OR SPRAY FITTINGS are recommended for

plain bearings with 360 sleeves. SPRAY FITTINGS are

recommended for half-sleeve bearings.

On 360 bearings, fittings are installed so their outlets are

above the bearing housing. On HALF BEARINGS, spray

fittings are installed to spray on the shaft near its line of entry

into the bearing.

The following general RULES FOR GROOVE LOCATIONS

in Oil Mist lubrication bearings are consistent with accepted

grooving practice for oil lubricated plain bearings, regardless

of the method of oil application:

A. Grooves should be located so that 90% of the surface

area of the ungrooved surface (usually the shaft) passes

over one oil groove during each cycle of motion. This

rule is best represented by a longitudinal groove

extending 90% of the sleeve length in a rotating bearing.

Following this rule, OSCILLATING BEARINGS may

require several longitudinal grooves. In small oscillating

bearings these primary grooves can be connected by a

circumferential secondary groove with a single

application fitting supplying all grooves. On large

bearings of this type, a fitting should be used for each

longitudinal groove.

B. Groove volumes should be kept to a minimum. With a

constant source of lubricant input, large volume grooves,

acting as reservoirs, are not required. Large volume

grooves can be a disadvantage on machine start-up, if

oil has completely drained from the groove volume

during a shutdown period. For this reason, application

fittings should not be spaced further than FIVE INCHES

apart in bearings over five inches long.

C. All groove edges or housing parting line edges facing

the oncoming sliding surface should be rounded or

chamfered to prevent scraping the oil from the shaft.

D. Grooves should be in the unloaded zone of

hydrodynamically lubricated bearings. On large

bearings of this type the groove should be close to the

area where the shaft enters the load zone.

The RULES FOR VENTING plain bearings are:

A. Grooves are also used to vent plain bearings. For this

purpose, longitudinal grooves should extend to within

1/4 from the end of the sleeve in horizontal bearings.

Circumferential grooves in vertical sleeves should be in

the upper third of the sleeve and a longitudinal groove

extending upward from this groove to the END of the

sleeve is preferred for venting and should be opposite

the application fitting inlet.

B. Bearings with very close tolerances or with contact seals

require a vent passage connected to the top of the

internal grooving. The inlet and vent passages may be

combined.

SLIDES AND WAYS

CFM CALCULATIONS

Application fittings installed in SLIDE:

cfm=A/800

Application fittings discharging ONTO WAYS:

cfm=A/400

Where A = TOTAL contact area in square inches

Generally, CONDENSING FITTINGS are used to deliver

lubricant through holes in slides. SPRAY FITTINGS are

used to supply oil to ways.

For SLIDES, provide at least one application fitting for each

six inches of slide width and four inches of slide length, or

fractions thereof. Thus, a slide seven inches wide by nine

inches long should carry six application fittings - two across

by three lengthwise. Fittings should discharge into

TRANSVERSE GROOVES extending 90% of slide width.

Grooves should be VENTED or inlets and vents may be

combined as illustrated for plain bearings.

For WAYS, provide at least one application fitting for each six

inches of contact width.

Where MULTIPLE FITTINGS are used, DIVIDE the

calculated CFM EQUALLY among them.

Oil Mist Application

Oil Mist Application

10

GEARS

CHAINS

CFM CALCULATIONS

CFM CALCULATIONS

Spur, bevel, helical, etc:

unidirectional

cfm = F(D1 + D2 + D3 +...)/160

reversing

cfm = F(D1 + D2 + D3 +...)/110

Worm gears, unidirectional cfm = F(2D1 + D2)/160

reversing

cfm = F(2D1 + D2)/110

PDR

ROLLER Chain, power transmitting cfm =

320

Where

F = Gear face width, in inches

D1 = Pitch diameter of small gear or worm, in inches

D2 = Pitch diameter of large gear, in inches

D3, etc = Pitch diameters of additional gears, in

inches

If D2, D3 or any gear is LARGER THAN 2D, (except worm), in

place of that larger gear USE 2D1.

SPRAY FITTINGS OR NOZZLES are used to spray directly

on gears.

Provide a spray fitting for each TWO INCHES OF FACE

WIDTH or fraction thereof.

Where MULTIPLE FITTINGS are used across a WIDE GEAR

FACE, DIVIDE the calculated CFM EQUALLY among them.

For moderately loaded GEAR TRAINS, sprays directed at

every second or third gear in the train will generally suffice.

Using the formula, calculate the total cfm requirement for the

train. Proportion this by eyeball estimate to the lubrication

points selected. Use more or larger fittings on larger gears or

on those with more mesh points.

For HEAVILY LOADED GEAR TRAINS, provide sprays for

all mesh point, estimating proportioning to determine number

or sizes of fittings.

For UNIDIRECTIONAL operation, direct spray at load side of

gear teeth.

For REVERSING service, direct spray toward gear axis:

(100S )

S 3

cfm = WD

100

600

Where P = Pitch of chain or sprocket, in inches

D = Pitch diameter of small sprocket, in inches

R = Number of rows of chain rollers

W = Width of chain in inches

S = rpm of small sprocket

CONVEYOR Chain cfm = 3DW + 0.1LW

500

Where D = Diameter of drive sprocket, in inches

W = Width of chain, in inches

L = Length of chain, in inches

SILENT Chain

( )

SPRAY FITTINGS are used for chain lubrication.

For ROLLER and CONVEYOR chains, direct spray onto

edges of link plates. For single strand roller and for conveyor

chains, apply about one-half of the calculated cfm to each

row of link plates.

