Beruflich Dokumente

Kultur Dokumente

AAIB Bulletin: 5/2010 G-Ceed EW/C2007/10/02

Hochgeladen von

Deep VaidhyaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

AAIB Bulletin: 5/2010 G-Ceed EW/C2007/10/02

Hochgeladen von

Deep VaidhyaCopyright:

Verfügbare Formate

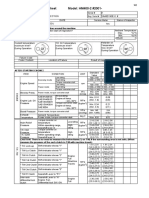

AAIB Bulletin: 5/2010

G-CEED

EW/C2007/10/02

ACCIDENT

Aircraft Type and Registration:

Savannah Jabiru, G-CEED

No & Type of Engines:

1 Jabiru Aircraft Pty 2200 piston engine

Year of Manufacture:

August 2006

Date & Time (UTC):

20 October 2007 at 1030 hrs

Location:

Near Mergate Hall, Bracon, Norfolk

Type of Flight:

Private

Persons on Board:

Crew - 1

Passengers - 1

Injuries:

Crew - None

Passengers - None

Nature of Damage:

Nose landing gear bent backwards, slight indentation

on the underside of the engine cowling and forward

fuselage

Commanders Licence:

Private Pilots Licence

Commanders Age:

51 years

Commanders Flying Experience:

247 hours (of which 11 were on type)

Last 90 days - 4 hours

Last 28 days - 1 hour

Information Source:

AAIB Field Investigation

This investigation was conducted in parallel with the

Another aircraft (G-CEFY) with a Jabiru 2200 engine

investigation into G-JAAB, also published in this AAIB

suffered a similar engine failure. Both engines had less

Bulletin, 5/2010.

than 50 hours of usage since manufacture and the failures

were caused by high temperatures generated within the

Synopsis

cylinders, softening the piston material which led to the

About 5 minutes after takeoff the pilot of G-CEED

piston rings becoming trapped in their grooves. This

performed a FREDA check and saw that the engine

allowed engine lubricating oil (or vapour) to enter the

indications were normal. Immediately after completing

combustion chamber, which allowing pre-ignition to

this check she saw smoke in the cabin and less than a

occur, leading to burn-through of the piston crown and

minute later the engine seized. The pilot established

for oil to be expelled overboard.

the aircraft in a glide and landed in a nearby field. The

approach and landing were smooth but the surface was

Both engines had been modified at manufacture to

rough, causing the nose landing gear to fold backwards.

comply with Jabiru Service Letter JSL 002-1 titled

The pilot and passenger exited the aircraft without injury

Jabiru Engine Economy Tuning which introduced lean

and there was no fire.

burn jets into the carburettor.

Crown copyright 2010

37

AAIB Bulletin: 5/2010

G-CEED

EW/C2007/10/02

History of the flight G-CEED

Engineering examination G-CEED

The pilot of G-CEED carried out a pre-flight inspection

The engine was taken to the manufacturers UK agent

and topped up the fuel tank with premium unleaded

where a strip examination was carried out under AAIB

Mogas. She noticed that the engine oil level was within

supervision. When the engine was stripped the No 3

limits. About 5 minutes after takeoff the pilot carried

piston was found to have burnt through from top to

out an after-takeoff/cruise FREDA check and saw that

bottom (Figure 1). There was evidence of piston seizure

all the engine indications were normal. Immediately

and partial seizures within the cylinders and excessive

after completing this check she saw smoke in the cabin

heat discolouration of the crankshaft and connecting

and less than a minute later the engine seized. The

rod bearings, indicative of the engine having run with

pilot established the aircraft in a glide and landed in a

insufficient lubricating oil. External examination of

nearby field. The approach was smooth but the landing

the engine did not reveal evidence of an oil leak but

was into a rough agricultural field, which caused the

there was evidence of oil having been blown out of the

nose landing gear to fold backwards. The pilot and

engine breather pipe.

passenger exited the aircraft without injury and there

was no fire.

