Beruflich Dokumente

Kultur Dokumente

10.11 Quality Assurance: Actual

Hochgeladen von

crysOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

10.11 Quality Assurance: Actual

Hochgeladen von

crysCopyright:

Verfügbare Formate

Lesson 10 - Reliability of Welding Filler Metals

1 dari 1

Lesson 1

The Basics of Arc

Welding

http://www.esabna.com/euweb/AWTC/Lesson10_21.htm

LESSON X

10.10.2.4

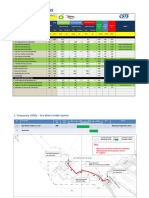

Table 2, referred to in Schedule I above, lists the Required Tests necessary

for actual certification, and in all cases, does not include all tests included in the applicable

Lesson 2

Common Electric

Arc Welding

Processes

Lesson 3

Covered Electrodes

for Welding

Mild Steels

Current

Chapter

Table of

Contents

AWS Filler Metal Specification. When the intensity of testing is not specified on an order,

the product will be tested to ESAB standard testing intensity which equals or exceeds those

tests required under Schedule I above.

10.10.2.5

Go To Test

As an example, stainless steel covered electrodes will only be tested for (1)

chemical analysis and (2) calculated ferrite content as required by the AWS Filler Metal

Procurement Guidelines A5.01-93. Any additional testing must be specified.

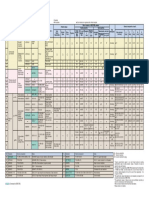

10.11 QUALITY ASSURANCE

Lesson 4

Covered Electrodes

for Welding Low

Alloy Steels

Lesson 5

Welding Filler Metals

for Stainless Steels

Pressure Vessel Code, Section III. This means that the program assures accurate documentation, close control of the raw materials including the steel and flux ingredients,

in-process controls and checks, and complete traceability of each lot of product produced.

It also includes close control of the inspection and measuring equipment which assures

accurate testing and certification of test results.

10.11.0.1

Lesson 6

Carbon & Low Alloy

Steel Filler Metals GMAW,GTAW,SAW

Lesson 7

Flux Cored Arc

Electrodes Carbon

Low Alloy Steels

Glossary

ESAB has based its Quality Assurance Program around NCA 3800 of the ASME Boiler and

Turn Pages

Both the Hanover, Pennsylvania and Ashtabula, Ohio Quality System Programs

have been accepted by the ASME as material manufacturers. This means that customers

using our products for nuclear and other applications to ASME requirements need not audit

our Quality Program. Copies of the ASME Quality System Certificates for both plants are

shown in figures 10 and 11. These certificates are issued only after an in-plant audit by an

ASME representative, and are valid for a three year period.

10.11.0.2

Search

Chapter

(Faster

Download)

In addition, facilities in Hanover, PA; Ashtabula, OH; Niagara Falls, NY; and

Monterrey, Mexico have been certified to ISO 9002. This quality standard was first established in 1987 by the International Organization for Standardization in Geneva, Switzerland.

Lesson 8

Hardsurfacing

Electrodes

Search

Document

(Slower

Download)

Certification to this standard covers all areas of product manufacturing, including general

management, production, research, purchasing, engineering, human resources, and quality

assurance. Receipt of this certificate eliminates the costly time consuming audits normally

required by our customers. Copies of these certificates are shown in figures 12 through 15.

Lesson 9

Estimating &

Comparing Weld

Metal Costs

Lesson 10

Reliability of Welding

Filler Metals

COPYRIGHT 2000 THE ESAB GROUP, INC.

09/12/2013 14:53

Das könnte Ihnen auch gefallen

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideVon Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideBewertung: 3.5 von 5 Sternen3.5/5 (7)

- AWS Cdes Listing PDFDokument14 SeitenAWS Cdes Listing PDFSha Mas Sha100% (1)

- AWS-Welding CodesDokument11 SeitenAWS-Welding CodesPradip Tapan Banerjee100% (2)

- Impact Toughness Deficiencies in ASME SA-350 LF2 Flanges (2017)Dokument10 SeitenImpact Toughness Deficiencies in ASME SA-350 LF2 Flanges (2017)Gopi Selvaraj100% (1)

- Mechanical Requirements for Shoora Aba Dam DesignDokument67 SeitenMechanical Requirements for Shoora Aba Dam DesignMustafa UsalanNoch keine Bewertungen

- High-Strength Low-Alloy Structural Steel Plate With Atmospheric Corrosion ResistanceDokument2 SeitenHigh-Strength Low-Alloy Structural Steel Plate With Atmospheric Corrosion ResistanceGustavo SuarezNoch keine Bewertungen

