Beruflich Dokumente

Kultur Dokumente

AK-GK P GB

Hochgeladen von

Miguel OrhlOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

AK-GK P GB

Hochgeladen von

Miguel OrhlCopyright:

Verfügbare Formate

HAUG Ionization

for the elimination

of electrostatic

charges

HAUG ionizing systems

serve to neutralize electrostatic charges. These disruptive

charges can be found on various material webs, where they

interfere with the production process and attract dust particles

as well as other quality-reducing substances.

For more than 45 years HAUG has been researching,

developing and producing devices aimed at overcoming this

problem. This concerns all industries which are processing

materials with poor electrical conductibility.

The Air Knife

belongs to the group of air gates. As the name already

indicates, these are ionizers which are supported by air flows.

The effectiveness of the Air Knife can be explained by the

special design of the air discharge nozzle which creates the

so-called "Coanda effect".

AK GK

Applications

Plastic processing industry:

Film processing, packaging machines, sheet extruders, etc.

Textile industry:

Weaving and spinning mills, textile finishing, etc.

Graphics industry:

Screen and pad printing machines, photo and film

processing machines, folding machines, etc.

Paint shops:

Car painting, painting of plastic components, etc.

HAUG Ionizing Systems

consist of the following components: a power pack which

supplies the ionizer by means of a high-voltage transformer with

7 to 8 kV. The various ionizers are connected to the power

pack.

ill. 3

24 33

The Coanda effect

In contrast to full jet nozzles (ill.1), with the Coanda effect the

ionized air comes out of a slotted nozzle producing a flat jet.

The special construction of the bottom-side of the Air Knife

causes an unilateral reduction in injection (air suction from the

atmosphere), thus creating negative pressure so that the

ionized air is directed to the material web.

ill. 1

ill. 2

Air flow without deflection

due to uniform injection

The Coanda effect

Air flow with deflection

Slotted nozzle

Injection

Top

Deflection

Vacuum

Air flow

Possible Air Knife configurations

Air Knife

+ Multistat power pack

(for all-electronic production monitoring)

+ EI VS ionizing bar

(specifically for high-speed machines)

or

Air Knife

+ EN 8 power pack

(standard)

+ EI RN ionizing bar

(standard)

Ionizing bar

Ionized air flow

Special features and advantages

Reducing the injection affords the air blast operated Air Knife

ionization unit two particularly positive aspects:

The air discharge speed is increased, resulting in increased

effective depth. This in turn permits a greater operating

distance of the Air Knife to the material web.

The slot jet has a wider angle of dispersion (ill. 3), which is

expanded from 24 to 33. A larger surface is therefore

covered with ionizing, neutralizing air.

HAUG GmbH & Co. KG

Friedrich-List-Str. 18

D-70771 Leinf.-Echterdingen

Phone: +49 711 / 94 98-0

Telefax: +49 711 / 94 98-298

HAUG Biel AG

Johann-Renfer-Str. 60

CH-2500 Biel-Bienne 6

Phone: +41 32 / 344 96 96

Telefax: +41 32 / 344 96 97

Germany

www.haug.de

E-mail: info@haug.de

Switzerland

www.haug-ionisation.com

E-mail: info@haug-biel.ch

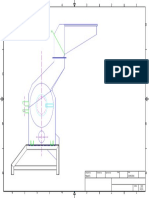

Technical data Air Knife

Type:

AK GK

Order-No: 04.0000.000

Basic unit for one ionizing bar

Dimensions:

72 x 35 mm

Lengths:

120 3000 mm

Nozzles:

Slotted nozzle

Operating temperature: +5 C to +50 C

Storage/transport temperature:

-15 C to +60 C

Smallest bending radius (cable): R 50

Subject to technical changes!

