Beruflich Dokumente

Kultur Dokumente

SS900-General Tunnel Construction - 161026

Hochgeladen von

jologscresenciaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SS900-General Tunnel Construction - 161026

Hochgeladen von

jologscresenciaCopyright:

Verfügbare Formate

PART K- TUNNELING WORKS

ITEM SS900 GENERAL TUNNEL CONSTRUCTION

1.

GENERAL TUNNEL CONSTRUCTION REQUIREMENTS

The construction of the Tipo Tunnel shall be accomplished using Sequential Excavation Method

(SEM). The principles and requirements of this method shall be strictly adhered to during the

execution of the work. The Contractor shall employ competent personnel with expertise and

experience with SEM for tunnel works. The Contractor shall assure that all personnel responsible for

the tunneling works are familiar with the concepts and requirements for the tunnel construction using

SEM. The specifications, requirements and details set-forth in the contract documents are intended to

provide information and requirements to personnel with knowledge and experience with this specified

method. The Contractors lack of knowledge and/or experience in the specified tunneling methods

shall not relieve him of his contractual obligations, and requirements and liabilities.

The Contractor shall carry out all work in accordance with applicable Labour, Safety, Hygiene and

Environmental Protection requirements and laws for the work being performed, contract requirements

of Manila North Tollways Corporation (MNTC) and the laws and regulations of Subic Bay

Metropolitan Authority (SBMA).

2.

TUNNEL CONSTRUCTION CONCEPT

Tunnels shall be constructed in accordance with the concepts of SEM which is defined as a method

where surrounding rock or soul formations of a tunnel or underground opening are integrated into an

overall ring-like support structure. The following principles must be observed:

3.

The geotechnical behaviour must be taken into account

Adverse states of stresses and deformations must be avoided by applying appropriate means

of support in due time

The completion of the invert gives the above mentioned ring-like structure the static

properties of a tube

The support means can/should be optimized according to the admissible deformations

General control, geotechnical measurements and constant checks on the optimization of the

pre-established support means must be performed.

TUNNEL SECURITY AND ACCESS

The Contractor shall be responsible for the security and tunnel entry in and around all tunnels work

areas. Tunnel security and exit/entry procedures and controls shall be detailed in the Contractors

Safety plan for the Works. The Contractor shall co-ordinate and plan tunnel security and entry with

others having access to the tunnels, including all interfacing contractors, so as not to disrupt or

interfere with their operations.

3.1

TUNNEL ENTRY/EXIT PROCEDURES

The Contractor shall establish a procedure for recording all tunnel entry and exits, preventing

unauthorized tunnel entry. This procedure, as a minimum, shall incorporate name cards and

entry/exit records at all tunnel portals to record the entrance and exit of all personnel.

The Contractor shall set up and operate a system whereby only those persons entitled to be on the

Site and/or in the tunnels can enter the Site and/or tunnel(s). The Contractor shall provide specific

points of entry through a security fence or barricade. The Contractor shall provide gates and barriers

at such points of entry and maintain a twenty-four hour security guard or other security personnel as

necessary to maintain security and prevent unauthorized entry.

Special Provisions and Supplemental Specifications

NLEX Segment Subic Freeport Expressway (SFEX)

Preparation of Detailed Engineering Design (DED) for Road Widening

K-1

PART K- TUNNELING WORKS

3.2

TUNNEL SECURITY

The Contractor shall provide and maintain fences and barricades in first class condition. Notice

signs shall be displayed at intervals (as consented by the Engineer) around the Site and portal areas

to warn the public of the dangers of entrance.

During the progress of the Works the Contractor shall maintain such security patrols over areas of

the Works as may be necessary to protect the work and prevent unauthorized entry.

3.3

TUNNEL COMMUNICATION REQUIREMENTS

The Contractor shall provide and maintain both a complete wired and a wireless telephone

communication system capable of providing clear and concise communication between all tunnel

work and the tunnel portals. The communication systems shall also provide for communication

between the tunnel works, Contractors site office, and Employers and Engineers site offices.

