Beruflich Dokumente

Kultur Dokumente

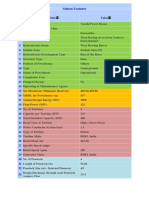

Kel IV Report

Hochgeladen von

AnoopAsokanOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Kel IV Report

Hochgeladen von

AnoopAsokanCopyright:

Verfügbare Formate

Industrial visit report, 2015

KEL, Mamala

CHAPTER 1

KEL, MAMALA

1.1 INTRODUCTION

KEL is one among the largest, most vibrant, and productive Public Sector

Undertaking, and is fully owned by the Government of Kerala. A multi-product engineering

company, consistently catering to an envious client base, ranging from the army and air force

of India to world-renowned space research organizations, highly competent engineering

companies to mammoth institutions likes the Indian Railways. The company with four stateof-the-art manufacturing units spread across Kerala has a pan India presence with marketing

offices in major metros and select cities.

Established in 1964 in the State of Kerala, India, the Kerala Electrical & Allied

Engineering Co.Ltd. (KEL) is a multifaceted company fully owned by the State government.

Through its five production facilities, located in various districts of the State, this ISO 9001:

2000 complaint company provides basic engineering services / products besides executing

projects of national significance for high profile clients like the various defence

establishments.

The company manufactures and markets products like general purpose brushless

alternators, brushless alternators for lighting and air-conditioning of rail coaches, medium

power and distribution transformers as well as structural steel fabrications.The product

categories for defence applications include high frequency alternators, frequency convertors,

special alternators and power packs for missile projects. The power packs designed and

supplied by the company for missile projects like Falcon, Prithvi, Trishul and Akash have

been pioneering efforts. The company has also supplied special alternators to the Army

(Military Power Cars) and Air Force (Radar Applications).

The companys all-India marketing network with regional offices in all metro cities

cater to major institutional clients like the State Electricity Boards, Indian Railways and

various defence establishments besides the general market clients

Dept: Of Mechanical Engineering

Page 1

Industrial visit report, 2015

KEL, Mamala

1.2 STRUCTURAL DIVISION

The Structural Engineering Division of KEL in its Mamala Unit, specializes in the

design, fabrication and commissioning of hydraulic gates and hoists and their controlling

equipment used in dams for power and irrigation projects. Many such projects have been

successfully executed, by this division on a turnkey basis, all over India.

The KEL structural division, with a capacity of 1200 MT per annum undertakes the

design and construction of steel bridges, factory buildings, storage tanks, fabrication of

pressure vessels and other industrial steel structures, as per customer specification. For the

Railways, KEL undertakes the fabrication and manufacture of bogie frames, bogie bolster,

head stocks for railway coaches and wagons.

1.2.1 PRODUCT RANGE

Hydraulic gates, hoists and controlling equipment. Fabrication of structural steel.

Railways bogies, Suspension bridges.

1.2.2 MAJOR PROJECTS UNDERTAKEN

Gerusoppa Dam, Karnataka for Karnataka Power Corp. Ltd.

Hydro-mechanical works Penstock, stoplog gate, gantry crane, hoist

Upper Tunga, Karnataka for Karnataka Neeravari Nigam Ltd.

Radial gates, rope drum hoists, stoplog gate, gantry crane

Mansi Wakal, Udaipur, Rajasthan for ITD Cementation India Ltd.

Radial gates, vertical gates, stoplog gate, hoists

Narmada Project for J P Associates

Dept: Of Mechanical Engineering

Page 2

Industrial visit report, 2015

KEL, Mamala

Slide gates

Bogie frames for BFAT Wagons for BEML

Bogie frames for EMU Coaches for ICF

1.3 TRANSFORMER DIVISION

Fig 1.1 Transformer

The Transformer Division of KEL at Mamala, Ernakulum, was established in 1969,

with the technical assistance of BHEL, to manufacture supreme quality transformers, for

various State Electricity Boards, Government Departments, Public and Private Sector

Companies. This division, ISO 9001 certified by TUV, boasts of a long sustained list of

extremely satisfied clients, many of whom who have stood by KEL, for decades. A fitting

testimony to the trustworthy performer the robust energy efficient transformers of KEL. Over

the years, relying on the unmatched quality of KEL transformers, electricity boards across

India perfectly maintain a healthy power distribution supply system.