Accessories

Air hose

up to 500 mm total length AK GK

from 501 mm total length AK GK

Order-No.: X-6616

Order-No.: X-6617

A -A

72 1

10

35

Internal thread M 6

57

12

Direction of air flow

Length depending on requirement (120 500 mm)

Air connection

R 1/4" x 9

Fastening nut

Fastening nut

~76 1

25

10

Connecting cable

length depending on requirement

Ionizing bar type EI VS

Bar length + 10 mm

A

=

HV connection

=

=

n x 50

V 1.3

Fastening nuts between the first and second clamping screw

50

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Health Safety and Environment PolicyDokument2 SeitenHealth Safety and Environment PolicyMiguel OrhlNoch keine Bewertungen

- EEII CeramicHeating ProductFlyer 140129 ScreenDokument2 SeitenEEII CeramicHeating ProductFlyer 140129 ScreenMiguel OrhlNoch keine Bewertungen

- Ehs - Company Policy: Environmental - Health - SafetyDokument1 SeiteEhs - Company Policy: Environmental - Health - SafetyMiguel OrhlNoch keine Bewertungen

- RibbonBlendes PaulOAbbeDokument4 SeitenRibbonBlendes PaulOAbbeMiguel OrhlNoch keine Bewertungen

- Chevron 2013 CR GlossaryDokument1 SeiteChevron 2013 CR GlossaryMiguel OrhlNoch keine Bewertungen

- Chain Conveyor GB@GBDokument8 SeitenChain Conveyor GB@GBMiguel OrhlNoch keine Bewertungen

- 34 2 1 Chain Conveyor RL RM in Line Shutter GB@GBDokument1 Seite34 2 1 Chain Conveyor RL RM in Line Shutter GB@GBMiguel OrhlNoch keine Bewertungen

- Rotary ConditionerDokument7 SeitenRotary ConditionerMiguel OrhlNoch keine Bewertungen

- Tank Drawings Example PDFDokument2 SeitenTank Drawings Example PDFMiguel OrhlNoch keine Bewertungen

- Motridal CocleeDokument8 SeitenMotridal CocleeMiguel OrhlNoch keine Bewertungen

- UtlDokument2 SeitenUtlMiguel OrhlNoch keine Bewertungen

- Nestix Cutting EsiteDokument3 SeitenNestix Cutting EsiteMiguel OrhlNoch keine Bewertungen

- Weiler MixerSS ENGDokument2 SeitenWeiler MixerSS ENGMiguel OrhlNoch keine Bewertungen

- Code of Business Conduct and EthicsDokument5 SeitenCode of Business Conduct and EthicsMiguel OrhlNoch keine Bewertungen

- Nestix Cutting EsiteDokument3 SeitenNestix Cutting EsiteMiguel OrhlNoch keine Bewertungen

- Integrated Talent MGT Matters 2844606Dokument4 SeitenIntegrated Talent MGT Matters 2844606Miguel OrhlNoch keine Bewertungen

- Plano Mecánico Puente GruaDokument1 SeitePlano Mecánico Puente GruaAbel Valderrama PerezNoch keine Bewertungen

- Examplefile: Rendering Engine Browser Platform (S) Engine Version Css GradeDokument1 SeiteExamplefile: Rendering Engine Browser Platform (S) Engine Version Css GradeMiguel OrhlNoch keine Bewertungen

- Automatic Car ShelterDokument1 SeiteAutomatic Car ShelterMiguel OrhlNoch keine Bewertungen

- Automatic Wall Shutter-Single Panel MODEL 502: Ratings Features FrameDokument1 SeiteAutomatic Wall Shutter-Single Panel MODEL 502: Ratings Features FrameMiguel OrhlNoch keine Bewertungen

- Conveyor Belt EBS 40 M1 100x450 2M8 U0 V U0 BR EasyDokument2 SeitenConveyor Belt EBS 40 M1 100x450 2M8 U0 V U0 BR EasyMiguel OrhlNoch keine Bewertungen

- 2014 Invoice Style PDFDokument1 Seite2014 Invoice Style PDFMiguel OrhlNoch keine Bewertungen

- Auto Exhaust Damper MODEL 611: Ratings Features FrameDokument1 SeiteAuto Exhaust Damper MODEL 611: Ratings Features FrameMiguel OrhlNoch keine Bewertungen

- 3 PDFDokument1 Seite3 PDFMiguel OrhlNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 4 TH BatchDokument37 Seiten4 TH Batchanil kumarNoch keine Bewertungen

- Free Standing Intake Tower AnalysisDokument12 SeitenFree Standing Intake Tower AnalysisBhushan RaisinghaniNoch keine Bewertungen

