Beruflich Dokumente

Kultur Dokumente

Air Electricity

Hochgeladen von

NurettinAlpCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Air Electricity

Hochgeladen von

NurettinAlpCopyright:

Verfügbare Formate

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Kurtz GmbH

03.09.02.mz.sme

page 1

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Contents

Demonstration of consumption

Saving potential

Kurtz GmbH

03.09.02.mz.sme

page 2

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Energy- media costs in Germany

Media

Costs

Water

2,81

Electricity

0,1176 /kWh

Gas/oil/electricity

0,0332 /kWh

Steam

23-30

Air

0,0204 /Nm

/m

/t

Kurtz GmbH

03.09.02.mz.sme

page 3

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Distribution of energy costs

11%

4%

7%

58%

20%

Steam

Water

Air

Electricity

Vacuum

Kurtz GmbH

03.09.02.mz.sme

page 4

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Kurtz GmbH

03.09.02.mz.sme

page 5

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Analysis of process steps

1.

2.

3.

4.

Air consumption during filling

Air consumption during drainage

Air consumption during demoulding

Air consumption of control

5. Consumption of the conveying system

(Presentation:

Energy for foam Energy consumption during

pre-expanding, transporting and storage)

Kurtz GmbH

03.09.02.mz.sme

page 6

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Analysis of process steps

Air throughput (m3/h)

Chamber pressure MI (bar)

Chamber pressure MII (bar)

Filling

Ejection

Kurtz GmbH

03.09.02.mz.sme

page 7

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Analysis of process steps

Air throughput (m3/h)

Chamber pressure MI (bar)

Chamber pressure MII (bar)

Filling

Drainage

Ejection

Kurtz GmbH

03.09.02.mz.sme

page 8

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Kurtz GmbH

03.09.02.mz.sme

page 9

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Filling methods

Conventional filling

Pressure filling with closed material tank

Pressure filling with back pressure in the

mould

Filling using a crack (crack filling)

Kurtz GmbH

03.09.02.mz.sme

page 10

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Use of pressure filling

for large series production

with difficult moulding contours

when polyolefine materials are processed

increased air consumption !!!

Simple operation without any problems

Kurtz GmbH

03.09.02.mz.sme

page 11

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Pressure filling steps

1. Pressure increase

the filling pressure is built up in the material pressure tank

2. Filling

Closing piston and material outlet are opened

Material beads are transported into the mould

3. Back-blowing

When the mould is filled, a back presssure is

created at the injector opening

filling air is diverted

material flows back into the tank

Closing piston and material outlet are closed

Kurtz GmbH

03.09.02.mz.sme

page 12

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Pressure filling pressure increase

Mould

Material tank

with

compressed

air

Fill injector

Kurtz GmbH

03.09.02.mz.sme

page 13

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Pressure filling steps

1. Pressure increase

the filling pressure is built up in the material tank

2. Filling

Closing piston and material outlet are opened

Material beads are transported into the mould

3. Back-blowing

When the mould is filled, a back presssure is

created at the injector opening

filling air is diverted

material flows back into the tank

Kurtz GmbH

03.09.02.mz.sme

Closing piston and material outlet are closed

page 14

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Pressure filling - filling

Mould

Materia ltank

with

compressed

air

Fill injector

Kurtz GmbH

03.09.02.mz.sme

page 15

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Pressure filling, steps

1. Pressure increase

the filling pressure is built up in the material tank

2. Filling

Closing piston and material outlet are opened

Material beads are transported into the mould

3. Back-blowing

When the mould is filled, a back pressure is

created at the injector opening

Filling air is diverted

Material flows back into the tank

Closing piston and material outlet are closed

Kurtz GmbH

03.09.02.mz.sme

page 16

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Pressure filling back blowing

Mould

Venting valve at

the pressure fill

device is open

Fill injector

Kurtz GmbH

03.09.02.mz.sme

page 17

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Luft

Consumers:

Injector

Pressure fill tank

Liruft

Air consumption during pressure filling

SAir = VInjector + VTank

Kurtz GmbH

03.09.02.mz.sme

page 18

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Air consumption during pressure filling

Air consumption during filling depends on:

Pressure tank

Filling time

Design of fill injectors

Kurtz GmbH

03.09.02.mz.sme

page 19

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Air quantities with increased tank pressure

0,25

Air quantity [Nm]

0,2

0,15

0,1

0,05

Air quantity

fillers [Nm]

0

0,5

Air quantity

tank [Nm]

0,8

1

Tank pressure [bar]

1,5

Kurtz GmbH

03.09.02.mz.sme

page 20

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Total air consumption with increased tank pressure

0,3

0,29

Air quantity [Nm]

0,28

0,27

0,26

0,25

0,24

0,23

0,22

0,21

0,2

0,5

0,8

1,5

Tank pressure [bar]

With tank pressures over 1 bar increased air consumption!

