Beruflich Dokumente

Kultur Dokumente

Din 7603 PDF

Hochgeladen von

Luciano Fontes0%(1)0% fanden dieses Dokument nützlich (1 Abstimmung)

4K Ansichten10 SeitenOriginaltitel

DIN 7603.pdf

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0%(1)0% fanden dieses Dokument nützlich (1 Abstimmung)

4K Ansichten10 SeitenDin 7603 PDF

Hochgeladen von

Luciano FontesCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 10

DEUTSCHE NORM. May 2001

Ring seals and gaskets

Ics 23,040.80 Supersedes

November 1994 edition,

Dichtringe

In keeping with current practice in standards published by the International Organization for Standardization

(ISO), a comma has been used throughout as the decimal marker.

Foreword

‘This standard has been prepared by Technical Committee Rohrverschraubungen of the Normenausschuss

Rohrleitungen und Damptkesselanlagen (Pipelines and Pressure Vessels Standards Committee).

Amendments

This standard differs from the November 1994 edition as follows:

a) The dimensions and mass of ring seals and gaskets which are not to be used for new designs are now

dealt with in Appendix A.

b) Dimension r, has been specified for type C gaskets.

©} Dimension d, has been corrected for gaskets of nominal size 21 x 26.

d) The specifications for service temperatures have been amended (cf. table 3)

9} The standard has been editorially revised.

Previous editions

DIN 7603: 1986-07, 1941%-05, 1961-01, 1961-09, 1968-03, 1994-11

All dimensions are in millimetres.

1 Scope

This standard specifies dimensions and materials for ring seals and flat or filled gaskets designed for use

with compression couplings (e.g. as specified in DIN 3850 or DIN 7604) or pipe plugs (as specified in

DIN 908},

2 Normative references

This standard incorporates, by dated or uiidated reference, provisions from other publications. These

normative references are cited at the appropriate places in the text, and the titles of the publications are

listed below. For dated references, subsequent amendments to or revisions of any of these publications

apply to this standard only when incorporated in it by amendment or revision. For undated references, the

latest edition of the publication referred to applies.

CIN 908 Hexagon socket screw plugs with parallel screw thread

DIN.3850 Compression couplings - Overview

Continued on pages 2 to 10.

Translation by DIN-Sprachendienst.

In case of doubt, the German-language original should be consulted as the authoritative text.

a Ral No DINT60S 2007-0

Sa rea oer aay ot zoe cama fp ee gino” sake O07

Page 2

DIN 7603 : 2001-05

DIN 7601 Compression couplings with ball-type nipples ~ Overview e

DIN 737 Vulcanized fibre products ~ Types

DIN EN ISO 6506-1 Metallic materials - Brinell hardness test - Part 1: Test method (ISO 6506-1 : 1999)

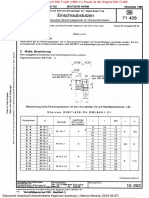

3. Dimensions and designation

‘The designs shown are for illustrative purposes only, but the dimensions of rings seals and gaskets shall be as.

specified.

Type A Flat gasket ‘Type C Filled gasket Type D O-ring

vy Raney Approx. sheet —!

Ray vA thickness: 0.3mm. 4 42

i— wat ———

f 1 = ito

i] Tesga/ | on || i aa 1

a

eeve4

Figure 1: Gasket and ring seal dimensions (notation)

Designation of a type A gasket (A) of nominal size 16 x20, made of vulcanized fibre (Vf

Gasket DIN 7603 - A 16 x 20- VE

Page 3

DIN 7603 : 2001-05

Table 1: Gasket and ring seal dimensions

| ] 1 ht

| p Type A Type © | Type D

' Material |

| ]

FA

al Al

inal size | a |e n

Nominal siz le i | aca | Oo |n

| | cu FA Pro Pr | CuFA | Prg |

| Maxi-| ME | | SIFA | Pr

mum} 20 st

size VE,Zn

vo3)

axe [4279

+038

5 x 75 | 5275

rsto2}is02 | 4

séx 8 [5770

65x 95 | 67 72° 140.2 [05201 | 03

+03]