- Simulation Structure With SW Motion-Remote LoadDokument21 SeitenSimulation Structure With SW Motion-Remote LoadAlexDiazNoch keine Bewertungen

- Fermi Theory of Beta Decay (Contd.) : Dr. Sanjay KumarDokument13 SeitenFermi Theory of Beta Decay (Contd.) : Dr. Sanjay KumarnjhgffyfNoch keine Bewertungen

- Academic Year 2020 - 2021 - ODD Semester PH8151 - Engineering Physics Unit-V Crystal PhysicsDokument10 SeitenAcademic Year 2020 - 2021 - ODD Semester PH8151 - Engineering Physics Unit-V Crystal PhysicsBala NandaNoch keine Bewertungen

- SHS General Chemistry 2Dokument350 SeitenSHS General Chemistry 2John Luis Reyes90% (20)

- Royal Physicist: 18.3 Schur 'S Lemmas and Grand Orthogonality Theorem (GOT)Dokument6 SeitenRoyal Physicist: 18.3 Schur 'S Lemmas and Grand Orthogonality Theorem (GOT)Sagar RawalNoch keine Bewertungen

- Redox Practice Quiz 11Dokument2 SeitenRedox Practice Quiz 11rk_gummaluri5334100% (1)

- Revision Test PhysicsDokument56 SeitenRevision Test PhysicsAkshay Khanzode100% (4)

- Dynamics 22010 IbDokument16 SeitenDynamics 22010 IbAshwin DanielNoch keine Bewertungen

- BC YES Calculator MCDokument10 SeitenBC YES Calculator MCbingfang wuNoch keine Bewertungen

- Parts of Single Point Cutting ToolDokument8 SeitenParts of Single Point Cutting ToolMukesh sutharNoch keine Bewertungen

- Lecture 1-2 PDFDokument49 SeitenLecture 1-2 PDFASHISH MEENANoch keine Bewertungen

- Compressor MaterialsDokument4 SeitenCompressor MaterialsAhmed HassanNoch keine Bewertungen

- Atwood MachineDokument4 SeitenAtwood MachineanisahNoch keine Bewertungen

- Reservoir ModelingDokument4 SeitenReservoir ModelingHaseen KaurNoch keine Bewertungen

- Effect of Structure-Directing Agent On AlPO4-n Synthesis From Aluminum DrossDokument5 SeitenEffect of Structure-Directing Agent On AlPO4-n Synthesis From Aluminum DrossXantos YulianNoch keine Bewertungen

- IEC - 60034-17 - 2002 Motor Induccion Con VDFDokument22 SeitenIEC - 60034-17 - 2002 Motor Induccion Con VDFnovitopoNoch keine Bewertungen

- Power Divider, Combiner and CouplerDokument60 SeitenPower Divider, Combiner and Couplergaurav_juneja_4Noch keine Bewertungen

- Cern HistoryDokument164 SeitenCern HistoryMarco PonteNoch keine Bewertungen

- EC312 Lesson 15 Antenna Fundamentals-StudentsDokument14 SeitenEC312 Lesson 15 Antenna Fundamentals-StudentsDonnNoch keine Bewertungen

- Drying Introduction, DefinationDokument15 SeitenDrying Introduction, DefinationChintan ModiNoch keine Bewertungen

- PolistirenDokument15 SeitenPolistirenMaria TnsNoch keine Bewertungen

- Question 1142815Dokument8 SeitenQuestion 1142815phantomghost6413Noch keine Bewertungen

- DPM FluentDokument182 SeitenDPM Fluentபார்த்தசாரதி சுப்ரமணியன்Noch keine Bewertungen

- MODULE 3 - Electric Field-Electric Flux-Gauss's LawDokument9 SeitenMODULE 3 - Electric Field-Electric Flux-Gauss's LawPatrick CruzNoch keine Bewertungen

- ProsidingDokument465 SeitenProsidingMuhammad Arif Setiawan100% (1)

- Theory of EquabilityDokument7 SeitenTheory of EquabilitySwarnav MajumderNoch keine Bewertungen

- PRIPLAST Polyester Polyols Derived From Dimerized Fatty AcidsDokument30 SeitenPRIPLAST Polyester Polyols Derived From Dimerized Fatty AcidsA MahmoodNoch keine Bewertungen