Kurtz GmbH

03.09.02.mz.sme

page 21

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Air consumption during pressure filling

Air consumption during filling depends on:

Tank pressure

Filling time

Design of fill injectors

Kurtz GmbH

03.09.02.mz.sme

page 22

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Influence of increased tank pressure on filling time

0,3

0,29

6,5

0,28

6

Filling time [s]

0,27

5,5

0,26

0,25

4,5

0,24

0,23

4

0,22

3,5

3

0,50

0,21

0,60

0,70

0,80

0,90

1,00

1,10

1,20

1,30

1,40

Filling [s]

Fllzeit

time [s]

Total air

Luftmenge

quantity

gesamt

[Nm]

0,2

1,50

Tank pressure [bar]

The higher the tank pressure, the faster the filling!

Kurtz GmbH

03.09.02.mz.sme

page 23

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Air consumption during pressure filling

Air consumption during filling depends on:

Tank pressure

Filling time

Design of fill injectors

Kurtz GmbH

03.09.02.mz.sme

page 24

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Selection of fill injectors

Comparison of air throughput

1000

900

800

700

600

Air throughput

[l/min]

500

400

300

200

100

0

Nymphius

Kurtz Standard

Sarga

Kurtz

Schaltdrossel

Filler types

Kurtz GmbH

03.09.02.mz.sme

page 25

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Selection of fill injectors

Comparison of loading:

Materialdurchsatz 100 Liter -Material

Beladung =

[ Liter -Flluft = %]

Luftdurchs atzFller

The transport capacity of filler is considered

Kurtz GmbH

03.09.02.mz.sme

page 26

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Selection of fill injectors

Comparison of loading

12,00

10,00

8,00

Loading

[%]

6,00

4,00

2,00

0,00

Kurtz Standard

Kurtz Schaltdrossel

Nymphius

Sarga

Filler types

Kurtz GmbH

03.09.02.mz.sme

page 27

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Influence of fill injectors

Comparison of filling costs

Filling costs = air costs + machine costs

The factor time is considered!

Kurtz GmbH

03.09.02.mz.sme

page 28

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Selection of fill injectors

Comparison of filling costs

12

10

8

Filling costs

[cent/Zykl]

6

4

2

0

Kurtz Schaltdrossel

Kurtz Standard

Nymphius

Sarga

Filler types

Kurtz GmbH

03.09.02.mz.sme

page 29

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Influence of fill injectors

Influence of fill injector on costs

Injektor

Kurtz Schaltdrossel

Nymphius

Filling

Additional

costs p.a. costs

[]

48.700

0

198.300

149.600

Production facility with 15m moulding area, two-shift operation

Kurtz GmbH

03.09.02.mz.sme

page 30

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Filling costs

The most economic filling process:

Short filling time

High loading

Achievement of required parts quality

Kurtz GmbH

03.09.02.mz.sme

page 31

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

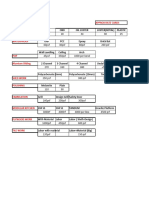

Pressure filling, data

Volume of pressure fill tank

Machine

Quantity Volume VDF

Tot.Vol. VDF,ges

K44-K57

40 l

40 l

K66-K710

60 l

60 l

K810-K813

90 l

90 l

K1013-K1314

90 l

180 l

K1317-K1121

90 l

270 l

Usual standard configuration of pressure fill devices

(configuration may vary accord. to special application and

customer request)

Kurtz GmbH

03.09.02.mz.sme

page 32

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Pressure filling - equipment

better

2 small pressure tanks can be better adapted to variable filling

conditions

Kurtz GmbH

03.09.02.mz.sme

page 33

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Kurtz GmbH

03.09.02.mz.sme

page 34

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Use of drainage

With heavy moulds

With high cooling requirement (large quantity of cooling

water)

For mouldings with low content of residual moisture

Kurtz GmbH

03.09.02.mz.sme

page 35

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Analysis of process steps

Air throughput (m3/h)

Chamber pressure MI (bar)

Chamber pressure MII (bar)

Filling

Drainage

Ejection

Kurtz GmbH

03.09.02.mz.sme

page 36

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Use of Drainage

With heavy moulds

With high cooling requirement (large quantity of cooling

water)

For mouldings with low content of residual moisture

Kurtz GmbH

03.09.02.mz.sme

page 37

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Consists of:

Tansfer air

Demoulding air

Kurtz GmbH

03.09.02.mz.sme

page 38

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Demoulding

Less air requirement with use of

mechanical ejectors

When an automatic handling system

is used the requirement of

demoulding air is reduced

Increased air requirement with AZA

(2x transfer air)

Kurtz GmbH

03.09.02.mz.sme

page 39

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Air requirement for control

The same for all machines (approx. 0.15m/cycle) with min 6 bar

Air for valves (control air)

Air for valves (drives)

This amount of consumption can be neglected. The more so because there is no

saving potential.