Dept: Of Mechanical Engineering

Page 3

Industrial visit report, 2015

KEL, Mamala

The transformer division with an annual production capacity of 6,00,000 kVA soon

after its inception, emerged as a major player in designing and manufacturing Distribution

Transformers of ratings up to 5,000 kVA, 33 kV Class. Manufacturing custom-built

transformers, for specific requirements, is yet another speciality of KEL. The KEL

transformer factory is one of the first few transformer factories in India, to get ISO 9001

Certification. KEL transformers, approved by the national test house, various state electricity

boards and power corporations in the country, are type tested at Central Power Research

Institute, Bangalore

Through in-house R&D efforts, KEL transformers were customized to suit stringent

requirements and trends innovations continue as an on-going process to deliver specific

transformer types and designs of various ratings. In this pursuit of excellence, the resourceful

design department of KEL, uses state-of-the-art software to design world-class transformers,

optimized for maximum reliability, durability, and energy efficiency, compatible to the

standards set by the Bureau of Energy Efficiency (BEE).

Banking on its inherent strength, in technological excellence, and an uncompromising

commitment to quality, the Transformer division of KEL, is all set for substantial growth. By

forgoing new alliances. By exploring new vistas.

1.4 QUALITY SYSTEM

ISO 9001 Quality Management System for design, procurement, manufacturing,

testing, erection, commissioning and servicing of transformers. Certified by TUV.

1.5 PRODUCT RANGE

Distribution Transformers of ratings upto 5,000 kVA, 33 kV class of types such as

oil-filled and resin impregnated dry type; on load tap changing with Automatic Voltage

Regulation.

1.6 DIVISIONS OF KEL

Dept: Of Mechanical Engineering

Page 4

Industrial visit report, 2015

KEL, Mamala

1.6.1 TRANSFORMER DIVISION AT MAMALA UNIT

Distribution Transformers of ratings upto 5000 kVA, 33 kV class of types such as

oil-filled and resin impregnated dry type; on load tap changing with Automatic

Voltage Regulation.

Future-ready Product Range: Resin Cast Dry Type, Special Application Transformers

such as EMU, LOCO, Dynamic Reactive Power Compensation and Furnace

Transformers.

1.6.2 STRUCTURAL ENGINEERING DIVISION AT MAMALA UNIT

Design, fabrication and commissioning of hydraulic gates and hoists and their

controlling equipment.

Design and construction of steel bridges, factory buildings, storage tanks, fabrication

of pressure vessels and other industrial steel structures.

Fabrication and manufacture of bogie frames, bogie bolster, head stocks for railway

coaches and wagons.

1.6.3 TRAIN LIGHTING ALTERNATOR DIVISION AT KUNDARA UNIT

Inductor type brushless alternator for train lighting and air-conditioning -1 kW to 40

Kw with RRU/ERRU

12 kW alternators specially designed for powering Janashatabdi Express Trains of

Indian Railways.

Inductor Type brushless alternator for automobiles and for charging systems in diesel

engines 12 V, 24 V upto 50 A.

High frequency alternator 400 Hz; upto 100 kVA.

Dept: Of Mechanical Engineering

Page 5

Industrial visit report, 2015

KEL, Mamala

Ground power units for starting Avro and Dornier aircrafts and for powering Boeing

aircrafts.

Ground Support units with dual voltage system for starting fighter aircrafts.

DC, AC power frequency and high frequency power pack for missile firing auxiliary

power support.

BLDC Fan

1.6.4 LT SWITCHGEAR DIVISION AT OLAVAKKOD UNIT

Fuse Switches

Changeover Switches

Porcelain Fuse Units and Cutouts

Distribution fuse boards and industrial type switch boards

Distribution Boards (SPN & TPN 2 to 16 ways)

1.7 MACHINES AND EQUIPMENTS

1.7.1 PRESS BREAKER

Dept: Of Mechanical Engineering

Page 6

Industrial visit report, 2015

KEL, Mamala

Fig 1.1 Press breaker

A press brake, also known as a brake press, is a machine tool for bending sheet and

plate material, most commonly sheet metal .It forms predetermined bends by clamping the

work piece between a matching punch and die.

Specification:

Model number: 08 /80 HH

SL NO / year

: 8/2000

Stroke /min

: 300 mm

Main motor HP/RPM: 10/1460

BENDING PROCESS

Typically, two C-frames form the sides of the press brake, connected to a table at the

bottom and on a moveable beam at the top. The bottom tool is mounted on the table with the

top tool mounted on the upper beam.

