Beruflich Dokumente

Kultur Dokumente

Toautocj 7 1746

Hochgeladen von

Senthil KumarOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Toautocj 7 1746

Hochgeladen von

Senthil KumarCopyright:

Verfügbare Formate

Send Orders for Reprints to reprints@benthamscience.

ae

1746

The Open Automation and Control Systems Journal, 2015, 7, 1746-1751

Open Access

Dynamic Simulation System Using DOF Picking Robot

Xiaojun Liu*

Department of Logistics and Information Management, Zhuhai College of Jilin University, Zhuhai 519041, Guangdong,

China

Abstract: A visualized dynamic simulation platform of picking robot based on OpenGL and Matlab is established in order to verify the validity of kinematics analysis and visually reflect the motion process.The robot kinematic model is established with D-H method and the forward kinematic solution for the robot is obtained. The inverse kinematic solution is

solved by using the simplified inverse transformation method according to the operation features of the robot. Solidworks

is adopted to set up 3D robot model, which is transformed through Deep Exploration into cpp formatted files that can be

recognized by OpenGL. Visualized simulation verification is conducted on the forward and the inverse kinematic solution

and the grabbing motion of the manipulator are conducted on the simulation platform based on VisualC++6.0 and

OpenGL. Track planning is carried out for each of the manipulator joints by means of Matlab Robotics Toolbox. It is illustrated by the simulation results that the kinematic model established by D-H approach reflects the real motion conditions of the robot, and both the forward and inverse kinematic solutions are correct.

Keywords: DOF, Dynamic Simulation, OpenGL, kinematic model, Matlab.

1. INTRODUCTION

As the largest vegetable producing and consuming country, China witnesses a continuous and stable development of

vegetable production in recent years, with the cultivated area

increasing from 95 million mu in 1990 to 295 million mu in

2011 and the yield from 195 million ton to 679 million ton.

Meanwhile, however, it faces some challenges and problems

demanding prompt solution, among which the most important issue is that the agricultural production technique is relatively backward and the level of mechanization and automation has a large gap with the developed countries. Agricultural producers endure high labour intensity; moreover, improper manual work methods damage the garden stuff vegetation and affect the quality and quantity of garden stuff production (X.Y. Tang, 2005) [1].

Harvesting or picking is the most effort-requiring and

time-consuming link in vegetable production operation.

Moreover, it requires picking in due time to guarantee the

product quality, which is the most laborious in the whole

operation. With the aging of population and the decrease of

farming labor force, it is more and more significant to research and develop fruit and vegetable picking robot [2-5].

There appeared many picking robots at the end of last

century at abroad. In particular, Japan is in the lead in this

field in the world. The tomato picking robot developed by

KONDO-N, et al. in Japan, is based on SCORBOT-ER

industrial robot. (K.K. Guptal 2006) With 7 degree of

1874-4443/15

freedom and equipped with 4 wheels, it can walk about in

the field and conduct target location for picking through binocular vision. The eggplant picking robot, jointly developed

by Japan National Institute of Vegetable and Tea and Gifu

University, consist of ccd machine vision system, 5 DOF

industrial manipulator, end effector and running gear, with a

picking success rate of 62.5 and an operating speed of

64.1s/each.

In recent years, scholars in China also start the research

and development of picking robot. Jian Song, etc, utilize

optimization design method for the design of the robot body

structure parameters in accordance with the eggplant growth

and distribution space, develop the basic machine of picking

robot of 4 degrees of freedom. The overall testing system

operates in stable and reliable way with a grabbing success

rate of 89% and average elapsed time of 37.4s (N. Kondo

et al., 1996) [6, 7].

In the intelligent tomato picking robot end effector based

on multi-sensor information fusion and open control system

designed by Jizhan Liu, etc, its vacuum chuck device of the

execution system can separate the fruit from the fruit bunch,

its finger gripper mechanism can grasp the tomato firmly,

and the fruit stem disconnecting device can cut off the fruit

stem with laser (J.Z. liu et al. 2008) [8].

Vegetable picking robot through the movement of each

and every joint (Shigehiko et al. 2002) as an important constituent part of robotics, Robot kinematics mainly studies the

relationships of the displacement, speed and acceleration of

the connecting rods of the robot motion arm, whose purpose

is to establish the relationships among spatial positions of the

robot moving components and end effectors so as to provide

2015 Bentham Open

Dynamic Simulation System Using DOF Picking Robot

The Open Automation and Control Systems Journal, 2015, Volume 7

1747

theoretical basis and technical parameters for robot control

(P. Cui 2011, Yang, Chifu 2010) [9].

