Beruflich Dokumente

Kultur Dokumente

Anticorit BW 366

Hochgeladen von

Jashim UddinOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Anticorit BW 366

Hochgeladen von

Jashim UddinCopyright:

Verfügbare Formate

ANTICORIT BW 366

High-performance corrosion preventive wax

Description

Advantages/Benefits

ANTICORIT BW 366 is a barium-free, high

performance corrosion protection wax with a solvent.

It produces a thick, touch resistant, long-term

corrosion protection film.

The thixotropic ANTICORIT BW

applicable also on vertical surfaces.

366

is

Easy applied

Thixotropic product, doesnt run off

Thermally stable film

Excellent corrosion protection

easy

ANTICORIT BW 366 is usable for most different

applications: It is used as underbody protection and

hollow-corrosion-protection in the car-industry.

It

provides an excellent corrosion protection on semifinished parts, press-tools and moulds. ANTICORIT

BW 366 is also ideal for the long-term preservation of

vehicles and equipment for the construction industry

and for farming.

Specifications

ANTICORIT BW 366 is approved by MAN under

M 3082 Typ D2

Application

ANTICORIT BW 366 is applied by spraying, rolling or

brushing. Concerning spraying, the valid safety

precautions must be taken into consideration. At

longer storage a thickening, caused by the thixotropic

additives, may occur. The original quality is recreated

simply by stirring. ANTICORIT BW 366 can be

removed with solvents.

August 2008 GDUK Page 1 of 2

Health, Safety and Environment - information is provided for

products in the relevant Safety Data Sheet. This provides guidance on

potential hazards, precautions and first-aid measures, together with

environmental effects and disposal of used products.

While the information and figures given here are typical of current

production and conform to specification, minor variations may occur. No

warranty expressed or implied is given concerning the accuracy of the

information or the suitability of the products

FUCHS LUBRICANTS (UK) PLC

New Century Street, Hanley

GB-Stoke-on-Trent, Staffordshire, ST1 5HU

Tel: +44-1782 -20 37 00

Fax: +44-1782 -20 20 73

Email: contact-uk@fuchs-oil.com

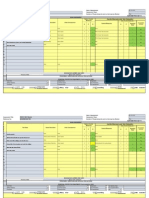

CHARACTERISTICS: ANTICORIT BW 366

Characteristics

Unit

Colour

Test Method

Brown

Density at 15C

kg/m3

875

DIN 51 757

Flashpoint

40

DIN ISO 2592

Film weight

g/m2

38

FLV-F-03 *)

Evaporation residue

55

FLV-V-01 *)

Run-off time at 20C

60

DIN 53 211 **)

Drying time

min

60

Dropping point of the film

140

DIN ISO 2176

Salt spray test

hours

800

DIN 50 021-SS

Condensation climate

cycles

> 100

DIN 50 017-KFW

Humidity chamber

hours

1000

ASTM-D 1748

Indoor-storage

months

12 36 ***)

Open-shed storage

months

12 36 ***)

Outdoor-storage

months

6 24 ****)

Corrosion Protection Data (St 1405)

Corrosion Protection

*) FLV = Test procedure of FUCHS EUROPE SCHMIERSTOFFE GMBH

**) directly after the production

***) packed Fe-material, < 65 % rF, heated

****) packed Fe-material, < 65 % rF, tempered climate

August 2008 GDUK Page 2 of 2

Health, Safety and Environment - information is provided for

products in the relevant Safety Data Sheet. This provides guidance on

potential hazards, precautions and first-aid measures, together with

environmental effects and disposal of used products.