1.7.2 MILLING MACHINE

Dept: Of Mechanical Engineering

Page 7

Industrial visit report, 2015

KEL, Mamala

Fig 1.2 Milling machine

Milling machines are tools designed to machine metal, wood, and other solid

materials. Often automated, milling machines can be positioned in either vertical or

horizontal orientation to carve out materials based on a pre-existing design. These designs are

often CAD directed, and many milling machines are CNC-operated, although manually and

traditionally-automated milling devices are also common. Milling machines are capable of

dynamic movement, both of the tool and the workpiece, and many milling machines can

perform multi-axis machining. Because of variations in orientation, operation and

application, milling machines have varying functions and different operating principles.

1.7.3 LATHE

A lathe is a machine tool which rotates the workpiece on its axis to perform various

operations such as cutting, sanding, knurling, drilling, or deformation, facing, turning, with

tools that are applied to the workpiece to create an object which has symmetry about an axis

of rotation.

Dept: Of Mechanical Engineering

Page 8

Industrial visit report, 2015

KEL, Mamala

Fig 1.3 Lathe

Lathes are used in woodturning, metalworking, metal spinning, thermal spraying,

parts reclamation, and glass-working. Lathes can be used to shape pottery, the best-known

design being the potter's wheel. Most suitably equipped metalworking lathes can also be used

to produce most solids of revolution, plane surfaces and screw threads or helices. Ornamental

lathes can produce three-dimensional solids of incredible complexity. The workpiece is

usually held in place by either one or two centres, at least one of which can typically be

moved horizontally to accommodate varying workpiece lengths. Other work-holding

methods include clamping the work about the axis of rotation using a chuck or collet, or to

a faceplate, using clamps or dogs. Examples of objects that can be produced on a lathe

include candlestick holders, gun barrels, cue sticks, table legs, bowls, baseball bats, musical

instruments (especially woodwind instruments), crankshafts, and camshafts.

1.7.4 GEAR HOBBING MACHINE

Hobbing is

a machining process

for gear

cutting,

cutting splines,

and

cutting sprockets on a hobbing machine, which is a special type of milling machine. The

teeth or splines are progressively cut into the workpiece by a series of cuts made by a cutting

tool called a hob. Compared to other gear forming processes it is relatively inexpensive but

still quite accurate, thus it is used for a broad range of parts and quantities. It is the most

widely used gear cutting process for creating spur and helical gears and more gears are cut by

hobbing than any other process since it is relatively quick and inexpensive.

Dept: Of Mechanical Engineering

Page 9

Industrial visit report, 2015

KEL, Mamala

Fig 1.4 Gear hobbing machine

Specification:

Type

: FO-10

M/C No : 0421163

Max Dia : 1 m

Cutters

: 3.5 to 10 module

1.7.5 ROLLING MACHINE

Dept: Of Mechanical Engineering

Page 10

Industrial visit report, 2015

KEL, Mamala

Fig 1.5 Rolling machine

A Plate Rolling Machine is a machine that will roll different kind of metal sheet into a

round or conical shape. It can be also called Roll bending machine plate bending

Machine or rolling machine. They are different kinds of Technology to roll the metal

plate:

4 Roller machine: Anatomy; a Top-Roll, the Pinching-Roll, and two Side-Rolls.

The flat metal plate is placed in the machine on either side and "pre-bent" on the same side.

The Side-Rolls do the work of bending. The Pinching Roll holds the plate.

3 Roll Machines (Variable Pitch aka Variable Geometry): Anatomy; One Pressing Top-Roll,

Two Pressing Side-Rolls The 3 Roll Variable Geometry works by having all three rolls being

able to move and tilt. The Top-Roll moves on the vertical plane. The Side-Rolls move on the

horizontal plane.

When rolling, the Top-Roll presses the metal plate between the two Side-Rolls. The

advantage of having the Variable 3 Roll is the ability to roll many thicknesses and diameters

of cylinders. For example; The Side-Rolls are what produce the mechanical advantage. With

the Side-Rolls all the way open, then you have the maximum mechanical advantage. With the

Side-Rolls all the way in, you have the least mechanical advantage.

1.7.6 DRILLING MACHINE

Dept: Of Mechanical Engineering

Page 11

Industrial visit report, 2015

KEL, Mamala

Fig 1.6 Drilling machine

Drilling is a cutting process that uses a drill bit to cut or enlarge a hole of

circular cross-section in solid materials. The drill bit is a rotary cutting tool, often multipoint.

The bit is pressed against the workpiece and rotated at rates from hundreds to thousands

of revolutions per minute. This forces the cutting edge against the workpiece, cutting

off chips (swarf) from the hole as it is drilled. Exceptionally, specially-shaped bits can cut

holes of non-circular cross-section; a square cross-section is possible.