All four pistons and cylinders were submitted to

Engine description

metallurgical examination. Examination of the No 3

the Materials Department at QinetiQ for a detailed

piston showed pre-ignition to be the most likely cause

The Jabiru 2200 is a four-stroke horizontally-opposed

of the burn-through; pre-ignition occurs when the

four cylinder piston engine, normally aspirated and air

fuel/air mixture in the cylinder ignites before the plug

cooled. The displacement is 2,200 cc which produces

sparks. The fuel burns and expands before the piston

nominally 85 hp at 3,300 rpm. The fuel specified is

is in the correct position, which causes large stresses in

either Avgas 100/130 (preferred) or Mogas with an

the engine and can cause localised heating sufficient to

octane rating of 95 or above. The carburettor is pressure

burn through the piston crown as was seen in this case.

compensated and is mounted to a plenum chamber in

The QinetiQ report stated that common causes of heat

the sump casing by a flexible rubber coupling. From

build-up are:

the plenum chamber the fuel/air mixture is delivered to

the cylinders via individual inlet pipes. There is no fuel

Carbon deposits.

mixture control in the cockpit. The fuel/air mixture is

Wrong spark plug heat range.

set up during manufacture, installation or maintenance.

Lean fuel mixture.

There is one cylinder head temperature sensor, mounted

Combustible

under the No 4 cylinder spark plug, which is connected

contaminants

within

the

combustion area (oil, diesel, kerosene).

to a gauge in the cockpit.

Insufficient engine cooling (air or oil).

The engine is fitted to a wide range of manufactured and

Carbon deposits were unlikely to be the cause in this

home-built Light Sport Aircraft worldwide.

case; no carbon build-up was observed in the cylinders

and the engine was relatively new (43 hours since

manufacture). The spark plugs in the cylinders received

Crown copyright 2010

38

AAIB Bulletin: 5/2010

G-CEED

EW/C2007/10/02

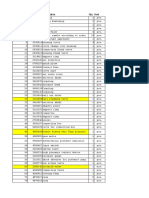

Courtesy of QinetiQ

Figure 1

No 3 piston from G-CEED showing pre-ignition damage and burn-through

were NGK D9EA, those specified by the manufacturer.

strength and piston No 3 had been affected more than

For the pistons to seize, the excessive heat must

piston No 2. The piston rings of pistons Nos 1, 3 and 4

have been present prior to the piston crown burning-

were all seized in the grooves. It is possible that a loss

through, possibly caused by a lean fuel mixture and/or

of strength in the pistons allowed the grooves to close

insufficient engine cooling. Excessive heat can cause

up, trapping the rings.

pre-ignition. After the piston rings seized, engine oil

The examination of the four exhaust valves did not

could have entered the combustion chamber causing,

or contributing to, pre-ignition.

identify thermal cracking or corrosion, associated with

Metallurgical checks carried out on pistons 2 and 3

engines. As the engine in G-CEED was virtually new, it

indicated that they had been overheated.

may be that the exhaust gases were hotter than typical,

hotter than typical exhaust gases, seen in other Jabiru

Energy

but it was too early in the valves lives to develop fatigue

dispersive X-ray (EDX) analysis showed that the pistons

cracks.

were manufactured from a high-silicon aluminium

alloy, typical of automotive pistons. Hardness testing

indicated that both pistons Nos 2 and 3 had been

affected by overheating, which had reduced their

Crown copyright 2010

39

AAIB Bulletin: 5/2010

G-CEED

Other information G-CEED

EW/C2007/10/02

or exhaust manifold systems and no restriction within

the engine oil supply system. There was, however,

The engineering examination did not show indications

good evidence of the onset of piston seizure within

of significant leaks at the cylinder head seals, inlet or

the cylinders and burn-through of the No 3 piston

exhaust systems and no restriction within the engine

(Figure2).

oil supply system. The engine had a total of 43 hours

in use since it was installed into the aircraft as a new

Three cylinders and their associated pistons were taken

unit and had a 25-hour maintenance check carried out in

to the Materials Department at QinetiQ for detailed

accordance with the manufacturers requirements.

metallurgical examination.