While the information and figures given here are typical of current

production and conform to specification, minor variations may occur. No

warranty expressed or implied is given concerning the accuracy of the

information or the suitability of the products

FUCHS LUBRICANTS (UK) PLC

New Century Street, Hanley

GB-Stoke-on-Trent, Staffordshire, ST1 5HU

Tel: +44-1782 -20 37 00

Fax: +44-1782 -20 20 73

Email: contact-uk@fuchs-oil.com

Das könnte Ihnen auch gefallen

- High-Performance Corrosion Wax for Long-Term ProtectionDokument2 SeitenHigh-Performance Corrosion Wax for Long-Term ProtectionAdnanNoch keine Bewertungen

- High-Performance Corrosion WaxDokument2 SeitenHigh-Performance Corrosion WaxSibaram DasNoch keine Bewertungen

- Anticorit BW 366 PDFDokument2 SeitenAnticorit BW 366 PDFRantho TariganNoch keine Bewertungen

- High-Performance Corrosion WaxDokument2 SeitenHigh-Performance Corrosion WaxRonald Mario Kupa AnticonaNoch keine Bewertungen

- High-Performance Corrosion WaxDokument2 SeitenHigh-Performance Corrosion WaxRonald Mario Kupa AnticonaNoch keine Bewertungen

- Gasket Remover (DS) 125-03017Dokument2 SeitenGasket Remover (DS) 125-03017Teguh RiswantoNoch keine Bewertungen

- Dicrea SX 46Dokument1 SeiteDicrea SX 46Marcelo Ferreira MeloNoch keine Bewertungen

- Lukoil Stabio DDokument2 SeitenLukoil Stabio DRoberto Alfaro EspinozaNoch keine Bewertungen

- PREMIUM Hydraulic Oil 32 46 68 - TDSDokument1 SeitePREMIUM Hydraulic Oil 32 46 68 - TDSazimchemNoch keine Bewertungen

- TDS - Motul VIS 46 - ENDokument2 SeitenTDS - Motul VIS 46 - ENnghiaNoch keine Bewertungen

- Isoflex Topas NB 52 152Dokument4 SeitenIsoflex Topas NB 52 152tapuskof1Noch keine Bewertungen

- AcryGuard TDS 2020Dokument3 SeitenAcryGuard TDS 2020sarah magdyNoch keine Bewertungen

- Quintolubric 888-68 TLDokument4 SeitenQuintolubric 888-68 TLKaly7Noch keine Bewertungen

- Anticorit KL 7: Corrosion Preventive Oil Description BenefitsDokument3 SeitenAnticorit KL 7: Corrosion Preventive Oil Description BenefitsEmin MešićNoch keine Bewertungen

- Ti Vulkodurit 1691-75-231k enDokument3 SeitenTi Vulkodurit 1691-75-231k enRichard ZunkNoch keine Bewertungen

- Agip Dicrea PDFDokument2 SeitenAgip Dicrea PDFdunghtvcNoch keine Bewertungen

- Adinoll Cliptec XHS 280 EnglishDokument6 SeitenAdinoll Cliptec XHS 280 EnglishCleiton Luiz CordeiroNoch keine Bewertungen

- ISO 9001 Certified Master Distributor and ConverterDokument2 SeitenISO 9001 Certified Master Distributor and ConverterAriani AmaliaNoch keine Bewertungen

- .Au ProductsAndServices Pages LubricantProDokument3 Seiten.Au ProductsAndServices Pages LubricantProabid azizNoch keine Bewertungen

- Bpxe 8STBGZDokument2 SeitenBpxe 8STBGZSaeed QahremaniNoch keine Bewertungen

- Flupec Catalog SimeringuriDokument315 SeitenFlupec Catalog Simeringuriman666onNoch keine Bewertungen

- Firestop Systems Technical SubmittalDokument44 SeitenFirestop Systems Technical Submittalakosirhockz100% (1)

- Aliphatic Acrylic Polyurethane Finish CoatDokument4 SeitenAliphatic Acrylic Polyurethane Finish CoatDexter R. RoqueNoch keine Bewertungen

- Carter VP-CS (08.10.02)Dokument1 SeiteCarter VP-CS (08.10.02)D Wahyu BawonoNoch keine Bewertungen

- Aircol SW RangeDokument2 SeitenAircol SW RangeDouglas Neves - UnaxNoch keine Bewertungen

- Mobilgrease XHP 460Dokument3 SeitenMobilgrease XHP 460Jaime Miloz Masle JaksicNoch keine Bewertungen

- Optimol Longtime PD 1 + 2 eDokument2 SeitenOptimol Longtime PD 1 + 2 ericardoruedaNoch keine Bewertungen

- GM DEXRON VI Automatic Transmission FluidDokument1 SeiteGM DEXRON VI Automatic Transmission FluidNamer HajiNoch keine Bewertungen