In this paper, the author begins with establishing the robot mathematic model with Denavit-Hartenberg method, and

applies OpenGL and Matlab to conduct kinematics analysis

and simulation study on 5 DOF picking robot, which solves

the problem of kinematics analysis such as tedious analysis

procedure, large calculation amount and being Error-prone in

traditional multi-rigid-body system, meanwhile visually displayed the kinematic performance of the robot movement

mechanism in the form of simulation animation and diagram,

providing a strong guarantee for the follow-up robot motion

trail planning and the rationality verification of structure

parameters [10].

2. KINEMATICS ANALYSIS OF PICKING MANIPULATOR

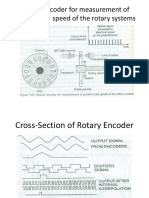

Fig. (2). Picking robot joint coordinate system.

2.1. Establishment of Robot Coordinate System

From (Fig. 1), according to D-H method define each

connecting rod with 4 parameters: torsion angle i, rod piece

length ai , joint angle i, horizontal distance di, all shown in

Table 1.

The degree of freedom needed for the manipulator is analyzed and determined in accordance with the requirement of

the eggplant picking process. The design requires for moderate amount of the degree of freedom without too many redundant ones so as to avoid the increase of control difficulty

and structure complexity. This paper adopts five degree of

freedom, namely, waist rotation, shoulder luffing, elbow

luffing, wrist luffing and wrist turning, to match the grabbing

process on the basis of actual demand. The structure is

shown as in (Fig. 1).

2.2. Kinematical Equation

When the spatial relationship between the two adjacent

connecting rods i-1and i changes in accordance with the following motions, the coordinate transformation can be accomplished.

1) Revolve i around axes Zi-1 until it reaches the position where axes Xi-1 is parallel to axes Xi;

2) Translate distance di along axes Zi-1 to cause Xi-1 to

be collinear with Xi;

3) Translate distance ai along Xi to cause the coordinate

system origins of the connecting rods to be coincided;

4) Revolve angle i along Xi to cause axes Zi-1 to be

collinear with axes Zi.

Repeat the above steps, and we can realize the transformation of coordinates from the robot base to the first joint, then

to the second joint until the end effector. The 4 times of homogeneous transformation is presented in transformation

matrix Ai:

Ai = Rot (z ,* i )( Trans (0,0, d i ) ( Trans (ai ,0,0) ( Rot ( x, ) i )

Fig. (1). Five degree of freedom picking manipulator schematic

diagram.

The picking manipulator can be regarded as a connecting

rod that is constituted with a series of joints. Each connecting

rod eatablish a coordinate system It adopts 44 homogeneous transformation matrix to describe the spatial position

relationship of the adjacent robot rod pieces, thus translates

the complicated kinematic question into equivalence transformation matrix of the reference coordinate system of the

end effectors and reference coordinate system. Establish

modeling of the connecting rod and joints according to Denavit-Hartenberg as in (Fig. 2) [11].

&cos * i

$ sin *

i

=$

$ 0

$

% 0

' sin * i cos ) i

cos * i cos ) i

sin ) i

0

sin * i sin ) i

' cos * i sin ) i

cos )

0

ai cos * i #

ai sin * i !!

di !

!

1 "

Eq. (1)

For the rotary joint, when the coordinate system of each

robot connecting rod is specified, the parameters i, i and di

are constant. In this case, matrix A becomes function of variable i. For the robot with n rotational joints, the general

transformation of coordinates between the base and the end

effectors is:

Tn = 0T1 1T2 2T3!n !1Tn = A1 A2 A3 ! An

Eq. (2)

1748 The Open Automation and Control Systems Journal, 2015, Volume 7

Table 1.

Xiaojun Liu

Picking robot joint parameter table.

i

di

Variable Range

Link (mm)

-90

180

L1=340mm

90

L2=350mm

L3

150

L3=350mm

-90

L4

120

L4=0

90

L5 =80mm

According to equations (1) and equation (2) can elicit

that the picking robot with 5 DOF, the end effector pose relative to the base coordinates can be expressed as (Xiong

youping, 1996):

T5 = A1 A2 A3 A4 A5

&c1c234c5 + s1s5 ' c1c234 s5 + s1c5 ' c1s234 ' d 4 s1 + a3c1c23 + a2c1c2 #

$s c c ' c s ' s c s ' c c ' s s

d 4c1 + a3 s1c23 + a2 s1c2 !!