Examination of the

three cylinders showed that No 3 piston and cylinder

The engine was found to have been configured in

exhibited characteristics similar to the No 3 piston

accordance with Service Letter JSL 002-1 titled

and cylinder from G-CEED. The piston/cylinder head

Jabiru Engine Economy Tuning which was issued

interface exhibited sooting on one side of the cylinder,

in December 2004. A fuel sample was taken from

with the corresponding edge of the piston exhibiting

the aircraft and analysis showed that it was 95 octane

burn-through (Figure 2). The internal surface of the

unleaded gasoline (ULGAS, BS EN 228:2004), with no

cylinder showed evidence of minor wear and material

evidence of contamination from another fuel product.

pick-up from the piston at the point of the piston

Incident to Jabiru 2200 engine fitted to G-CEFY

burnthrough. Skirt wear was observed on the piston

This incident occurred 3 February 2008 at Brookfarm

from G-CEED. Minor wear was observed below the

airfield, Lancashire. Following an uneventful pre-flight

burn-through with the opposite skirt exhibiting more

inspection by the pilot/owner, which included checking

severe wear. The other two pistons both exhibited skirt

the engine oil level, the engine was started and power

wear similar to the No 3 piston. One of the pistons

checks carried out. After a normal taxi, takeoff and climb

showed evidence of damage to the edge of the piston

to 500 ft at full power, the pilot lowered the nose, reduced

crown with reciprocating wear and material pick-up

the power to 2,600 rpm and continued in a shallow climb

on the internal surface of the cylinder. The damage

to 1,000 ft. Following a gentle turn the engine tone

appeared to be purely mechanical, with no evidence of

suddenly changed, as if a spark plug had failed. The

burn-through as seen in the No 3 piston.

similar to that observed in the examination of the engine

pilot returned to the airfield and landed safely. Two

witnesses at the airfield are reported to have said that

Examination of the piston rings and oil scraper rings

they observed a trail of smoke behind the aircraft.

showed that the lower piston ring was seized in the

closed position on one of the pistons and on another the

Engineering examination G-CEFY

upper ring was seized at the area of the damage, so that

The engine, which had completed 48.9 hours since

it was flush with the piston edge. The other end of the

manufacture, was removed from the aircraft and sent

piston ring was free to move. On the No 3 piston both

to an aircraft engineering organisation for examination.

the lower piston ring and oil scraper ring were seized in

The examination did not show any evidence of an oil

the closed position.

leak, significant leaks at the cylinder head seals, inlet

Crown copyright 2010

40

AAIB Bulletin: 5/2010

G-CEED

EW/C2007/10/02

Courtesy of QinetiQ

Figure 2

No 3 piston from G-CEFY showing pre-ignition damage and burn-through

The visual examination of the three pistons and

Jabiru Service Letter JSL 002-1

cylinders showed that an engine failure similar to that

Jabiru JSL 002-1 was issued on 13 December 2004, titled

of G-CEED. In both cases the engines exhibited seized

Jabiru Engine Economy Tuning which introduced the

piston and oil scraper rings, piston skirt wear and

Economic Tuning Kit. This kit contained new idle,

burnthrough.

needle and main carburettor jets, a new needle and fitting

instructions. This Service Letter introduced lean burn

The engine in G-CEFY was found to have been

jets into the carburettor to improve fuel consumption at

configured in accordance with Service Letter JSL0021

titled Jabiru Engine Economy Tuning which was

cruise power.

issued in December 2004.

Jabiru Service Bulletin JSB 018-1

Jabiru Service Bulletin

JSB 018-1 titled Jabiru Engine Tuning had not been

installed and was not a mandatory requirement. The

Jabiru JSB 018-1 was issued on 5 October 2007, titled

aircrafts owner stated that only 95 octane unleaded

Jabiru Engine Tuning. The Service Bulletin introduced

Mogas had been used since the engine was installed as

richer running jets into the carburettor to replace those

a new unit.

introduced by Service Letter JSL 002-1.

