Beruflich Dokumente

Kultur Dokumente

Corrossion Monitor, Probe

Hochgeladen von

Ummer BavaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Corrossion Monitor, Probe

Hochgeladen von

Ummer BavaCopyright:

Verfügbare Formate

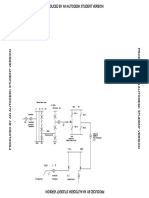

Injection and Sampling Systems

for High Pressure (HPTM and MHTM) Access Systems

Protective Cover

NPT Threaded

Side Tee

Solid Plug

To Feed Pump

or Sampling

Cylinder

Access Fitting

Injection Nut

Flanged

Side Tee

Quill

Open

Head with

Cap & Core

NPT with

Nozzle

Figure 1

Injection and Sampling systems are fundamental to corrosion control and process control programs.

They are applicable to a large variety of processes in the petroleum, chemical, and water treatment

industries. Injection systems are used to inject a wide range of chemicals into processes. Such

chemicals include biocides, demulsifiers, corrosion inhibitors, oxygen scavengers, glycol and monoethylene glycol, dewaxers, methanol, odorizers, and product additives.

Injection systems may be as simple as using an open-ended tube that allows for even distribution of

the injected chemical or as complex as using a head with a cap and core to obtain precise atomization of the chemical.

Sampling systems are used to take samples of the process fluid or medium. Such samples are then

analyzed in the laboratory for inhibitor concentration levels, the presence of metal ions, oxygen levels, scale forming compounds, and a wide range of process parameters.

Injection Systems

Injection Point

The art of chemical injection is a complex

technology. Irrespective of the type of injection

or injected fluid, several factors relative to the

process system and the injection system must be

considered. Principal factors are:

The maximum fluid velocity is usually at the

center of the line. Therefore, the most effective

position for injection is generally at the center of

the pipe in the direction of the product flow. If

the line is to be pigged, the injection point may

be flush with the pipe wall. This eliminates the

need to remove the injection probe before pigging operations begin. On pipelines this means

that injection is perpendicular to the product

flow. Top of the line may be used if the injection is required to be oblique or horizontal to the

product flow.

Pressure Differential

This is the difference between the injection

pump pressure and the process line or vessel

pressure. Ideally the pressure differential should

be 100 PSI (6.8 Bar). However, varied injection

rates can be achieved by changing the pressure

differential.

Temperature

Temperature directly affects viscosity. Ideally the

temperature of both the injected chemical and

the line product should be about 70 F (21 C).

Viscosity

This is the measure of a fluid's resistance to flow.

The more viscous the fluid the smaller the spray

angle.

Spray Angle

Spray angle is affected by viscosity, spray distance, and pressure differential.

Spray Coverage

This is the theoretical coverage area.

Specific Gravity

The specific gravity of a liquid is the density

ratio of the liquid to water. The flow rate of a

liquid is affected by its specific gravity.

Injection Rate

This is the amount of chemical to be injected

within a specified time and is defined as Gallons

Per Hour (GPH), Liters Per Day (LPD), etc. Injection Systems are available for injection rates

varying from 0.1 GPH (0.38 liters/hr) to 65.7

GPH (250 liters/hr).

Injection - 2

A typical Two-Inch System Injection Assembly

is shown in Figure 1. A Sampling system uses

the same components. The various components

of the assembly are:

1.

An Access Fitting body with a side Tee

through which the fluid transfer takes place.

The Tee may be threaded or welded. Welded

Tees are either flanged or buttweld nipples.

Threaded Tees are based on an NPT tapped

hole in the fitting body. The Tee size is rated

according to the injection rate and viscosity

of the injected chemical.

2.

A Solid Plug Assembly inside the fitting

body is used to carry an injection nut that has

the injection tube/nozzle assembly screwed

into its base.

3.

An Injection/Sampling Nut is a multiple

use device that replaces the nut on the end of

the solid plug. It is used to direct the injected

product to the injection tube or atomization

device. An Injection Nut sizing chart is

shown in Table 1.