- A Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersVon EverandA Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersBewertung: 3.5 von 5 Sternen3.5/5 (19)

- API 6A RadiographyDokument4 SeitenAPI 6A RadiographyminakshissawantNoch keine Bewertungen

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesVon EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNoch keine Bewertungen

- Tes-W-109.01-R0-General Welding CriteriaDokument23 SeitenTes-W-109.01-R0-General Welding CriteriaUtkucan KILIÇNoch keine Bewertungen

- Fracture Toughness Requirements For ASME Section VIII Vessels For Temperatures Colder Than 77KDokument6 SeitenFracture Toughness Requirements For ASME Section VIII Vessels For Temperatures Colder Than 77KbiomechanicsNoch keine Bewertungen

- SBI - Certificate To Be Submitted by Pensioner - ChandigarhDokument1 SeiteSBI - Certificate To Be Submitted by Pensioner - ChandigarhMsinghNoch keine Bewertungen

- 4-Week Weight Loss ChallengeDokument6 Seiten4-Week Weight Loss ChallengeTammy JacksonNoch keine Bewertungen

- SS Weld SpecificationDokument39 SeitenSS Weld SpecificationmurugesanNoch keine Bewertungen

- Standards - Application Standards, Codes of Practice and Quality LevelsDokument10 SeitenStandards - Application Standards, Codes of Practice and Quality LevelsMaxwell G SihotangNoch keine Bewertungen

- 6.water Treatment and Make-Up Water SystemDokument18 Seiten6.water Treatment and Make-Up Water Systempepenapao1217100% (1)

- Welder Qualification (ALL CODES)Dokument3 SeitenWelder Qualification (ALL CODES)narutothunderjet216Noch keine Bewertungen

- Cathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesVon EverandCathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesBewertung: 4.5 von 5 Sternen4.5/5 (5)

- Keys To Biblical CounselingDokument7 SeitenKeys To Biblical CounselingDavid Salazar100% (6)

- 72957d3bb1659d7c77dbf6b6c550abeeDokument41 Seiten72957d3bb1659d7c77dbf6b6c550abeerasheedillikkalNoch keine Bewertungen

- Assembling Flanged Joints Procedure1 PDFDokument34 SeitenAssembling Flanged Joints Procedure1 PDFcrysNoch keine Bewertungen

- Chemicals Zetag DATA Powder Magnafloc 351 - 0410Dokument2 SeitenChemicals Zetag DATA Powder Magnafloc 351 - 0410PromagEnviro.comNoch keine Bewertungen

- Sabp A 022Dokument40 SeitenSabp A 022Muhammad Awais100% (3)

- D1 4scopeDokument3 SeitenD1 4scopesunparamarNoch keine Bewertungen

- ASTM A537 Standard SpecificationDokument4 SeitenASTM A537 Standard SpecificationLeon SanchezNoch keine Bewertungen

- Astm A356Dokument6 SeitenAstm A356Srinivasan KrishnamoorthyNoch keine Bewertungen

- Pipeline and Energy Plant Piping: Design and TechnologyVon EverandPipeline and Energy Plant Piping: Design and TechnologyBewertung: 5 von 5 Sternen5/5 (2)

- PT Alphacon's Single V Butt Joint WPSDokument20 SeitenPT Alphacon's Single V Butt Joint WPScrys0% (1)

- A952A952MDokument7 SeitenA952A952MSoumya ChatterjeeNoch keine Bewertungen

- AwsDokument14 SeitenAwssarkararup75% (4)

- Saes L 130Dokument5 SeitenSaes L 130Ahmed Kabel100% (1)

- ITP Installation of Boiler - R1Dokument14 SeitenITP Installation of Boiler - R1crys100% (4)

- Heal Yourself in Ten Minutes AJDokument9 SeitenHeal Yourself in Ten Minutes AJJason Mangrum100% (1)

- Q1, Module 1, Lesson 2Dokument10 SeitenQ1, Module 1, Lesson 2Jerome A. GomezNoch keine Bewertungen

- Electrical Interview Questions & Answers - Hydro Power PlantDokument2 SeitenElectrical Interview Questions & Answers - Hydro Power PlantLaxman Naidu NNoch keine Bewertungen

- Adult Congenital Heart Disease Board ReviewDokument76 SeitenAdult Congenital Heart Disease Board ReviewOQAB13Noch keine Bewertungen

- TVL-SMAW 12 - Week 4 - Lesson 2 - International Welding Codes and StandardsDokument12 SeitenTVL-SMAW 12 - Week 4 - Lesson 2 - International Welding Codes and StandardsNelPalalon100% (1)