Crown copyright 2010

41

AAIB Bulletin: 5/2010

G-CEED

EW/C2007/10/02

Carburettor mounting effect on cylinder head

temperature

improve fuel consumption at cruise power. However,

A UK CAA-Licensed Aircraft Maintenance Engineer,

richer running jets into the carburettor to replace those

and owner of a Jabiru-engined aircraft, conducted tests

introduced by Service Letter JSL 002-1.

Jabiru JSB 0181, issued in October 2007, introduced

with differing angles of mounting the carburettor to

From the similarity of the events and their timing, it

the plenum chamber, and at the same time monitoring

is likely that the same overheating mechanism that

cylinder head temperatures (CHT) and exhaust gas

temperatures (EGT).

appeared to have affected the valves in G-JAAB and

He found that by tilting the

G-BCIP was present in the piston failures in G-CEED

carburettor 10 to 15 left and right he could obtain a

rise and fall in CHTs between Nos 1 & 3 cylinders and

and G-CEFY.

Nos 2 & 4 of up to 50C and EGTs up to 120C.

Safety action

Discussion G-CEED and G-CEFY

Following the failures of a number of Jabiru 2200 engines

This investigation was conducted in parallel with the

in the UK (including G-CEED (10/07), G-CEFY (2/08)

investigation into G-JAAB, also published in this

and G-JAAB (9/07)) the AAIB informed the engine

AAIB Bulletin, 5/2010. The evidence from the valve

manufacturer. A number of overheat-related failures

failures in the Jabiru 2200 engines in G-JAAB and

occurred in France at about the same time. The engine

G-BCIP indicated that overheating of the valves was

manufacturer has a continuing programme of product

at least a contributory factor and this was consistent

quality improvement and the number of such events

with the timing of Jabiru JSL 002-1, which had

reported to the AAIB and the LAA (Light Aircraft

introduced lean burn jets into the carburettor to

Association) has decreased since that period.

Crown copyright 2010

42

Das könnte Ihnen auch gefallen

- Air Crash Investigations - Crew in Disarray, The Crash of Sibir Airlines Flight C7 778Von EverandAir Crash Investigations - Crew in Disarray, The Crash of Sibir Airlines Flight C7 778Noch keine Bewertungen

- Accidente Bell 206B CanadaDokument9 SeitenAccidente Bell 206B CanadaGuillermo Hernandez PerdomoNoch keine Bewertungen

- Report 10 7X001 C525A StuttgartDokument9 SeitenReport 10 7X001 C525A StuttgartMorgen GumpNoch keine Bewertungen

- General Aviation Airworthiness Alerts 43-16 Alert 54 01-01-1983Dokument13 SeitenGeneral Aviation Airworthiness Alerts 43-16 Alert 54 01-01-1983JacksonNoch keine Bewertungen

- BOEING 777-333ER, C-FITW Toronto-Lester B. Pearson International Airport, OntarioDokument17 SeitenBOEING 777-333ER, C-FITW Toronto-Lester B. Pearson International Airport, OntarioMorgen GumpNoch keine Bewertungen

- Report - DCA21FA085 - 102652 - 9 - 8 - 2023 7 - 28 - 01 PMDokument22 SeitenReport - DCA21FA085 - 102652 - 9 - 8 - 2023 7 - 28 - 01 PMJose A. HerreraNoch keine Bewertungen

- TSBC BAC 050615 A05p0137Dokument8 SeitenTSBC BAC 050615 A05p0137bombardierwatchNoch keine Bewertungen

- Northway Aviation AccidentDokument8 SeitenNorthway Aviation AccidentjamesgmccreaNoch keine Bewertungen