1.7.7 GRINDING MACHINE

A grinding machine, often shortened to grinder, is any of various power tools

or machine tools used for grinding, which is a type of machining using an abrasive wheel as

the cutting tool. Each grain of abrasive on the wheel's surface cuts a small chip from the

workpiece via shear deformation. Grinding is used to finish workpieces that must show high

surface quality (e.g., low surface roughness) and high accuracy of shape and dimension. As

the accuracy in dimensions in grinding is on the order of 0.000025 mm, in most applications

it tends to be a finishing operation and removes comparatively little metal, about 0.25 to 0.50

Dept: Of Mechanical Engineering

Page 12

Industrial visit report, 2015

KEL, Mamala

mm depth. However, there are some roughing applications in which grinding removes high

volumes of metal quite rapidly. Thus, grinding is a diverse field.

The grinding machine consists of a bed with a fixture to guide and hold the work

piece, and a power-driven grinding wheel spinning at the required speed. The speed is

determined by the wheels diameter and manufacturers rating. The grinding head can travel

across a fixed work piece, or the work piece can be moved while the grind head stays in a

fixed position.

Fine control of the grinding head or table position is possible using a Vernier calibrated hand

wheel, or using the features of numerical controls.

Fig 1.7 Grinding machine

Grinding machines remove material from the work piece by abrasion, which can

generate substantial amounts of heat. To cool the work piece so that it does not overheat and

go outside its tolerance, grinding machines incorporate a coolant. The coolant also benefits

the machinist as the heat generated may cause burns. In high-precision grinding machines

(most cylindrical and surface grinders), the final grinding stages are usually set up so that

they remove about 200 nm (less than 1/10000 in) per pass - this generates so little heat that

even with no coolant, the temperature rise is negligible.

1.7.8 SHAPER MACHINE

Dept: Of Mechanical Engineering

Page 13

Industrial visit report, 2015

KEL, Mamala

Fig 1.8 Shaper machine

A shaper is a type of machine tool that uses linear relative motion between the

workpiece and a single-point cutting tool to machine a linear toolpath. Its cut is analogous to

that of a lathe, except that it is (archetypally) linear instead of helical. (Adding axes of

motion can yield helical toolpaths, has also done in helical plaining.) A shaper is analogous to

a planer, but smaller, and with the cutter riding a ram that moves above a stationary

workpiece, rather than the entire workpiece moving beneath the cutter. The ram is moved

back and forth typically by a crank inside the column; hydraulically actuated shapers also

exist.

1.7.9 POWER HACKSAW

Power hacksaws are used to cut large sizes (sections) of metals such as steel. Cutting

diameters of more than 10/15mm is very hard work with a normal hand held hacksaw.

Therefore power hacksaws have been developed to carry out the difficult and time

consuming work. The heavy arm moves backwards and forwards, cutting on the backwards

stroke.

Dept: Of Mechanical Engineering

Page 14

Industrial visit report, 2015

KEL, Mamala

Fig 1.9 Power hacksaw

1.7.10 WELDING

ARC WELDING

Arc welding is a type of welding that uses a welding power supply to create

an electric arc between an electrode and the base material to melt the metals at the welding

point. They can use either direct (DC) or alternating (AC) current, and consumable or nonconsumable electrodes. The welding region is usually protected by some type of shielding

gas, vapour, or slag. Arc welding processes may be manual, semi-automatic, or fully

automated. First developed in the late part of the 19th century, arc welding became

commercially important in shipbuilding during the Second World War. Today it remains an

important process for the fabrication of steel structures and vehicles.

Arc welding is a type of welding that uses a welding power supply to create

an electric arc between an electrode and the base material to melt the metals at the welding

point. They can use either direct (DC) or alternating (AC) current, and consumable or nonconsumable electrodes. The welding region is usually protected by some type of shielding

gas, vapour, or slag. Arc welding processes may be manual, semi-automatic, or fully

automated. First developed in the late part of the 19th century, arc welding became

commercially important in shipbuilding during the Second World War. Today it remains an

important process for the fabrication of steel structures and vehicles.

Dept: Of Mechanical Engineering

Page 15

Industrial visit report, 2015

KEL, Mamala

Fig 1.10 Arc welding

To supply the electrical energy necessary for arc welding processes, a number of

different

power

supplies

can

be

used.