- Lesson 10 - 17Dokument1 SeiteLesson 10 - 17crysNoch keine Bewertungen

- A859A859M-04 (Reapproved 2014) PDFDokument5 SeitenA859A859M-04 (Reapproved 2014) PDFHadi HowaidaNoch keine Bewertungen

- Steel Castings, Ferritic and Martensitic, For Pressure-Containing Parts, Suitable For Low-Temperature ServiceDokument5 SeitenSteel Castings, Ferritic and Martensitic, For Pressure-Containing Parts, Suitable For Low-Temperature Servicethiagorep17Noch keine Bewertungen

- Age-Hardening Alloy Steel Forgings For Pressure Vessel ComponentsDokument10 SeitenAge-Hardening Alloy Steel Forgings For Pressure Vessel ComponentsDhanush NairNoch keine Bewertungen

- Astm A992Dokument2 SeitenAstm A992MUHAMEDNoch keine Bewertungen

- Astm F 519-97 E98Dokument12 SeitenAstm F 519-97 E98Jorge ToribioNoch keine Bewertungen

- Forged Carbon and Alloy Steel Flanges For Low-Temperature ServiceDokument5 SeitenForged Carbon and Alloy Steel Flanges For Low-Temperature ServiceJosé Ramón GutierrezNoch keine Bewertungen

- A 105 - A 105M - 02 Qtewns9bmta1ts1sruq - PDFDokument7 SeitenA 105 - A 105M - 02 Qtewns9bmta1ts1sruq - PDFXuân Giang NguyễnNoch keine Bewertungen

- Forged Carbon and Alloy Steel Flanges For Low-Temperature ServiceDokument5 SeitenForged Carbon and Alloy Steel Flanges For Low-Temperature Servicegaso99Noch keine Bewertungen

- Simbolizare Sarme de SuduraDokument4 SeitenSimbolizare Sarme de SuduraTeodor EzaruNoch keine Bewertungen

- A 826 - A826m - 95 Qtgyni05nqDokument5 SeitenA 826 - A826m - 95 Qtgyni05nqsachinguptachdNoch keine Bewertungen

- Astm A1026 - 1 (En)Dokument2 SeitenAstm A1026 - 1 (En)svvasin2013Noch keine Bewertungen

- Soundness of Welds in Steel by Comparison To Graded Astm Reference RadiographsDokument3 SeitenSoundness of Welds in Steel by Comparison To Graded Astm Reference RadiographsVivi VargasNoch keine Bewertungen

- Piping Fittings of Wrought Carbon Steel and Alloy Steel For Moderate and High Temperature ServiceDokument8 SeitenPiping Fittings of Wrought Carbon Steel and Alloy Steel For Moderate and High Temperature ServiceSriniramu SriniramuNoch keine Bewertungen

- Materials System SpecificationDokument13 SeitenMaterials System SpecificationMoustafa Bayoumi100% (1)

- Piping Components Spec for Low Temp ServiceDokument6 SeitenPiping Components Spec for Low Temp ServiceFlorante NoblezaNoch keine Bewertungen

- PP 2006 03Dokument4 SeitenPP 2006 03Born ToSinNoch keine Bewertungen

- G0146 01Dokument8 SeitenG0146 01wellbeingempireNoch keine Bewertungen

- Appendix A. Weld Metal / Welding Procedure Specification Toughness Verification TestDokument2 SeitenAppendix A. Weld Metal / Welding Procedure Specification Toughness Verification TestRicardoNoch keine Bewertungen

- A227A227M Mechanical SpringDokument4 SeitenA227A227M Mechanical Springecaph244Noch keine Bewertungen

- Astm A105 - 05Dokument5 SeitenAstm A105 - 05Stéphane LevasseurNoch keine Bewertungen

- Astm A965x 2021aDokument7 SeitenAstm A965x 2021aamitNoch keine Bewertungen

- ASTM B 368 Camara CassDokument5 SeitenASTM B 368 Camara CassIvan MontenegroNoch keine Bewertungen

- Astm A877.a877mDokument5 SeitenAstm A877.a877mOS Laboratory100% (1)

- A105-2010 Flange ACDokument5 SeitenA105-2010 Flange ACbmalbertNoch keine Bewertungen

- ASTM-A234-A234M-23_unlockedDokument7 SeitenASTM-A234-A234M-23_unlockedrashid isaarNoch keine Bewertungen

- Ecfn Aus Ci 0100 Spe 01006 (C PDF)Dokument9 SeitenEcfn Aus Ci 0100 Spe 01006 (C PDF)Janeth MeraNoch keine Bewertungen