The Contractor shall maintain at all times both wired and wireless communication systems in full

working order. The communication systems and equipment shall be suitable for use in all area(s),

providing clear and dependable communication. This shall be subject to approval by any/all relevant

authority(s) prior to use.

The communication systems shall incorporate underground communication stations (telephone

receptacle with bell and Indication lamp) within 50m of any work and at 100-meter intervals along

the driven tunnel. The Contractor shall provide and maintain communication systems until the

completion and acceptance of all tunnel work or as otherwise required by the Engineer.

4.

DAILY TUNNEL REPORTING REQUIREMENTS

a

The Contractor shall prepare daily records and reports of all work that shall include, but not

necessary be limited to the following information and data:

duration of sequential excavation,

all personnel working in tunnel areas,

any and all tunnel work stoppages, with reason(s) for stopping work,

all instrument recordings with appropriate graphs,

weather conditions,

tunnel work equipment,

any/all tunnel water inflows,

size of excavated sections,

length of advance,

station numbers,

photographs (not less than 12 Megapixels) of all tunnel faces after excavation, before

support system installation,

the location and number of supports system members etc. for each round, and

reports and records required under specific specification requirements.

(a)

The Contractors daily records/report shall be submitted to the Engineer before 10 AM on the

following working day, and

(b)

During tunnel excavation operations, the Contractor shall, as witnessed in the presence of the

Engineer, record in detail geological conditions and prepare geological maps with necessary

photographs attached to evaluate the suitability of excavation methods and supports. These

details and maps shall serve as the basis for anticipating geological conditions ahead of the

excavated tunnel face.

Special Provisions and Supplemental Specifications

NLEX Segment Subic Freeport Expressway (SFEX)

Preparation of Detailed Engineering Design (DED) for Road Widening

K-2

PART K- TUNNELING WORKS

5.

6.

6.1

6.2

6.3

GENERAL REPORTING ASSISTANCE AND OPERATING REQUIREMENTS

a

The Contractor shall immediately notify the Engineer in case of substantial difference between

actual geological conditions and anticipated ones, or when severe changes in geological

conditions are observed.

For the recording of geological data by the Engineer, the Contractor shall give all necessary

assistance, and provide all labour, facilities and equipment as may be required by the Engineer.

The Contractor shall monitor the tunnel support systems, and report any damage to the support

systems immediately upon discovery to the Engineer. If the damage is serious, temporary

remedial action shall be taken with temporary propping, including evacuating the area and

posting warning signs accordingly.

The Contractor shall submit a support remedial

program to the Engineer for review and approval as soon as possible, and perform the remedial

measures expeditiously based on the approved program or direction of the Engineer.

(c)

In addition to monitoring the support system, the Contractor shall, carry out regular

maintenance of all tunnels including but not limited to, light bulb replacement, cleaning, water

removal, water pipe maintenance, and cable maintenance. Maintenance shall be deemed to

include all repair work required to maintain all equipment in working order, and

(d)

The Engineer shall when necessary (in the opinion of the Engineer), require the Contractor to

carry out remedial work to the tunnel support system(s) and/or grouting. Such instructions shall

not relieve the Contractor of his responsibility for monitoring and repairing the tunnel support

system.

TUNNEL SURVEYING

GENERAL REQUIREMENTS

a

The Contractor shall be responsible for carrying out all necessary surveying to assure that the

tunnel route, elevation and profile is in conformance with drawing requirements. Additional

requirements for tunnel surveying shall refer to Specification Section SS910 Tunnel

Concrete Lining for tunnel concrete lining tolerances, and Specification Section SS914

NATM Instrumentation for geotechnical monitoring during excavation, and

During the construction of the tunnel, the Contractor shall continuously check the tunnel

routing and locate permanent reference points.

PERMANENT REFERENCE POINTS

a

Permanent reference points shall be continuously located and installed along the tunnel route,

no later than one day after installation of the tunnel support system.