4. The Injection/Sampling Tube or Nozzle.

a. Quill is an open-ended tube cut at a 45

angle with a slot. It utilizes the turbulence

created by its unique design to achieve

distribution of the injected chemical into

the product flow. Injection Tube Quills

are clog proof and give extremely good

dispersion of the inhibitor if the product

flow is 15 ft. per second or greater. As

with the Open Tube, injection rate must

be controlled at the injection pump or

shut-off valve.

b. Open is an open tube. The natural turbulence within the pipeline is used to insure

even distribution. There is essentially no

pressure differential experienced at the

orifice, so it is necessary to control the

injection rate at the injection pump or the

shut-off valve.

c. NPT is similar to the Open Tube but is

threaded at the dispersion end, thus allowing attachment of female nozzle assemblies. Injection may be perpendicular to

the flow with the use of a straight nozzle

or parallel to the flow with the use of a

right angle nozzle.

d. Head with Caps, Cores, and Strainers

are the various devices that, when attached

to the dispersion end of the Injection

Tube, permit atomization of the fluid as it

is injected into the product line or vessel.

The assemblies can be provided in complete units that contain caps, cores, and

strainers. The head has female threads

to match threads on the caps, cores, and

strainers, so that these attachments can

easily be replaced.

5. Nipples are used with threaded Tee Access

Fitting bodies and are the means of connecting the shut-off valve to the Access Fitting

body.

6. Shut-Off Valves are required to cut off the

injection flow and maintain pressure integrity

through the Tee when the Solid Plug Assembly is being removed or replaced. They are

also used to control the injection flow rate.

A Nipple and Shut-Off Valve sizing chart is

given in Table 3.

7. Check Valves are optional items that may be

fitted either within the Injection Tube or in

the inlet line to the Access Fitting Body Tee.

8. The Injection or Feed Pump must be

capable of generating sufficient injection

line pressure to overcome the line operating

pressure and thus create the required pressure

differential across the atomizing nozzle or

injection tube.

Materials of Construction

All components are manufactured from 316 SS

as standard with the exception of seals and

packing. These materials comply with the

requirements of NACE Standard MR-0175

Recommended Materials for sulfide stress

cracking environments.

Injection Tube Sizing

(Lengths are rounded down to the nearest 1/4",

except for flush devices which are rounded down

to the nearest 1/8".)

Center of Line Non-Flange Fitting

Open/Quill: (FH + PD/2) - (2.04 + N) = L

Head:

(FH + PD/2) - (2.04 + N) = L

*NPT:

(FH + PD/2) - (3.353 + N) = L

Center of Line Flange Fitting

Open/Quill: (FH + PD/2 + MF) - (2.04 + N) = L

Head:

(FH + PD/2 + MF) - (2.04 + N) = L

*NPT:

(FH + PD/2 + MF) - (3.353 + N) = L

Flush Non-Flange Access Fitting

Open/Quill: (FH + PW) - (2.04 + N) = L

Head:

(FH + PW) - (2.04 + N) = L

*NPT:

(FH + PW) - (3.353 + N) = L

Flush Flange Access Fitting

Open/Quill: (FH + PW + MF) - (2.04 + N) = L

Head:

(FH + PW + MF) - (2.04 + N) = L

*NPT:

(FH + PW + MF) - (3.353 + N) = L

FH

PW

N

L

MF

PD

IL

=

=

=

=

=

=

=

Access Fitting Height

Pipe Wall Thickness

Injection Nut Length

Injection Tube Length

Mating Flange Height

Pipe Outer Diameter

Insertion Length into Pipe or Vessel

* Length of tube is based on nozzle length of 1.313".

Nozzle is sold separately.

Injection - 3

How to Order

A) Access Fitting Body height and Tee size may be determined from the Access Fitting literature.

B) The Injection Nut size may be determined from Table 1.

Model Length (Fitting type / Height)

IQN ------ X ---1 - 1.75" (HP / 5.25")

2 - 2.75" (HP / 6.25")

3 - 3.75" (HP / 7.25")

4 - 4.75"

5 - 5.50" (HP / 8.25")

6 - 3.50" (MH / all heights)

Probe End Thread

---- X ---0 - N/A

1 - 1/8" - 27 NPT

2 - 1/4" - 18 NPT

3 - 3/8" - 18 NPT

4 - 1/2" - 14 NPT

5 - 3/4" - 14 NPT

6 - 3/8" - 24 UNF - 2B

7 - 7/16" - 20 UNF - 2B

8 - 1/2" - 20 UNF - 2B

9 - 9/16" - 18 UNF - 2B

A - 5/8" - 18 UNF - 2B

Seal Material

---- X ---0 - N/A

1 - Viton o-ring /

Teflon backing ring

2 - Ethylene propylene /

Teflon backing ring

3 - Kalrez o-ring /

Teflon backing ring

4 - Hydrin o-ring /

Teflon backing ring

5 - Nitrile o-ring /

Teflon backing ring

6 - Teflon o-ring /

Teflon backing ring

Alloy Code

---- XXX

158 - 316 SS

A12 - C276

Table 1

C) Determine Injection Tube Thread size required. Determine the Type. Calculate the Injection

Tube Length using the sizing formulas. Use this information to determine the Part # from Table 2.