7 x15) | 7.2 °°

v8

8 x15 | 82 °>

1sxoz|iz02 | 4

10 «135 fio2 “e°

$03

a

1 x16 [roo “2

12 155 [12.2

; +03

t2 x19 [122 "0

14 x18 faz “2

14 x20 [iaz “05|

503)

|

15 x19 fis2 “9 | |

15 x23") [15,2 "5° 1,8£02|1,5+0,150,5+0,1 | 0,8

$08)

16 x20 {162 °F

a7 xn [72 "209 2,) ca

we x22 fea"? b19 2.) 02

+03 0

0 23:9 bo

20 x24 202 oz

v0 0

a1 x26 fe12 "3 ]259 90| ozs

| 2 x27 22% )269 8,| om

-| | | esos |rss02| «

|

23 x28 (23,9 *°l7,9 2] o2s | |

[= == lesa °28l289 8,| 025 |exoe 2402 |1x018 | os lastoalz+oe | 6

25 xa0 [250 °o% a9 9.) oas | | |

+) These sizes are particulary suitable for use with air brakes (materials: Zn and VA)

(continued)

Page 4

DIN 7603: 2001-05

ao «a7 [408 “621469 82) 09s

Tate ni

; @

| Type A [Type © | Type 0

| [ag ee ee

f |

weneaise] fe | | | ly

| Prg | Pr i

| |

|

| | |

—

| {

| |

|

} |

1£015 | 08 2sz04\2x09 | 6 e

| ;

| | |

1 |

; ae | |

a Ee an oe a |

Ee oe |

5 |

42 x49 [42,3 "9 °|48,9 52) 098

lee 2202 |2202 |140,15 | 08 |2szo4|2e

4a xsi [443 ~05\509 9] 035 !

-03

fF 25402/2402

_0,| 04 |

Tos] 0 |

60 x68 [60.5 "9° (67.8 | 04

3405 |2520,4) 10

-03

4 x72 [ea *25\r1.2 2.) 04

Fae 8 ons |

(continued) e

Po

Pages

DIN 7603 : 2001-05

Table 1 (concluded)

al

inalsize| 4, | a, | e

Nominal see} a, | dy ||

cu | FA | Pro | Pr | CURA) Prg

Max-| SFA | Pr

size | | | Vf, Zn

°

m7 fos Phe | ow rt

era bee _2,) oa | |

|

aie bre 24] os |

——— "| —lasxoz|es02 |15202| 03 |s208 |2sz04| 10

80 x 90 foe 8.) os

os x 95 fs7 oe 0.) os | f | |

|

go «100 for “2608 _25| 05 | |

Table 2: Mass

_ _ ‘Mass per 1000 units, inkg (225 9%6))_

Nominal size Type A aA ee cue ee

Mi_[ Prg | Pr | Al Cu | Zn ‘alfa! StFA CuFA] al [St cu

4 8 [0,066)0,096/ 0.0171 0,010/0,089| 0,294] — [0,085] 0,200 | 0,222 [0,081 | 0.235 | 0,266

&_= 78 |0,03010,022!0,010| 0,008 |.055| 0,176] — 0.085) 0,160. 0.178} 0,053] 0,158 0.178

[55x 8 _[0.043)0,024/ 0.011 |0,007 | 0.058; 0.191 | — [0.071] 0,173 | 0,192 [0,057] 0,166 | 0.188

[65% 95 |0,088/ 0,035 | 0,016 | 0,010 0,085, 0.280 0,080) 0.218 | 0.242 |0,088| 0,241 | 0.274

[7 x18 [0,373 0228/0,113] 0,089 [0.559] 1eaa[taval — [| — j— [—|— [—

8 11,5 [0,092/ 0,051 /0.028/ 0,014 [0,124] 0,962 [0.412[ — | 0,125] 0,328 | 0.939 [0,120] 0,399 | 0.384

10135 [0,111 [0052] 0,02810,017|0,150| 0.455 [0.403] — [0.188/ 0368 | 0.408 .14s{ 0.000 |0.400|

| 12x15 |0,195/0,107 0.033) 0,020/0.264 0,767 1.87 | — [0218) 0516 | 0575]0,263| 0,734] 0.631 |