For MULTIPLE STRAND roller chain, divide the calculated

cfm by the number of rows of rollers to find the spray

FITTING SIZE for the inner rows of link plates. For the two

outer rows of link plates, divide calculated cfm by two times

the number of roller rows.

For SILENT chain, provide one spray fitting for each 1/2 inch

of width, starting 1/4 inch from outside edges. To SIZE

fittings, divide calculated cfm by twice the chain width.

For best results, position fittings to spray on the INSIDE OF

THE SLACK STRAND.

If spraying the SLACK STRAND, direct the spray slightly

AGAINST the chain motion.

If spraying the WORKING STRAND, point the spray slightly

in the direction of chain motion.

Oil Mist Application

MIST GENERATOR FLOW CHARACTERISTICS

11

12

Oil Mist Application

MIST GENERATOR FLOW CHARACTERISTICS

Oil Mist Application

13

SELECTION OF Oil Mist GENERATING COMPONENTS

TO OBTAIN OIL/AIR RATIO OF 0.4 CUBIC INCH OIL/HOUR/CFM AIR

The minimum ambient temperature and the oil viscosity for any intended application are used to locate a point on this chart.

The location of this point provides information used to determine the Oil Mist equipment requirements for the intended

application.

CERTAIN OIL ADDITIVES CAN AFFECT THE OIL/AIR RATIO, OR STOP THE GENERATION OF MIST.

OIL VISCOSITY RATING VS. ESTIMATED MINIMUM AMBIENT TEMPERATURE

14

Oil Mist Application

RESERVOIR REFILL INTERVAL

The chart relates mist flow and intervals at which various Alemite Oil Mist reservoirs will require refilling.

Curves are based on a mist density of 0.6 cubic inches of oil per hour per cfm of mist.

Curves are labeled with nominal reservoir capacities, but are based on actual usable cubic inches from FULL mark to nozzle

starvation.

Ranges covered by curves are those available with Alemite standard reservoir and mist head combinations.

Oil Mist Application

15

AIR PIPING

PRESSURE DROP PER 100 FEET OF PIPE-psi

AIR FLOW

@100psi

@75F

(cfm)

1/8

.269I.D.

16

15

13

20

23

35

14

45

23

33

PIPE SIZE

1/4

.364I.D.

3/8

.493 I.D.

100

1/2

.622 I.D.

3/4

.824 I.D.

MIST PIPE SIZING

MIST FLOWSCFM

SIZE

ID-in

1/4 tube

3/8 tube

1/2 tube

0.194

0.305

0.444

1/8 pipe

1/4 pipe

3/8 pipe

AREA-in2

@12fps

@15 fps

@18fps

@20fps

@24fps

0.030

0.073

0.155

0.148

0.365

0.774

0.185

0.457

0.968

0.222

0.548

1.161

0.246

0.609

1.290

0.296

0.731

1.548

0.269

0.364

0.493

0.057

0.104

0.191

0.284

0.520

0.954

0.355

0.650

1.193

0.426

0.780

1.432

0.474

0.867

1.591

0.568

1.041

1.909

1/2 pipe

3/4 pipe

1 pipe

0.622

0.824

1.049

0.304

0.533

0.864

1.519

2.666

4.321

1.899

3.333

5.402

2.279

3.999

6.481

2.532

4.444

7.202

3.039

5.333

8.643

11/4 pipe

11/2 pipe

2 pipe

1.380

1.610

2.067

1.496

2.036

3.356

7.479

10.179

16.778

9.349

12.725

20.974

11.218

15.267

25.165

12.464

16.965

27.963

14.957

20.358

33.556

21/2 pipe

3 pipe

2.469

3.068

4.788

7.393

23.939

36.963

29.925

46.207

35.905

55.440

39.898

61.601

47.878

73.927

3/16 hose

1/4 hose

3/8 hose

0.188

0.250

0.375

0.028

0.049

0.110

0.138

0.245

0.552

0.174

0.307

0.690

0.207

0.368

0.828

0.231

0.409

0.920

0.276

0.491

1.104

1/2 hose

3/4 hose

1 hose

0.500

0.750

1.000

0.196

0.442

0.785

0.982

2.209

3.927

1.227

2.761

4.909

1.473

3.313

5.890

1.636

3.682

6.545

1.964

4.418

7.854

11/4hose

11/2hose

1.250

1.500

1.227

1.767

6.136

8.836

7.670

11.045

9.204

13.254

10.227

14.726

12.272

17.672

Oil Mist Application

16

SLOPE OF MIST MANIFOLD TOWARD GENERATOR

OIL VISCOSITY

(SSU@100F)

MINIMUM AMBIENT OR MANIFOLD TEMPERATURE

0F

32F

50F

75F

100F

100

5.3

3.7

3.0

2.4

2.1

180

8.8

5.4

4.1

3.0

2.5

300

10.5

6.1

4.6

3.7

2.9

500

12.2

7.2

5.5

4.4

3.5

800

18.0

8.5

6.5

5.1

4.0

1500

11.0

8.8

6.1

4.9

2500

15.0

10.4

7.1

5.4

5000

14.4

9.0

6.

*PERCENT SLOPE OF MANIFOLD

*2% slope equals 2 drop every 100 of manifold

Table Notes:

1. Table is for manifold where condensed oil flow is opposite the mist flow.

2. Table is for installations in continuous operation. For systems operating one or two shifts daily, divide slope in Table by 2.

Oil Mist Application

17

MIST APPLICATION FITTINGS

Mist fittings are metering orifices which deliver mist, with minimum condensation, to machine elements.