The maximum spacing of the reference points shall be no more than 100 meters along

straight sections of the tunnel, and no more than 50 meters along curved sections.

The installation of the reference points shall be to the satisfaction of and/or as required by the

Engineer. The location of the reference points shall not conflict with other parts of the work,

and

Reference points shall be rechecked and verified at one-kilometer intervals in conjunction

with the completion of the tunnel support systems.

LONGITUDINAL PROFILE SURVEY

The Contractor shall perform (and provide to the Engineer) longitudinal profile survey of the tunnel

lining, by means of closed traverse, upon completion of the tunnel work.

Special Provisions and Supplemental Specifications

NLEX Segment Subic Freeport Expressway (SFEX)

Preparation of Detailed Engineering Design (DED) for Road Widening

K-3

PART K- TUNNELING WORKS

7.

MATERIALS

Materials necessary for tunnel construction shall be in accordance with relevant material

specifications.

8.

8.1

CONSTRUCTION REQUIREMENTS

GENERAL

Tunnel construction shall comply with specification requirements for components as described in

the relevant Specification Sections.

8.2

9.

9.1

PERMANENT ELECTRICAL COMPONENTS

a

The permanent electrical components associated with the tunnel work shall be provided by and

installed under a separate contract, except those parts shown on the Drawings. This includes

such items as the electrical conduit and accessories.

In accordance with the requirements of Sub-Clause 4.6 Co-operation, it shall be

Contractors responsibility to fully coordinate his work, work schedule, procedures

operations with such contractor(s). The Contractor shall coordinate his work activities

construction procedures to assure the proper and timely installation of all such materials

equipment by others, and

Failure to provide all necessary and proper arrangements and coordination shall not constitute

grounds for delay of work and/or additional compensation.

the

and

and

and

MEASUREMENT AND PAYMENT

STRENGTHENING OF SUPPORT SYSTEMS AND TUNNEL GROUTING

The strengthening of support systems and grouting of tunnel (as directed and or approved by the

Engineer) shall be paid for at applicable unit rates for the associated work item(s).

9.2

TUNNEL SECURITY AND ACCESS

No separate measurement or payment will be made for this work. All other direct costs incurred

under the construction of the Tipo Tunnel are deemed paid for directly or indirectly under other

direct costs shown in the Bill of Quantities.

9.3

TUNNEL DAILY REPORTING REQUIREMENTS

No separate measurement or payment will be made for this work. All other direct costs incurred in

the construction of the Tipo Tunnel are deemed paid for directly or indirectly under other direct

costs shown in the Bill of Quantities.

9.4

GENERAL REPORTING ASSISTANCE AND OPERATING REQUIREMENTS

No separate measurement or payment will be made for this work. All other direct costs incurred

under the construction of the Tipo Tunnel are deemed paid for directly or indirectly under other

direct costs shown in the Bill of Quantities.

9.5

TUNNEL MAINTENANCE

Tunnel maintenance costs are deemed paid for directly or indirectly under other direct costs shown

in the Bill of Quantities.

Special Provisions and Supplemental Specifications

NLEX Segment Subic Freeport Expressway (SFEX)

Preparation of Detailed Engineering Design (DED) for Road Widening

K-4

PART K- TUNNELING WORKS

9.6

TUNNEL SURVEYING

Tunnel surveying costs are deemed paid for directly or indirectly under other direct costs shown in

the Bill of Quantities..

9.7

TUNNEL CONSTRUCTION COMMUNICATIONS

Costs incurred in providing Tunnel Construction Communications are deemed paid for directly or

indirectly under other direct costs shown in the Bill of Quantities.

10. SUBMITTALS

The following submittals shall be provided by the Contractor in accordance with requirements of

this Specification Section:

a

Tunnel security and exit/entry procedures and controls shall be detailed in the Contractors

Safety plan and be approved by the Engineer prior to the commencement of tunnel work.

