Beruflich Dokumente

Kultur Dokumente

Matlab-Simulink Controller Design

Hochgeladen von

Mohamed SomaiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Matlab-Simulink Controller Design

Hochgeladen von

Mohamed SomaiCopyright:

Verfügbare Formate

The 2nd Power and Energy Conversion Symposium (PECS 2014)

Melaka, Malaysia

12 May 2014

MATLAB-SIMULINK CONTROLLER DESIGN

FOR ADRUINO TARGET ON AC MOTOR

CONTROL APPLICATION

Shamsul Aizam Zulkifli

Dept. of Electrical Power Engineering

Faculty of Electrical and Electronics Engineering,

Universiti Tun Hussein Onn Malaysia

86400 Parit Raja, Batu Pahat, Johor, Malaysia

Suhairiyanti Mohd Yusof, Ahmad Hussain Hussian, Ahamd Izzat

Mod Arifin, Mohd Saiful Najib Ismail@Marzuki, Wan Ahmad

Khusairi Wan Chek and Faizul Rizal Mohamed Tazudin

Fakulti Kejuruteraan Elektrik

Universiti Teknologi Mara (Terengganu)

Sura Hujung, 23000 Dungun, Terengganu, Malaysia

Simulink library and then downloaded to the Adruino

microcontroller without changing to C programming in order

to see the performance of the Adruino with the inverter in

MATLAB-Simulink based library.

Due to this reason, a simple control method for ac motor

controller is applied to the modern power electronics

devices. As the results, many of researchers have come out

with various controllers in order to control the parameters of

electric motor such as the speed, voltage and current. The

three phase ac motor also known as a non linear

characteristics and for that reason the nonlinear controller is

needed [2]. From the control parameters of the ac motor, the

current input is important in order to determine the

smoothness rotation of the ac motor. This current regulation

is controlled by controlling the pulse-width-modulated

(PWM) that will be developed in the DSP devices [6][7].

The controller that can be applied to ac motor can be

categorized into two, which are the active and passive

controller [3][4][5]. The active controller is a controller that

responded to the reference target such as Field Oriented

Control (FOC), Direct Torque Control (DTC), Proportional

Integral Derivatives (PID), fuzzy control, nueral network,

Sliding Mode Control (SMC), and Hysteresis control. For

the passive control, it is based on the time control system

response.

At the end of this paper, the dual loop controls that is

combined the hyterisis current control with the PID

controller model has been developed in the MATLABSimulink and will be tested in the experimental by using the

Adruino DSP, the 3-phase inverter and the ac motor in order

to see the current response. As a result the performance

characteristics will be observed in terms of output motor line

current, the switching algorithm for the Adruino and the

inverter output voltage.

AbstractThis paper explains, the implementation of

MATLAB-simulink block diagram with the Adruino DSP

target in order to control the output current of the 3-phase

inverter for ac motor application. There is no programming

code has been involved but only uses the target preferences

blocks that are available in the MATLAB-Adruino library.

The current controller has been developed by using the PIDHyterisis control in order to determine the efficiency of the

controller to control the motor current. The system was been

tested on the 1kW inverter output and was connected to the 3

phase induction motor with rating of 375W.

Index TermsMATLAB,

Hyterisis.

Simulink,

Adruino,

PID,

I. INTRODUCTION

As known, ac motor is the widely used education motors

for non electrical engineering student in order to understand

the concepts of moving object from one direction to another

direction. In doing so, the controller device needs to be

developed. It can be developed by combining the

microcontroller or Digital Signal Processing (DSP) device

with the ac motor. The controller must have high switching

frequency or slow switching frequency. As stated, the DSP

is a device that able to generate miliseconds response that is

needed for the 50Hz AC signal. The Adruino, Rasberry PI,

ezdsp TI board or d-space are the examples of the DSP

platform. Generally, the TI ezdsp and d-space are applied

for high level application such as in power system

application or in high precision application while the

Adruino, Rasberry PI, PIC are for low level application.

