Beruflich Dokumente

Kultur Dokumente

DSDA Sulphuric Acid Plant

Hochgeladen von

AbijithCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

DSDA Sulphuric Acid Plant

Hochgeladen von

AbijithCopyright:

Verfügbare Formate

DSDA Sulphuric Acid Plant

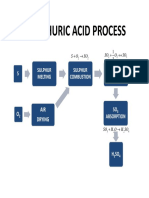

Process outline

Sulphur melting

Sulphur filtration

Sulphur burning

Cooling of gas and steam

Contact synthesis

Acid synthesis

Air drying and absorption

Oleum facility and absorption

General

Combustion of sulphur with air to give sulphur dioxide and

oxygen in desired rate for conversion to sulphur trioxide.

Cataytic oxidation of sulphur dioxide to sulphur trioxide.

Process

Sulphur Melting

Sulphur is fed into mixer compartment of sulphur and contains

steam coils supplied with saturated steam. It melts liquid sulphur

at 132-135 C. I t overflows into dusty sulphur compartment and

subsequently to pre-coat compartment where temperature is

maintained constant to keep it at molten state. The agitator in

theses tanks prevent the ash from settling. Water is taken out by

evaporator.

Sulphur Filtration

Ash normally found in the sulphur is very fine and hence removed

by pre-coat method of filtration by means of pressure leaf filter .

Sulphur Burning

From the sulphur storage pit, sulphur is pumped through steam

jacketed pipe by means of submerged centrifugal pumps and fed

into combustion furnace. The required air is supplied by Howden

burner.

In furnace, sulphur completely burns in air supplied by blower to

form sulphur dioxide the reaction is exothermic

Temperature of outgoing gas is raised to above 1000 which is

higher than the optimum temperature of 425 required for

conversion.

Cooling Of Gas And Steam Generation

Cooling of gases is carried out by a water tube waste heat boiler

having 2 heat exchanger bundles in series. Hot gases passing

over a series of boiler element is cooled down while a steam is

generated in the boiler corresponding to a temp of 200 C .Steam

is generated in the boiler at a rate of approx. 3 kg of steam per kg

of sulphur. The DM water required for boiler is from dissolved

oxygen and carbon dioxide and is then pumped to the boiler.

Contact Synthesis

The mixture of gases is then admitted into the first pass of a

convertor having 4 passes. In the single shell, a pass consisting of

a section of the convertor in which the gas is brought into contact

with one layer of catalyst and cooling does not take place

(

The temperatures are maintained by a system of waste heat

boiler and heat exchanger. The gas is rooted after the first and

4th layers using boilers and economizer.

Air Drying And Absorption

The air drying tower is packed with stoneware material. The air

steam flows from bottom to top while 96% sulphuric acid flows

the tower evenly distributed.

The sulphuric acid absorbs moisture contained in the air and gets

heated up. Heat is removed in acid water.

Sulphur trioxide contained in gases is absorbed in two absorption

towers, intermediate and final absorption column. Continuous

addition of sulphuric acid (96%)from the drying tower reduces the

concentration which build as the sulphur trioxide is absorbed

.Further process water is admitted and maintain the concentration

acid at 98.4%.

Oleum Facility

Basic feature involved in this manufacture is absorption of sulphur

trioxide present in gas in 98.4% sulphuric acid to give oleum

containing 24% free sulphur trioxide. Oleum circulation is done by

circulation pump .

Production

The products 98.4% acid and oleum are bled of the absorption

system through product acid cooler and production oleum cooler

to acid storage and oleum storage tanks respectively. The

unabsorbed gas containing a maximum of 0.06% sulphur dioxide

is sent tothe atmosphere throught the exit stack.

Das könnte Ihnen auch gefallen

- Static Equipment PDFDokument37 SeitenStatic Equipment PDFMedinaNoch keine Bewertungen

- Fertilizer: Methods of Production: Anhydrous Ammonia (NH Raw Materials: HDokument8 SeitenFertilizer: Methods of Production: Anhydrous Ammonia (NH Raw Materials: HindumathijayakaranNoch keine Bewertungen

- Unit 5 Sulphur Recovery UnitDokument32 SeitenUnit 5 Sulphur Recovery Unitkhalimn100% (1)

- Urgent Punch ListDokument42 SeitenUrgent Punch ListsugiantobarusNoch keine Bewertungen

- Lead Chamber Process For H2so4Dokument11 SeitenLead Chamber Process For H2so4Zamir Khan100% (3)

- BPVC I p-2Dokument2 SeitenBPVC I p-2Ingeniería Thermo PressionNoch keine Bewertungen