The Contractor shall submit warning sign samples and a warning sign location plan to the

Engineer for concurrence. Signs shall be placed in accordance with samples and per the plan

acceptable to the Engineer, prior to the commencement of any tunnel work.

The Contractors daily records/report shall be submitted to the Engineer daily, before 10 AM

on the following working day, and.

The Contractor shall perform (and provide to the Engineer) longitudinal profile surveys of the

tunnel lining, by means of closed traverse, upon completion of the tunnel work.

Special Provisions and Supplemental Specifications

NLEX Segment Subic Freeport Expressway (SFEX)

Preparation of Detailed Engineering Design (DED) for Road Widening

K-5

Das könnte Ihnen auch gefallen

- Shear in Inclined WebsDokument2 SeitenShear in Inclined WebsjologscresenciaNoch keine Bewertungen

- Methods and Procedure of Tunnel SurveyingDokument4 SeitenMethods and Procedure of Tunnel SurveyingTanuj Sharma100% (1)

- Comparison Between 2d and 3d Behaviour of Sheet Piles by Finite Element MethodDokument16 SeitenComparison Between 2d and 3d Behaviour of Sheet Piles by Finite Element MethodtavialimNoch keine Bewertungen

- NAME: Awodutire Olajide MAT - NO.: 2017/6403 Lecturer: Arc Alabi O. A. Date: May 2019Dokument8 SeitenNAME: Awodutire Olajide MAT - NO.: 2017/6403 Lecturer: Arc Alabi O. A. Date: May 2019Friday NdujiubaNoch keine Bewertungen

- Numerical Methods and Implementation in Geotechnical Engineering – Part 1Von EverandNumerical Methods and Implementation in Geotechnical Engineering – Part 1Noch keine Bewertungen

- Breakdown of Cost Estimate: Beverly Hills Subd., Antipolo CityDokument4 SeitenBreakdown of Cost Estimate: Beverly Hills Subd., Antipolo CityjologscresenciaNoch keine Bewertungen

- Table 1.6 Bridge Cost Per L.M.Dokument7 SeitenTable 1.6 Bridge Cost Per L.M.sefin_02Noch keine Bewertungen

- Eccentric FootingDokument3 SeitenEccentric FootingVarunn VelNoch keine Bewertungen

- Survey Manual: State of New Hampshire Department of Transportation 2010Dokument142 SeitenSurvey Manual: State of New Hampshire Department of Transportation 2010Muhammad Sajid100% (1)

- Optimal Stabilisation of Deltaic LateriteDokument8 SeitenOptimal Stabilisation of Deltaic LateritethaynarethNoch keine Bewertungen

- Methods and EstimationDokument31 SeitenMethods and EstimationPrinceRanaNoch keine Bewertungen

- Basic Civil - Module 2Dokument40 SeitenBasic Civil - Module 2SEKHAR JNoch keine Bewertungen

- Theory and Application of Excavation Management System For Slurry TBM in SingaporeDokument18 SeitenTheory and Application of Excavation Management System For Slurry TBM in SingaporeSAMİ ENİS ARIOĞLUNoch keine Bewertungen

- Engr. John Michael GargulloDokument4 SeitenEngr. John Michael GargulloHendrix Rivera OrtegaNoch keine Bewertungen

- Cec 309 Note-1Dokument3 SeitenCec 309 Note-1AbdulrafiuNoch keine Bewertungen

- CV304 Engineering GeologyDokument5 SeitenCV304 Engineering GeologySATHEESHKUMAR PNoch keine Bewertungen

- Embankment ConstructionDokument25 SeitenEmbankment ConstructionVikalp AwasthiNoch keine Bewertungen

- 1705 1530 1615 Introduction 3d TunnelDokument12 Seiten1705 1530 1615 Introduction 3d TunnelJunaida WallyNoch keine Bewertungen

- Elementarysurvey PDFDokument167 SeitenElementarysurvey PDFStanley OnyejiNoch keine Bewertungen