Model

IQ ---

Thread Size

---- X ---1 - 1/8" NPT

2 - 1/4" NPT

3 - 1/2" NPT

4 - 3/4" NPT

Type

---- XX ---01 - Quill

02 - Open

03 - NPT for a Nozzle

04 - Head w/ Cap & Core

Alloy

---- XXX ---158 - 316 SS

A12 - C276

Length Designation

---- XXXX

Length in inches,

stated in 2 decimal

place format

(Ex: 6 1/4" = 0625)

Table 2

D) A Nipple & Shut-Off Valve to match the Tee of the Access Fitting Body may be selected from Table 3.

Access Fitting

Tee Size

1/4"

1/2"

3/4"

1"

Valve

316 SS

Part No.

HA700022158

HA700023158

HA700027158

HA700029158

Nipple, 4 in (100 mm)

316 SS Sch. 80

Part No.

HA700018158

HA700019158

HA700020158

HA700021158

Table 3

E) If applicable, select a suitable Nozzle Type or Cap & Core Assembly from Table 4.

1/4" FNPT Noz.

PR626213903

PR626213904

PR626213906

Nozzle Type / Part Number

1/4" MNPT Noz.

Cap & Core Assem. (9/16")

PR609713903

PR609713904

PR609713906

PR617613903

PR617613904

PR617613906

Orifice

Size

Expected Flow Rate

in GPH @ 100 PSI

.006

.012

.016

.48

.64

.96

Table 4

Metal Samples Company

A Division of Alabama Specialty Products, Inc.

152 Metal Samples Rd., Munford, AL 36268 Phone: (256) 358-4202 Fax: (256) 358-4515

E-mail: msc@alspi.com Internet: www.metalsamples.com

Houston Office: 6327 Teal Mist Lane, Fulshear, TX 77441 Phone: (832) 451-6825

Das könnte Ihnen auch gefallen

- Materials System SpecificationDokument13 SeitenMaterials System SpecificationUmmer BavaNoch keine Bewertungen

- Dervos Ball Valve API 607 CertificateDokument10 SeitenDervos Ball Valve API 607 CertificateUmmer BavaNoch keine Bewertungen

- Bhaijann Menu For This WeekDokument2 SeitenBhaijann Menu For This WeekUmmer BavaNoch keine Bewertungen

- Document Responsibility: Piping Standards Committee SAES-L-105 Issue Date: 7 July 2013 Next Planned Update: 7 July 2018 Piping Line ClassesDokument1 SeiteDocument Responsibility: Piping Standards Committee SAES-L-105 Issue Date: 7 July 2013 Next Planned Update: 7 July 2018 Piping Line ClassesUmmer BavaNoch keine Bewertungen

- API & Asme PSV, PZV Orifice AreaDokument2 SeitenAPI & Asme PSV, PZV Orifice AreaUmmer BavaNoch keine Bewertungen

- Dj1 Dj2 Unb Unt Unl Ver 1.5Dokument2 SeitenDj1 Dj2 Unb Unt Unl Ver 1.5ajayssarode100% (1)

- Lifting LugDokument4 SeitenLifting LugUmmer BavaNoch keine Bewertungen

- I Need A Company Phone For My Project Purpose, So Please Take Necessary Action For ThatDokument1 SeiteI Need A Company Phone For My Project Purpose, So Please Take Necessary Action For ThatUmmer BavaNoch keine Bewertungen

- PMP-Basics You Need To Know: By: Pradeep Patel PMPDokument14 SeitenPMP-Basics You Need To Know: By: Pradeep Patel PMPUmmer BavaNoch keine Bewertungen

- Professional Objective: Ummer Bava VDokument2 SeitenProfessional Objective: Ummer Bava VUmmer BavaNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- GautierDokument164 SeitenGautierDimitar NedkovNoch keine Bewertungen

- Installation of Water HeatersDokument5 SeitenInstallation of Water HeatersLaura KurniawanNoch keine Bewertungen

- SBI Clerk Mains Bolt 2023 OliveboardDokument160 SeitenSBI Clerk Mains Bolt 2023 OliveboardMaahi ThakorNoch keine Bewertungen

- Awareness and Application of Ms Iec - Iso 31010 - 2011 Risk Assessment Techniques1 PDFDokument21 SeitenAwareness and Application of Ms Iec - Iso 31010 - 2011 Risk Assessment Techniques1 PDFasushk0% (1)