- Airbus A330-243 G-OMYT 12-13 Incl AddDokument3 SeitenAirbus A330-243 G-OMYT 12-13 Incl AddridwansadelyNoch keine Bewertungen

- DFT Avsafety PDF 02904Dokument8 SeitenDFT Avsafety PDF 02904Sosa VelazquezNoch keine Bewertungen

- TSBC Bac 050607 A05p0132Dokument9 SeitenTSBC Bac 050607 A05p0132bombardierwatchNoch keine Bewertungen

- Rans S10 Sakota, G-BVCB: History of FlightDokument4 SeitenRans S10 Sakota, G-BVCB: History of FlightSantiago PiedraNoch keine Bewertungen

- AAIB Bulletin: 10/2021 G-CGTC AAIB-27032: All Times Are UTCDokument23 SeitenAAIB Bulletin: 10/2021 G-CGTC AAIB-27032: All Times Are UTCVitNoch keine Bewertungen

- Aviation Investigation Report A02P0179Dokument12 SeitenAviation Investigation Report A02P0179唐波Noch keine Bewertungen

- AAIB Bulletin: 1/2021 G-Fseu AAIB-26442: All Times Are UTCDokument3 SeitenAAIB Bulletin: 1/2021 G-Fseu AAIB-26442: All Times Are UTCmates isNoch keine Bewertungen

- Aero Vodochody L-39ZO AlbatrosDokument8 SeitenAero Vodochody L-39ZO AlbatrosratherbeglidingNoch keine Bewertungen

- A01C0217Dokument6 SeitenA01C0217vonmanoNoch keine Bewertungen

- AAIB Bulletin: 7/2015 G-Gava EW/C2014/08/02: FootnoteDokument28 SeitenAAIB Bulletin: 7/2015 G-Gava EW/C2014/08/02: FootnoteDuvan CoronadoNoch keine Bewertungen

- Enstrom 280FX G-OJBB 02-23Dokument27 SeitenEnstrom 280FX G-OJBB 02-23Clinto BabuNoch keine Bewertungen

- Cf34-8e 72-A0221Dokument8 SeitenCf34-8e 72-A0221Stephen Hyde100% (1)

- General Aviation Airworthiness Alerts 43-16 Alert 46 05-01-1982Dokument7 SeitenGeneral Aviation Airworthiness Alerts 43-16 Alert 46 05-01-1982JacksonNoch keine Bewertungen

- Analysis of A Failed Pratt & Whitney JT9D-7R4 Turbofan EngineDokument14 SeitenAnalysis of A Failed Pratt & Whitney JT9D-7R4 Turbofan EngineАлександр ТумановNoch keine Bewertungen

- Colomban MC-30 Luciole G-CIBJ 11-19 InvestigationDokument4 SeitenColomban MC-30 Luciole G-CIBJ 11-19 InvestigationHua Hidari YangNoch keine Bewertungen

- 3602-Report 1999 002-0Dokument7 Seiten3602-Report 1999 002-0ARULKUMARSUBRAMANIANNoch keine Bewertungen

- Generator Valve Driving Gear Valve Retainer Guide Breakage: 1. Engine ModelDokument2 SeitenGenerator Valve Driving Gear Valve Retainer Guide Breakage: 1. Engine ModelRani NoumanNoch keine Bewertungen

- 213158Dokument47 Seiten213158turboshaftNoch keine Bewertungen

- General Aviation Airworthiness Alerts 43-16 Alert 55 02-01-1983Dokument14 SeitenGeneral Aviation Airworthiness Alerts 43-16 Alert 55 02-01-1983JacksonNoch keine Bewertungen

- Failure Analysis: Topic HDokument32 SeitenFailure Analysis: Topic HSujeet ChauhanNoch keine Bewertungen

- AAIBDokument3 SeitenAAIBUnion userNoch keine Bewertungen

- National Transportation Safety Board: Docket No. SA-542 Exhibit No. 15-ADokument41 SeitenNational Transportation Safety Board: Docket No. SA-542 Exhibit No. 15-AGFNoch keine Bewertungen