The mist must be converted to liquid oil by the machine element.

The fittings are made of brass. Color - black.

The air flow graph shows average output.

INLET 1/8 NPTF (FEMALE)

OUTLET

1/8 PTF* (m)

380791-2

380791-4

380791-6

INLET 1/4 OD

TUBE FTG

ORIFICE

OUTLET

1/4 NPTF (m)

OUTLET

1/8 PTF* (m)

DIAMETER

LENGTH

FLOW

AREA

381303-4

381303-6

381303-10

381303-16

381290-2

381290-4

381290-6

381290-10

381290-16

.032

.045

.055

.078

.089

.44

.44

.44

.44

.44

.00078

.00159

.00237

.00484

.00622

*SAE Special Short.

PREFERRED ARRANGEMENT.

INLET AND OUTLET CAN BE

INTERCHANGED

WHERE NECESSARY.

PART NO. INCLUDES:

381289-2,-4,-6,-10, OR -16 FTG

328301-4 COMP. NUT

328302-4 COMP. SLEEVE

18

Oil Mist Application

CONDENSING APPLICATION FITTINGS

Condensing fittings are metering elements which convert mist to liquid oil within the fitting. The condensed oil flows by gravity to

the machine element.

The fittings are made of brass. Color - silver.

The air flow graph shows average output.

INLET 1/8 NPTF (f)

OUTLET 1/8 PTF * (m)

381281-06

381281-1

381281-2

381281-3

381281-4

381281-5

INLET 1/4 OD TUBE FTG

OUTLET 1/8 PTF *(m)

381282-1

381282-2

381282-3

381282-4

381282-5

ORIFICE (BAFFLED)

SIZE

LENGTH

FLOW AREA

SLOT .014 R

.38

.0003

SLOT .020 R

.38

.0006

2 SLOTS .020 R

.38

.0012

3 SLOTS .020 R

.38

.0018

5 SLOTS .020 R

.38

.0030

6 SLOTS .020 R

.38

.0036

*SAE Special Short.

PREFERRED ARRANGEMENT.

INLET AND OUTLET CAN BE INTERCHANGED WHERE NECESSARY.

Oil Mist Application

19

SPRAY APPLICATION FITTINGS

Spray fittings are metering orifices which convert a high percentage of mist to an oil spray.

The fittings are made of brass. Color - olive drab.

The air flow graph shows average output.

INLET 1/8 NPTF

OUTLET 1/8 NPTF

381283-1

381283-2

381283-3

381283-5

381283-8

INLET 1/4 OD TUBE FTG

OUTLET 1/8 NPTF

381288-1

381288-2

381288-3

381288-5

381288-8

DIAMETER

.024

.035

.042

.055

.067

ORIFICE

LENGTH

1.38

1.38

1.38

1.38

1.38

FLOW AREA

.000452

.000962

.00138

.00237

.00352

Oil Mist Application

20

SPRAY NOZZLE APPLICATION FITTINGS

Spray nozzles contain one or more metering orifices which convert a high percentage of mist to an oil spray. The capacity of

each metering orifice is nearly equal to that of one -8 spray fitting.

The nozzles are made of brass.

NO. OF

TOTAL

ONE END THREADED

BOTH ENDS THREADED ORIFICES FLOW

1/2 NPTF (m)

1/4 NPTF (m) 1/2 PTF*(m)

3/4 NPTF (m)

.067 DIA.

1.38 LG.

AREA

SQ. IN.

326370-1

383588-1

384280-1

.00352

326370-2

383588-2

384280-2

.00704

326370-3

383588-3

384280-3

.01056

326370-4

383588-4

384280-4

.01408

326370-5

383588-5

384280-5

.01760

326370-6

383588-6

384280-6

.02112

326370-7

383588-7

384280-7

.02464

326370-8

384280-8

.02816

326370-9

384280-9

.03168

384280-10

10

.03520

383617-11

11

.03872

383617-12

12

.04224

383617-13

13

.04576

383617-14

14

.04928

32670-10

*SAE Short

383617-10

Oil Mist Application

21

SPRAY NOZZLE APPLICATION FITTINGS

(continued)

Dash number for each curve indicates number of .067 diameter orifices in nozzle and is used as suffix of nozzle part number.

The flow through one .067 diameter orifice is .56 cfm at a pressure drop of 60 inches water column, and .68 cfm at 80 inches

water column.

The nozzle air flow graph shows average output.

Oil Mist Application

22

BASIC OIL MIST GENERATOR ELECTRICAL INTERCONNECTION DIAGRAM

TABLE OF COMPONENTS

CODE

COMPONENT

SOL A

SOLENOID AIR SHUT-OFF VALVE

TS-2

OIL HEATER THERMOSTAT

OH

OIL HEATER

HPS

MIST HIGH PRESSURE SWITCH (NO.2)

LPS

MIST LOW PRESSURE SWITCH (NO.1)

LLS

LOW LEVEL SWITCH

TS-1

AIR HEATER THERMOSTAT

TS-3

LOW AIR TEMPERATURE SWITCH

AH

AIR HEATER

**CAP.

CAPACITOR

ON THERMO-AIRE GENERATORS ONLY

AUTOMATIC REFILL KIT

RSS

REFILL AND SIGNAL SWITCH

SOL R

SOLENOID OIL REFILL VALVE

NOTES:

1. This is the interconnection diagram for Oil Mist generators, but most models do not incorporate all the electrical

components.