- Rhodia Tds Technyl C 548b v15 enDokument2 SeitenRhodia Tds Technyl C 548b v15 enDejan PekićNoch keine Bewertungen

- RUBRIC HM 68 en FR Motul 48880 20210713Dokument2 SeitenRUBRIC HM 68 en FR Motul 48880 20210713Quy NguyenNoch keine Bewertungen

- P004916 Commercial Vehicle Multi Purpose Grease K2K 20 15 en - GBDokument1 SeiteP004916 Commercial Vehicle Multi Purpose Grease K2K 20 15 en - GBSaeed QahremaniNoch keine Bewertungen

- Galva Brite Zinc-Aluminum CoatingDokument2 SeitenGalva Brite Zinc-Aluminum CoatingDee DeeNoch keine Bewertungen

- Rand Oh Di So 22324668100220Dokument2 SeitenRand Oh Di So 22324668100220Crystal RojasNoch keine Bewertungen

- PDS - Mobilgrease XHP 460 SeriesDokument3 SeitenPDS - Mobilgrease XHP 460 SeriesJuanSantillanNoch keine Bewertungen

- 04 TD Dichtol GBDokument2 Seiten04 TD Dichtol GBsusu222000Noch keine Bewertungen

- Ti e Protegol 32-45 Jan 12Dokument3 SeitenTi e Protegol 32-45 Jan 12ruben quedo salazarNoch keine Bewertungen

- Traxit eDokument4 SeitenTraxit ePero KolevNoch keine Bewertungen

- Product Data Sheet: Optimol OptipitDokument2 SeitenProduct Data Sheet: Optimol OptipitFBNoch keine Bewertungen

- Tectyl 502CDokument2 SeitenTectyl 502Cmoinu85Noch keine Bewertungen

- Ficha Técnica Lubricante Multo PropósitoDokument2 SeitenFicha Técnica Lubricante Multo Propósitogerman llanoNoch keine Bewertungen

- Industrial Brochure ISS 3 FEB11Dokument6 SeitenIndustrial Brochure ISS 3 FEB11yorkshirewizardNoch keine Bewertungen

- Castrol Longtime PD1 & PD2 Product Data SheetDokument3 SeitenCastrol Longtime PD1 & PD2 Product Data SheetAmit NaikNoch keine Bewertungen

- Data SheetDokument8 SeitenData SheettomychalilNoch keine Bewertungen

- Molylub GoldTex T 46 KnittingDokument1 SeiteMolylub GoldTex T 46 KnittingismoyoNoch keine Bewertungen

- Ultramax 68 Hydraulic Oil-PI SheetDokument2 SeitenUltramax 68 Hydraulic Oil-PI SheetNgila João AndréNoch keine Bewertungen

- Interbond 808 - Cargo Oil Tanks PDFDokument26 SeitenInterbond 808 - Cargo Oil Tanks PDFjasonwu1115Noch keine Bewertungen

- Klüberquiet BQ 72-72 EN enDokument4 SeitenKlüberquiet BQ 72-72 EN enaligholiNoch keine Bewertungen

- Perfecto T RangeDokument2 SeitenPerfecto T RangecarmaNoch keine Bewertungen

- Silicone RTV Boss 310Dokument2 SeitenSilicone RTV Boss 310Vinaya Almane DattathreyaNoch keine Bewertungen

- Technical Data Sheets: Fluid FilmDokument5 SeitenTechnical Data Sheets: Fluid FilmRAHULNoch keine Bewertungen

- Product Information Navisyn De: DescriptionDokument2 SeitenProduct Information Navisyn De: DescriptionGabriel NogueiraNoch keine Bewertungen

- Loctite 5699™: Technical Data SheetDokument3 SeitenLoctite 5699™: Technical Data Sheetgazwang478Noch keine Bewertungen

- Sikafloor - 264 EngDokument5 SeitenSikafloor - 264 Engbassem kooliNoch keine Bewertungen

- Mobil Velocite Oil Numbered YDokument2 SeitenMobil Velocite Oil Numbered YAndey RibalkoNoch keine Bewertungen