Kurtz GmbH

03.09.02.mz.sme

page 40

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Effect of spacer frames

Steam chamber volume K68:

150 l

Extension of volume by 100 mm spacer frame:

48 l

Volume increase in percent:

32%

M1 + M2

Aufbau

Volume increase increased consumption of transfer air, during drainage and for

ejection air

Minimal steam chamber volume omptimum consumption

Kurtz GmbH

03.09.02.mz.sme

page 41

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Check list for planning

Energy Agenda

Air consumption planning stage

RE:

No.

Action required

Proper design of infrastructure

Separate air connections for high and low pressure

Include possible extension steps of plant

Better two small pressure fill tanks than one big one

Done

5

6

Kurtz GmbH

03.09.02.mz.sme

page 42

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Check list produktion

Energy Agenda

Re:

No.

Air consumption - production

Action required

Filling as short as possible, as long as necessary

Use of economic fill injectors

Economic use of transfer air, ejection air and AZA

Automatic handling reduces air requirment during

ejection

Volume of steam chambers as much reduced as

possible (spacer frames, steam chamber reductions)

Done

Kurtz GmbH

03.09.02.mz.sme

page 43

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Check list maintenance

Energy Agenda

Re:

Air consumption - maintenance

No.

Action required

Minimize leakages

Done

2

3

Kurtz GmbH

03.09.02.mz.sme

page 44

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Kurtz GmbH

03.09.02.mz.sme

page 45

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Analysis of electricity consumers

1. Hydraulic plant

2. Vacuum pumps

3. Side channel fans

4. Control

5. Demoulding device

Kurtz GmbH

03.09.02.mz.sme

page 46

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

[k

W]

5,0

Electric power consumption

2,5

Demoulding

Condensation

Autoclave

Cros steam

03.09.02.mz.sme

Purging

Filling

Mould

closing

Kurtz GmbH

Stabilization with vacuum

Time

page 47

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Total power consumption

0,5

p[bar]

P[kWh]

with saver circuit

without saver circuit

0,4

0,3

0,2

0,1

0

0

-0,1

50

100

150

200

250

t[s]

0

300

-1

Kurtz GmbH

03.09.02.mz.sme

page 48

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Power consumption of hydraulic pumps

use of hydraulic drive only with drive movement

without drive movement only basic load

actual consumption approx. 70% of nominal capacity of motor

Kurtz GmbH

03.09.02.mz.sme

page 49

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Design and operation conditions for hydraulic pumps

Hydraulic pump design

Capacity of hydraulic pump depending on number and size of closing cylinders.

(3,0 - 7,5 kw)

Conveying quantity designed, to achieve mould movement speeds of 330mm/s.

Operation pressure selected, to achieve the necessary closing forces at the

mould.

Capacity requirement of the hydraulic pump only depending on physical conditions.

Kurtz GmbH

03.09.02.mz.sme

page 50

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Design and operation conditions for hydraulic pumps

Energy saving potential

Switch off hydraulic pump after locking and switch on

shortly before the step stabilization is finished.

Adaption of hydraulic pressure to required closing forces.

Kurtz GmbH

03.09.02.mz.sme

page 51

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Power consumption of vacuum pumps

Almost constant current consumption over the entire area of use

Kurtz GmbH

03.09.02.mz.sme

page 52

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Design and operation conditions for water ring vacuum pumps

Design vacuum pump

Suction capacity depending on volume of steam chamber

Required suction capacity achieved by number of used standard vacuum pumps

(at present max. 4)

Low saving potential, as continuous operation is required:

Bias of condenser with vacuum

Drainage over vacuum pump

Kurtz GmbH

03.09.02.mz.sme

page 53

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Single vacuum and central vacuum system

Saving potential

Central vacuum system

For production facilities with more than 5-7 machines, depending on size

Single vacuum

Central vacuum

system

One or more pumps at a

machine

Pumps are running

continuously

Central vacuum station with

4 6 pumps

Some pumps are running

continuously

Remaining pumps only if

required

Kurtz GmbH

03.09.02.mz.sme

page 54

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Power consumption of side channel fans

Capacity requirement of side channel fan only during filling of the

material tank.

Nominal capacities of motors 0.75 KW 5.5 KW

Kurtz GmbH

03.09.02.mz.sme

page 55

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Power consumption of control

Capacity requirement of control relatively constant.

Per machine with power consumption < 500 W

Kurtz GmbH

03.09.02.mz.sme

page 56

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Power consumption of demoulding device

Capacity requirement of motors only during drive movements.

Vertical stroke

0,75-1.75 KW

Horizontal stroke 0.5 KW

Stacking table

0.5 KW

Kurtz GmbH

03.09.02.mz.sme

page 57

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Check list for planning

Energy Agenda

Electricity usage planning stage

RE:

No.