2. Terminal boxes having the same terminal strip numbering are recommended for Modular Design Generators.

3. These terminal numbers are used in the recommended elementary diagrams (in this section) for all Oil Mist Units, even

though most models do not incorporate all the electrical components.

4. The recommended elementary diagrams in this section are intended to be representative of the majority of desired

hookups. Where feasible, likely alternatives are shown.

5. Some circuits will require removal of jumpers 2-5, 5-6 and/or 9-10.

**High volume Thermo-Aire Generators only.

Oil Mist Application

23

RECOMMENDED ELEMENTARY WIRING DIAGRAMS FOR OIL MIST SYSTEMS

WITHOUT OIL HEATERS

These wiring diagrams are recommended for Oil Mist systems integral with a single machine. CR relay (5) can be used to

interlock machine start and stop with Oil Mist system operation. DS-1(1) can be omitted if machine is equipped with a power

disconnect.

Sequence of Operation (upper diagram):

1. Manually closing DS-1 (1) energizes the air solenoid (4), allowing air to flow to the Oil Mist generator. Closing DS-1 also

energizes the red light (6) and CR(5); therefore, CR contact (2) is open, and machine cannot be started.

2. When sufficient manifold pressure is attained, LPS (5) opens, de-energizing CR and the red light. The machine can now be

started by closing PB-1.

Function of CR Contacts:

1. With CR contacts in location #1, machine cannot be started without Oil Mist system, and will shut down when there is low

oil level, low manifold pressure, or high manifold pressure.

2. With CR contacts in location #2, machine cannot be started without Oil Mist System, but once machine is started, failure of

the Oil Mist system will energize red light, but will not shut down the machine.

Sequence of Operation (lower diagram):

1. Manually closing DS-1(1) starts the Oil Mist system simultaneously with the machine, and failure of the Oil Mist System will

only energize the red light (5).

24

Oil Mist Application

RECOMMENDED ELEMENTARY WIRING DIAGRAMS FOR OIL MIST SYSTEMS WITH

OIL HEATERS AND SIGNALS

These wiring diagrams are recommended for Oil Mist systems integral with a single machine. CR relay (3) can be used to

interlock machine start-and-stop with Oil Mist system operation.

An alternate relay CR-2(7) can be wired in series with DS-3, and CR omitted.

Where DS-1(1) is operated just prior to machine start, the oil heater should be wired upstream of DS-1. DS-1 can be omitted

if machine is equipped with a power disconnect.

Sequence of Operation (upper diagram):

1. Manually closing DS-1(1) energizes the oil heater (2) and the red light(5) indicating power on.

2. Manually closing DS-2(8) energizes the air solenoid, allowing air to flow to Oil Mist generator.

3. When sufficient manifold pressure is attained, LPS(4) de-energizes the green light (4) and optional relay coil CR(3).

4. If CR is used, machine can now be started.

Also, DS-3(6) may now be closed to lock in howler H for annunciation of system fault.

Sequence of Operation (lower diagram):

1. In diagram below, WS Light Signal unit 380745 is used in place of the individual red and green lights above.

In case of malfunction, the red light and howler H, if used, will be energized.

Sequence of operation is the same, except there is no indication when DS-3 can be closed without energizing the red light

and howler.

Also, there is no indication of power-on when DS-1 is closed to energize the oil heater; instead, the green light indicates the

air solenoid is energized.

Oil Mist Application

25

RECOMMENDED ELEMENTARY WIRING DIAGRAMS FOR OIL MIST SYSTEMS WITH

AIR AND OIL HEATERS AND SIGNALS

These wiring diagrams are recommended where Oil Mist is lubricating a machine segment of a multiple-machine operation.

Malfunction of the Oil Mist system energizes the warning signals, but does not stop the machine.

WS alarm signal units are interchangeable in either circuit arrangement.

Upper circuit shows air heater on same power input as control circuits.

Lower circuit shows air heater on separate power input.

Upper circuit can include 2CR relay (4) for interlocking machine start with proper Oil Mist system operation.

When 2CR is used, 2CR contacts in start circuit are normally open.

Upper circuit, as shown, is for MODULAR SERIES Thermo-Aire generators. For HIGH VOLUME units (2000 watt air heater),

replace TS-1 and AH(3)with Heater Control Relay (HCR) coil, and connect TS-1, AH and HCR contacts as shown in lower diagram.

Sequence of Operation (upper diagram):

1. Power across the input lines energizes the oil heater (1).

2. Manually closing DS-1(2) starts the Oil Mist system.

3. When Oil Mist system is stabilized, DS-2(6,8) is closed to lock in WS alarm, (Light Signal 380745), H Howler 380732, and

optional 2CR relay.

Sequence of Operation (lower diagram):

WS light signals (lamp 60 watts maximum) are shown in place of the alarm circuit shown above, and DS-2 is not required.

2CR relay cannot be used in circuit below, unless the WS alarm system shown in upper diagram is used.

1. Manually closing DS-1(1,5) starts the Oil Mist system.

2. When the Oil Mist system is stabilized, all warning lights are de-energized.

26

Oil Mist Application

RECOMMENDED WIRING DIAGRAMS FOR OIL MIST SYSTEMS WITH OIL AND AIR

HEATERS AND INDIVIDUAL SIGNALS

This wiring diagram is recommended where Oil Mist is lubricating a machine segment of a multiple-machine operation, and

neon pilot lights are used (with master warning signals) to indicate the cause of malfunction.

Malfunction of the Oil Mist system energizes the warning signals, but does not stop the machine. The circuit shows air heater

on a separate power input.