- OCG Product RangeDokument2 SeitenOCG Product RangeDayanand SharmaNoch keine Bewertungen

- Klüberquiet BQH 72-102: Product InformationDokument4 SeitenKlüberquiet BQH 72-102: Product Informationduy tanNoch keine Bewertungen

- 97 145Dokument2 Seiten97 145anon_251242493Noch keine Bewertungen

- Pds Psx700 Jan 2008Dokument3 SeitenPds Psx700 Jan 2008mjayhawk28Noch keine Bewertungen

- Corroban 1183 DX Protects Metal Parts from CorrosionDokument2 SeitenCorroban 1183 DX Protects Metal Parts from CorrosionAbhinayKumarNoch keine Bewertungen

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsVon EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsBewertung: 5 von 5 Sternen5/5 (1)

- Kluber lubricants product listDokument36 SeitenKluber lubricants product listJashim Uddin100% (1)

- List of Bangladeshi Yarn Manufacturers with Production Capacity and Export DataDokument26 SeitenList of Bangladeshi Yarn Manufacturers with Production Capacity and Export DataJashim UddinNoch keine Bewertungen

- Safety Data Sheet: Section 1: Identification of The Substance/mixture and of The Company/undertakingDokument7 SeitenSafety Data Sheet: Section 1: Identification of The Substance/mixture and of The Company/undertakingJashim UddinNoch keine Bewertungen

- Biz PlanDokument13 SeitenBiz Planalbert486Noch keine Bewertungen

- Textile Today EMagazine July 2018 IssueDokument96 SeitenTextile Today EMagazine July 2018 IssueJashim UddinNoch keine Bewertungen

- Lubricants Guide 2011Dokument106 SeitenLubricants Guide 2011thehrao100% (1)

- Textile Today EMagazine July 2018 IssueDokument96 SeitenTextile Today EMagazine July 2018 IssueJashim UddinNoch keine Bewertungen

- List of Garment Factory Accidents in Bangladesh 2013-2017Dokument10 SeitenList of Garment Factory Accidents in Bangladesh 2013-2017Jashim UddinNoch keine Bewertungen

- Accord Building Standard DhakaDokument74 SeitenAccord Building Standard DhakaVivek Kumar BhandariNoch keine Bewertungen

- Industrial - Nye LubricantsDokument3 SeitenIndustrial - Nye LubricantsJashim UddinNoch keine Bewertungen

- Lubricants Asia sales report analysisDokument5 SeitenLubricants Asia sales report analysisJashim UddinNoch keine Bewertungen

- REV-1 Gas Turbine OilDokument1 SeiteREV-1 Gas Turbine OilJashim UddinNoch keine Bewertungen

- 70961Dokument1 Seite70961Jashim UddinNoch keine Bewertungen

- Leave Application Form TitleDokument1 SeiteLeave Application Form TitleJashim UddinNoch keine Bewertungen

- Chapter-12: Labor Relations & Collective BargainingDokument20 SeitenChapter-12: Labor Relations & Collective BargainingJashim UddinNoch keine Bewertungen

- GPL 12800 (80) AhDokument1 SeiteGPL 12800 (80) AhismailNoch keine Bewertungen

- Variant ConfigurationDokument62 SeitenVariant ConfigurationAhmed Talaat100% (9)

- Is 4032 - 1985Dokument45 SeitenIs 4032 - 1985yogeshbadyalNoch keine Bewertungen

- Caterpillar Cat 330L EXCAVATOR (Prefix 8FK) Service Repair Manual (8FK00001 and Up)Dokument27 SeitenCaterpillar Cat 330L EXCAVATOR (Prefix 8FK) Service Repair Manual (8FK00001 and Up)kfm8seuuduNoch keine Bewertungen

- Paulson 2007 Year End Report Earns Nearly 600Dokument16 SeitenPaulson 2007 Year End Report Earns Nearly 600Tunaljit ChoudhuryNoch keine Bewertungen

- Graphics Coursework GcseDokument7 SeitenGraphics Coursework Gcseafiwhlkrm100% (2)

- Guidelines Regarding The Handling of Cable Drums During Transport and StorageDokument5 SeitenGuidelines Regarding The Handling of Cable Drums During Transport and StorageJegan SureshNoch keine Bewertungen