- V2500 Eng 72 0660Dokument43 SeitenV2500 Eng 72 0660sujit50% (2)

- Fuel Pumps Left in Off PositionDokument7 SeitenFuel Pumps Left in Off PositionherbuelNoch keine Bewertungen

- Operator E-Jets News Rel 031Dokument11 SeitenOperator E-Jets News Rel 031jivomirNoch keine Bewertungen

- Converting The Lycoming O-290-G Ground Power Unit Tor An Aircraft Engine by Donald C Pridham (Edited)Dokument113 SeitenConverting The Lycoming O-290-G Ground Power Unit Tor An Aircraft Engine by Donald C Pridham (Edited)Charles Kuss100% (3)

- Engine Failure WGBDokument33 SeitenEngine Failure WGBRohan SinhaNoch keine Bewertungen

- Aaib S3-2012 G-RedwDokument8 SeitenAaib S3-2012 G-RedwLexFalconerNoch keine Bewertungen

- Failure Analysis of Centrifugal Fan's BearingDokument8 SeitenFailure Analysis of Centrifugal Fan's BearingMuhd Fadzlee ZNoch keine Bewertungen

- SupersededDokument19 SeitenSupersededasd123Noch keine Bewertungen

- Powerplant InstallationDokument3 SeitenPowerplant InstallationEduardo ReyNoch keine Bewertungen

- FTS 02-10-2013Dokument16 SeitenFTS 02-10-2013rizcst9759100% (2)

- Boeing 737-36E Freighter TF-BBF 12-17Dokument10 SeitenBoeing 737-36E Freighter TF-BBF 12-17hakanbalaban415Noch keine Bewertungen

- AIRWORTHINESS APPROVAL Yak 52Dokument6 SeitenAIRWORTHINESS APPROVAL Yak 52ace.bookNoch keine Bewertungen

- Operator E-Jets News Rel 07Dokument12 SeitenOperator E-Jets News Rel 07PDDELUCA100% (1)

- (12.2.624) Aviation Refueling Business: A Goldmine of OpportunitiesDokument6 Seiten(12.2.624) Aviation Refueling Business: A Goldmine of OpportunitiesMuhammed SulfeekNoch keine Bewertungen

- Aircraft Useful Info - Must ReadDokument10 SeitenAircraft Useful Info - Must Readsyedumarahmed52Noch keine Bewertungen

- Tp6980e 4 2010Dokument32 SeitenTp6980e 4 2010oguier100% (1)

- 9FA Failures in DabholDokument10 Seiten9FA Failures in Dabholsenthil031277100% (3)

- A01F0020Dokument8 SeitenA01F0020vonmanoNoch keine Bewertungen

- SFAR 88 Related Operating Rules and Special Maintenance RequirementsDokument74 SeitenSFAR 88 Related Operating Rules and Special Maintenance RequirementsJoko Dwi Edi SusiloNoch keine Bewertungen

- License Help For Canadian Engineers1Dokument49 SeitenLicense Help For Canadian Engineers1chans117Noch keine Bewertungen

- Icas-90-5 3 2Dokument10 SeitenIcas-90-5 3 2andrei.mtantiangcoNoch keine Bewertungen

- DFT Avsafety PDF 500970Dokument6 SeitenDFT Avsafety PDF 500970Blaze123xNoch keine Bewertungen

- 737 Incident ReportDokument61 Seiten737 Incident ReportAbdul Qadeer Khan100% (1)

- Mogas Use KNKTDokument38 SeitenMogas Use KNKTrayaduqsNoch keine Bewertungen

- Storch Flight Manual - Eng Version 28 - 04 - 05 PDFDokument51 SeitenStorch Flight Manual - Eng Version 28 - 04 - 05 PDFandre_jvcNoch keine Bewertungen