The circuit can include 4 CR relay (15) for interlocking machine start with proper Oil Mist system operation. When 4 CR is

used, 4 CR contacts in the start circuit are normally open.

Oil Mist Application

TYPICAL OIL-MIST SYSTEM PIPING SCHEMATIC

27

28

Oil Mist Application

NOTES ON USE OF APPLICATION FITTING SELECTION CHART

1. Basic Design Manifold Pressure is 20 inches water column.

2. Minimum recommended vent area equals twice the application fitting orifice area.

3. Minimum recommended manifold pressure for mist fittings is 2 H20.

4. Minimum recommended manifold pressure for spray fittings is 8 H20.

5. Minimum recommended manifold pressure for condensing fittings is 12 H20.

6. Design manifold pressure of 40 H20 is recommended for:

a. Direct spray applications over 2000 fpm.

b. Applications where the ambient temp. at the fittings is close to the minimum recommended.

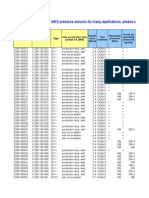

APPLICATION FITTING SELECTION CHART

APPLICATION FITTING

ORIFICE

TYPE

NO.

SIZE

LENGTH

-2

.032 DIA

.44

-4

.045 DIA

.44

MIST

-6

.055 DIA

.44

-10

.078 DIA

.44

-16

.089 DIA

.44

-05

SLOT .014R

.38

-1

SLOT .020R

.38

-2

2 SLOTS

.38

CONDENSING - 3

3 SLOTS

.38

-4

5 SLOTS

.38

-5

6 SLOTS

.38

CONDENSED

6 SLOTS &

.38

SPRAY

-6

.067 DIA

.97

-1

.024 DIA

1.35

SPRAY

-2

.035 DIA

1.38

FITTING

-3

.042 DIA

1.38

-5

.055 DIA

1.38

-8

.067 DIA

1.38

-1

.067D(1)

1.38

-2

.067D(2)

1.38

-3

.067D(3)

1.38

-4

.067D(4)

1.38

-5

.067D(5)

1.38

-6

.067D(6)

1.38

SPRAY

-7

.067D(7)

1.38

NOZZLE

-8

.067D(8)

1.38

-9

.067D(9)

1.38

- 10

.067D(10)

1.38

- 11

.067D(11)

1.38

- 12

.067D(12)

1.38

- 13

.067G(13)

1.38

-14

.067D(14)

1.38

FLOW AREA

.00078

.00159

.00238

.00478

.00622

.0003

.0006

.0012

.0018

.0030

.0036

.0036

.00045

.00096

.00138

.00353

.00353

.00705

.01058

.01410

.01763

.02115

.02468

.02820

.03173

.03526

.03878

.04231

.04583

.04936

APPLICATION FITTINGS STANDARD CFM

PRESSURE DROP-- INCHES WATER

2

5

8

12

20

30

40

.018

.033

.047

.030

.079

.095

.110

.036

.067

.096

.122

.161

.195

.224

.048

.100

.143

.184

.240

.290

.334

.100

.210

.295

.380

.495

.615

.715

.120

.280

.400

.520

.680

.830

.960

.013

.018

.024

.029

.031

.042

.055

.065

.062

.083

.109

.131

..091

.125

.164

.195

.149

.206

.271

.321

.178

.246

.312

.368

DIA.

.047

.064

.087

.111

.125

.028

.040

.055

.070

.089

.096

AREA

.00173

.00322

.00477

.00968

.012??

.00062

.00126

.00238

.00385

.00622

.00724

.132

.022

.038

.060

.118

.230

.240

.480

.720

.960

1.20

1.44

1.68

1.92

2.16

2.40

2.64

2.88

3.12

3.36

.096

.035

.052

.060

.078

.096

.096

.136

.166

.191

.213

.234

.250

.266

.290

.302

.313

.328

.344

.358

.00724

.00096

.00212

.002??

.004??

.00724

.00724

.01453

.02164

.02865

.03563

.04301

.04909

.05557

.06605

.0716?

.07???

.08???

.09294

.10066

.018

.030

.040

.090

.180

.190

.380

.570

.760

.950

1.14

1.33

1.52

1.71

1.90

2.09

2.28

2.47

2.66

.185

.029

.052

.078

.159

.300

.310

.620

.930

1.24

1.55

1.86

2.17

2.48

2.79

3.40

3.41

3.72

4.03

4.34

.236

.035

.066

.095

.198

.370

.380

.760

1.14

1.52

1.90

2.28

2.66

3.04

3.42

3.80

4.18

4.56

4.94

5.32

.277

.040

.078

.112

.230

.420

.460

.920

1.38

1.84

2.30

2.76

3.22

3.68

4.14

4.60

5.06

5.52

5.98

6.44

MIN. VENT

Oil Mist Application

29

SUMMARY OF CALCULATIONS FOR CFM INPUTS TO MACHINE ELEMENTS

based on oil/air ratio of 0.4 cubic inch oil/hour/cfm air

ROLLING ELEMENT BEARINGS (ANTI-FRICTION)

A. Moderate Service

B. Heavy Service

C. Rolling Mill Service

Spray and mist fittings are used.

cfm = DR/40

D = shaft diameter in inches

cfm = DR/20

R = number of rows of elements

cfm = DR/14

PLAIN BEARINGS

A. Moderate Service

B. Heavy Service

C. Heavy Service, High Loss

Condensing and spray fittings are used.

cfm = LD/100

L = bearing length in inches

cfm = LD/60

D = shaft diameter in inches

cfm = LD/30

SLIDES AND GIBS

WAYS

Condensing fittings are used.

cfm = A/800

cfm = A/400

A = maximum contact area in square

inches

Spray fittings are used.