- BOON ASME IX NOTESDokument31 SeitenBOON ASME IX NOTESPRAVEENNoch keine Bewertungen

- Materials System SpecificationDokument6 SeitenMaterials System SpecificationAwais CheemaNoch keine Bewertungen

- A266A266M-13 Standard Specification For Carbon Steel Forgings For Pressure Vessel Components PDFDokument5 SeitenA266A266M-13 Standard Specification For Carbon Steel Forgings For Pressure Vessel Components PDFManuel Antonio Santos VargasNoch keine Bewertungen

- Alloy 52MDokument11 SeitenAlloy 52Mharan2000Noch keine Bewertungen

- Saes L 131Dokument10 SeitenSaes L 131samsurendran_mech4020Noch keine Bewertungen

- API577 IDC Weld Inspect Aug15 PDFDokument7 SeitenAPI577 IDC Weld Inspect Aug15 PDFMohamad AzuwanNoch keine Bewertungen

- Hot Isostatically-Pressed Alloy Steel Flanges, Fittings, Valves, and Parts For High Temperature ServiceDokument8 SeitenHot Isostatically-Pressed Alloy Steel Flanges, Fittings, Valves, and Parts For High Temperature ServiceDarwin DarmawanNoch keine Bewertungen

- Pt. Intan Anugrah PersadaDokument1 SeitePt. Intan Anugrah PersadacrysNoch keine Bewertungen

- Pt. Intan Anugrah Persada: Void VoidDokument1 SeitePt. Intan Anugrah Persada: Void VoidcrysNoch keine Bewertungen

- Pt. Intan Anugrah PersadaDokument1 SeitePt. Intan Anugrah PersadacrysNoch keine Bewertungen

- Sdb-Atap Tower A Db-Fire Atap Tower A Pp-Lift.2A Pp-Lift.1A: Pt. Intan Anugrah PersadaDokument1 SeiteSdb-Atap Tower A Db-Fire Atap Tower A Pp-Lift.2A Pp-Lift.1A: Pt. Intan Anugrah PersadacrysNoch keine Bewertungen

- Pt. Intan Anugrah PersadaDokument1 SeitePt. Intan Anugrah PersadacrysNoch keine Bewertungen

- Installation of Stop Contact, Cable Tray and Panel Location on Level 3 & 5Dokument1 SeiteInstallation of Stop Contact, Cable Tray and Panel Location on Level 3 & 5crysNoch keine Bewertungen

- 328 PDFDokument1 Seite328 PDFcrysNoch keine Bewertungen

- Sound system installation plans for Treepark City CikokolDokument1 SeiteSound system installation plans for Treepark City CikokolcrysNoch keine Bewertungen

- Vac 110 PDFDokument1 SeiteVac 110 PDFcrysNoch keine Bewertungen

- Cipta Sukses, PT.: Pt. Intan Anugrah PersadaDokument1 SeiteCipta Sukses, PT.: Pt. Intan Anugrah PersadacrysNoch keine Bewertungen

- Summary Progress & Status Piping Work-Cut of Date 16 Des 2017Dokument16 SeitenSummary Progress & Status Piping Work-Cut of Date 16 Des 2017crysNoch keine Bewertungen

- Vac 112 PDFDokument1 SeiteVac 112 PDFcrysNoch keine Bewertungen

- Vac 105 PDFDokument1 SeiteVac 105 PDFcrysNoch keine Bewertungen

- Vac 113 PDFDokument1 SeiteVac 113 PDFcrysNoch keine Bewertungen

- PASCAL Check Valves CatalogueDokument19 SeitenPASCAL Check Valves Cataloguecrys100% (1)

- Lift Dan Gondola 06-11-2015Dokument8 SeitenLift Dan Gondola 06-11-2015crysNoch keine Bewertungen

- RFCC T PJ GS 0900 Project Quality Plan (B)Dokument44 SeitenRFCC T PJ GS 0900 Project Quality Plan (B)crysNoch keine Bewertungen

- Indonesia LNGDokument22 SeitenIndonesia LNGcrys100% (1)

- Asme31 3Dokument1 SeiteAsme31 3crysNoch keine Bewertungen

- Spark Arrestor Safety GuideDokument6 SeitenSpark Arrestor Safety GuidecrysNoch keine Bewertungen

- CV FreasmanDokument2 SeitenCV FreasmancrysNoch keine Bewertungen

- RFCC-T-PJ-GS-0900 Project Quality Plan (B) PDFDokument23 SeitenRFCC-T-PJ-GS-0900 Project Quality Plan (B) PDFcrysNoch keine Bewertungen