The

most

common

classification

is

constant current power supplies and constant voltage power supplies. In arc welding, the

voltage is directly related to the length of the arc, and the current is related to the amount of

heat input. Constant current power supplies are most often used for manual welding

processes such as gas tungsten arc welding and shielded metal arc welding, because they

maintain a relatively constant current even as the voltage varies. This is important because in

manual welding, it can be difficult to hold the electrode perfectly steady, and as a result, the

arc length and thus voltage tend to fluctuate. Constant voltage power supplies hold the

voltage constant and vary the current, and as a result, are most often used for automated

welding processes such as gas metal arc welding, flux cored arc welding, and submerged arc

welding. In these processes, arc length is kept constant, since any fluctuation in the distance

between the wire and the base material is quickly rectified by a large change in current. For

example, if the wire and the base material get too close, the current will rapidly increase,

which in turn causes the heat to increase and the tip of the wire to melt, returning it to its

original separation distance.

The direction of current used in arc welding also plays an important role in welding.

Consumable electrode processes such as shielded metal arc welding and gas metal arc

welding generally use direct current, but the electrode can be charged either positively or

negatively. In welding, the positively charged anode will have a greater heat concentration

and, as a result, changing the polarity of the electrode has an impact on weld properties. If the

Dept: Of Mechanical Engineering

Page 16

Industrial visit report, 2015

KEL, Mamala

electrode is positively charged, it will melt more quickly, increasing weld penetration and

welding speed. Alternatively, a negatively charged electrode results in more shallow

welds. Non-consumable electrode processes, such as gas tungsten arc welding, can use either

type of direct current (DC), as well as alternating current (AC). With direct current however,

because the electrode only creates the arc and does not provide filler material, a positively

charged electrode causes shallow welds, while a negatively charged electrode makes deeper

welds. Alternating current rapidly moves between these two, resulting in medium-penetration

welds. One disadvantage of AC, the fact that the arc must be re-ignited after every zero

crossing, has been addressed with the invention of special power units that produce a square

wave pattern instead of the normal sine wave, eliminating low-voltage time after the zero

crossings and minimizing the effects of the problem. Duty cycle is a welding equipment

specification which defines the number of minutes, within a 10 minute period, during which

a given arc welder can safely be used. For example, an 80. A welder with a 60% duty cycle

must be "rested" for at least 4 minutes after 6 minutes of continuous welding. Failure to

observe duty cycle limitations could damage the welder. Commercial- or professional-grade

welders typically have a 100% duty cycle.

GAS WELDING

Fig 1.11 Gas welding

Oxy-fuel welding (commonly called oxyacetylene welding, oxy welding, or gas

welding in the U.S.) and oxy-fuel cutting are processes that use fuel gases and oxygen

to weld and cut metals, respectively. French engineers Edmond Fouch and Charles Picard

Dept: Of Mechanical Engineering

Page 17

Industrial visit report, 2015

KEL, Mamala

became the first to develop oxygen-acetylene welding in 1903.[1] Pure oxygen, instead of air,

is used to increase the flame temperature to allow localized melting of the workpiece material

(e.g. steel) in a room environment. A common propane/air flame burns at about 2,000 C

(3,630 F), a propane/oxygen flame burns at about 2,500 C (4,530 F), and an

acetylene/oxygen flame burns at about 3,500 C (6,330 F).

Oxy-fuel is one of the oldest welding processes, besides forge welding. Still used in

industry, in recent decades it has been less widely utilized in industrial applications as other

specifically devised technologies have been adopted. It is still widely used for welding pipes

and tubes, as well as repair work.

In oxy-fuel welding, a welding torch is used to weld metals. Welding metal results

when two pieces are heated to a temperature that produces a shared pool of molten metal.

The molten pool is generally supplied with additional metal called filler. Filler material

depends upon the metals to be welded. In oxy-fuel cutting, a torch is used to heat metal to

its kindling temperature. A stream of oxygen is then trained on the metal, burning it into a

metal oxide that flows out of the kerf as slag. Torches that do not mix fuel with oxygen

(combining, instead, atmospheric air) are not considered oxy-fuel torches and can typically

be identified by a single tank (Oxy-fuel cutting requires two isolated supplies, fuel and

oxygen). Most metals cannot be melted with a single-tank torch.

CONCLUSION

Industrial visit at KEL, Mamala was a very good experience. We got some practical

experience along with theoretical knowledge. We got practical experience on different

machines and equipments in the firm. The systematic arrangement of the various department

in the firm is a noticeable thing. The cooperation of workers within the firm is an appreciable

one.