- Chapter III With Plant CapacityDokument13 SeitenChapter III With Plant Capacitymonkey d. luffyNoch keine Bewertungen

- Sulfur and Sulfuric AcidDokument20 SeitenSulfur and Sulfuric AcidZakia LuthfianaNoch keine Bewertungen

- 7 - Sulfur & Sulfuric Acid TaughtDokument58 Seiten7 - Sulfur & Sulfuric Acid TaughtsahibjotNoch keine Bewertungen

- Sulphuric AcidDokument14 SeitenSulphuric AcidNoman AslamNoch keine Bewertungen

- Fired HeatersDokument31 SeitenFired Heatersapi-3709413100% (10)

- 8.8 Boiler Efficiency TestDokument17 Seiten8.8 Boiler Efficiency TestRINJUNoch keine Bewertungen

- BP Voy 3Dokument16 SeitenBP Voy 3Victor PerkinsNoch keine Bewertungen

- Process Flow Diagram For Ammonia SynthesisDokument6 SeitenProcess Flow Diagram For Ammonia SynthesisHanan Ahmed Ibrahim100% (1)

- Two Main Types of Production Process For Ammonia Synthesis Gas Are Currently in Operation in EuropeDokument9 SeitenTwo Main Types of Production Process For Ammonia Synthesis Gas Are Currently in Operation in EuropetauseefaroseNoch keine Bewertungen

- Ammonia PlantDokument10 SeitenAmmonia PlantHemal Patel Sam100% (3)

- SAPDokument16 SeitenSAPsourav84Noch keine Bewertungen

- Scope of Works Shuwaikh Power Station 11802-SWK-SOW-ME-002 Rev 4Dokument98 SeitenScope of Works Shuwaikh Power Station 11802-SWK-SOW-ME-002 Rev 4nestorNoch keine Bewertungen

- Sulfuric Acid Production PDFDokument66 SeitenSulfuric Acid Production PDFTrần Kiên100% (2)

- Expected Useful LifeDokument7 SeitenExpected Useful LifeTiffany CombsNoch keine Bewertungen

- Ammonia ManufacturingDokument16 SeitenAmmonia ManufacturingMuhammad Irfan MalikNoch keine Bewertungen

- AmmoniaDokument17 SeitenAmmoniaMubarak Ahmad100% (1)

- Process Control SystemsDokument32 SeitenProcess Control SystemsRohit GadekarNoch keine Bewertungen

- Look at Claus Unit DesignsDokument11 SeitenLook at Claus Unit DesignsNacho MatosNoch keine Bewertungen

- Energy Conservation in Sugar Industry1Dokument59 SeitenEnergy Conservation in Sugar Industry1Sumit Bhati100% (1)

- Sulphuric Acid (H SO4)Dokument44 SeitenSulphuric Acid (H SO4)Faisal Azis RamadhanNoch keine Bewertungen

- Sulfuric Acid Manufacture: Analysis, Control and OptimizationVon EverandSulfuric Acid Manufacture: Analysis, Control and OptimizationBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Hydrogen ProductionDokument14 SeitenHydrogen ProductionAbid YusufNoch keine Bewertungen

- Process Description Sulphuric AcidDokument2 SeitenProcess Description Sulphuric AcidAbdul QayyumNoch keine Bewertungen

- Overview of The ProcessDokument10 SeitenOverview of The ProcessChaitanya PottiNoch keine Bewertungen

- Lant in PT. Petrokimia Gresik: Flow Diagram of The Process To Making Sulfuric AcidDokument3 SeitenLant in PT. Petrokimia Gresik: Flow Diagram of The Process To Making Sulfuric AcidAnisa SudarmajiNoch keine Bewertungen

- Sru UnitDokument6 SeitenSru Unitparthdpatel131822Noch keine Bewertungen

- Sulphur Acid Process (Scribd)Dokument7 SeitenSulphur Acid Process (Scribd)Poon CYNoch keine Bewertungen

- Chemical Recovery at The Sulphate Pulp Mill005Dokument4 SeitenChemical Recovery at The Sulphate Pulp Mill005mahotkatNoch keine Bewertungen

- Production of Specialty Chemicals From A Coal Gasification Acid Gas Waste StreamDokument26 SeitenProduction of Specialty Chemicals From A Coal Gasification Acid Gas Waste StreamAbubakar Ahmed MagzoubNoch keine Bewertungen

- Process Description Nitric Acid ProductionDokument2 SeitenProcess Description Nitric Acid ProductionLaman AlipashayevaNoch keine Bewertungen