The advancement and with the new simple structure of

DSPs have attracted more and more non technical expert to

use and applied the Adruino or Rasberry PI

as a

microcontroller. Due to this advantage, it makes the target

such as the Adruino is easy to install and to troubleshoot

when it been applied to the exsisting power converters that

available today.

Today, the Adruino is capable to communicate with the

MATLAB [1] by using the C programming that is based on

the MATLAB software. Until this paper has been written,

the MATLAB-Simulink for Adruino target never been tested

with the power converters devices such as the inverter. Due

to this finding, this paper is focused to test a simple

controller that will be developed using the MATLAB-

THE PROPOSED TOPOLOGY

Figure 1 shows the block diagram of the project. It

consists of 6 main parts which are the DC source input, the

gate driver circuit, the three phase inverter, the 375W three

phase ac motor as a load, the current sensors and the

Adruino target board. The Adruino is used to test the

controller that has been developed in the MATLABSimulink

327

The 2nd Power and Energy Conversion Symposium (PECS 2014)

Melaka, Malaysia

12 May 2014

The 3-phase inverter was designed to produce 1kW

output that can support about 450V input at the DC source.

The inverter is known as voltage source inverter where it is

the standard used inverter nowadays and it is easy to control

[acul]. The gate driver is needed in order to supply a suitable

voltage for the MOSFET for the inverter. It will produce six

PWM signals that are needed by the inverter.

The ac motor that been used in this project, is a three

phase induction motor rating of 0.37kW, 400V, and 1A

input with maximum rotation speed of 1000rpm. As the

input to the Adruino, the current sensor has been used in

order to give current feedback signal from the ac motor back

to the Adruino.

GATE DRIVER

CIRCUIT

DC POWER SUPPLY

THREE PHASE

INDUCTION

MOTOR

THREE PHASE

INVERTER

Figure 2: Hyterisis band

The function of Analog to Digital (ADC) and Digital to

Analog (DAC) that are shown in Figure 3 are used to change

the input signal from the hardware output to the pc digital

input or vice versa. These bloks are available in the MatlabSimulink where the models are embedded in the

microcontroller by using the Arduino target installer.

PWM

PWM

PWM

HYSTERISIS

CURRENT CONTROL

TECHNIQUE

CURRENT SENSOR

Figure 1: The proposed topology

A. Development of the controller sturcture

The hysteresis control is a nonlinear control that able to

control the nonlinear element such as the ac motor with

simple arrangement or lagging behind condition [13] in

order to have past information for future prediction [14].

There is several methods that can be used for ac motor

control such as Direct torque control (DTC), two hyteresis

comparators [15] and uses the triangle signal in the error

block to minimizes the flux and torque ripple of the ac motor

[16].

Figure 3 : Controller design

In this project the hysteresis current controller is used in

order to generate the PWM signal based on Figure 2. This B. The experimental setup

method has been chosen because the robustness of the

controller to adopt with the changing of the input

The hardware or experimental setup was developed as

control.The hyterisis controller has been designed in

shown in Fig. 4. From Fig.4, the three phase induction

MATLAB-Simulink environment as shown in Figure 3. This

motor has been selected as the test load. The main parts of

project also implements outher loop control by using the PID

this experimental setup are the Adruino, the gate driver and

controller in order to improve the performance of the overall

the 3 phase inverter that have been modelled using Proteus

controller. The general equation of PID control is given in

and changes to 2 layer printed circuit board in order to have

Equation 1.

complete experimental setup. Since the PWM output from

the Adruino is 5 V, the gate driver is needed to increase this

( )

( )

( )

( )

(Eq.1)

( )

voltage before been connected to the 3 phase inverter.

328

The 2nd Power and Energy Conversion Symposium (PECS 2014)

Melaka, Malaysia

12 May 2014

the reference current (red). It indicates that the controller that

has been designed capable to track the reference current.