- PfizerWorks structure improves efficiencyDokument2 SeitenPfizerWorks structure improves efficiencyDigitizedReaper73% (11)

- Tutorial: Energy Profiles ManagerDokument6 SeitenTutorial: Energy Profiles ManagerDavid Yungan GonzalezNoch keine Bewertungen

- Keystone - Contractors - Book 16 05 12 FinalDokument9 SeitenKeystone - Contractors - Book 16 05 12 Finalfb8120Noch keine Bewertungen

- Nikita Project 01-06-2016Dokument38 SeitenNikita Project 01-06-2016Shobhit GoswamiNoch keine Bewertungen

- Task Based Risk Assesment FormDokument2 SeitenTask Based Risk Assesment FormKolluri SrinivasNoch keine Bewertungen

- Armed Struggle in Africa (1969)Dokument167 SeitenArmed Struggle in Africa (1969)Dr.VolandNoch keine Bewertungen

- Wireshark Lab: 802.11: Approach, 6 Ed., J.F. Kurose and K.W. RossDokument5 SeitenWireshark Lab: 802.11: Approach, 6 Ed., J.F. Kurose and K.W. RossN Azzati LabibahNoch keine Bewertungen

- Proposed Construction of New Kutulo Airstrip - RetenderDokument112 SeitenProposed Construction of New Kutulo Airstrip - RetenderKenyaAirportsNoch keine Bewertungen

- Powder CharacterizationDokument21 SeitenPowder CharacterizationecternalNoch keine Bewertungen

- Manual de Motores Vol 4Dokument75 SeitenManual de Motores Vol 4Gabriel Piñon Conde100% (1)

- Integrated Building Management Platform for Security, Maintenance and Energy EfficiencyDokument8 SeitenIntegrated Building Management Platform for Security, Maintenance and Energy EfficiencyRajesh RajendranNoch keine Bewertungen

- Đề Số 1 - Đề Phát Triển Đề Minh Họa 2023Dokument20 SeitenĐề Số 1 - Đề Phát Triển Đề Minh Họa 2023Maru KoNoch keine Bewertungen

- Schoology App Login DirectionsDokument5 SeitenSchoology App Login Directionsapi-234989244Noch keine Bewertungen

- Asset-V1 RICE+46 6 4010+2021 Q1+type@asset+block@MCQs For HO SDH New WBCS 2nd SM 2nd Class Constitution QDokument5 SeitenAsset-V1 RICE+46 6 4010+2021 Q1+type@asset+block@MCQs For HO SDH New WBCS 2nd SM 2nd Class Constitution QSourin bisalNoch keine Bewertungen

- Lesson 3 - Subtract Two 4-Digit Numbers - More Than One Exchange 2019Dokument2 SeitenLesson 3 - Subtract Two 4-Digit Numbers - More Than One Exchange 2019mNoch keine Bewertungen

- E. Market Size PotentialDokument4 SeitenE. Market Size Potentialmesadaeterjohn.studentNoch keine Bewertungen

- Emmanuel James Oteng, F. Inst. L. Ex. Legal Executive LawyerDokument3 SeitenEmmanuel James Oteng, F. Inst. L. Ex. Legal Executive Lawyeremmanuel otengNoch keine Bewertungen

- POLS219 Lecture Notes 7Dokument7 SeitenPOLS219 Lecture Notes 7Muhammad Zainal AbidinNoch keine Bewertungen

- DB51 BTP 160 8PDokument1 SeiteDB51 BTP 160 8Pnagaraj.ss@quest-global.comNoch keine Bewertungen

- Tabel Condenstatori SMDDokument109 SeitenTabel Condenstatori SMDAllYn090888Noch keine Bewertungen

- Alvarez vs. COMELECDokument5 SeitenAlvarez vs. COMELECvanessa3333333Noch keine Bewertungen

- Laude vs. Ginez-Jabalde (MCLE)Dokument29 SeitenLaude vs. Ginez-Jabalde (MCLE)Justin CebrianNoch keine Bewertungen

- Essential earthquake preparedness stepsDokument6 SeitenEssential earthquake preparedness stepsRalphNacisNoch keine Bewertungen