[42 x16 [0,230/0.126]0.038|0,025/0.311 | 0,05 | 1.08 | — [0.234] 0554 0.615 |0,300| 0.876 | 9.990

12 «19 |0.461|0,282/0,199]0,085|0,601| 2,01 [2.28 |ieze] — | — |— | —|— |—

14x18 |0,264)0.145 fo.s56) 1,03 [1.17 | — [0.268] 0,635 | 0,705 0,340] 0.990] 1.12

14 x20 _[0,440|0,242 0.595] 1,73 | 1,96 [1,71 [0.428] 0,965 | 1,07 [162 | 184

15 x19 |0,280|0,154|0,047|0,028 [078] 1,10 | 1.25 | — [0.286] 0.675 | 0.747 |0.360) 7,05 | 1.10

15 x23 Josaa|o.364| aia fess] -| -| -1-| —-1 —

16 x20 |o,800/6.165) 0.050) 0,080 0,408) 1.178) 1.98 | — [o.00)ari2 oreo lose] ua [ize |

a7_ x21 |0,920/0,176|0.053]0,032|0.498|1.28 [1.43 | — [0a42) 0.755 | 0.897 [o.a06| 1.18 | 1.04

18x22 ]o.26|0.180|0.055]0,039|0.44) 1.20 [1.48 | — oss|0789|0.880/0.404[1.25 [1.40

20x24 ]0,980]0.198| 0,060 0.096 0.486] 1.42 [1.16 | —|o,s8a| 0.71 0.966 |o.468/7.96 [1.58 |

1) Mass calculated taking the density as,

1,8kg/dm? for FA 8,9 kg/d? for Cu

1.3 kg/dm? for VE 1,2 kg/d? for asbestos-free filler material type C)

2,7 kg/dms for Al 7,14 kg/dm® for Zn

7,85 kg/dm? for St

(continued)

Page 6

DIN 7603 - 2001-05

Table 2 (concluded) e

‘Mass per 1000 units, nkg 25%) |

Type A “Type Type D

Nominal size|“Fa-[-VF_| Pra] Pr Al] St [Gu | 2h AIPA] StFAGuFA| Al] St_| Gu |

Bix 26 [0.500] 0.276|0.08510.050] 0675. 1.96, 222) — 0.508) 3.17] 1.20]0.630) 1.89] 2.06

22 0.5221 0,288| 0,087 / 0,052 0.705: 2,05 | 2.92 0.517] 1.23] 1.95[0,656] 1.92| 2.17

0.705] 0,986{0,17710.054|0.950, 2.77| a24| — ode] 146 | 1.62[0.945| 2.75| 12

0.733} 0,403/0,184/0,055|0.900) 2.98) 3.26 | — 0.665) 1.66 |0.980| 2.85] 3.25|

0765) 0422 0.190, 0.057] 1.03 | 29a a0] — aes 4.73 2.98] 3.38

s10,197/0,059/1,07 | 3,10! 351| — jo7te 173 3.05 | 3.45|

[sai] 3.641 0.740. 1.67 | 1,85 [3.18] 3.60

0,845] 0.460/ 02121 0064] 1.14 | 3.9:| 375| — 0,765, 1,72] 191|1,13 | 320] a7

Jia [0.620'0200' 0084/1562 | 441] 5.00] — o9ss] 214] 28 1a [are] 468

1.20 | 0,655) 0.298) 0.090|1,60 | 4.66| 5.27] 1.015) 2.28 | 253/150 | 437] 494]