- Mek 2000 April 95 SR - No.5Dokument2 SeitenMek 2000 April 95 SR - No.5Bhupender RamchandaniNoch keine Bewertungen

- Piper SB 955 Engine Mount Nose Gear AttachmentDokument6 SeitenPiper SB 955 Engine Mount Nose Gear AttachmentGeorgios AsimakopoulosNoch keine Bewertungen

- Fuel Tank Safety Level 2 SummaryDokument7 SeitenFuel Tank Safety Level 2 SummaryMuhammad CahyartoniNoch keine Bewertungen

- Damage of The Main Engine No. 1 Cylinder Exhaust Valve Driving UnitDokument2 SeitenDamage of The Main Engine No. 1 Cylinder Exhaust Valve Driving UnitRani NoumanNoch keine Bewertungen

- Bios Details and CurrentDokument4 SeitenBios Details and CurrentDeep VaidhyaNoch keine Bewertungen

- Towards Green Growth: A Summary For Policy Makers May 2011Dokument28 SeitenTowards Green Growth: A Summary For Policy Makers May 2011Deep VaidhyaNoch keine Bewertungen

- Educare SummaryDokument4 SeitenEducare SummaryDeep VaidhyaNoch keine Bewertungen

- Gujarati HonoursDokument24 SeitenGujarati HonoursDeep Vaidhya100% (1)

- World Environment DayDokument2 SeitenWorld Environment DayDeep VaidhyaNoch keine Bewertungen

- Handbook - RTIDokument25 SeitenHandbook - RTIDeep VaidhyaNoch keine Bewertungen

- Working Papers: The Success of Divestitures in Merger Enforcement: Evidence From The J&J - Pfizer TransactionDokument29 SeitenWorking Papers: The Success of Divestitures in Merger Enforcement: Evidence From The J&J - Pfizer TransactionDeep VaidhyaNoch keine Bewertungen

- Important Days and DatesDokument6 SeitenImportant Days and DatesDeep VaidhyaNoch keine Bewertungen

- Nilkanth NewsletterDokument10 SeitenNilkanth NewsletterDeep VaidhyaNoch keine Bewertungen

- H¡XLPFDP DPG Pfu D'F Sá Ngu Ńhfƒp¡ Lydgp¡ Ltufp RKNPF¡V Vpzqp¡Fu A N¡ D - M Cysáƒp Eyhpƒƒu F'LXDokument1 SeiteH¡XLPFDP DPG Pfu D'F Sá Ngu Ńhfƒp¡ Lydgp¡ Ltufp RKNPF¡V Vpzqp¡Fu A N¡ D - M Cysáƒp Eyhpƒƒu F'LXDeep VaidhyaNoch keine Bewertungen

- COCO P3 EXE TOYO PCE 000 STA GA 0002 AYBJ00120 - Rev.0 - APDokument5 SeitenCOCO P3 EXE TOYO PCE 000 STA GA 0002 AYBJ00120 - Rev.0 - APNazrilMizarNoch keine Bewertungen

- Pittman Full Product CatalogDokument67 SeitenPittman Full Product CatalogKhoa NguyễnNoch keine Bewertungen

- Srod V8.2.0 - Prediction of Rod Pumping System Performance: in BalanceDokument6 SeitenSrod V8.2.0 - Prediction of Rod Pumping System Performance: in BalancePresident PCNoch keine Bewertungen

- Massey Ferguson 8780 8780XP COMBINE (EFF SN W55101-HL87999) Parts Catalogue ManualDokument23 SeitenMassey Ferguson 8780 8780XP COMBINE (EFF SN W55101-HL87999) Parts Catalogue ManualdidkskmdmdmNoch keine Bewertungen

- Oil Pumps: Air-OperatedDokument25 SeitenOil Pumps: Air-OperatedskyNoch keine Bewertungen

- FZ FiDokument59 SeitenFZ FiRIDERZ CHOICENoch keine Bewertungen

- Sec6 8035Dokument355 SeitenSec6 8035Benmorsli AhceneNoch keine Bewertungen

- Converter Cat1 2 PDFDokument242 SeitenConverter Cat1 2 PDFMarcos MontesNoch keine Bewertungen