Figure 4: The experimental setup

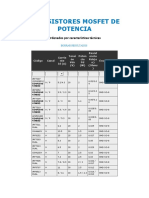

Power Transistor (MOSFET SPP11N60C3) and a capacitor

are act as voltage source inverter or full bridge inverter. It is

where the power transistor is capable to handle the

maximum voltage up to 600V or 1kW output.

Figure 6: Reference and feedback current

Figure 7 shows the three phase output line current at the

inverter. It shows that the lines current are balanced where

the three phases are shifted equally. These line currents are

in sinusoidal waveform due to the low pass filter that has

been used at the inverter output.

II. SIMULATION VERIFICATION

From the simulation analysis, the Power System

Blockset and Simulink models were used in order to study

the characteristics of the inverter output with a dummy load.

Figure 5 shows the complete simulation diagram in

MATLAB. It consists of the inverter with six IGBTs which

are connected to the PWM signals at each of the gate pins.

The PWM signal receives from the PID-hysteresis current

controller. For the simulation purpose, the three phase ac

motor is replaced with the 1 resistor and 5mH inductor.

Figure 7: The output current at the inverter

III. HARDWARE VERIFICATION

As seen from Figure 6, the input signal to the Adruino is

in sinusoidal waveform. Due to this, the output that needs to

be generated from the Adruino is in Sinusoidal Pulse Wave

Modulation (SPWM) signal. Figure 8 shows the SPWM

output after the gate driver circuit. These signals will be used

to switch on and off the power MOSFET inside the inverter

circuit.

Figure 5: The Simulink simulation

The detail of the controller is shown in Figure 3 where

for the simulation analysis the ADC and DAC blocks have

been removed.

Figure 6 shows the response of the feedback current from

the load with the current target reference. From this figure,

it shows that the feedback current (green) is followed with

329

The 2nd Power and Energy Conversion Symposium (PECS 2014)

Melaka, Malaysia

12 May 2014

Figure 10 shows the inverter output current. It

indicates that the current waveform is not in sinusoidal

waveform but the motor is still running smoothly. This

problem has been recognized where it is the wrong selection

of the low pass filter sizing. For the next paper the better

design of low pass filter will be used.

IV. CONCLUSION

As a conclusion, the closed loop system for simulation

and hardware results show the function of the Adruino as a

target DSP is able to read the controller design block that

has been developed in the MATLAB-Simulink environment.

This explains that, with the mathematical equations of any

controllers and without to change to programming code, the

Adruino can still works as DSP platform. This will help the

new players of DSP with less experience in programming to

applied the Adruino microcontroller with the power

converters applications as in teaching non electrical

engineering student.

Figure 8: SPWM switching using Adruino

Figure 9 shows the inverter output phase voltage.

This output is measured at the inverter circuit before the

load. It shows the phase voltage is in the square-wave signal

mode. To get the smooth sine wave filtering process must be

done at the output signal.

REFERENCES

[1]

Mathworks

(MATLAB)

Manual,

www.mathworks.com/hardware-support/arduinomatlab.html, excess on Disember 2013

[2] S. Zulkii and M. Ahmad, Linear generator models in

simulink block,in Power and Energy (PECon), 2010 IEEE

International Conference on,pp. 226 231, 292010-dec.1

2010.

[3] Bong-hwan Kwan ,Tac-woo and Jang-hyoun Youm , A

novel SVM-based hystettsis current controller, LEEE Trans.

Ind. Application, vol. 13,no. 2,pp. 297-307,1998.

[4] B.K.Bose,An adaptive hysteresis-band current controller

technique of a voltage-fed PWM inverter for machine drive

system,EEE Trans. Ind. Application, vol. 37, no. 5, pp.

402408,1990.

[5] C.T.Pan and T.Y.Chang, An improved hysteresis cmnt

controller for reducing switching fi-equency, EEE

Trans.Power Electronic, vol. 9, no. 1, pp. 97-104, 1994.