Action required

Proper design of infrastruture

Include possible extension steps of plant

Use central vacuum system where possible

Done

4

5

6

Kurtz GmbH

03.09.02.mz.sme

page 58

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Check list production

Energy Agenda

RE:

No.

Electricity usage - production

Action required

Use saver circuit for hydraulic aggregate

Adapt hydraulic pressure to requirements

Shortest possible and most economic use of vacuum

Done

4

5

Kurtz GmbH

03.09.02.mz.sme

page 59

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Check list maintenance

EnergyAgenda

Electricity usage - maintenance

RE:

No.

Action required

Facilitate smooth running of demoulding device with

proper lubrication

Done

2

3

Kurtz GmbH

03.09.02.mz.sme

page 60

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Thank you for your attention !

Kurtz GmbH

03.09.02.mz.sme

page 61

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Pressure filling, data

Amortization

Erlenbach

Nymphius

Sarga

125

250

50

0,00908

0,01760

0,03253

0,55

1,06

1,95

8,72

16,90

31,23

43,60

84,48

156,14

174,40

337,94

624,56

Amortizations time

Behl

Bentzen

Erlenbach

Nymphius

Sarga

Saving purchase

price number hours number days number weeks number months

165

2027,1

126,7

25,3

6,3

190

3808,9

238,1

47,6

11,9

165

1164,6

72,8

14,6

3,6

40

61,3

3,8

0,8

0,2

240

155,0

9,7

1,9

0,5

Kurtz GmbH

03.09.02.mz.sme

page 62

Energy from the Outlet

Air and ElectricityExample

Usage in Shape

air throughput

Moulding Machines

Make

Kurtz

Erlenbach

Heitz

Type

EPS short stroke

MF5 (at one air connect.)

with 42mm dia.

Adjustment

fix

fix

fix

KBM

KBM

Nymphius

Vario short stroke, steps 1-8 step 1-8

long stroke (LS), 200/28/26/16 fix

J18 LS 28 mmdia.

fix

Volume stream

179

380

220

60 - 180

135

130

Kurtz GmbH

03.09.02.mz.sme

page 63

Energy from the Outlet

Air and ElectricityExample

Usage in Shape

drainage

Moulding Machines

Consumption per cycle

V& E

VE = V& E * pmax * t

l

VE = 60 sbar

* 1,5bar * 3s

pmax

VE = 270l

Air throughput approx. 60-90 l/(s *bar)

(60 with K68, 90 with K1014)

Pressure in the air supply

Drainage time 3s

z

Kosten Jahr *sekunde = 0,09 mzs 0,0204 m 288000 Jahr

= 600 Jahr s

Unnecessary drainage costs 600 per year!!!

Kurtz GmbH

03.09.02.mz.sme

page 64

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Example transfer

V = VDK * l * p e

Streaming factor 3 ... 5

VDK

Volume

1

* 0,3bar

V = 150l * 3 bar

V = 135l

of steam

chamber from which

transfer is made

e.g. 150 l at MI side with

K810

Transfer air

pe

Over pressure

approx. 0,3 bar

Kosten Zyklus = 0,135m * 0,0204 m Norm

= 0,003

/ Zyklus

Every cycle costs 0,3 Cent, that is 900/year*

Unnecessary transfer and demoulding air costs 400/year**

Kurtz GmbH

03.09.02.mz.sme

page 65

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Example demoulding

VEntformen = A S * VS,Entformen

VS, Entformen Specific air requirement

during demoulding

approx. 0,5m/m z

= 0,48m * 0,5 mm

AS

= 0,24m

Kosten Zyklus = 0,24m * 0,0204

= 0,5

moulding area

Cent / Zyklus

Every cycle costs 0,5 Cent, that is 1440/year*

Unnecessary transfer and demoulding air costs 400/year

Kurtz GmbH

03.09.02.mz.sme

page 66

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Example demoulding demoulding ejector

Kurtz GmbH

03.09.02.mz.sme

page 67

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Example Kurtz helps you save money

1.

Example:

Efficient filling Comparison of fill injectors of different manufacturers/ Venturi

nozzle design

Comparative calculation to save costs

2.

Example:

Low pressure circuit for ejector air, with comparative calculation

Kurtz GmbH

03.09.02.mz.sme

page 68

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Conversion in normal litres

Conversion of throughput under pressure in throughput in normal litres

V& N = V& 1 pe

V& N

V& 1

Volume steaom in normal litres

Volume stream with pabs

Absolute pressure

= atmospherical pressure +

over pressure

pe

Relative pressure = over

pressure

= absolute pressure

atmospherical pressure

Kurtz GmbH

03.09.02.mz.sme

page 69

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Calculation data / values

Estimate value:

1 m/h compressed air with 7,5 bar over pressure 0,106

kWh

1 l/s compressed air with pe=7,5 bar 0,029 kWh 3,463

10-3

1kWh 0,1176

1Nm air = 0,0204

Kurtz GmbH

03.09.02.mz.sme

1Nm= standard cubicmeter

page 70

Values for Germany

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Leakage costs

Hole diameter

Leakage with 7,3

bar [l/s]