4,24 0,673) 0,305] 0,092|1.65 | 4.90) saa] — 1,04 | 2.44 | 2.60 a 4.65 | 5.29

30 [0,713)0,92310.097|1,74 | 807] 5.73] — 1,10 | 248] 2.75] 163 | 4.74/ 5.38

o.7a2)0.30210.10011.79 5.20| 8.08] — 1.66 | 2.54] 2.2|1,74 | 5.07] 5.71

41 0.767/0,948)0,10411.88 | 5.47] 615 1.18 | 266 | 2.95/18 | 5.33) 605 e

“174 [0,943]0,428|0,128)2.42 | 673) 696 340 | 342 [2.16 | 628] 7.08

7.76 [0.966] 0496| 0.132237 | 686 7.80

4.83 [1.02 [0.457] 0.19812.47 | 720] 6.15| —

491 [1.08 [0.47@]0.144]2.68 | 7.60| 8.50/

32 [7.95 [1,08 [0.47a|0,144]2.68 | 7.67] 9.68

55 [2,07 [1.14 10.518!0,1562.80 | 8.15) 9.23,

2.15 11.18 [0,540] 0,162/2,90 | @.45| 956

2.90 [1.60 |oe70[ 741385 [11.4 [120

3.00 [1.67 |0,900] 0,100] 4,06 [11.8 [134

3.11 [1.72 |0.930[0.185)420 | 122 [138

3.16 | 350|2.20 | 6,50 7.40

a30| 366/200 | 674) 7.62

aaa ae21241 | 7.00] 7.95

ast | 390/245 [7.14] 810

3,74 | 4,15 [2,62 | 7,56) 8,55

57 3.83 | 4,30 [270 | 7.84] 8.87

60 477 | 630/390 {114 [129

2 492 | 5.46 |408 1417 [192

63 500] 886/412 [120 [135

e4 Jara [175 [0.9a2/0.187|430 [123 [1205] — [eas | 5.101 S65 [41 [12.15] 108

66 [3.22 [1.77 [0.965|0.199)4.35 [126 | 143 585/493 [12.6 [143 |

8 ]32 | 1.85" | 1,000] 0.200|4.48 | 190 | 148 | 600/446 [129 | 146

72

74

73

a4

38

90

2.63 | 41

3.52 [1.98 11.08 [0.213/ 460 | 1385] 18.7 6.35 |4.74 | 13.65] 156

358 [1.97 [1.07 [o2ta]4a3 | 140 [159

i

[7651553 | 160 [18.0

4,68 (2.50 [1.40 [0,280/6.95 | 186 [209 368 | 7.99] 820/591 [172 | 195

5000 276 [1.80 |0,a00|6.75 [196 [22.0 | — [9.00 797) 875[6a1 i184 [215 e

5.86 [9,20 [1,76 To,s52|7.90 [2 0 [26.1 | — [460 | 895) 995|7.38 [217 [246 |

80 x 5.95 [325 [1,79 [0,356/8,00 [231 |263 | — [473 | 928! 100 |7,60 [221 |252

[as 25 [625 [aaa [198 [oa76leas [245 |o78 | — [4.95 | 070107 17.62 [228 [259

[90100 [6.61 3.63 2,00 |0,400/8,95 [259 [205 | — [5.23 [102 [11.9 [8.96 [249 [27.6

‘See page 5 for’)

4 Materials

PageT

DIN 7603 : 2001-05

The type of ring seal or gasket is to be selected as a function of the application, medium conveyed and service

temperature and shall be the subject of agreement between manufacturer and user.

‘The material specifications for types A and D gaskets shall be taken from table 3, those for type C gaskets from

table 4. Use of other materials shall be the subject of agreement.

Table 3: Types A and D ring seals and gaskets

Ring seal or gasket

‘Symbol Material Maximum service Type(s)

temperature, in °C

FA) __| Asbestos-free material’) 150

‘Aluminium of grade Alea (11), ——*|

ow hardness: 32 HB to 45 HB®) | 200

cu ‘Copper; hardness: 45 HB max) 300 aL :

Peg impregnated paper 120

Pr___| Unimpregnated paper I 80

St__[ Sof tos heroes: 80HB 1 95 |_—_—_400

Vulcanized fibre of type vf 2110 5

_ or VF 3111 as in DIN 7737 Ee) us

Zine of grade 99,5 300 A

) Materials suitable for higher service temperatures shall be the subject of agreement

2) See DIN EN ISO 6506-1 for hardness testing

3) Short-term water vapour resistance at 160°C.