1 234 5

1 5

1 234

= $ 1 234 5 1 5

$ ' s234c5

!

s234 s5

' c234

' a3 s23 ' a2 s2

$

!

0

0

0

1

%

"

& nx ox a x p x #

$n o a p !

= $ y y y y!

$ nz oz a z p z !

$

!

%0 0 0 1 "

cle solid works is selected for modeling, which then trans

forms the component format through Deep Exploration into

cpp formatted files that can be recognized by OpenGL, displays and assemble s the model at appropriate position in

MFC through calling glCallList(), and imports the model

into OpenGL, as shown in the flow chart (Fig. 3).

Eq. (3)

The right-hand end of the equation is the end effector

pose. The end effector pose matrix can be solved if the manipulator joint variables are known, and vice versa (M. Lu

2011, Lara-Molina 2010).

The problem of the forward kinematic solution of the

picking robot is to solve the pose of the end effector relative

to the given coordinate system with the known joint variables and geometric parameters of the connecting rod. From

formula 2 and formula 3, the pose of the end effector of the 5

DOF picking robot is attained.

The issue of inverse robot kinematic solution is to determine the joint variable values with the given position and

posture of the end effector relative to the spatial coordinate

system with the given geometric parameters of the connecting rod of the robot. In this paper, a simplified inverse transformation method is adopted to solve the inverse kinematic

solution of the robot. In this method, one or several inverse

transformation matrixes are multiplied before the matrix

transformation, and then the corresponding elements on both

side of the equation are compared to achieve the goal of

solving the inverse kinematic solution(W.Lu 2011).

3. OPENGL SIMULATION SYSTEM

OpenGL API provides some basic geometry shape drawing, for instance, dot, line, surface, cube, sphere, cylinder,

circular cone, etc. Nevertheless, it will be a difficult and tedious process to only use the built-in API for modeling when

constructing complicated robot geometry shapes. In this arti-

Fig. (3). The flow chart of model import OpenGL.

3.1. Implementation of Dynamic Simulation

OpenGL software package adopted in this article is independent of hardware and can operate in several operating

systems, so it does not have interface problems. The steps of

combing OpenGL and windowsGDI are as follows.

1) Call function setpixelFomart and set pixel format;

2) Establish drawing description list;

3) Acquire equipment list and correlate it to description

list;

4) Call OpenGL command to conduct drawing job;

5) Call swapBuffer to refresh contents on the screen;

6) Release DC and RC when finishing;

Dynamic Simulation System Using DOF Picking Robot

As the positive direction of Z axis of 3-D coordinate system in OpenGL faces the screen and the observer, it is not

corresponding to the coordinate system used by the manipulator. Use translation and rotation function to transform anew

the coordinate, as shown in (Fig. 4).

Fig. (4). Waist coordinate system transformation.

For the sake of the troubles for drawing that every time

calling the rotation and translation functions they will be

accumulated to the model view matrix in OpenGL, OpenGL

supplies a unit matrix to reset the origin, i.e., resetting the

coordinate system origin by multiplying by the unit matrix.

Load unit matrix code as follows:

glMatrixMode();

glLoadIdentity();

In order to conveniently load unit matrix into the matrix

stack, glPushMatrix () is employed to press the present matrix into the matrix stack. Call glPushMatrix () to revert the

matrix to the original state when you want to recover the

present matrix.

For displaying animation effect, OpenGL provides double buffers---when it displays foreground buffering one image, the background buffer is drawing the next image, --which enables the animation to be consistent. Define a timer

and call SwapBuffer()

3.2. Simulation Result and Analysis

Acquire the robot end effector position and poserelative

to reference coordinate system, i.e., the pose matrix, with

given variables of the joints linking the connecting rods in

the simulation system. Meanwhile, in accordance with the

five given joint angle, each robot joint rotates correspondingly in the simulation platform so as to get a new position

and pose.