- Behavior of Unsaturated Soils For Road Pavement Structure Under Cyclic LoadingDokument272 SeitenBehavior of Unsaturated Soils For Road Pavement Structure Under Cyclic LoadingDiana CapisondaNoch keine Bewertungen

- New Austrian Method Used Design of Soft-Ground Tunnels For Washington MetroDokument4 SeitenNew Austrian Method Used Design of Soft-Ground Tunnels For Washington MetroJothimanikkam SomasundaramNoch keine Bewertungen

- TunnellingDokument39 SeitenTunnellingICKCRANANoch keine Bewertungen

- IV. Concrete Sub Topic PDFDokument60 SeitenIV. Concrete Sub Topic PDFNico100% (1)

- Temporary Excavation Support System For A New Railway Bridge and Highway Underpass in Pittsburgh, Pennsylvania by Andrew G. Cushing and Christopher J. LewisDokument8 SeitenTemporary Excavation Support System For A New Railway Bridge and Highway Underpass in Pittsburgh, Pennsylvania by Andrew G. Cushing and Christopher J. LewisAndrew CushingNoch keine Bewertungen

- Pregrouting For Leakage Control and Rock Improvement 2165 784X 1000226Dokument4 SeitenPregrouting For Leakage Control and Rock Improvement 2165 784X 1000226Abhilash UrsNoch keine Bewertungen

- A New Correlation Between SPT and CPT For Various Soils PDFDokument7 SeitenA New Correlation Between SPT and CPT For Various Soils PDFginasuhandiniNoch keine Bewertungen

- Metro de Madrid PresentationDokument39 SeitenMetro de Madrid PresentationMarton CavaniNoch keine Bewertungen

- Time Dependent Movements On The Billy Bishop Toronto City Airport Pedestrian Tunnel, Ontario, CanadaDokument15 SeitenTime Dependent Movements On The Billy Bishop Toronto City Airport Pedestrian Tunnel, Ontario, CanadaAndrew CushingNoch keine Bewertungen

- Safety Control For Development Adjacent To Existing MRT Structures and Observed Field Performance S. K. KongDokument7 SeitenSafety Control For Development Adjacent To Existing MRT Structures and Observed Field Performance S. K. KongTuntun TatNoch keine Bewertungen

- References Traffic TunnellingDokument92 SeitenReferences Traffic TunnellingValderi FerreiraNoch keine Bewertungen

- Experimental Tests On Tunnel Precast Segmental Lining With Fiber Reinforced ConcreteDokument8 SeitenExperimental Tests On Tunnel Precast Segmental Lining With Fiber Reinforced ConcretemetropodikasNoch keine Bewertungen

- Lesson Learn From Instrumentation Tunnel ProjectDokument16 SeitenLesson Learn From Instrumentation Tunnel ProjectNguyen Quoc KhanhNoch keine Bewertungen

- CHAPTER 2 (Introduction To The Construction Industry)Dokument16 SeitenCHAPTER 2 (Introduction To The Construction Industry)Saidatul SazwaNoch keine Bewertungen

- Introduction To Soil Mechanics Lecture PDFDokument15 SeitenIntroduction To Soil Mechanics Lecture PDFMayolitesNoch keine Bewertungen

- Highway Engineering: ReferencesDokument6 SeitenHighway Engineering: ReferencesZain GxNoch keine Bewertungen

- TunnelingDokument18 SeitenTunnelingmihretabNoch keine Bewertungen

- Scope of Civil EngineeringDokument8 SeitenScope of Civil EngineeringYogendra PatilNoch keine Bewertungen

- Crossrail TunnelsDokument15 SeitenCrossrail TunnelsPeter AyubaNoch keine Bewertungen

- ..-HKIE-download-Tunnel Related Failures PDFDokument11 Seiten..-HKIE-download-Tunnel Related Failures PDFAbdelali SolNoch keine Bewertungen

- S O S O E: Care of TapesDokument5 SeitenS O S O E: Care of TapesMOHAMED0% (1)

- SEM Mined Tunnel PDFDokument3 SeitenSEM Mined Tunnel PDFqaisarmehboob82Noch keine Bewertungen