[6] D.M.Brod and D.W.Novotny, Current control of VSI PWM

inverter, IEEE Trans. Ind. Application, vol. IA-2, no.4,pp.

562-569,1985

[7] S.Nonaka, New GTO Current source inverter with PWM

control techniques, IEEE Trans. Ind. Application, vol.1A-2,

no. 2, pp. 430436, 1986.

[13] Bertotti, Giorgio (1998). Hysteresis in magnetism: For

physicists, materials scientists, and engineers, Academic

Press. ISBN 978-0-12-093270-2.

[14] Mielke, A.; Roubicek, T. (2003). "A Rate-Independent Model

for Inelastic Behavior of Shape-Memory Alloys". Multiscale

Model. Simul. 1 (4): 571597.

[15] J.Rodri, Guezy, J.Pontty, C.Silvay, S.Kouroy, A.Liendoy, J.

Rebolledoy, Hysteresis current control of a vector controlled

induction motor and DTC: an assessment, Int. J. Electronics,

Vol. 91, No. 11, November 2004, 639651

[16] R.K.Behera and S.P.Das, Improved direct torque of

induction motor with dither injection, Sadhana Vol. 33,

Part 5, October 2008, pp. 551564.

Figure 9 : Inverter output voltage

Figure 10: Inverter current output

330

Das könnte Ihnen auch gefallen

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsVon EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsNoch keine Bewertungen

- Single Phase Induction Motor Speed ControlDokument35 SeitenSingle Phase Induction Motor Speed ControlHarshit Sengar100% (2)

- Four - Quadrant Control SystemsDokument4 SeitenFour - Quadrant Control SystemsRICHARDNoch keine Bewertungen

- Real-Time Simulation Technology for Modern Power ElectronicsVon EverandReal-Time Simulation Technology for Modern Power ElectronicsNoch keine Bewertungen

- Paper G Ermie 15-1Dokument45 SeitenPaper G Ermie 15-1abellNoch keine Bewertungen

- Design and Implementation of Water Bill Control System Based GSMDokument5 SeitenDesign and Implementation of Water Bill Control System Based GSMPeter MulengaNoch keine Bewertungen

- Knowledge is "Real Power": Introduction to Power QualityVon EverandKnowledge is "Real Power": Introduction to Power QualityNoch keine Bewertungen

- PLC PF CorrectrDokument22 SeitenPLC PF CorrectrAbhishek Mani50% (2)

- Closed Loop Control For A Brushless DC Motor To RuDokument1 SeiteClosed Loop Control For A Brushless DC Motor To RuscribsunilNoch keine Bewertungen

- 3D Photovoltaic Devices Complete Self-Assessment GuideVon Everand3D Photovoltaic Devices Complete Self-Assessment GuideNoch keine Bewertungen

- Mebre ProposalDokument12 SeitenMebre Proposalmere mezgebeNoch keine Bewertungen

- Unit 4 Power Quality Management in Smart Grid Emc - Electromagnetic CompatibilityDokument18 SeitenUnit 4 Power Quality Management in Smart Grid Emc - Electromagnetic CompatibilityMathumathi TNoch keine Bewertungen

- DC Motor Speed Control Using PWMDokument14 SeitenDC Motor Speed Control Using PWMVincent KorieNoch keine Bewertungen

- Wireless Power Transfer SynopsisDokument3 SeitenWireless Power Transfer Synopsisa d100% (1)

- 3 Phase Cascaded H-Bridge InverterDokument7 Seiten3 Phase Cascaded H-Bridge InverterAnil ShahNoch keine Bewertungen

- Thesis 1Dokument2 SeitenThesis 1Sarwer Hussain FaisalNoch keine Bewertungen

- Fuzzy Logic Control of Three Phase Induction Motor: A ReviewDokument3 SeitenFuzzy Logic Control of Three Phase Induction Motor: A ReviewInternational Journal of Innovative Science and Research Technology100% (1)