3.2.1. Kinematics Inverse Solution and Grabbing Motion

Verification

According to the requirements of picking object identification and location result, seek the robot kinematics inverse

solution using the kinematics inverse solution method proposed in this article. Transfer respectively inverse solution

result to the picking robot. Define the coordinates of the target grabbing point in procedure. The computer acquires the

The Open Automation and Control Systems Journal, 2015, Volume 7

1749

inverse solution and track planning,conducts dynamic simulation, completes the target grabbing and verifies kinematics

inverse solution algorithm. Fig. (5) shows the animation

simulation of the manipulator fetching process. It can be

seen from the OpenGL visualized simulation result that the

inverse solution method proposed in this article is simple and

effective with accurate result.

Fig. (5). Animation simulation manipulator fetching process.

4. MANIPULATOR KINEMATICS

VERIFICATION AND SIMULATION

PARAMETER

The robot kinematics forward and inverse solutions are

verified through OpenGL-based robot dynamic simulation.

However, it does not obtain the relation curve of the picking

robot displacement, speed and accelerated speed. Matlab

Robotics Toolbox developed and maintained by Australian

scientist Peter Corke is a series of Matlab-based robotics

toolbox, which is convenient for robot modeling and getting

kinematic parameter curves of each joint.( Corke et al. 1995)

4.1. Robotics Toolbox Modeling

When using RoboticSToolbox to structure a robot object,

it firstly needs to build each joint and then implements the

whole robot object by means of joint combination. To completely structure a robot object, it needs D-H parameters,

joint types (translation or revolution joint), joint quality and

gear ratio [12].

Robotics Toolbox modeling is proceeded according to D-H

parameter list. Set command as follows:

L =LINK([alpha A theta D sigma], CONVENTION);

Among which, alpha A theta D sigma represent respectively torsion angle, rod piece length, joint angle, horizontal

distance, joint type; CONVENTION represents D-H type.

The Matlab-based picking robot model established as

shown in (Fig. 6) is composed of the most basic elements of

joint-type robot- joints and connecting rods. It is in original

state, i.e. all joint moves and angles are zero.

4.2. Track Planning and Simulation

Picking robot motion tracks fall into two types --- space

joint track and Cartesian space track. Robot track planning is

to work out the position, speed and accelerated speed needed

by the joints in motion in order to complete the operation.

Joint space track planning is chosen because it is too com-

1750 The Open Automation and Control Systems Journal, 2015, Volume 7

Xiaojun Liu

plex for planning in Cartesian space and liable to have cases

of no solution.

Fig. (6). Manipulator mod.

Fig. (8). Joint speed cure curve of 3.

The toolbox provides function jtraj for interpolation to

the joint, whose call format is [q,qd,qdd]=jtraj(qr,qz,t);

Q matrix row represent the rotation angle of each joint of

the actual sampling point, and the latter two represent respectively speed vector and accelerated speed vector.

The tracks of Joint 3 in sampling time from the initial

position qr to the final position qz are shown as in (Figs. 79). It is observed that the end effector does not produce

strenuous vibration during the entire motion procedure meeting the job requirement.

It is verified that the theoretical calculation result from

(4), (5) in D-H coordinate system is identical with the simulation result.

Displacement and speed curve chart can reflect the real

motion conditions and be applied to picking robot control.

Fig. (9). Join speed t curve of 3.

CONCLUSION

Picking robot of 5 DOF is developed in order to improve

the economy and adaptability of the picking robot. It adopts

5-DOF open motion chain which connects the waist, the big

arm, the small arm and the wrist in series through the rotational joints. The robot completes the picking operation

through movements of each joint. The objective of studying

robot kinematics is to establish the relationship of the spatial

position between the robot motion components and the end

effector, to build mathematic model of the robot arm movements, and provide theoretical basis and technical parameters

for robotic control.

Fig. (7). Joint displacement curve of 3.

It applies dynamic simulation technology based on

OpenGL and Matlab to the design and development of picking robot, displays dynamically the whole mechanism

Dynamic Simulation System Using DOF Picking Robot

The Open Automation and Control Systems Journal, 2015, Volume 7

motion process, verifies the validity of the control algorithmic, and obtains the robot kinematic parameter curve. It

is illustrated by the simulation results that the kinematic

model established by D-H approach reflects the real motion

conditions of the robot, and both the forward and inverse

kinematic solutions are correct. The research applies computer dynamic simulation technology to agricultural robot

design. Compared with the traditional method of manufacturing trial product, it not only saves the input of manpower

and material resources, but also greatly shortens the mechanism design and development cycle. As a modernized design

means, virtual design technology will certainly have an important influence on the development of agricultural equipment.

