Beruflich Dokumente

Kultur Dokumente

TEK 1502 Battery Refurbishment

Hochgeladen von

AndrewOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

TEK 1502 Battery Refurbishment

Hochgeladen von

AndrewCopyright:

Verfügbare Formate

TEK 1502 Battery refurbishment

The original cells were 2200mA C NiCd cells.

C cells are now usually 2500mA and 3300mA.

This procedure means that the unit becomes a carrier for replaceable cells and has a

higher capacity than the original unit.

The resulting unit has essentially the same physical dimensions as the original.

1. Waste several hours using all the well known NiCd toasting techniques for

short lived and or partial success.

2. Dismantle old battery.

a. remove fuse

b. remove heat sink/end plate.

c. remove long bolts holding the side plates together. Note the

polarization of these bolts.

d. heat pipe side plates fall off. Clean off the old heat sink compound.

e. clip wires close to end cells.

f. remove cells (save for wasting more time trying to revive them!)

3. Wash side panels in hot water.

4. Dry and wipe inside with acetone. Take care, the plastic is soluble in acetone.

5. Strip 60cm/2ft of silver

plated braid from good

quality inch coax.

6. Flatten the coax and put

a small dab of neoprene

contact adhesive on

each end of the long

pieces and

appropriately on the

shorter, end contact,

pieces.

7. Put a dab of adhesive,

coincident with the braid

ends, on the end plates.

8. attach the braid to the

end plates.

9. Solder the wires from the socket assembly to the appropriate end braid pieces.

Remember to thread the threaded support piece onto the wires. Note the

polarity.

10. Solder the wires from the socket assembly to the appropriate end braid pieces.

Remember to thread the threaded support piece onto the wires. Note the

polarity.

11.Position new cells.

Wrap with a single strap of Kaptan tape.

11. Partially assemble socket end into the inside of the bottom end plate. Note

orientation/polarity of socket. Do not fully tighten bottom two screws. This

eases overall reassembly.

12. Insert threaded end plate into heat sink end

13. Place on other cover plate assembly.

14. Loosely screw the on the socket plate.

15. Attach heat pipe side plate. Note correct orientation.

16. Slide in bolts through the spacers and screw loosely into nuts.

17. Repeat for other side plate.

18. Apply heat sink compound to the end of these components.

19. Position the heat sink.

20. Screw the two screw that go into the plastic side plates. This holds the heat

sink in position for the more entertaining task of screwing the remaining 4

screws through the heat sink and the plastic end plate into the well hidden

threaded end plate.

21. Tighten all the screws.

22. replace the fuse.It should be possible to use a 3A

polyswitch

or a

Quickblow, with a bit of leg

bending. The TEK type parts are very expensive.

23. Give the unit a good equalizing charge at 1.5 A for an hour then 400mA for

24hrs.

The end result and the 6 culprits, including the one that I tried surgery on!

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1091)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Aviation GasolineDokument4 SeitenAviation GasolineAnonymous QM0NLqZONoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- DIGIPRO 1000s REV2.0.pdf Manuel Pancho PDFDokument5 SeitenDIGIPRO 1000s REV2.0.pdf Manuel Pancho PDFJohnny Tenezaca Duarte50% (2)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Norma Sae j328-2005Dokument7 SeitenNorma Sae j328-2005Robert Rockwood100% (1)

- Rate Analysis: SL. No Labour/Material/Others Day Quatity/10m3 Rate Per Amount in RsDokument9 SeitenRate Analysis: SL. No Labour/Material/Others Day Quatity/10m3 Rate Per Amount in Rsmuralidhar munireddyNoch keine Bewertungen

- Ficha Técnica Cat DEO - 15W40 & 10W30Dokument2 SeitenFicha Técnica Cat DEO - 15W40 & 10W30RhuanNoch keine Bewertungen