GEARS

REVERSING GEARS

cfm = F(D1 + D2 + D3, etc.)/160 F = gear face width in inches

cfm = F(D1 + D2 + D3, etc.)/110 D1 = pitch diameter of small gear or worm

gear inches

WORM GEARS

cfm = F(2D1 + D2)/160

D2 = pitch diameter of large gear in inches

REVERSING WORM GEARS

D3, etc. = pitch diameter of additional gears

cfm = F(2D1 + D2)/110

If D2, D3, or any gear is larger than 2D1, in place of the larger gear, use 2D1

Spray fittings are used.

ROLLER CHAIN, POWER TRANSMITTING

SILENT CHAIN

CONVEYOR CHAIN

cfm = PDR

320

(S/100)3

cfm = WD

600

(S/100)3

Spray fittings are used.

cfm = 3DW + 0.1 LW

500

P = pitch of chain or sprocket in inches

D = pitch dia. of small sprocket in inches

R = number of rows of chain rollers

W = width of chain in inches

S = rpm of small sprocket

D = diameter of drive sprocket in inches

W = width of chain in inches

L = length of chain in inches

CAMS

Spray fittings are used.

cfm = FD/400

RECIRCULATING ROLLING ELEMENT NUTS

(ANTI-FRICTION BALL NUTS)

Spray and mist fittings are used.

D DR

D = pitch diameter of nut

CFM = 30 + 300

R = number of rows of elements

F = face width of cam in inches

D = maximum diameter of cam in inches

For heavy-duty bearings, with oil sumps, very lightly loaded: cfm = DR/80. Double-lip seals: D = D/40.

NOTES

NOTES

NOTES

Alemite Oil Mistual

Application Manual

7845 Little Avenue,

Charlotte, NC 28226

Phone: 704-542-6900

Toll-Free US/Canada: 866-4-Alemite

Fax US/Canada: 800-648-3917

w w w. a l e m i t e . c o m

02/04

Das könnte Ihnen auch gefallen

- GrimmerSchmidt CompressorsDokument43 SeitenGrimmerSchmidt CompressorsJulioCalderonOrtiz73% (11)

- Bosch Injector Data SheetDokument124 SeitenBosch Injector Data SheetThibaut Lrt56% (9)

- Downstream - Processing - Lecture 5rnjDokument8 SeitenDownstream - Processing - Lecture 5rnjqwertyuNoch keine Bewertungen

- GeislingerDokument5 SeitenGeislingerSameh Jeep100% (1)

- Kohler Lincoln VentmeterDokument14 SeitenKohler Lincoln VentmeterGilmer CaceresNoch keine Bewertungen

- Generate Electricity From Park Revolving DoorDokument39 SeitenGenerate Electricity From Park Revolving Doortariq7660% (5)

- Form I Integrated Science End of Year ExamDokument10 SeitenForm I Integrated Science End of Year ExamMiss Rambaran100% (2)

- Oil Mist Lubrication PDFDokument35 SeitenOil Mist Lubrication PDFmatteus boldrocchioNoch keine Bewertungen

- Alemite Oil Mist ManualDokument34 SeitenAlemite Oil Mist ManualWong DaNoch keine Bewertungen

- Oil Mist Lubrication TutorialDokument14 SeitenOil Mist Lubrication Tutorial최승원Noch keine Bewertungen

- W4-316E - Descaling Technology For High-Quality Surfaces - 2Dokument8 SeitenW4-316E - Descaling Technology For High-Quality Surfaces - 2Benyamin heidariNoch keine Bewertungen

- Hevvy Hns Brocuhre enDokument11 SeitenHevvy Hns Brocuhre enJacobo MartínezNoch keine Bewertungen

- Diamondfaces The New Dimension in Mechanical Seal TechnologyDokument20 SeitenDiamondfaces The New Dimension in Mechanical Seal TechnologyadamNoch keine Bewertungen

- PresentationDokument27 SeitenPresentationVishal SalveNoch keine Bewertungen

- LSA - Our Brands: Presented By: ToDokument42 SeitenLSA - Our Brands: Presented By: ToFathi Ben YahmedNoch keine Bewertungen

- SKF P-289Dokument3 SeitenSKF P-289seansotoNoch keine Bewertungen

- Spherical Plain Bearings GuideDokument8 SeitenSpherical Plain Bearings Guideabooali_abbadan4684Noch keine Bewertungen

- SKF Group: Tom Johnstone, President and CEODokument30 SeitenSKF Group: Tom Johnstone, President and CEOJuan Diego JulyNoch keine Bewertungen

- O&m RnaaDokument20 SeitenO&m RnaaГеннадий ПарфентьевNoch keine Bewertungen

- Compresor CentrifugoDokument6 SeitenCompresor Centrifugoalegria_systemsNoch keine Bewertungen

- Advancements in Mechanical Sealing - API 682 4Th Edition PDFDokument19 SeitenAdvancements in Mechanical Sealing - API 682 4Th Edition PDFReyes SanchezNoch keine Bewertungen

- Eagle Report 4Dokument34 SeitenEagle Report 4Priya Pawar100% (1)

- f15 Alvania 1029 enDokument1 Seitef15 Alvania 1029 enSatyen LalaNoch keine Bewertungen

- PileDriverIIIPump Modesl2331etc A50 92Dokument8 SeitenPileDriverIIIPump Modesl2331etc A50 92Juan Santiago RojasNoch keine Bewertungen