[2]

[3]

[4]

[5]

[6]

[7]

[8]

CONFLICT OF INTEREST

The author confirms that this article content has no conflict of interest.

[9]

[10]

[11]

ACKNOWLEDGEMENTS

This work is supported by Shandong province science

and technology development project (No.2011YD03048)

and Shandong Provincial Natural Science Foundation, china

(No.Y2008G32) and Shandong Provincial universities Scientific Research Project (No.J09LG53).

[12]

1751

J. Z. Liu, P. P. Li, and Z. G. Li, Hardware design of the endeffector for tomato-harvesting robot, Transactions of the Chinese

Society for Agricultural Machinery, vol. 39, no. 3, pp. 109-112,

2008.

K. K. Gupta, and R. Gupta, Wavelet based speckle filtering of the

SAR images, International Review on Computers and Software,

vol. 1, no. 3, pp. 224-232, 2006.

F. A. Lara-Molina, J. M. Rosrio, and D. Dumur, "Architecture of

predictive control for a Stewart platform manipulator," 8th World

Congress on IEEE Intelligent Control and Automation (WCICA),

2010, 2010.

M. Lu, and H.J. Zhao, Modified self-adaptable wavelet transform

arithmetic in image edge detection, Application Research of Computers, vol. 28, no. 1, pp. 385-387, 2011.

N. Kondo, M. Monta, T. Fujiura, Fruit harvesting robot in Japan,

Advances in Space Research, vol. 18, no. 2, pp. 181-184, 1996.

P. Cui, Z. Chen, and X.C. Zhang, Statics analysis of apple-picking

robot humanoid manipulator, Transactions of the Chinese Society

for Agricultural Machinery, vol. 42, no. 2, pp. 149-153, 2011.

S. Hayashi, K. Ganno, and Y. Ishii, Robotic harvesting system for

eggplants, JARQ, vol. 36, no. 6, pp. 163-168, 2002.

X.Y. Tang, and T.Z. Zhang, Robotics for fruit and vegetable harvesting: a review, Robot, vol. 27, no. 1, pp. 90-96, 2005.

Y. Xiong, "Roboics" Chain Machi Press, China, pp. 145-155.

Y. Chifu, Y. Zhengmae, O.O. Peter, and H. Junwei, "Modeling and

simulation of spatial 6-DOF parallel robots using Simulink and

Simmechanics, In: 3rd IEEE International Conference on Computer Science and Information Technology (ICCSIT), vol. 4, pp.

444-448, 2010.

W. Lu, A.G. Song, and J.R. Cai, Structural design and kinematics

algorithm research for orange harvesting robot, Journal Of Southeast University, vol. 41, no. 1, pp. 95-100, 2011.

REFERENCES

[1]

P. Corke, A computer tool for simulation and analysis: the Robotics Toolbox for MATLAB, In: Proceedings of the National

Conference on Australian Robot Association, 1995.

Received: June 16, 2015

Revised: August 23, 2015

Accepted: September 11, 2015

Xiaojun Liu; Licensee Bentham Open.

This is an open access article licensed under the terms of the (https://creativecommons.org/licenses/by/4.0/legalcode), which permits unrestricted, non-commercial

use, distribution and reproduction in any medium, provided the work is properly cited.

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Unit 4Dokument31 SeitenUnit 4Senthil KumarNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- ROS based Indoor Navigation Simulation Using SLAMDokument8 SeitenROS based Indoor Navigation Simulation Using SLAMSenthil KumarNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Digital LogicDokument11 SeitenDigital LogicSenthil KumarNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Introduction To Field Programmable Gate Arrays (Fpgas)Dokument8 SeitenIntroduction To Field Programmable Gate Arrays (Fpgas)Senthil KumarNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- ROS based Indoor Navigation Simulation Using SLAMDokument8 SeitenROS based Indoor Navigation Simulation Using SLAMSenthil KumarNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- A Comparison of Fuzzy Logic and PID Controller For A Single-Axis Solar Tracking SystemDokument14 SeitenA Comparison of Fuzzy Logic and PID Controller For A Single-Axis Solar Tracking SystemSenthil KumarNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Ignition SystemsDokument10 SeitenIgnition Systemselvergonzalez1Noch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- CNN in Deep LearningDokument1 SeiteCNN in Deep LearningSenthil KumarNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Moazzam 2019Dokument6 SeitenMoazzam 2019Senthil KumarNoch keine Bewertungen