Energy costs

[/a]

131

10

1320

27

3560

10

105

14066

Kurtz GmbH

03.09.02.mz.sme

page 71

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Adjustment values without drainage

Formteil:

Materialtype

Drcke

Gegendruck Fllen I

Behlterdruck Fllen II

Fluidisieren I

Flluftdruck geregelt I

Gegendruck Fllen II

Fluidisieren II

Flluftdruck geregelt II

Behlterdruck bei

Rckblasen

Druckhaltung Fllbehlter

Querdampf Festseite

Querdampf Fahrseite

Autoklav Festseite

Autoklav Fahrseite

Lego

EPS-Mix

[bar]

1,00

6,00

-

Zeiten

Vorblasen/ Druckaufbau

Druckfllen I

Druckfllen II

Fller freiblasen

Fller schlieen

Rckblasen

Dampfverzgerung

[s]

2,00

1,00

0,70

Wege

Eilgang schlieen

Spalt

auf bei AZA

zu bei AZA

Kriechgang ffnen

Auslaventil ffnen

bergabeluft aus

0,80

0,80

1,20

1,20

Splen

Querdampf Festseite

Querdampf Fahrseite

Autoklav

Kondensieren

Khlen dosiert, Festseite

Khlen dosiert, Fahrseite

Entwssern

Stabilisieren mit Vakuum

Kondensator Khlen

bergabeluft vor ffnen

2,00 Auswerfen ein (Entn. Einf.)

3,00 Auswerfluft ein

0,00 Auswerfer Fller ein

4,00 Auswerfluft aus

0,50 ffnungshub Stop

1,50 Entnahme Warteposition

1,50 Entnahme Einfahrposition

- Entnahme Abholposition

20,00

15,00

1,00

Summe (soll)

Summe (ist)

52,20

53,00

[mm]

0,00

-

Kurtz GmbH

03.09.02.mz.sme

page 72

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Adjustment values with drainage

Formteil:

Materialtype

Drcke

Gegendruck Fllen I

Behlterdruck Fllen II

Fluidisieren I

Flluftdruck geregelt I

Gegendruck Fllen II

Fluidisieren II

Flluftdruck geregelt II

Behlterdruck bei

Rckblasen

Druckhaltung Fllbehlter

Querdampf Festseite

Querdampf Fahrseite

Autoklav Festseite

Autoklav Fahrseite

Lego

EPS-Mix

[bar]

1,00

6,00

-

Zeiten

Vorblasen/ Druckaufbau

Druckfllen I

Druckfllen II

Fller freiblasen

Fller schlieen

Rckblasen

Dampfverzgerung

[s]

2,00

1,00

0,70

Wege

Eilgang schlieen

Spalt

auf bei AZA

zu bei AZA

Kriechgang ffnen

Auslaventil ffnen

bergabeluft aus

0,80

0,80

1,20

1,20

Splen

Querdampf Festseite

Querdampf Fahrseite

Autoklav

Kondensieren

Khlen dosiert, Festseite

Khlen dosiert, Fahrseite

Entwssern

Stabilisieren mit Vakuum

Kondensator Khlen

bergabeluft vor ffnen

2,00 Auswerfen ein (Entn. Einf.)

3,00 Auswerfluft ein

0,00 Auswerfer Fller ein

4,00 Auswerfluft aus

0,50 ffnungshub Stop

1,50 Entnahme Warteposition

1,50 Entnahme Einfahrposition

2,00 Entnahme Abholposition

20,00

15,00

1,00

Summe (soll)

Summe (ist)

54,20

55,00

[mm]

0,00

-

Kurtz GmbH

03.09.02.mz.sme

page 73

Energy from the Outlet

Air and Electricity Usage in Shape Moulding Machines

Design diagram hydraulic pump

Kurtz GmbH

03.09.02.mz.sme

page 74

Das könnte Ihnen auch gefallen

- Energy For ProductivityDokument65 SeitenEnergy For ProductivityNurettinAlpNoch keine Bewertungen

- LTH ComparisonDokument35 SeitenLTH ComparisonNurettinAlpNoch keine Bewertungen

- Plant LayoutDokument59 SeitenPlant LayoutNurettinAlpNoch keine Bewertungen

- Block Mold Air and Steam CurrentDokument38 SeitenBlock Mold Air and Steam CurrentNurettinAlpNoch keine Bewertungen

- Steam Consumption Shape MouldingDokument57 SeitenSteam Consumption Shape MouldingNurettinAlp100% (1)

- Energy Consumption PreexpandingDokument80 SeitenEnergy Consumption PreexpandingNurettinAlp100% (1)

- Styropor Processing Guide - Rev3Dokument3 SeitenStyropor Processing Guide - Rev3NurettinAlpNoch keine Bewertungen