- 08 PU-lubrication Pinion For Gearings PDFDokument4 Seiten08 PU-lubrication Pinion For Gearings PDFSugiharto RichardNoch keine Bewertungen

- Gear Drive Issues Why Belt Is BetterDokument5 SeitenGear Drive Issues Why Belt Is BetterfranzumarragaNoch keine Bewertungen

- 32600EFSI 10-3 Lubrication PumpsDokument18 Seiten32600EFSI 10-3 Lubrication PumpsEnrique CastilloNoch keine Bewertungen

- Vs VSR Inj Manual 3 2004Dokument17 SeitenVs VSR Inj Manual 3 2004Mark DiNoch keine Bewertungen

- Kiln Gear Ring Oil Automatic SprayDokument78 SeitenKiln Gear Ring Oil Automatic SprayAdi IrpaiNoch keine Bewertungen

- 01 Cyclone Basics Problem SolvingDokument21 Seiten01 Cyclone Basics Problem SolvingdeepakattavarNoch keine Bewertungen

- A Procedure For Lube Oil FlushingDokument9 SeitenA Procedure For Lube Oil FlushingBrosGeeNoch keine Bewertungen

- Starjet InstructionsDokument54 SeitenStarjet InstructionsJUAN PABLO ACOSTA100% (1)

- 11 Lubrication SystemDokument19 Seiten11 Lubrication SystemMohammad Jahangir AlamNoch keine Bewertungen

- Maintenance Tips On OilDokument12 SeitenMaintenance Tips On OilAndrea StoneNoch keine Bewertungen

- Api 23 02Dokument4 SeitenApi 23 02montsegranNoch keine Bewertungen

- Beka EP1 Manual BooksDokument46 SeitenBeka EP1 Manual BooksSyahrulNoch keine Bewertungen

- Shaft Seal BulletinDokument2 SeitenShaft Seal Bulletinkoniks519Noch keine Bewertungen

- RENOLIT LST 00 Technical Data SheetDokument1 SeiteRENOLIT LST 00 Technical Data SheetQuoc HungNoch keine Bewertungen

- 08 Spray Nozzles Chain Lubrication PDFDokument2 Seiten08 Spray Nozzles Chain Lubrication PDFSugiharto RichardNoch keine Bewertungen

- Mechanical Seals According To StandardsDokument6 SeitenMechanical Seals According To StandardsSunit MishraNoch keine Bewertungen

- Reduce Oil Leakage with OT Oil Wiper Packing DesignDokument4 SeitenReduce Oil Leakage with OT Oil Wiper Packing DesignsaravananknpcNoch keine Bewertungen

- Journal Bearing LubricationDokument5 SeitenJournal Bearing LubricationkulilistrikNoch keine Bewertungen

- Tsubaki Backstop AntiretornoDokument12 SeitenTsubaki Backstop Antiretornomtbecerrap100% (1)

- Klüberfood NH1 94-402Dokument2 SeitenKlüberfood NH1 94-402Javier LemusNoch keine Bewertungen

- RS Clare Oil & Gas BrochureDokument12 SeitenRS Clare Oil & Gas BrochureVALENTIN PATRASNoch keine Bewertungen

- Sundyne LMC-347 Compressor Cross Section DiagramDokument1 SeiteSundyne LMC-347 Compressor Cross Section DiagrammohammadNoch keine Bewertungen

- Sleeve or Plain Bearing LubricationDokument3 SeitenSleeve or Plain Bearing LubricationVolety_Sarma_1703100% (1)

- 3.2 Atex GLRD enDokument19 Seiten3.2 Atex GLRD enatenciaj100% (1)

- 951 130 407 enDokument26 Seiten951 130 407 enli geneNoch keine Bewertungen

- Aeromats Aeropress Aeropress 10s Aerovac GeneralDokument2 SeitenAeromats Aeropress Aeropress 10s Aerovac Generalsaket2006Noch keine Bewertungen

- Component List For SKF Lubrication Systems ProductsDokument82 SeitenComponent List For SKF Lubrication Systems ProductsJorge Enrique Pulido AyalaNoch keine Bewertungen

- The Burgmann Ansitex: Flexibility at Its BestDokument38 SeitenThe Burgmann Ansitex: Flexibility at Its BestCuauhtemoc MartinezNoch keine Bewertungen

- Ensival CatalogDokument38 SeitenEnsival CatalogabsahkahNoch keine Bewertungen

- "Babbitt Metal": Presented By: Guided byDokument14 Seiten"Babbitt Metal": Presented By: Guided byraghavprince8400% (1)

- L Uk Labtecta Iap Oap 03Dokument4 SeitenL Uk Labtecta Iap Oap 03denizarazNoch keine Bewertungen

- Automatic and Manual GreasingDokument10 SeitenAutomatic and Manual GreasingAhmed SalahNoch keine Bewertungen

- Delta Fluid Systems - Notable Completed Projects Sept 2018Dokument27 SeitenDelta Fluid Systems - Notable Completed Projects Sept 2018Diego Armando MtzNoch keine Bewertungen

- Rider Ring Installation GuideDokument4 SeitenRider Ring Installation Guidepaulsonp_2Noch keine Bewertungen

- Ac Orc Bro Atlas CopcoDokument16 SeitenAc Orc Bro Atlas CopcojudarangocaNoch keine Bewertungen

- Single Line Progressive SystemsDokument70 SeitenSingle Line Progressive SystemsOverhaul QANoch keine Bewertungen