- Dubey 2016 Ijca 911675 PDFDokument4 SeitenDubey 2016 Ijca 911675 PDFSenthil KumarNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Dubey 2016 Ijca 911675 PDFDokument4 SeitenDubey 2016 Ijca 911675 PDFSenthil KumarNoch keine Bewertungen

- Dubey 2016 Ijca 911675 PDFDokument4 SeitenDubey 2016 Ijca 911675 PDFSenthil KumarNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Cdi 4 Stroke EngineDokument21 SeitenCdi 4 Stroke EngineJose Ricardo WilsonNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Dubey 2016 Ijca 911675 PDFDokument4 SeitenDubey 2016 Ijca 911675 PDFSenthil KumarNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- 7yx3d Yy7bjDokument16 Seiten7yx3d Yy7bjSenthil KumarNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- nrrb7 p0gkv PDFDokument17 Seitennrrb7 p0gkv PDFSenthil KumarNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- RetrofittingDokument8 SeitenRetrofittingSenthil KumarNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- Reinforcement Learning Robotics ResearchDokument7 SeitenReinforcement Learning Robotics ResearchSenthil KumarNoch keine Bewertungen

- Dubey 2016 Ijca 911675 PDFDokument4 SeitenDubey 2016 Ijca 911675 PDFSenthil KumarNoch keine Bewertungen

- Feedback DevicesDokument14 SeitenFeedback DevicesSenthil KumarNoch keine Bewertungen

- MF6505 CNC SyllabusDokument2 SeitenMF6505 CNC SyllabusSenthil KumarNoch keine Bewertungen

- BacklashDokument15 SeitenBacklashSenthil KumarNoch keine Bewertungen

- MF6505 CNC SyllabusDokument2 SeitenMF6505 CNC SyllabusSenthil KumarNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Machine Vision BasicsDokument29 SeitenMachine Vision BasicsSenthil KumarNoch keine Bewertungen

- 17 Power Screw Drives and Their EfficiencyDokument15 Seiten17 Power Screw Drives and Their EfficiencyPRASAD326100% (2)

- Construction Details of CNCDokument80 SeitenConstruction Details of CNCSenthil KumarNoch keine Bewertungen

- Lecture 25 Rapid Prototyping PDFDokument7 SeitenLecture 25 Rapid Prototyping PDFbvnareshNoch keine Bewertungen

- FDM Design Tech PDFDokument7 SeitenFDM Design Tech PDFSenthil KumarNoch keine Bewertungen

- FDM Rapid Prototyping PDFDokument5 SeitenFDM Rapid Prototyping PDFSenthil KumarNoch keine Bewertungen

- RT R T: TechnologyDokument3 SeitenRT R T: TechnologySenthil KumarNoch keine Bewertungen

- 01 ElectricalDokument15 Seiten01 ElectricalKrishna KrishNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Financial Accounting & ReportingDokument4 SeitenFinancial Accounting & Reportingkulpreet_20080% (1)

- Grammar Level 1 2013-2014 Part 2Dokument54 SeitenGrammar Level 1 2013-2014 Part 2Temur SaidkhodjaevNoch keine Bewertungen

- Polystylism in The Context of Postmodern Music. Alfred Schnittke's Concerti GrossiDokument17 SeitenPolystylism in The Context of Postmodern Music. Alfred Schnittke's Concerti Grossiwei wuNoch keine Bewertungen

- How Should Management Be Structured British English StudentDokument7 SeitenHow Should Management Be Structured British English Studentr i s uNoch keine Bewertungen

- JKFBDDokument2 SeitenJKFBDGustinarsari Dewi WNoch keine Bewertungen

- Week 4 CasesDokument181 SeitenWeek 4 CasesMary Ann AmbitaNoch keine Bewertungen

- 5E Lesson PlanDokument3 Seiten5E Lesson PlanSangteablacky 09100% (8)

- DC Rebirth Reading Order 20180704Dokument43 SeitenDC Rebirth Reading Order 20180704Michael MillerNoch keine Bewertungen

- Aspartame Literature ReviewDokument10 SeitenAspartame Literature Reviewapi-272556824Noch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Dukic WarehouselayoutsDokument14 SeitenDukic Warehouselayoutsrohitkamath7Noch keine Bewertungen