- Lecture NotesDokument102 SeitenLecture NotesAnitha MuthukumaranNoch keine Bewertungen

- TunnelsDokument25 SeitenTunnelsSreeNoch keine Bewertungen

- Tunnel ConstructionDokument9 SeitenTunnel ConstructionJayan VijayanNoch keine Bewertungen

- SEM NATM Design and ContractingDokument5 SeitenSEM NATM Design and Contractingapi-3714473100% (2)

- Tunnel and Bridge AssessmentsDokument77 SeitenTunnel and Bridge AssessmentsmoomeejeeNoch keine Bewertungen

- Jack Micro PDFDokument48 SeitenJack Micro PDFHizbar ArsjadNoch keine Bewertungen

- DSI ALWAG-Systems Pantex Lattice Girders EDokument8 SeitenDSI ALWAG-Systems Pantex Lattice Girders Epramods_8Noch keine Bewertungen

- Soil Erosion Measurement and Control TechniquesDokument12 SeitenSoil Erosion Measurement and Control TechniquessezaitanyoluNoch keine Bewertungen

- Shotcrete Lining in A TunnelDokument13 SeitenShotcrete Lining in A TunnelNaveen R100% (1)

- Natm New Austrian Tunneling MethodDokument19 SeitenNatm New Austrian Tunneling MethodnarendraNoch keine Bewertungen

- Road ConstructionDokument91 SeitenRoad ConstructionRA MagallanesNoch keine Bewertungen

- Lombardi TunnelDokument26 SeitenLombardi Tunnelani1167Noch keine Bewertungen

- Geotechnical Assessment and Methods For New Construction - Sam AriaratnamDokument20 SeitenGeotechnical Assessment and Methods For New Construction - Sam AriaratnamZAMIRNoch keine Bewertungen

- Tunnelling MethodsDokument15 SeitenTunnelling Methodsrohit_iitd080% (1)

- Geometric Design ManualDokument240 SeitenGeometric Design ManualRiyaad MandisaNoch keine Bewertungen

- CofferdamDokument16 SeitenCofferdamHong VeasnaNoch keine Bewertungen

- RTA Spec. - Soil InvenstigationDokument2 SeitenRTA Spec. - Soil InvenstigationSheril Chandrabose100% (1)

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985Von EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985Noch keine Bewertungen

- Ground Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980Von EverandGround Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980Noch keine Bewertungen

- Developments in Geotechnical EngineeringVon EverandDevelopments in Geotechnical EngineeringBewertung: 5 von 5 Sternen5/5 (2)

- Specifications A4Dokument43 SeitenSpecifications A4jologscresenciaNoch keine Bewertungen

- Special Power of Attorney SampleDokument1 SeiteSpecial Power of Attorney SamplejologscresenciaNoch keine Bewertungen

- Structural Calcs SampleDokument7 SeitenStructural Calcs SamplejologscresenciaNoch keine Bewertungen

- City of Building OfficialDokument1 SeiteCity of Building OfficialjologscresenciaNoch keine Bewertungen

- Structural Calcs Sample 2Dokument1 SeiteStructural Calcs Sample 2jologscresenciaNoch keine Bewertungen

- Structural CalculationsDokument43 SeitenStructural CalculationsjologscresenciaNoch keine Bewertungen

- Friday, January 22, 2016, 12:57 PM: Page 1 of 18 E:/Users/Jlsdavid/Documents/De Guzman/Staad - Frame/Frame - DG - AnlDokument18 SeitenFriday, January 22, 2016, 12:57 PM: Page 1 of 18 E:/Users/Jlsdavid/Documents/De Guzman/Staad - Frame/Frame - DG - AnljologscresenciaNoch keine Bewertungen

- Electrical NotesDokument1 SeiteElectrical NotesjologscresenciaNoch keine Bewertungen