- NEA U M Recip Compressors Pocket Brochure PRDokument5 SeitenNEA U M Recip Compressors Pocket Brochure PRMadhana GopalNoch keine Bewertungen

- MC PLB High Pressure Stage Casing Pump BrochureDokument8 SeitenMC PLB High Pressure Stage Casing Pump BrochureKheir-eddine BenchouchaNoch keine Bewertungen

- Alemite Oil Mist ManualDokument34 SeitenAlemite Oil Mist ManualCatalina SaldarriagaNoch keine Bewertungen

- Practical Experience With Oil Mist LubricationDokument8 SeitenPractical Experience With Oil Mist Lubricationannccknarime100% (1)

- Mifab Interceptor PDFDokument8 SeitenMifab Interceptor PDFBashir SaadehNoch keine Bewertungen

- Alemite Carbon Shield - CatalogDokument12 SeitenAlemite Carbon Shield - CatalogAdolfo EirasNoch keine Bewertungen

- Pall 0293 Series BreathersDokument2 SeitenPall 0293 Series BreathersAdolfo EirasNoch keine Bewertungen

- Pall 0293 Series Breathers PDFDokument2 SeitenPall 0293 Series Breathers PDFAdolfo EirasNoch keine Bewertungen

- Diesel BugDokument3 SeitenDiesel BugAdolfo EirasNoch keine Bewertungen

- Transient Stability Improvement of Power System Using UpfcDokument18 SeitenTransient Stability Improvement of Power System Using UpfcMuhammadWaqarNoch keine Bewertungen

- Bài Tập Đọc Hiểu Tiếng Anh Lớp 9 HKIIDokument4 SeitenBài Tập Đọc Hiểu Tiếng Anh Lớp 9 HKIIPhương Thu Vũ ThịNoch keine Bewertungen

- OZM-Katalog 2016Dokument23 SeitenOZM-Katalog 2016Chonk LeeNoch keine Bewertungen

- An overview of common vehicle indicatorsDokument9 SeitenAn overview of common vehicle indicatorsNikhitaNoch keine Bewertungen

- Totse Knowledge Thread 4Dokument14 SeitenTotse Knowledge Thread 4negzNoch keine Bewertungen

- The Breaker Failure Protection BFP Schemes in UtilitiesDokument9 SeitenThe Breaker Failure Protection BFP Schemes in UtilitiesTrigras Bangun PerkasaNoch keine Bewertungen

- Improving Power System Stability Through Integrated Power System Stabilizers - 100520Dokument25 SeitenImproving Power System Stability Through Integrated Power System Stabilizers - 100520soumyanitcNoch keine Bewertungen

- Module 2Dokument79 SeitenModule 2uditNoch keine Bewertungen

- Cit Asci tr334 PDFDokument18 SeitenCit Asci tr334 PDFraguerreNoch keine Bewertungen

- Mx37y Technical DescriptionDokument38 SeitenMx37y Technical DescriptionVladimir PeshicNoch keine Bewertungen

- ONGC Ar201718Dokument454 SeitenONGC Ar201718Vrind JainNoch keine Bewertungen

- 02 - Chemical Equilibrium (Theory) Module-3-1Dokument18 Seiten02 - Chemical Equilibrium (Theory) Module-3-1Raju SinghNoch keine Bewertungen

- ACME AHX Water-Cooled Condenser - 06.10 PDFDokument3 SeitenACME AHX Water-Cooled Condenser - 06.10 PDFhappale2002Noch keine Bewertungen

- Boiler Operation Manual ESB - WOPDokument115 SeitenBoiler Operation Manual ESB - WOPMoaaz Khan100% (1)

- Chemistry 3202 Reaction Rates and Equilibrium NotesDokument4 SeitenChemistry 3202 Reaction Rates and Equilibrium NotesMorgan SearsNoch keine Bewertungen

- Engineer's and Contractor's Sticker DetailsDokument4 SeitenEngineer's and Contractor's Sticker DetailssartajNoch keine Bewertungen

- 9 Electronics TDokument44 Seiten9 Electronics TBieonWongNoch keine Bewertungen

- 1st PU Chemistry May 2015 PDFDokument2 Seiten1st PU Chemistry May 2015 PDFPrasad C M69% (16)

- GM ST 382B 85 1985 Light Duty Truck CKGP Series Service Manual 1984 Revision PagesDokument55 SeitenGM ST 382B 85 1985 Light Duty Truck CKGP Series Service Manual 1984 Revision PagesBrian NormanNoch keine Bewertungen

- Water Supply Sanitary Eng PDFDokument5 SeitenWater Supply Sanitary Eng PDFReddy NaveenNoch keine Bewertungen

- Boq - Sewer Pump Station Example: Project Name, Town Tender NoDokument8 SeitenBoq - Sewer Pump Station Example: Project Name, Town Tender Nodelovan cheikhoNoch keine Bewertungen

- O Level Physics 2018 Past PaperDokument20 SeitenO Level Physics 2018 Past PaperfordalNoch keine Bewertungen

- Rotational Motion Engineering Mechanics IIT KanpurDokument67 SeitenRotational Motion Engineering Mechanics IIT KanpurNitin SharmaNoch keine Bewertungen

- DCVDokument35 SeitenDCVTanoj Patro100% (1)

- Automatic Water Tank Level Controller Motor Driver Circuit - Engineering Project Without Microcontroller - Circuits Gallery PDFDokument29 SeitenAutomatic Water Tank Level Controller Motor Driver Circuit - Engineering Project Without Microcontroller - Circuits Gallery PDFEi Po Po AungNoch keine Bewertungen