- Grade 7 and 8 November NewsletterDokument1 SeiteGrade 7 and 8 November Newsletterapi-296332562Noch keine Bewertungen

- Energy Cable Accessories Epp1984 EngDokument156 SeitenEnergy Cable Accessories Epp1984 EngSathiyanathan ManiNoch keine Bewertungen

- 7sd610 CatalogueDokument35 Seiten7sd610 CatalogueTntngn Petualang100% (1)

- Teacher Evaluation in A Blended Learning EnviornmentDokument11 SeitenTeacher Evaluation in A Blended Learning Enviornmentapi-287748301Noch keine Bewertungen

- New Process Performance IE4 Motors: Product NotesDokument2 SeitenNew Process Performance IE4 Motors: Product NotesCali MelendezNoch keine Bewertungen

- Gas Plant Improves C3 Recovery With Lean Six Sigma ApproachDokument9 SeitenGas Plant Improves C3 Recovery With Lean Six Sigma ApproachganeshdhageNoch keine Bewertungen

- 01 SQL ErrorsDokument2.085 Seiten01 SQL ErrorsM. temNoch keine Bewertungen

- Transition SignalsDokument10 SeitenTransition Signalshana nixmaNoch keine Bewertungen

- Operator'S Manual: E-Series Ultraviolet Hand LampsDokument9 SeitenOperator'S Manual: E-Series Ultraviolet Hand LampsGuiss LemaNoch keine Bewertungen

- Micronta 12VDC Power Adapter 273-1653A InstructionsDokument2 SeitenMicronta 12VDC Power Adapter 273-1653A Instructions240GL guyNoch keine Bewertungen

- S9300&S9300E V200R001C00 Hardware Description 05 PDFDokument282 SeitenS9300&S9300E V200R001C00 Hardware Description 05 PDFmike_mnleeNoch keine Bewertungen

- Introduction To Ada Solo Project: Robert Rostkowski CS 460 Computer Security Fall 2008Dokument20 SeitenIntroduction To Ada Solo Project: Robert Rostkowski CS 460 Computer Security Fall 2008anilkumar18Noch keine Bewertungen

- Resistive Capacitive Inductive and Magnetic Sensor Technologies by Winncy Y Du PDFDokument400 SeitenResistive Capacitive Inductive and Magnetic Sensor Technologies by Winncy Y Du PDFlocthaiquoc83% (6)

- Diagnostic Exam Review Phy10Dokument24 SeitenDiagnostic Exam Review Phy10Kayla DollenteNoch keine Bewertungen

- Weapon Lights and Targeting LasersDokument3 SeitenWeapon Lights and Targeting LasersバラモスまさゆきNoch keine Bewertungen

- SWIFT Case Study Accord EADS 200808Dokument3 SeitenSWIFT Case Study Accord EADS 200808maheshbendigeri5945Noch keine Bewertungen

- Getting To Windows 10:: Microsoft's New Options For Upgrading and OnboardingDokument4 SeitenGetting To Windows 10:: Microsoft's New Options For Upgrading and OnboardingMarcus IPTVNoch keine Bewertungen

- RS232STATUSMONDokument1 SeiteRS232STATUSMONashish.boradNoch keine Bewertungen

- Serial NumberDokument3 SeitenSerial NumberNidal Nakhalah67% (3)

- AR Porta CabinDokument2 SeitenAR Porta CabinVp SreejithNoch keine Bewertungen

- مثال تطبيقي في النمذجة والمحاكاة باستخدام CSIMDokument11 Seitenمثال تطبيقي في النمذجة والمحاكاة باستخدام CSIMأكبر مكتبة كتب عربيةNoch keine Bewertungen

- ECSS E ST 50 03C (31july2008)Dokument43 SeitenECSS E ST 50 03C (31july2008)jsadachiNoch keine Bewertungen

- 11kv BB1Dokument1 Seite11kv BB1Hammadiqbal12Noch keine Bewertungen

- BB TariffDokument21 SeitenBB TariffKarthikeyanNoch keine Bewertungen

- PROSIS Part Information: Date: Image Id: Catalogue: ModelDokument2 SeitenPROSIS Part Information: Date: Image Id: Catalogue: ModelAMIT SINGHNoch keine Bewertungen

- Times of India - Supply Chain Management of Newspapers and MagazinesDokument18 SeitenTimes of India - Supply Chain Management of Newspapers and MagazinesPravakar Kumar33% (3)