- Roof Framing Plan Lower Roof Framing Plan Lally Col. Layout: Jose G.S. DavidDokument1 SeiteRoof Framing Plan Lower Roof Framing Plan Lally Col. Layout: Jose G.S. DavidjologscresenciaNoch keine Bewertungen

- De Guzman P-01Dokument1 SeiteDe Guzman P-01jologscresenciaNoch keine Bewertungen

- Proposed Two-Storey Building: Nava Residence Paranaque, Metro Manila JLSD 14-Jan-13Dokument2 SeitenProposed Two-Storey Building: Nava Residence Paranaque, Metro Manila JLSD 14-Jan-13jologscresenciaNoch keine Bewertungen

- A Simplified Guide For Building Permit Application in Antipolo CityDokument1 SeiteA Simplified Guide For Building Permit Application in Antipolo CityjologscresenciaNoch keine Bewertungen

- Design Criteria - RevDokument3 SeitenDesign Criteria - RevjologscresenciaNoch keine Bewertungen

- Purlin DiagramDokument1 SeitePurlin DiagramjologscresenciaNoch keine Bewertungen

- Project: Proposed Additional Storey (Residential Building) Location: Pasig City Owner: Mr. Arsenio BustillosDokument7 SeitenProject: Proposed Additional Storey (Residential Building) Location: Pasig City Owner: Mr. Arsenio BustillosjologscresenciaNoch keine Bewertungen

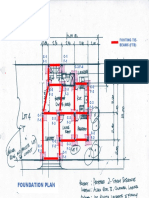

- Foundation Plan: C-1 F-1 C-1 F-1Dokument3 SeitenFoundation Plan: C-1 F-1 C-1 F-1jologscresenciaNoch keine Bewertungen

- A3Dokument1 SeiteA3jologscresenciaNoch keine Bewertungen

- A4Dokument1 SeiteA4jologscresenciaNoch keine Bewertungen

- A5Dokument1 SeiteA5jologscresenciaNoch keine Bewertungen

- Sample Truss DiagramDokument1 SeiteSample Truss DiagramjologscresenciaNoch keine Bewertungen

- Sample Column DesignDokument1 SeiteSample Column DesignjologscresenciaNoch keine Bewertungen

- Proposed Two-Storey Residential: Nava Residence Paranaque, Metro ManilaDokument1 SeiteProposed Two-Storey Residential: Nava Residence Paranaque, Metro ManilajologscresenciaNoch keine Bewertungen

- A6Dokument1 SeiteA6jologscresenciaNoch keine Bewertungen

- A2Dokument1 SeiteA2jologscresenciaNoch keine Bewertungen

- Design Criteria ExampleDokument3 SeitenDesign Criteria Examplejologscresencia100% (1)

- Design CriteriaDokument1 SeiteDesign CriteriajologscresenciaNoch keine Bewertungen

- Transverse MomentsDokument3 SeitenTransverse MomentsjologscresenciaNoch keine Bewertungen

- 5620 SAM Rel 14 License Point Configuration ToolDokument416 Seiten5620 SAM Rel 14 License Point Configuration Toolluis100% (1)

- Determinant of Nurses' Response Time in Emergency Department When Taking Care of A PatientDokument9 SeitenDeterminant of Nurses' Response Time in Emergency Department When Taking Care of A PatientRuly AryaNoch keine Bewertungen

- Tribes Without RulersDokument25 SeitenTribes Without Rulersgulistan.alpaslan8134100% (1)

- JO 20221109 NationalDokument244 SeitenJO 20221109 NationalMark Leo BejeminoNoch keine Bewertungen

- Saflex-Dg - 41 Data SheetDokument5 SeitenSaflex-Dg - 41 Data SheetrasheedgotzNoch keine Bewertungen

- Source:: APJMR-Socio-Economic-Impact-of-Business-Establishments - PDF (Lpubatangas - Edu.ph)Dokument2 SeitenSource:: APJMR-Socio-Economic-Impact-of-Business-Establishments - PDF (Lpubatangas - Edu.ph)Ian EncarnacionNoch keine Bewertungen