- Clarification 17Dokument1 SeiteClarification 17crysNoch keine Bewertungen

- GENERATOR SET CSTS INSTALLATION STATUS AND PROGRESS REPORTDokument1 SeiteGENERATOR SET CSTS INSTALLATION STATUS AND PROGRESS REPORTcrysNoch keine Bewertungen

- Spec PDFDokument1 SeiteSpec PDFcrysNoch keine Bewertungen

- Aluminium Valve FinalDokument5 SeitenAluminium Valve FinalcrysNoch keine Bewertungen

- PTA Resolution for Donation to School WashroomDokument2 SeitenPTA Resolution for Donation to School WashroomMara Ciela CajalneNoch keine Bewertungen

- Honda PCX150Dokument137 SeitenHonda PCX150Akchu KadNoch keine Bewertungen

- Health Programs Activities Timeframe Expected Output Child CareDokument3 SeitenHealth Programs Activities Timeframe Expected Output Child CareC SamNoch keine Bewertungen

- Batson Et All - 2007 - Anger and Unfairness - Is It Moral Outrage?Dokument15 SeitenBatson Et All - 2007 - Anger and Unfairness - Is It Moral Outrage?Julia GonzalezNoch keine Bewertungen

- Lesson 8 - Philippine Disaster Risk Reduction and Management SystemDokument11 SeitenLesson 8 - Philippine Disaster Risk Reduction and Management SystemMary Joy CuetoNoch keine Bewertungen

- SmithfieldDokument11 SeitenSmithfieldandreea143Noch keine Bewertungen

- Atomic and Molecular PhysicsDokument28 SeitenAtomic and Molecular PhysicsAvinash GuptaNoch keine Bewertungen

- The Role of Play Therapists in Children's Transitions: From Residential Care To Foster CareDokument11 SeitenThe Role of Play Therapists in Children's Transitions: From Residential Care To Foster Caresherry_hoang_1Noch keine Bewertungen

- Treating Thyroid Emergencies: Myxedema Coma and Thyroid StormDokument17 SeitenTreating Thyroid Emergencies: Myxedema Coma and Thyroid StormMarlon UlloaNoch keine Bewertungen

- VERALLIA WHITE-BOOK EN March2022 PDFDokument48 SeitenVERALLIA WHITE-BOOK EN March2022 PDFEugenio94Noch keine Bewertungen

- Requirement & Other Requirement: 2.311 Procedure For Accessing Applicable LegalDokument2 SeitenRequirement & Other Requirement: 2.311 Procedure For Accessing Applicable Legalkirandevi1981Noch keine Bewertungen

- Rice Research: Open Access: Black Rice Cultivation and Forming Practices: Success Story of Indian FarmersDokument2 SeitenRice Research: Open Access: Black Rice Cultivation and Forming Practices: Success Story of Indian Farmersapi-420356823Noch keine Bewertungen

- Bespoke Fabrication Systems for Unique Site SolutionsDokument13 SeitenBespoke Fabrication Systems for Unique Site Solutionswish uNoch keine Bewertungen

- Generate Profits from Bottled Water Using Atmospheric Water GeneratorsDokument20 SeitenGenerate Profits from Bottled Water Using Atmospheric Water GeneratorsJose AndradeNoch keine Bewertungen

- Climate Change and Global Warming and Its Impact On BangladeshDokument7 SeitenClimate Change and Global Warming and Its Impact On BangladeshAminulHoqueNoch keine Bewertungen

- Environmental Science OEdDokument9 SeitenEnvironmental Science OEdGenevieve AlcantaraNoch keine Bewertungen

- 2022 TESAS PublicationDokument103 Seiten2022 TESAS PublicationNathan LakaNoch keine Bewertungen

- Smart Goals ExerciseDokument2 SeitenSmart Goals Exerciseapi-594661640Noch keine Bewertungen

- CWK-IDD-009-CC-2020: Reference Checking Consent and Authorization Form Candidate's Full NameDokument1 SeiteCWK-IDD-009-CC-2020: Reference Checking Consent and Authorization Form Candidate's Full NamePopa Alina-ManuelaNoch keine Bewertungen

- CV Dang Hoang Du - 2021Dokument7 SeitenCV Dang Hoang Du - 2021Tran Khanh VuNoch keine Bewertungen

- Schneider - Cptg010 en (Print)Dokument16 SeitenSchneider - Cptg010 en (Print)el_koptan00857693Noch keine Bewertungen

- Fischer FBN II BoltDokument5 SeitenFischer FBN II BoltJaga NathNoch keine Bewertungen