- 2500 KW Forced Draft Cooling TowerDokument2 Seiten2500 KW Forced Draft Cooling Towerleojay24Noch keine Bewertungen

- BioEnergy VKKDokument24 SeitenBioEnergy VKKdane05Noch keine Bewertungen

- 2009 Product Catalogue v2Dokument261 Seiten2009 Product Catalogue v2renoyaboNoch keine Bewertungen

- EconomiserDokument19 SeitenEconomiserGaurav KumarNoch keine Bewertungen

- Chimedza W: Boiler Blowdown Heat Recovery ProjectDokument34 SeitenChimedza W: Boiler Blowdown Heat Recovery ProjectBlessed ZiyambeNoch keine Bewertungen

- Vdocuments - MX Boiler Book Cleaver BrooksDokument1.391 SeitenVdocuments - MX Boiler Book Cleaver BrooksTecnico A Lazaro CardenasNoch keine Bewertungen

- Energy Efficiency Upgrades for Sugar Factory BoilersDokument8 SeitenEnergy Efficiency Upgrades for Sugar Factory BoilersTade GaromaNoch keine Bewertungen

- FD Fan Sizing CalculationDokument3 SeitenFD Fan Sizing CalculationkumarananyarupeshNoch keine Bewertungen

- Positioning of Air Cooled CondensersDokument9 SeitenPositioning of Air Cooled CondensersAlexNoch keine Bewertungen

- Final Mini Project ReportDokument30 SeitenFinal Mini Project ReportRatheesh SNoch keine Bewertungen

- 3194 PDF PDFDokument7 Seiten3194 PDF PDFdillipsh123Noch keine Bewertungen

- Jumag Gesamtkatalog enDokument24 SeitenJumag Gesamtkatalog enatisz333Noch keine Bewertungen

- Compact Heatless Air DryersDokument1 SeiteCompact Heatless Air DryersBossman Instruments TechnologyNoch keine Bewertungen

- Design Guide for Air Slide Conveyor SystemsDokument2 SeitenDesign Guide for Air Slide Conveyor SystemsAhmedRizk100% (1)

- p405 01Dokument8 Seitenp405 01Utku KepcenNoch keine Bewertungen

- Khan 2000Dokument18 SeitenKhan 2000HIMANSHU YADAVNoch keine Bewertungen

- Dynamic Model of a Once-Through Steam GeneratorDokument8 SeitenDynamic Model of a Once-Through Steam GeneratorFrancesco CordellaNoch keine Bewertungen

- Generate Power from Waste Heat with Infinity Turbine Organic Rankine Cycle SystemsDokument4 SeitenGenerate Power from Waste Heat with Infinity Turbine Organic Rankine Cycle SystemsDeepali Fulwani Sawanpally0% (1)

- Dci Epe Bladder AccumulatorsDokument43 SeitenDci Epe Bladder AccumulatorsMiguel YudegoNoch keine Bewertungen

- SMP - Boiler Prs Part-R02Dokument41 SeitenSMP - Boiler Prs Part-R02Kathir Siva100% (1)

- Area 1Dokument16 SeitenArea 1Camille LachicaNoch keine Bewertungen

- 1 Clivet Chiller Product Lineup BrochureDokument2 Seiten1 Clivet Chiller Product Lineup BrochureTony NguyenNoch keine Bewertungen

- 1 - Transmittal No. R0051734-CTCDokument7 Seiten1 - Transmittal No. R0051734-CTCNanang Cesc UttaNoch keine Bewertungen

- Formato Stock de MaterialDokument12 SeitenFormato Stock de Materialjaanavic20010Noch keine Bewertungen

- Sample Calculations For PG Test - SCLDokument14 SeitenSample Calculations For PG Test - SCLc s shekarNoch keine Bewertungen

- 880 Series Inverted Bucket Steam TrapsDokument2 Seiten880 Series Inverted Bucket Steam TrapsCherbee FerrerNoch keine Bewertungen

- Pumps and Cooling TowersDokument51 SeitenPumps and Cooling TowersMikho SaligueNoch keine Bewertungen

- MPRA - Paper - 17206 PDFDokument22 SeitenMPRA - Paper - 17206 PDFa.mNoch keine Bewertungen

- Munters GTEC BrochureDokument4 SeitenMunters GTEC BrochureMohamed El ArabiNoch keine Bewertungen

- Oil-X Evolution: High Efficiency Compressed Air FiltersDokument24 SeitenOil-X Evolution: High Efficiency Compressed Air FiltersAdegallasNoch keine Bewertungen

- Thermal Design of Heat ExchangersDokument24 SeitenThermal Design of Heat ExchangersArunNoch keine Bewertungen

- Design of Air IDokument5 SeitenDesign of Air IInvedeNoch keine Bewertungen

- Heat Rate of Thermal Power PlantDokument15 SeitenHeat Rate of Thermal Power Plantsameer betal100% (1)