- Project Report EngineeringDokument48 SeitenProject Report EngineeringSonu DhangarNoch keine Bewertungen

- Motion Sensors: BY:Abdulaziz Moosa & Peshkaft Hussein Superviced By: JawahirDokument20 SeitenMotion Sensors: BY:Abdulaziz Moosa & Peshkaft Hussein Superviced By: Jawahirabdulazizmoosa93Noch keine Bewertungen

- Project Report 2Dokument28 SeitenProject Report 2akhileshNoch keine Bewertungen

- Module Information Module Title Electric Drives and Control Module Code MMD2511Dokument4 SeitenModule Information Module Title Electric Drives and Control Module Code MMD2511Ashley KaNoch keine Bewertungen

- Speed Control of BLDC Motor For Electric Vehicle: Presented byDokument13 SeitenSpeed Control of BLDC Motor For Electric Vehicle: Presented byPawan Chauhan100% (1)

- Pe SS Final Ex 2010Dokument4 SeitenPe SS Final Ex 2010Saif UddinNoch keine Bewertungen

- Shubham SeminarDokument19 SeitenShubham SeminarShubham BodadeNoch keine Bewertungen

- Slip Power RecoveryDokument12 SeitenSlip Power Recoverysriharidino50% (2)

- Basic Concept For Electrical DesigningDokument2 SeitenBasic Concept For Electrical DesigningJoel RemegioNoch keine Bewertungen

- Questions & Answers On S-Domain AnalysisDokument33 SeitenQuestions & Answers On S-Domain Analysiskibrom atsbhaNoch keine Bewertungen

- Asynchronous ChipsDokument25 SeitenAsynchronous ChipsAbin Varkey Varghese100% (1)

- Lab 6 LCS 078Dokument13 SeitenLab 6 LCS 078Asad saeedNoch keine Bewertungen

- Speed Torque Conventions and Multi Quadrant OperationDokument2 SeitenSpeed Torque Conventions and Multi Quadrant OperationAglet100% (1)

- Simulation & Controlling of Brushless DC Motor Using PI/Fuzzy HybridDokument4 SeitenSimulation & Controlling of Brushless DC Motor Using PI/Fuzzy Hybridsunil kumarNoch keine Bewertungen

- Automatic Control of Street LightDokument63 SeitenAutomatic Control of Street LightMani RaoNoch keine Bewertungen

- Auto Selection of Any Available Phase in 3 Phase Supply SystemDokument2 SeitenAuto Selection of Any Available Phase in 3 Phase Supply Systemjimmie kiluxhNoch keine Bewertungen

- Nptel: High Voltage DC Transmission - Web CourseDokument2 SeitenNptel: High Voltage DC Transmission - Web Coursekmd_venkatsubbu0% (1)

- MTDC System PDFDokument17 SeitenMTDC System PDFAshok Kumar67% (3)

- محمود محمد عبد الفتاح حنفىDokument20 Seitenمحمود محمد عبد الفتاح حنفىMario Abd El NourNoch keine Bewertungen

- Three Phase Fault Analysis With Auto Reset For Temporary Fault and Trip ForDokument16 SeitenThree Phase Fault Analysis With Auto Reset For Temporary Fault and Trip ForFirstLearnNoch keine Bewertungen

- Resonant TransformerDokument15 SeitenResonant TransformerfelogonzaNoch keine Bewertungen

- Power System OperationDokument11 SeitenPower System OperationMATHANKUMAR.SNoch keine Bewertungen

- Control of HVDC Transmission System Based On MMCDokument22 SeitenControl of HVDC Transmission System Based On MMCAnand Parakkat ParambilNoch keine Bewertungen

- Speed Control of Induction Motor by Using IR11Dokument16 SeitenSpeed Control of Induction Motor by Using IR11Anuj TripathiNoch keine Bewertungen