Table 4: Type © gaskets

Gasket

symbol Material Maximum service Type

temperature, in °C

‘Aluminium of grade AlO9 (FT); |

AIFA | hardness 32 HB to 45 HB"), 200 ©

with an asbestos-ree fil _

Gopper; hardness: 45HB maximum’),

oe with an asbestos-free filler aa g =

Soft iron; hardness: 80 HB to 95 HB"),

ees with an asbestos-free filler oe iS

1) See DIN EN ISO 6506-1 for hardness testing

oa

Page 8

DIN 7603 : 2001-05

Appendix A e

Dimensions and mass of ring seals and gaskets which are not to be used for new designs

Table A.1: Dimensions

T i

| Type A [type © [Type 0 |

ie Material |

| a |

Al AL

sninal size | a, e

Nominal || st | | AFA | Gu

cu FA Prg | Pr} CuFA | Prg

Maxi-| Vf siFA | Pr

|mum| zn | | st

| vizn |

ep ros 0]

6 x10 |62°09/99 2] o2

osx11 | 67 7210.9 8.) o22 |

a x13 [82799129 boloas |1z02 j1202 jos5+01| 09 1.5402 |1202 | 4

8 x14

10 x14

10 x15

10 x16

12 x17

12 x18

1540,1905+0,1 | 0,3

18 x24

(continued)

Pages

DIN 7609 : 2001-05

e Table A.t (concluded)

al Lo a

Type A Type © | Type D

al al

Nominal size

st ara | Cu

cu FA Pro | Pr | CuFA | Prg

w j SFA | Pr

Zn | I 4 st

| | | | Vizn

2432 i | |

2538 | | |

+ |

26 x 32 | |

e 26x34 [26,3 *5°|93,9 5. i |

30 x38 | 2202] 2202 | 03 \2 04] 2403) 6

== peepee pee

36 a5 poof

42x51 | | i

isa | i

wsn58 [650 25600 29) ons |

Table A.2: Mass

- Mass per 1000 units, in kg 25H) =

Type A Type —Type B

Nominal size lea | Vi Prg | Pr | Al ‘St_[ Cu | Zn [AIFA] StFA CuFA| Al st_| cu

3x 8 [0,080/0,044|0,020[0,0121 0.115] 0,312] 0,354] — 10,102] 0,238 | 0,264 [0,099] 0,288 | 0.328]

@ +10 ]0,088|0.04910,022)0.013| 0,119] 0.346] 0.395] — [0.116] 02711 0306 |0.118/ 0,909] 0.374

65x11 ]0,112/0.062 0,028)0.017] 0.151] 0.498) 0496] — 0.140] 0.92, 0,366 (0.138) 0,402 | 0.487

@ 8 ~12 |0,109)0.060 0.028| 0.077] 0,148] 0,430| 0.488 — {0,144] 0.040 0,877 [0,195] 0.599 | 0.448

@_ 13 fo360|0085|0.056[0.025| 02051 096] 0636| — [o.7a| ove 046s o.7e] ote] 0889

8 (0,105 | 0,048 | 0,028] 0,256] 0,745| 0.845| — [0,238] 0,550 0,610 [0.214] 0,628] 0,710

10 x14 073) 0.095|0,020/ 0.176) 08] 0686) — [0.1731 0.408 0.453 [0,162] 0.472 | 0595

10087] 0044|0.017[ 0228| o4sa] 0788] — |o21010.498 0860|0.202| oes 0.758

10x16 0,124] 0061 |0,07/ 0,090) 0.882| 1,00 | — [0261] 0.648 0,720 /0.253| 0,737 | 0.637

12 a7 0,107/0052[0,081 0.16) 1.21 | 1,97 | — |o.s14| 0.725] 0.805 [0.386] 1.14 | 1.30

7218 0.215 0.065] 0,039|0.507) 1,53 | 174 | — |0.006| 0.47 [0.990 [0.485] 1.43 | 162

46 x22 |[0.490|0272]0,082|0,049|0.667| 1.94 | 220 | — [0.400| 1.08 | 1.20 |0.620| 1.80 | 205

47x28 [0552] 0286/0087|0,052|0705/ 2.08 [202 | — Tie [oseo)ast [172

18 x24 |0.545|0.900/0.000) 0.054/0.737| 2.14 | 2.42 | — [0326] 1.10 1,82 |0.680| 1,96 | 225