- Scrubber BasicsDokument5 SeitenScrubber BasicsCarla MontgomeryNoch keine Bewertungen

- Mathematical Procedure For Predicting Tube Metal Temperature in The Second Stage Reheater of The Operating Flexibly Steam BoilerDokument12 SeitenMathematical Procedure For Predicting Tube Metal Temperature in The Second Stage Reheater of The Operating Flexibly Steam BoilerraitoNoch keine Bewertungen

- Refrigeration COP CalculationDokument17 SeitenRefrigeration COP CalculationibrahimNoch keine Bewertungen

- R134a Water Cooled Packaged Water Chillers - Cooling Only - : UWD Series (40HP 120HP)Dokument39 SeitenR134a Water Cooled Packaged Water Chillers - Cooling Only - : UWD Series (40HP 120HP)MarceloRiosNoch keine Bewertungen

- Re-Commissioning Biomass GasifierDokument28 SeitenRe-Commissioning Biomass GasifierAdly Ranggana DityaNoch keine Bewertungen

- 3s Steam BoilerDokument13 Seiten3s Steam BoilertahirNoch keine Bewertungen

- Fan Curves 2 PDFDokument5 SeitenFan Curves 2 PDFdasmechNoch keine Bewertungen

- Boldrocchi Company Presentation 2013pdfDokument45 SeitenBoldrocchi Company Presentation 2013pdfKenny RuizNoch keine Bewertungen

- CH-14 Design Fundamentals of BoilerDokument15 SeitenCH-14 Design Fundamentals of BoilerRavi ShankarNoch keine Bewertungen

- Rightsizing Compressed Air SystemDokument6 SeitenRightsizing Compressed Air SystemRahul ChandrawarNoch keine Bewertungen

- List of Construction Material / CertificatesDokument4 SeitenList of Construction Material / CertificatesHanuman RaoNoch keine Bewertungen

- Gas Turbine Components and Brayton CycleDokument30 SeitenGas Turbine Components and Brayton CycleFaisal KhanNoch keine Bewertungen

- Isentropic Efficiencies of Turbines, Compressors and NozzlesDokument24 SeitenIsentropic Efficiencies of Turbines, Compressors and NozzlesgrandecaciqueNoch keine Bewertungen

- Condensate System PresentationDokument24 SeitenCondensate System Presentationмing junNoch keine Bewertungen

- 1999 - Peaceock - Robust Designs Evaporator Station - 2 PDFDokument14 Seiten1999 - Peaceock - Robust Designs Evaporator Station - 2 PDFnghiNoch keine Bewertungen

- Dls04e 0102Dokument26 SeitenDls04e 0102paulo josé sá patachoNoch keine Bewertungen

- Case Study Compressed AirDokument8 SeitenCase Study Compressed AirDinia Saleh100% (1)

- P 2010 ED tcm16 6752Dokument21 SeitenP 2010 ED tcm16 6752bharatonkarNoch keine Bewertungen

- Reducing Business Jet Carbon Footprint: Using the Power of the Aircraft Electric Taxi SystemVon EverandReducing Business Jet Carbon Footprint: Using the Power of the Aircraft Electric Taxi SystemNoch keine Bewertungen

- Energy Consumption PreexpandingDokument80 SeitenEnergy Consumption PreexpandingNurettinAlp100% (1)

- Styroporproduct OverviewDokument3 SeitenStyroporproduct OverviewNurettinAlpNoch keine Bewertungen

- Styropor Processing Guide - Rev3Dokument3 SeitenStyropor Processing Guide - Rev3NurettinAlpNoch keine Bewertungen

- Styropor Fire SafetyDokument10 SeitenStyropor Fire SafetyNurettinAlpNoch keine Bewertungen

- Technical Leaflet in Neopor (KN Series)Dokument2 SeitenTechnical Leaflet in Neopor (KN Series)NurettinAlpNoch keine Bewertungen

- Styropor MF312 TLDokument2 SeitenStyropor MF312 TLNurettinAlpNoch keine Bewertungen

- Styropor MF312 TLDokument2 SeitenStyropor MF312 TLNurettinAlpNoch keine Bewertungen

- Neopor TMDokument2 SeitenNeopor TMNurettinAlpNoch keine Bewertungen

- Styropor F 15 SeriesDokument2 SeitenStyropor F 15 SeriesNurettinAlp100% (1)

- Styropor MF262 TLDokument2 SeitenStyropor MF262 TLNurettinAlpNoch keine Bewertungen

- Styropor MF312 TLDokument2 SeitenStyropor MF312 TLNurettinAlpNoch keine Bewertungen

- Block - eDokument36 SeitenBlock - eNurettinAlp100% (1)

- Styropor MF162 TLDokument2 SeitenStyropor MF162 TLNurettinAlpNoch keine Bewertungen