- Speed Control of Hydraulic CylinderDokument3 SeitenSpeed Control of Hydraulic CylinderSriram SastryNoch keine Bewertungen

- Whirlpool Awm 6080Dokument17 SeitenWhirlpool Awm 6080pansatuilieNoch keine Bewertungen

- QAS 14 KD APP S/N APP207576 - APP225648: Spare Parts List: Portable GeneratorsDokument171 SeitenQAS 14 KD APP S/N APP207576 - APP225648: Spare Parts List: Portable Generatorsdmm tgctpNoch keine Bewertungen

- HLDokument15 SeitenHLthierrylindoNoch keine Bewertungen

- XRHS 1270E 315kW: Spare Parts ListDokument71 SeitenXRHS 1270E 315kW: Spare Parts ListyangNoch keine Bewertungen

- EEE 315 ELECTRICAL MACHINES III Supplementary EXAM - 2017Dokument5 SeitenEEE 315 ELECTRICAL MACHINES III Supplementary EXAM - 2017Abkul KunniNoch keine Bewertungen

- AAR Manual of Standards and Recommended Practices Brakes and Brake EquipmentDokument12 SeitenAAR Manual of Standards and Recommended Practices Brakes and Brake EquipmentDaniel Santacruz100% (1)

- Homework 7 Induction Motor 1Dokument3 SeitenHomework 7 Induction Motor 1JamrNoch keine Bewertungen

- Data Sheet: Mounting Kits According To DIN EN 15081Dokument2 SeitenData Sheet: Mounting Kits According To DIN EN 15081joseocsilvaNoch keine Bewertungen

- Marine Auxiliary Engine: SpecificationsDokument2 SeitenMarine Auxiliary Engine: SpecificationsContessa JamesNoch keine Bewertungen

- 14 - Cylinder Head - InspectionDokument9 Seiten14 - Cylinder Head - InspectionNazmul HassanNoch keine Bewertungen

- Copie de GS - EP - PVV - 112 - EN 1Dokument13 SeitenCopie de GS - EP - PVV - 112 - EN 1Tien HaNoch keine Bewertungen

- Ducati Monster S4R 2004 Owners Manual WWW - repairManualClubDokument88 SeitenDucati Monster S4R 2004 Owners Manual WWW - repairManualClubfxst1340100% (1)

- Spare Part Designation S40.1 S50.1 S63.1 S80.1: N/a N/aDokument3 SeitenSpare Part Designation S40.1 S50.1 S63.1 S80.1: N/a N/aeli saNoch keine Bewertungen

- BN 20367Dokument2 SeitenBN 20367HarmanNoch keine Bewertungen

- Pm-Clinic Inspection Sheet Model: Hm400-2 #2001-: (Mmaq)Dokument2 SeitenPm-Clinic Inspection Sheet Model: Hm400-2 #2001-: (Mmaq)Naughty VongNoch keine Bewertungen

- Bomag BPR 50 User Manual перекладDokument241 SeitenBomag BPR 50 User Manual перекладTaras KutsykNoch keine Bewertungen

- Exterran Vent ListDokument10 SeitenExterran Vent Listdilip matalNoch keine Bewertungen

- uPVC Conduits & FittingsDokument5 SeitenuPVC Conduits & FittingsderiNoch keine Bewertungen

- Air Cooled Chillers & Heat Pumps: Fullpower SeDokument5 SeitenAir Cooled Chillers & Heat Pumps: Fullpower SeAnarNoch keine Bewertungen

- Piston Displacement - 104132Dokument36 SeitenPiston Displacement - 104132Usman GhaniNoch keine Bewertungen

- Listado Repuestos BollfilterDokument9 SeitenListado Repuestos BollfilterJ. Salvador Calderon B.Noch keine Bewertungen