Dept: Of Mechanical Engineering

Page 18

Das könnte Ihnen auch gefallen

- Pankaj Final Industrial Training Report 1234Dokument36 SeitenPankaj Final Industrial Training Report 1234pankaj madhheshiyaNoch keine Bewertungen

- Runner Casted-Vs-Microguss Wangdi DDokument0 SeitenRunner Casted-Vs-Microguss Wangdi DsapkotamonishNoch keine Bewertungen

- Teachers Manual Diploma Hydropower EngineeringDokument270 SeitenTeachers Manual Diploma Hydropower Engineeringvessel100% (3)

- ChuzaChen Hydroelectric Power ProjectDokument13 SeitenChuzaChen Hydroelectric Power ProjectkanabaramitNoch keine Bewertungen

- Beml Report PDFDokument32 SeitenBeml Report PDFCrazy TamizhaNoch keine Bewertungen

- BP - Wheel Stud ToolDokument4 SeitenBP - Wheel Stud Toolwhmidi7331Noch keine Bewertungen

- Kerala Electricals & Allied Engineering-Organization StudyDokument6 SeitenKerala Electricals & Allied Engineering-Organization StudyDeepak KrishnaNoch keine Bewertungen

- Prajwal Rao K.BDokument44 SeitenPrajwal Rao K.BanthonykulaiNoch keine Bewertungen

- IV Report-Kerala Electrical & Allied Engineering Co. LTD, KollamDokument15 SeitenIV Report-Kerala Electrical & Allied Engineering Co. LTD, KollamJensheer Tp100% (1)

- THDC Summer TrainingDokument20 SeitenTHDC Summer TrainingabhilashNoch keine Bewertungen

- Planning of PykaraDokument4 SeitenPlanning of PykaraPradeep SaxenaNoch keine Bewertungen

- Sluice Gates ExportDokument20 SeitenSluice Gates ExportsaishankarlNoch keine Bewertungen

- Project Report - THDCILDokument36 SeitenProject Report - THDCILMukesh VermaNoch keine Bewertungen

- Internship Presentation by Himanshul Verma (181002)Dokument19 SeitenInternship Presentation by Himanshul Verma (181002)Himanshu Kapoor 008Noch keine Bewertungen

- CVP NewDokument23 SeitenCVP NewBhaskar ReddyNoch keine Bewertungen

- Is 2825 1969Dokument286 SeitenIs 2825 1969DEEPAK KUMAR MALLICKNoch keine Bewertungen

- Sikkim Hydro InitiativesDokument4 SeitenSikkim Hydro InitiativesVishnu VasanthNoch keine Bewertungen

- Salient FeaturesDokument3 SeitenSalient FeaturesAnonymous ESZmDGNoch keine Bewertungen

- DVDF Test SetDokument2 SeitenDVDF Test SetHiren VasaniNoch keine Bewertungen

- TidongDokument162 SeitenTidongSandeep AggarwalNoch keine Bewertungen

- Is 10096-2 (1983)Dokument17 SeitenIs 10096-2 (1983)slamienkaNoch keine Bewertungen

- Final ProjectDokument45 SeitenFinal Projectrahulshandilya2k100% (1)

- Assembly GateDokument1 SeiteAssembly GateSuranga C.DadallageNoch keine Bewertungen

- ET GTU Study Material E-Notes Unit-2 25102019120012PMDokument21 SeitenET GTU Study Material E-Notes Unit-2 25102019120012PMsarvaiya akshayNoch keine Bewertungen

- Portable Water TurbineDokument13 SeitenPortable Water TurbineAbin BrothersNoch keine Bewertungen

- National Institute of Technology, Rourkela Fluid Mechanics and Fluid Machines LaboratoryDokument11 SeitenNational Institute of Technology, Rourkela Fluid Mechanics and Fluid Machines LaboratoryBaishnaba KumbharNoch keine Bewertungen

- Parts of Sprial Casing: Satish 12S/ME145 Mechanical Engineering DepartmentDokument15 SeitenParts of Sprial Casing: Satish 12S/ME145 Mechanical Engineering DepartmentsatishNoch keine Bewertungen

- TENDER SPECIFICATIONS FOR 175t25t FLAMEPROOF EOT CRANEDokument79 SeitenTENDER SPECIFICATIONS FOR 175t25t FLAMEPROOF EOT CRANEsauravNoch keine Bewertungen

- Plant Load FactorDokument5 SeitenPlant Load FactorCh Srikanth ReddyNoch keine Bewertungen

- DVC Summer Training Report PDFDokument29 SeitenDVC Summer Training Report PDFArkadev GhoshNoch keine Bewertungen