- Electrical Engineering Laboratory V Course Code: Epo662: Simulation of Three-Phase Inverter With A PWM Control EPO662Dokument5 SeitenElectrical Engineering Laboratory V Course Code: Epo662: Simulation of Three-Phase Inverter With A PWM Control EPO662Danial AkramNoch keine Bewertungen

- Solution To Problem 203 Stress-Strain Diagram - Strength of Materials ReviewDokument2 SeitenSolution To Problem 203 Stress-Strain Diagram - Strength of Materials Reviewimrancenakk0% (1)

- Five Phase Brushless DC Machine Direct Drive SysteDokument10 SeitenFive Phase Brushless DC Machine Direct Drive SystePraveen Nayak BhukyaNoch keine Bewertungen

- PID ControllersDokument58 SeitenPID Controllerss12originalNoch keine Bewertungen

- Modeling Transformers With Internal Incipient FaultsDokument18 SeitenModeling Transformers With Internal Incipient FaultsDebajyoti Mishra100% (1)

- Cpe08 Midterm Exam Part 1and 2Dokument4 SeitenCpe08 Midterm Exam Part 1and 2Elle ElleNoch keine Bewertungen

- Speed Control of DC Motor by Various MethodsDokument5 SeitenSpeed Control of DC Motor by Various MethodsVIVA-TECH IJRINoch keine Bewertungen

- PV PQ Bus Switching Power Flow Pscc2008 - 128Dokument7 SeitenPV PQ Bus Switching Power Flow Pscc2008 - 128kcirrenwodNoch keine Bewertungen

- Closed Loop DC Motor Speed ControlDokument3 SeitenClosed Loop DC Motor Speed ControlKhayaz KunhabduNoch keine Bewertungen

- Basic PLC Scada MCQDokument2 SeitenBasic PLC Scada MCQjoshikaustubhp070Noch keine Bewertungen

- Drives Manual Final EeeDokument60 SeitenDrives Manual Final EeenandhakumarmeNoch keine Bewertungen

- Smart Generator Monitoring System in Industry Using MicrocontrollerDokument6 SeitenSmart Generator Monitoring System in Industry Using Microcontrolleryassine moujbaniNoch keine Bewertungen

- 8085 Microprocessor Kit DescriptionDokument51 Seiten8085 Microprocessor Kit DescriptionPrince Blissful100% (1)

- Three Phase Firing Angle Contol Using Arm 7 ProcessorDokument3 SeitenThree Phase Firing Angle Contol Using Arm 7 ProcessorShravan JadhavNoch keine Bewertungen

- Smart Energy MeterDokument16 SeitenSmart Energy Meterjhansi gouravarapuNoch keine Bewertungen

- Speeed ControlDokument3 SeitenSpeeed ControlChristine GomezNoch keine Bewertungen

- TIA Portal PresentationDokument27 SeitenTIA Portal PresentationMohamed SomaiNoch keine Bewertungen

- Memoire Du MR D. ChekimaDokument75 SeitenMemoire Du MR D. ChekimaMohamed SomaiNoch keine Bewertungen

- Control of Pump PairsDokument9 SeitenControl of Pump Pairsketab_doostNoch keine Bewertungen

- Speed Control of Asynchronous Motor Usin PDFDokument12 SeitenSpeed Control of Asynchronous Motor Usin PDFMohamed SomaiNoch keine Bewertungen

- KNX Basics enDokument20 SeitenKNX Basics enAbhijith Sreevalsam100% (2)

- f13 EwjDokument31 Seitenf13 EwjMohamed SomaiNoch keine Bewertungen

- Neural Controller MatlabDokument10 SeitenNeural Controller MatlabNelson Oliveira de Jesus0% (1)