- Lecture 2 Inorganic Industries 2019Dokument41 SeitenLecture 2 Inorganic Industries 2019Mohamed AbdelaalNoch keine Bewertungen

- Sulfuric Acid Manufacturing ProcessDokument5 SeitenSulfuric Acid Manufacturing ProcessamirahabidinNoch keine Bewertungen

- Claus Process: From Wikipedia, The Free EncyclopediaDokument5 SeitenClaus Process: From Wikipedia, The Free EncyclopediaAshish SutariyaNoch keine Bewertungen

- HDTB SectorDokument7 SeitenHDTB SectorPartha AichNoch keine Bewertungen

- Sulphur RecoveryDokument5 SeitenSulphur RecoveryputrialdrianaNoch keine Bewertungen

- Claus ProcessDokument4 SeitenClaus ProcesspochisurNoch keine Bewertungen

- Chapter Two Feasibility Study 2.0 Methods of Producing Ammonium Sulphate, ( (NH) SO)Dokument9 SeitenChapter Two Feasibility Study 2.0 Methods of Producing Ammonium Sulphate, ( (NH) SO)Adeyoju RebeccaNoch keine Bewertungen

- Claus Process - WikipediaDokument26 SeitenClaus Process - WikipediaTatenda SibandaNoch keine Bewertungen

- Sulfuric Acid Manufacturing PlantDokument6 SeitenSulfuric Acid Manufacturing PlantmichsantosNoch keine Bewertungen

- OXIDATIONDokument36 SeitenOXIDATIONMansab AliNoch keine Bewertungen

- Black Liquor Incineration - Process, Chemistry and Ash Fusion Characteristics-By AjDokument41 SeitenBlack Liquor Incineration - Process, Chemistry and Ash Fusion Characteristics-By AjAnkit Jain100% (2)

- Tail Gas CleanupDokument3 SeitenTail Gas CleanupsatishchemengNoch keine Bewertungen

- Air Polluition ControlDokument37 SeitenAir Polluition ControlGendewa Tunas RancakNoch keine Bewertungen

- Process1 DraftDokument11 SeitenProcess1 DraftMichelle MendozaNoch keine Bewertungen

- Stage 1: Preparation of Sulphur DioxideDokument2 SeitenStage 1: Preparation of Sulphur Dioxidenajwasyafiqah_1Noch keine Bewertungen

- Industrial TrainingDokument25 SeitenIndustrial TrainingheroNoch keine Bewertungen

- Sulphuric Acid ManufactureDokument5 SeitenSulphuric Acid ManufactureLeonardo ColmenaresNoch keine Bewertungen

- Claus ProcessDokument6 SeitenClaus ProcessRafi AlgawiNoch keine Bewertungen

- Heavy Chemical IndustryDokument20 SeitenHeavy Chemical IndustryUsman AliNoch keine Bewertungen

- Oxidation: by Muhammad Umar MushtaqDokument18 SeitenOxidation: by Muhammad Umar MushtaqMuhammad OsamaNoch keine Bewertungen

- 10 Acid Plant DSC LeadDokument9 Seiten10 Acid Plant DSC LeadVikash BhaskarNoch keine Bewertungen

- Sulfur and Sulfuric AcidDokument24 SeitenSulfur and Sulfuric AciddhavalNoch keine Bewertungen

- National Fertilizers Limited Nan Gal PunjabDokument3 SeitenNational Fertilizers Limited Nan Gal PunjabNirmanyu JamwalNoch keine Bewertungen

- Advanced Minerals Engrng Presentation1F-1Dokument25 SeitenAdvanced Minerals Engrng Presentation1F-1LorraineNoch keine Bewertungen

- 2 Manufacture of Ammonia, Nitric Acid and Calcium Ammonium NitrateDokument14 Seiten2 Manufacture of Ammonia, Nitric Acid and Calcium Ammonium NitrateKarez MartoNoch keine Bewertungen

- Gasification Is A Process That Converts Organic or Fossil Based Carbonaceous MaterialsDokument11 SeitenGasification Is A Process That Converts Organic or Fossil Based Carbonaceous MaterialsEric CookNoch keine Bewertungen

- Basic Unit Operations AbsorptionDokument12 SeitenBasic Unit Operations AbsorptionPinak ChowdhuryNoch keine Bewertungen

- 1 ProcessDokument2 Seiten1 ProcessUmar DrazNoch keine Bewertungen

- Assignment 1 - ThermodynamicsDokument7 SeitenAssignment 1 - ThermodynamicsMd Afif AbrarNoch keine Bewertungen