- Pelton Turbine - Parts, Working and Design AspectsDokument11 SeitenPelton Turbine - Parts, Working and Design AspectsPrasenjit SahaNoch keine Bewertungen

- Module-VI (Dam Safety and Rehabilation)Dokument256 SeitenModule-VI (Dam Safety and Rehabilation)SANDIP ROYNoch keine Bewertungen

- Disclosure To Promote The Right To InformationDokument180 SeitenDisclosure To Promote The Right To InformationLuisAngelCordovadeSanchezNoch keine Bewertungen

- Jammu and Kashmir State Hydel Policy 2010Dokument25 SeitenJammu and Kashmir State Hydel Policy 2010u2mar100% (1)

- Boving Fouress Hydro TurbineDokument34 SeitenBoving Fouress Hydro TurbineArnab SinhaNoch keine Bewertungen

- 15 - Chapter 4 PDFDokument39 Seiten15 - Chapter 4 PDFNIRANJAN KB100% (1)

- Spec. no.C-9202-R2 - Oct 08Dokument32 SeitenSpec. no.C-9202-R2 - Oct 08Sumit ShyamalNoch keine Bewertungen

- Water Control Gates TrainingDokument132 SeitenWater Control Gates TrainingsaishankarlNoch keine Bewertungen

- Project Report NHPCDokument54 SeitenProject Report NHPCSandeep SinghNoch keine Bewertungen

- Tolerance For FastenersDokument9 SeitenTolerance For FastenersvikasgahlyanNoch keine Bewertungen

- Case Study - Nathpa Jhakri - Oct17 - 1 PDFDokument6 SeitenCase Study - Nathpa Jhakri - Oct17 - 1 PDFAdarsh Kumar ManwalNoch keine Bewertungen

- VSHP090041 Pelton T3341e 72dpiDokument8 SeitenVSHP090041 Pelton T3341e 72dpiJose Fuentes MendezNoch keine Bewertungen

- Single Hoist Crane Inspection Report 02-1008027 - J1607552 - NQC1108 - PDFDokument3 SeitenSingle Hoist Crane Inspection Report 02-1008027 - J1607552 - NQC1108 - PDFAnonymous N2Se0bYNoch keine Bewertungen

- K Lite Products Portfolio 2016 V 0Dokument56 SeitenK Lite Products Portfolio 2016 V 0TarunPatra100% (2)

- Procedimiento de Reparación TurbinaDokument4 SeitenProcedimiento de Reparación Turbinajaime huertasNoch keine Bewertungen

- Design of A Cost Effective Micro Hydro Power Generation System Using The Discharge Water of The Central Steam Power PlantDokument159 SeitenDesign of A Cost Effective Micro Hydro Power Generation System Using The Discharge Water of The Central Steam Power PlantNobel Engzen Du BermoyNoch keine Bewertungen

- 4 - Brochure Francis-TurbinesDokument5 Seiten4 - Brochure Francis-Turbinesmamok supraptoNoch keine Bewertungen

- Final Year Project ReportDokument20 SeitenFinal Year Project ReportAnkit PatelNoch keine Bewertungen

- Industrial Training ReportDokument26 SeitenIndustrial Training ReportDesh DeepakNoch keine Bewertungen

- Design and Analysis of Composite Drive ShaftDokument8 SeitenDesign and Analysis of Composite Drive ShaftInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Hydro Electric Power Plant 1Dokument94 SeitenHydro Electric Power Plant 1firaol temesgenNoch keine Bewertungen

- Is 7326 1 1992Dokument15 SeitenIs 7326 1 1992Chayan BiswasNoch keine Bewertungen

- Maithon PowerDokument8 SeitenMaithon Powerpraful_ingle6490Noch keine Bewertungen

- Hec Project ReportDokument30 SeitenHec Project ReportSudhanshu KumarNoch keine Bewertungen

- Power Calculations For Pelton TurbinesDokument19 SeitenPower Calculations For Pelton TurbinestamailhamNoch keine Bewertungen

- Hinduja National Power Corporation LIMITED (Hinduja Power Plant)Dokument2 SeitenHinduja National Power Corporation LIMITED (Hinduja Power Plant)Anurag AllaNoch keine Bewertungen

- Design and Fabrication of Cross Flow Turbine Ok DisegnoDokument39 SeitenDesign and Fabrication of Cross Flow Turbine Ok DisegnoAdson JuniorNoch keine Bewertungen