- View PaperDokument5 SeitenView Paperankit1979Noch keine Bewertungen

- Direct Torque Control of Induction Motor Using Artificial Neural NetworkDokument7 SeitenDirect Torque Control of Induction Motor Using Artificial Neural NetworkMohamed SomaiNoch keine Bewertungen

- Matlab Simulink As Simulation Tool For Wind Generation Systems Based On Doubly Fed Induction MachinesDokument22 SeitenMatlab Simulink As Simulation Tool For Wind Generation Systems Based On Doubly Fed Induction MachinesMohamed Somai100% (1)

- Structure Elucidation From XRD 1Dokument34 SeitenStructure Elucidation From XRD 1Meissha Ayu ArdiniNoch keine Bewertungen

- Are Excel BOM Templates Right For YOU?: Want More Info On BOM Management?Dokument20 SeitenAre Excel BOM Templates Right For YOU?: Want More Info On BOM Management?brian santosNoch keine Bewertungen

- Caloritech Technical DataDokument19 SeitenCaloritech Technical Datamoij100% (2)

- CapacitorDokument37 SeitenCapacitorAshok PradhanNoch keine Bewertungen

- A Harmonic Detection For Grid Connected PV Systems Under Non Linear Load Using Cuk ConverterDokument4 SeitenA Harmonic Detection For Grid Connected PV Systems Under Non Linear Load Using Cuk ConverterArivumaniNoch keine Bewertungen

- Trask Mixer MusingsDokument15 SeitenTrask Mixer MusingsFraesenfresseNoch keine Bewertungen

- The Oxidation of Niobium in The Temperature Range 450 176Dokument6 SeitenThe Oxidation of Niobium in The Temperature Range 450 176Ion AlbertoNoch keine Bewertungen

- 70616e Dspic33epxxxmu806810814 and Pic24epxxxgu810814 Data SheetDokument570 Seiten70616e Dspic33epxxxmu806810814 and Pic24epxxxgu810814 Data SheetAndre SantosNoch keine Bewertungen

- DEM 16101 TGH: LCD ModuleDokument12 SeitenDEM 16101 TGH: LCD ModuleZhivko Georgiev TerzievNoch keine Bewertungen

- Airtel Intelligent Power Management Unit (Ipmu)Dokument8 SeitenAirtel Intelligent Power Management Unit (Ipmu)Masaba Denis MadenNoch keine Bewertungen

- 830 Series: Silicon 28V Hyperabrupt Varactor DiodesDokument7 Seiten830 Series: Silicon 28V Hyperabrupt Varactor DiodesBILAL KIYANINoch keine Bewertungen

- Report On Police Siren CircuitDokument7 SeitenReport On Police Siren CircuitVishesh Gupta100% (1)

- SEM TheoryDokument50 SeitenSEM TheoryKamiNoch keine Bewertungen

- Rogowski Coil Transient Performance and Atp Simulation For Aplications in Protective RelaysDokument6 SeitenRogowski Coil Transient Performance and Atp Simulation For Aplications in Protective RelaysJose Alberto RodriguezNoch keine Bewertungen

- Junction Engineering-Based Modeling and Optimization of Deep Junction Silicon Single-Photon Avalanche Diodes For Device ScalingDokument6 SeitenJunction Engineering-Based Modeling and Optimization of Deep Junction Silicon Single-Photon Avalanche Diodes For Device ScalingKFSwNoch keine Bewertungen

- Infinitivo Pasado Y Participio Significado: Regular VerbsDokument3 SeitenInfinitivo Pasado Y Participio Significado: Regular VerbsHenry Patricio PinguilNoch keine Bewertungen

- SuperconductivityDokument16 SeitenSuperconductivityLakshay VohraNoch keine Bewertungen

- Index of Code LockDokument7 SeitenIndex of Code LockChirag MistryNoch keine Bewertungen

- 74F14 Hex Inverter Schmitt Trigger: General DescriptionDokument4 Seiten74F14 Hex Inverter Schmitt Trigger: General DescriptionCarlos PosadaNoch keine Bewertungen