- Datasheet PLASBLAK PE4637pdfDokument2 SeitenDatasheet PLASBLAK PE4637pdfGodesPow. Jose L. Godes: Entrenamiento con potenciaNoch keine Bewertungen

- Sodium Carbonate Production from Trona OreDokument17 SeitenSodium Carbonate Production from Trona OreVaanNoch keine Bewertungen

- STA-C Series - Super Trident Sewage Treatment PlantDokument2 SeitenSTA-C Series - Super Trident Sewage Treatment Plantanandsharma123Noch keine Bewertungen

- Rate CardDokument6 SeitenRate CardRavi SrivastavaNoch keine Bewertungen

- Chemistry Unit 3B NotesDokument13 SeitenChemistry Unit 3B NotesShuchi HossainNoch keine Bewertungen

- Astm D 4176 PDFDokument4 SeitenAstm D 4176 PDFAlexander Amado QuinteroNoch keine Bewertungen

- COMPACT 99B Inlet Valve ManualDokument4 SeitenCOMPACT 99B Inlet Valve Manualalwill09Noch keine Bewertungen

- Composition and Stability of Iron and Copper Citrate Complexes in Aqueous SolutionDokument9 SeitenComposition and Stability of Iron and Copper Citrate Complexes in Aqueous SolutionNitinPrachiJainNoch keine Bewertungen

- UV Led TransmittanceDokument6 SeitenUV Led TransmittanceAmandineNoch keine Bewertungen

- XMTC DatasheetDokument4 SeitenXMTC DatasheetSelva RajNoch keine Bewertungen

- Report Gas Adsorption Refrigeration Unit - 2020452596 - Eh2436Dokument7 SeitenReport Gas Adsorption Refrigeration Unit - 2020452596 - Eh2436Nurul Syahida SyafikaNoch keine Bewertungen

- Int Esws at Y9 Workbook Answers TTPPDokument37 SeitenInt Esws at Y9 Workbook Answers TTPPChrystal GraceNoch keine Bewertungen

- AFT ChempakDokument2 SeitenAFT ChempakbtjajadiNoch keine Bewertungen

- Air Pollution Control Technology Fact Sheet: EPA-452/F-03-017Dokument0 SeitenAir Pollution Control Technology Fact Sheet: EPA-452/F-03-017widhisaputrawijayaNoch keine Bewertungen

- Pipe and Fitting ChartDokument12 SeitenPipe and Fitting Chartyulianus_sr100% (2)

- ReasoningDokument43 SeitenReasoningrajkh0786Noch keine Bewertungen

- Indirect RestorationsDokument32 SeitenIndirect RestorationsNaji Z. Arandi100% (1)

- Depth Filter Sheets: BegerowDokument23 SeitenDepth Filter Sheets: BegerowKHUSH PATELNoch keine Bewertungen

- AAMA Vs Qualicoat 2018Dokument12 SeitenAAMA Vs Qualicoat 2018viet nguyen cao0% (1)

- Common polyatomic ions and their formulasDokument16 SeitenCommon polyatomic ions and their formulasskyline aviationNoch keine Bewertungen

- Jess 106Dokument16 SeitenJess 106Tej Krishan SinghNoch keine Bewertungen

- Coaxial Cables: Section VDokument6 SeitenCoaxial Cables: Section VFrancisco CamposNoch keine Bewertungen

- Objectives Identify The Two Main Classes of Vitamins. List Seven Minerals Your Body Needs inDokument28 SeitenObjectives Identify The Two Main Classes of Vitamins. List Seven Minerals Your Body Needs inyosysilalahiNoch keine Bewertungen

- Atex 2 PDFDokument2 SeitenAtex 2 PDFzainahmedscribdNoch keine Bewertungen

- DEP 30.48.00.32-Gen-Feb-2012 Coating of FastenersDokument17 SeitenDEP 30.48.00.32-Gen-Feb-2012 Coating of FastenersDevam RajNoch keine Bewertungen

- Boiler ConstructionDokument56 SeitenBoiler ConstructionRanvir RajNoch keine Bewertungen

- MCQs From CBSE Class 10 Science Chapter 1Dokument59 SeitenMCQs From CBSE Class 10 Science Chapter 1kamal kumarNoch keine Bewertungen

- NF A49-711 Steel Tubes External Polypropylene CoatingDokument40 SeitenNF A49-711 Steel Tubes External Polypropylene CoatingDARYONO sudaryonoNoch keine Bewertungen

- Refining and Petrochemicals CourseworkDokument9 SeitenRefining and Petrochemicals CourseworkMichael GregoryNoch keine Bewertungen

- Lecture 2 - Clinical and Lab Steps - Preliminary Impression-Preliminary Cast (3.03)Dokument42 SeitenLecture 2 - Clinical and Lab Steps - Preliminary Impression-Preliminary Cast (3.03)Ioachim FriedmannNoch keine Bewertungen