- Pelton Crane OCM OCR Sterilizer Service ManualDokument8 SeitenPelton Crane OCM OCR Sterilizer Service ManualWilliam Hernandez100% (1)

- A Guide For Flammable and Combustible Liquids: Under The Work Health and Safety Act 2011Dokument18 SeitenA Guide For Flammable and Combustible Liquids: Under The Work Health and Safety Act 2011overlord5555Noch keine Bewertungen

- Convective Heat Transfer Coefficients Table ChartDokument4 SeitenConvective Heat Transfer Coefficients Table Chartmiguel_vera6592Noch keine Bewertungen

- USAID-ICED II - 01 Biomass Potential, Market, Feedstock, Lesson Learnt - 191111Dokument66 SeitenUSAID-ICED II - 01 Biomass Potential, Market, Feedstock, Lesson Learnt - 191111Rais Rijal100% (2)

- Evaluation - Scheme Mechanical Engg.Dokument2 SeitenEvaluation - Scheme Mechanical Engg.Sudhir KushwahaNoch keine Bewertungen

- Hilti HIT-HY 200Dokument39 SeitenHilti HIT-HY 200Silviu SacuiuNoch keine Bewertungen

- Transient PDFDokument3 SeitenTransient PDFmohammed kadhimNoch keine Bewertungen

- Gas Sweetening by AminesDokument31 SeitenGas Sweetening by AminesBrayan MuñozNoch keine Bewertungen

- Valvula Check 6000 Lbsv3xDokument6 SeitenValvula Check 6000 Lbsv3xMaik AmayaNoch keine Bewertungen

- 01b Eval - Us - LetterDokument16 Seiten01b Eval - Us - LetternisannnNoch keine Bewertungen

- Dulevo Brochure 52-En.Dokument4 SeitenDulevo Brochure 52-En.mezzatNoch keine Bewertungen

- Electronics Connectors PDFDokument43 SeitenElectronics Connectors PDFMohammed Jahir Husain0% (1)

- Meurer Parts ListDokument2 SeitenMeurer Parts ListvinayNoch keine Bewertungen

- Instructions For Use: Washing MachineDokument84 SeitenInstructions For Use: Washing MachineeppoxroNoch keine Bewertungen

- Aluminium Prices PDFDokument13 SeitenAluminium Prices PDFvengadeshNoch keine Bewertungen

- C18-Andrew LiewDokument24 SeitenC18-Andrew LiewCheong Wen YuanNoch keine Bewertungen

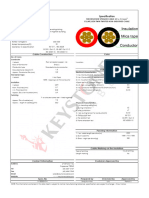

- Keystone Fire Alarm Cables (Twisted Pair Non Sheathed)Dokument3 SeitenKeystone Fire Alarm Cables (Twisted Pair Non Sheathed)Edwin LoquinaNoch keine Bewertungen

- Thermodynamic Stream TrapDokument2 SeitenThermodynamic Stream TrapMohammadAlAmeenNoch keine Bewertungen

- Ariston AML 125 Washer Dryer Manual (ENG)Dokument12 SeitenAriston AML 125 Washer Dryer Manual (ENG)Grant Dickson50% (2)

- Thermodynamics of Humid Air: Markku J. Lampinen Translated by Juho ArjorantaDokument39 SeitenThermodynamics of Humid Air: Markku J. Lampinen Translated by Juho ArjorantaĐoàn TrangNoch keine Bewertungen

- Anexo E Descripcin de Actividades VF PDFDokument100 SeitenAnexo E Descripcin de Actividades VF PDFLeonel IdrogoNoch keine Bewertungen

- Fennis 090302Dokument6 SeitenFennis 090302CIVIL ENGINEERINGNoch keine Bewertungen

- Heat Transfer by ConductionDokument2 SeitenHeat Transfer by ConductionEimAnm0% (1)

- Trends in Powder MetallurgyDokument39 SeitenTrends in Powder MetallurgyManjunath GowdaNoch keine Bewertungen