- 3D Integrated Circuits: Technical Seminar ReportDokument31 Seiten3D Integrated Circuits: Technical Seminar ReportRohit ChandranNoch keine Bewertungen

- Parallel Operation of Transformers IIIDokument3 SeitenParallel Operation of Transformers IIIGideon MoyoNoch keine Bewertungen

- Transistores Mosfet de PotenciaDokument15 SeitenTransistores Mosfet de PotenciaLuis SanchezNoch keine Bewertungen

- Circuit Safari HandbookDokument21 SeitenCircuit Safari Handbooky lNoch keine Bewertungen

- Analytical Modeling of Exposure Process in Pinned Photodiode CMOS Image SensorsDokument9 SeitenAnalytical Modeling of Exposure Process in Pinned Photodiode CMOS Image SensorsJackNoch keine Bewertungen

- L26 Microwave DiodesDokument16 SeitenL26 Microwave DiodesAmeya KadamNoch keine Bewertungen

- Docking Entertainment SystemDokument31 SeitenDocking Entertainment SystemJonathan Da SilvaNoch keine Bewertungen

- ELL 100 Introduction To Electrical Engineering: Ecture Perational MplifiersDokument72 SeitenELL 100 Introduction To Electrical Engineering: Ecture Perational Mplifierskurnia setiyawanNoch keine Bewertungen

- Two Resistor Model For Thermal Simulation-EDokument5 SeitenTwo Resistor Model For Thermal Simulation-EILikeScribd5050Noch keine Bewertungen

- SQUELCH CircuitDokument5 SeitenSQUELCH CircuitZaw Khaing WinNoch keine Bewertungen

- Diffusion in SiliconDokument71 SeitenDiffusion in Silicontb770% (1)

- Electronics All-in-One For Dummies, 3rd EditionVon EverandElectronics All-in-One For Dummies, 3rd EditionBewertung: 5 von 5 Sternen5/5 (2)

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialVon EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeVon EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeBewertung: 4.5 von 5 Sternen4.5/5 (9)

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosVon EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosBewertung: 5 von 5 Sternen5/5 (1)

- Analog Design and Simulation Using OrCAD Capture and PSpiceVon EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceNoch keine Bewertungen

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesVon EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesBewertung: 5 von 5 Sternen5/5 (1)

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonVon EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonBewertung: 5 von 5 Sternen5/5 (2)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionVon EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionBewertung: 4.5 von 5 Sternen4.5/5 (543)

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsVon EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsBewertung: 3.5 von 5 Sternen3.5/5 (2)

- Upcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Von EverandUpcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Bewertung: 4.5 von 5 Sternen4.5/5 (2)

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesVon EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesBewertung: 5 von 5 Sternen5/5 (1)

- Wearable Sensors: Fundamentals, Implementation and ApplicationsVon EverandWearable Sensors: Fundamentals, Implementation and ApplicationsEdward SazonovNoch keine Bewertungen

- Current Interruption Transients CalculationVon EverandCurrent Interruption Transients CalculationBewertung: 4 von 5 Sternen4/5 (1)

- Practical Electronics for Inventors, Fourth EditionVon EverandPractical Electronics for Inventors, Fourth EditionBewertung: 4 von 5 Sternen4/5 (3)

- ARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)Von EverandARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)Noch keine Bewertungen

- Build Your Own Electric Vehicle, Third EditionVon EverandBuild Your Own Electric Vehicle, Third EditionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Understanding Automotive Electronics: An Engineering PerspectiveVon EverandUnderstanding Automotive Electronics: An Engineering PerspectiveBewertung: 3.5 von 5 Sternen3.5/5 (16)

- Teach Yourself Electricity and Electronics, 6th EditionVon EverandTeach Yourself Electricity and Electronics, 6th EditionBewertung: 3.5 von 5 Sternen3.5/5 (15)