- State of Indiana, County of Marion, SS: Probable Cause AffidavitDokument1 SeiteState of Indiana, County of Marion, SS: Probable Cause AffidavitIndiana Public Media NewsNoch keine Bewertungen

- AIRs LM Business-Finance Q1 Module-5Dokument25 SeitenAIRs LM Business-Finance Q1 Module-5Oliver N AnchetaNoch keine Bewertungen

- Callaghan Innovation Annual Report 2018Dokument108 SeitenCallaghan Innovation Annual Report 2018Kerjasama P2BiotekNoch keine Bewertungen

- Chapter 6 Sequence PakistanDokument16 SeitenChapter 6 Sequence PakistanAsif Ullah0% (1)

- Emilia Perroni-Play - Psychoanalytic Perspectives, Survival and Human Development-Routledge (2013) PDFDokument262 SeitenEmilia Perroni-Play - Psychoanalytic Perspectives, Survival and Human Development-Routledge (2013) PDFMihaela Ioana MoldovanNoch keine Bewertungen

- EDUC 5240 - Creating Positive Classroom EnvironmentsDokument5 SeitenEDUC 5240 - Creating Positive Classroom EnvironmentsMay Phyo ThuNoch keine Bewertungen

- Hays Grading System: Group Activity 3 Groups KH PS Acct TS JG PGDokument1 SeiteHays Grading System: Group Activity 3 Groups KH PS Acct TS JG PGkuku129Noch keine Bewertungen

- How to use fireworks displays at Indian weddings to create magical memoriesDokument3 SeitenHow to use fireworks displays at Indian weddings to create magical memoriesChitra NarayananNoch keine Bewertungen

- HED - PterygiumDokument2 SeitenHED - Pterygiumterry johnsonNoch keine Bewertungen

- Grimoire of Baphomet A-Z EditionDokument18 SeitenGrimoire of Baphomet A-Z EditionTheK1nGp1N100% (1)

- Uk GeographyDokument9 SeitenUk GeographyStainbok MihaiNoch keine Bewertungen

- Ajaz CVDokument1 SeiteAjaz CVAjazNoch keine Bewertungen

- CLNC 2040 Reflection of Assistant ExperiencesDokument4 SeitenCLNC 2040 Reflection of Assistant Experiencesapi-442131145Noch keine Bewertungen

- Real Vs Nominal Values (Blank)Dokument4 SeitenReal Vs Nominal Values (Blank)Prineet AnandNoch keine Bewertungen

- Final Revised ResearchDokument35 SeitenFinal Revised ResearchRia Joy SanchezNoch keine Bewertungen

- TAFJ-H2 InstallDokument11 SeitenTAFJ-H2 InstallMrCHANTHANoch keine Bewertungen

- Evirtualguru Computerscience 43 PDFDokument8 SeitenEvirtualguru Computerscience 43 PDFJAGANNATH THAWAITNoch keine Bewertungen

- The Ramayana and The Sacred Palm Trees of Sumeria, Mesopotamia, Assyria and PhoeniciaDokument7 SeitenThe Ramayana and The Sacred Palm Trees of Sumeria, Mesopotamia, Assyria and PhoeniciaNeeta RainaNoch keine Bewertungen

- NAS Drive User ManualDokument59 SeitenNAS Drive User ManualCristian ScarlatNoch keine Bewertungen

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveVon EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveNoch keine Bewertungen

- The Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldVon EverandThe Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldBewertung: 4.5 von 5 Sternen4.5/5 (107)

- Defensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityVon EverandDefensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityBewertung: 5 von 5 Sternen5/5 (1)

- Chip War: The Quest to Dominate the World's Most Critical TechnologyVon EverandChip War: The Quest to Dominate the World's Most Critical TechnologyBewertung: 4.5 von 5 Sternen4.5/5 (227)

- The Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumVon EverandThe Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumBewertung: 3 von 5 Sternen3/5 (12)

- Scary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldVon EverandScary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldBewertung: 4.5 von 5 Sternen4.5/5 (54)

- Algorithms to Live By: The Computer Science of Human DecisionsVon EverandAlgorithms to Live By: The Computer Science of Human DecisionsBewertung: 4.5 von 5 Sternen4.5/5 (722)

- Digital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyVon EverandDigital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyBewertung: 4 von 5 Sternen4/5 (51)