- Inthe1 Converter Occurs Twice A Gas Cooling Through The Two Heat Exchanger Interbed Cooler and Process Gas CoolerDokument2 SeitenInthe1 Converter Occurs Twice A Gas Cooling Through The Two Heat Exchanger Interbed Cooler and Process Gas Coolerrudy_423522658Noch keine Bewertungen

- Modern Chemical ManufacturerDokument8 SeitenModern Chemical ManufacturerUltra Gamer (sishant)Noch keine Bewertungen

- GIRMADokument49 SeitenGIRMAGirma TesemaNoch keine Bewertungen

- Nitric Acid Process AbstractDokument2 SeitenNitric Acid Process AbstractEduardo MagallonNoch keine Bewertungen

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesVon EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNoch keine Bewertungen

- New Doc 2017-10-12Dokument2 SeitenNew Doc 2017-10-12AbijithNoch keine Bewertungen

- New Doc 2017-10-12 (1) - 3Dokument1 SeiteNew Doc 2017-10-12 (1) - 3AbijithNoch keine Bewertungen

- SIFLDokument28 SeitenSIFLAbijithNoch keine Bewertungen

- Anone PlantDokument2 SeitenAnone PlantAbijith100% (1)

- Anone PlantDokument2 SeitenAnone PlantAbijith100% (1)

- PP Lab Manual 2015Dokument20 SeitenPP Lab Manual 2015Abdul Fatir Khan100% (1)

- Asme I IntDokument24 SeitenAsme I IntSilvaNoch keine Bewertungen

- Boiler-Manual-Cb-Cbw 100 To 400Dokument132 SeitenBoiler-Manual-Cb-Cbw 100 To 400CayixNoch keine Bewertungen

- Standard PPT BecDokument87 SeitenStandard PPT Becamit singhNoch keine Bewertungen

- Data Brochure: Floating Action Mixing Control UP36Dokument24 SeitenData Brochure: Floating Action Mixing Control UP36jamppajoo2Noch keine Bewertungen

- DNV RulesDokument44 SeitenDNV RulesIslam HassanNoch keine Bewertungen

- Exergy Analysis of A Combined Gas/ Steam Turbine Cycle With A Supercharged BoilerDokument13 SeitenExergy Analysis of A Combined Gas/ Steam Turbine Cycle With A Supercharged BoilerAJER JOURNALNoch keine Bewertungen

- Che144 Marcet Boiler Lab ReportDokument9 SeitenChe144 Marcet Boiler Lab ReportAbdul AliffNoch keine Bewertungen

- BodyDokument69 SeitenBodyRoi Benedict BuenaNoch keine Bewertungen

- Glass Coil Heat-Exchangers AblazeDokument8 SeitenGlass Coil Heat-Exchangers AblazeRafique AjmeriNoch keine Bewertungen

- Boiler Documentation Air Flue Gas Path Ducts EJ Gates Dampers 1 5 Hrs PDFDokument90 SeitenBoiler Documentation Air Flue Gas Path Ducts EJ Gates Dampers 1 5 Hrs PDFaruntpeNoch keine Bewertungen

- 2001 - March - Boiler (Part 1)Dokument6 Seiten2001 - March - Boiler (Part 1)arunkumar23101Noch keine Bewertungen

- Boiler and Its TypesDokument11 SeitenBoiler and Its TypesParas RaoNoch keine Bewertungen

- Pel Tec Jednolisni 04 2013 EngDokument2 SeitenPel Tec Jednolisni 04 2013 EngAnghel Dumitriu0% (1)

- FLEXICOKING™ Technology For Resid UpgradingDokument27 SeitenFLEXICOKING™ Technology For Resid UpgradingFernando CallNoch keine Bewertungen

- MV RS Lisa - Time Charter Describtion: Owner: Romy Shipping AS, WWW - Mmred.noDokument3 SeitenMV RS Lisa - Time Charter Describtion: Owner: Romy Shipping AS, WWW - Mmred.noMeryNoch keine Bewertungen

- Manual Termostato EspañolDokument24 SeitenManual Termostato EspañoljuancgranadoNoch keine Bewertungen

- ASME IV-DefinitionsDokument1 SeiteASME IV-DefinitionsmgoethalsNoch keine Bewertungen

- Energy Audit and Energy Efficiency Improvement of Thermal Power PlantDokument47 SeitenEnergy Audit and Energy Efficiency Improvement of Thermal Power PlantroyaladdictedNoch keine Bewertungen

- ME8395 Thermal Engineering-2 Part - B QuestionsDokument5 SeitenME8395 Thermal Engineering-2 Part - B QuestionsMuruganNoch keine Bewertungen