- IV report-KERALA ELECTRICAL & ALLIED ENGINEERING CO. LTD, KOLLAMDokument15 SeitenIV report-KERALA ELECTRICAL & ALLIED ENGINEERING CO. LTD, KOLLAMAmmu ChathukulamNoch keine Bewertungen

- Prajwal Rao K.BDokument44 SeitenPrajwal Rao K.BHaroon HaneefNoch keine Bewertungen

- KEL Transformer DivisionDokument2 SeitenKEL Transformer DivisionRishma RamachandranNoch keine Bewertungen

- Indian Electrical Motors LimitedDokument12 SeitenIndian Electrical Motors LimitedPrashant PuriNoch keine Bewertungen

- Costing SheetDokument2 SeitenCosting SheetazadNoch keine Bewertungen

- Simple Shearing and Ploughing Cutting Force Model in Turning Operation With Nose Radius ToolDokument17 SeitenSimple Shearing and Ploughing Cutting Force Model in Turning Operation With Nose Radius ToolKasey ColeNoch keine Bewertungen

- Welders BizHouse - UkDokument3 SeitenWelders BizHouse - UkAlex BekeNoch keine Bewertungen

- Section C Tooling SuppliesDokument50 SeitenSection C Tooling SuppliesalltheloveintheworldNoch keine Bewertungen

- En Ds 20 EnsatsDokument7 SeitenEn Ds 20 Ensatsabelmil123Noch keine Bewertungen

- Syntec Programming v7Dokument125 SeitenSyntec Programming v7Damree EmirNoch keine Bewertungen

- Trip Wire Switches 2014 enDokument16 SeitenTrip Wire Switches 2014 enmamijatoNoch keine Bewertungen

- A Center Punch Is Used To Mark The Centre of A PointDokument4 SeitenA Center Punch Is Used To Mark The Centre of A PointemonNoch keine Bewertungen

- 1.welding Repair ProcdureDokument7 Seiten1.welding Repair Procduresethu1091Noch keine Bewertungen

- AIM: How Did Technological Developments Transform The United States?Dokument4 SeitenAIM: How Did Technological Developments Transform The United States?semamumcuNoch keine Bewertungen

- Pipe FlangesDokument7 SeitenPipe FlangesAli SafdarNoch keine Bewertungen

- Ke ProfileDokument4 SeitenKe Profilekermech21607Noch keine Bewertungen

- MODEL G0727 Vertical/Horizontal Benchtop Mill: Owner'S ManualDokument48 SeitenMODEL G0727 Vertical/Horizontal Benchtop Mill: Owner'S ManualJason BowmanNoch keine Bewertungen

- Self Tapping Screw StandardsDokument4 SeitenSelf Tapping Screw StandardsVino KumarNoch keine Bewertungen

- Catalogo Vespa 250 AbsDokument74 SeitenCatalogo Vespa 250 AbsJohnny Franqueira ArcosNoch keine Bewertungen

- Back To BasicsDokument13 SeitenBack To BasicsBruno SantosNoch keine Bewertungen

- 2.1 Theory of Metal Cutting Q&A For StudentDokument8 Seiten2.1 Theory of Metal Cutting Q&A For Studentnikhilbatham0% (1)

- List of Colt ARDokument39 SeitenList of Colt ARDavidArcherNoch keine Bewertungen

- WP12Dokument154 SeitenWP12cesar100% (1)

- Pro Light 1000Dokument250 SeitenPro Light 1000nightmared02Noch keine Bewertungen

- Wadkin AGS-P Sawbench Manual & Parts ListDokument52 SeitenWadkin AGS-P Sawbench Manual & Parts ListmarkandersonsaNoch keine Bewertungen

- Tap N DieDokument29 SeitenTap N DieMd Rasid SamsuriNoch keine Bewertungen

- V18-1 Tos Varnsdorf PDFDokument3 SeitenV18-1 Tos Varnsdorf PDFskidamdnevnoNoch keine Bewertungen

- Grating Catalogue SCRDokument16 SeitenGrating Catalogue SCRMihai TimofteNoch keine Bewertungen

- Milling Machine Report DelyDokument10 SeitenMilling Machine Report DelyFazdly Azilan0% (2)

- Lathe ManualDokument5 SeitenLathe Manualsaifulislam9442Noch keine Bewertungen

- Manual Coning Tool-BrochureDokument4 SeitenManual Coning Tool-BrochuresreekumarNoch keine Bewertungen

- Kent USA Kls1840n - 2660N ElectricalDokument39 SeitenKent USA Kls1840n - 2660N Electricalchidambaram kasiNoch keine Bewertungen