- HRM Practices in NepalDokument22 SeitenHRM Practices in NepalBodhiNoch keine Bewertungen

- .CLP Delta - DVP-ES2 - EX2 - SS2 - SA2 - SX2 - SE&TP-Program - O - EN - 20130222 EDITADODokument782 Seiten.CLP Delta - DVP-ES2 - EX2 - SS2 - SA2 - SX2 - SE&TP-Program - O - EN - 20130222 EDITADOMarcelo JesusNoch keine Bewertungen

- Building Material Supplier in GurgaonDokument12 SeitenBuilding Material Supplier in GurgaonRodidustNoch keine Bewertungen

- Naval TV SystemDokument24 SeitenNaval TV Systemsharmasandeep0010Noch keine Bewertungen

- Section 1 Company Overview StandardsDokument34 SeitenSection 1 Company Overview StandardsChris MedeirosNoch keine Bewertungen

- SSC Gr8 Biotech Q4 Module 1 WK 1 - v.01-CC-released-09May2021Dokument22 SeitenSSC Gr8 Biotech Q4 Module 1 WK 1 - v.01-CC-released-09May2021Ivy JeanneNoch keine Bewertungen

- Topic One ProcurementDokument35 SeitenTopic One ProcurementSaid Sabri KibwanaNoch keine Bewertungen

- Applications of Wireless Sensor Networks: An Up-to-Date SurveyDokument24 SeitenApplications of Wireless Sensor Networks: An Up-to-Date SurveyFranco Di NataleNoch keine Bewertungen

- 'Causative' English Quiz & Worksheet UsingEnglish ComDokument2 Seiten'Causative' English Quiz & Worksheet UsingEnglish ComINAWATI BINTI AMING MoeNoch keine Bewertungen

- Hitachi Vehicle CardDokument44 SeitenHitachi Vehicle CardKieran RyanNoch keine Bewertungen

- 2014 - Intelligence As A Predictor of Outcome in Short-And Long-Term PsychotherapyDokument9 Seiten2014 - Intelligence As A Predictor of Outcome in Short-And Long-Term PsychotherapyZayne CarrickNoch keine Bewertungen

- 123Dokument3 Seiten123Phoebe AradoNoch keine Bewertungen

- 1188 2665 1 SMDokument12 Seiten1188 2665 1 SMRita BangunNoch keine Bewertungen

- Load Chart Crane LiftingDokument25 SeitenLoad Chart Crane LiftingLauren'sclub EnglishBimbel Sd-sma100% (1)

- Nominal GroupDokument3 SeitenNominal GroupSrourNoch keine Bewertungen

- Job Satisfaction of Library Professionals in Maharashtra State, India Vs ASHA Job Satisfaction Scale: An Evaluative Study Dr. Suresh JangeDokument16 SeitenJob Satisfaction of Library Professionals in Maharashtra State, India Vs ASHA Job Satisfaction Scale: An Evaluative Study Dr. Suresh JangeNaveen KumarNoch keine Bewertungen

- Resume - James MathewsDokument2 SeitenResume - James Mathewsapi-610738092Noch keine Bewertungen

- Press Statement - Book Launching Shariah Forensic 27 Oct 2023Dokument4 SeitenPress Statement - Book Launching Shariah Forensic 27 Oct 2023aNoch keine Bewertungen

- Engineering Management: Class RequirementsDokument30 SeitenEngineering Management: Class RequirementsMigaeaNoch keine Bewertungen

- 11-Rubber & PlasticsDokument48 Seiten11-Rubber & PlasticsJack NgNoch keine Bewertungen

- FT2020Dokument7 SeitenFT2020Sam SparksNoch keine Bewertungen

- Management PriniciplesDokument87 SeitenManagement Priniciplesbusyboy_spNoch keine Bewertungen

- Philo Q2 Lesson 5Dokument4 SeitenPhilo Q2 Lesson 5Julliana Patrice Angeles STEM 11 RUBYNoch keine Bewertungen