20” x28 }o.s00/03900.100|0.060|010| 205 [266 | — losva|1si 145 [aras| 2.7 | 246

22x28 |0,779)0.427/0,129|0,078|1.05 | 3.06 | 3.45 | — [o.7aa]1.68 1,86 [0.920] 2.68 | 3.07

) Mass calculated taking the density as

1.8kg/dm* for FA 8,9 xgldm® for Cu

e 133ka/dm® for VE 1,2 kg/em® for asbestos-ree filer material (ype C)

217 kg/dm’ for Al 7.44 kg/d for Zn

7,85 kg/d for St

(continued)

ee eee

Page 10

DIN 7603 : 2001-05

Table A.2 (concluded)

“Wass por 1000 units, mn kg (25 9a)

Nominal size Type A [__TypeC__]_type

FA Wi [Pra] Pr | All St] Cu | 2n |AIFA| SIFA CuFA’ Al | st | Co

1.32 [0,725|0.380[0.098] 1.77 [614 [6as | — [1.16 2ae [26a [1621472 [50

1.35 [0,745 [0,936] 0,10211.82 [590 [600 | — [11a [246 [27a 1168 488 | 556

26x32 [0,995[0,544|0240[0075|1,34 | 88 | 440 | — [0840] a9 [240 | 124 362 | 410

26 »34 | 1,99 |0,770/0,348|0,105|1.88 | 5,49 | 622 | — [1,24 [252 [2.80 | 1.74| 5,08 | 5,75

pees Oe By deeds (200 eT

go a8 [18 [o.7olooa[oar7|2r4 [eae |70s — [rar [aes [ate | 196 [70 | 6a

a2 «40 [1.88 [0.828|0.421[0.126|2.27 1660 [7481 — [147 [308 [aaa [20a [60s [eee

38 46 ]1.96 [1.08 [o.aai|o.ta7|265 [7.70 [ave | — [17a [sas [aos [242 |7.08 | 00

a2_xs1 [246 [1,35 [0.10 (0,169|542 [905 toa | — [ier |aa7 [ase [aso [eas [oss

a5_vsa [262 [1.44 [o.660/0.196|862 0a [17 | — [eso [aaa [ase [ata [or ios

‘See page 9 for

Das könnte Ihnen auch gefallen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Din 73377 PDFDokument7 SeitenDin 73377 PDFLuciano FontesNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Din 50961 PDFDokument6 SeitenDin 50961 PDFLuciano Fontes100% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Eletronica Dgital 3 Cruzeiro Do SulDokument18 SeitenEletronica Dgital 3 Cruzeiro Do SulLuciano FontesNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- NB 98Dokument21 SeitenNB 98ALAN CARDOSO0% (1)

- NB 98Dokument21 SeitenNB 98ALAN CARDOSO0% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- NBR 5425 - Guia para Inspecao Por em No Controle E Certificacao de QualidadeDokument30 SeitenNBR 5425 - Guia para Inspecao Por em No Controle E Certificacao de QualidadeJulio Marchi100% (1)

- Unidade - CaDokument24 SeitenUnidade - CaLuciano FontesNoch keine Bewertungen

- NBR 14349 - União para Mangueira de Incêndio CorrigidaDokument1 SeiteNBR 14349 - União para Mangueira de Incêndio CorrigidaLuciano FontesNoch keine Bewertungen

- Portaria 547 de 2022 - MangueirasDokument17 SeitenPortaria 547 de 2022 - MangueirasLucianoNoch keine Bewertungen

- NBR 11861 - Mangueira de IncêndioDokument16 SeitenNBR 11861 - Mangueira de IncêndioLuciano FontesNoch keine Bewertungen

- Estrutura Da Carta PsicométricaDokument1 SeiteEstrutura Da Carta PsicométricaLuciano FontesNoch keine Bewertungen

- Tabela PsicrometriaDokument27 SeitenTabela PsicrometriaLuciano FontesNoch keine Bewertungen

- Chavetas ISODokument14 SeitenChavetas ISOLuciano FontesNoch keine Bewertungen

- MB 3472 - 1991 - Estacas - Prova de Carga EstáticaDokument5 SeitenMB 3472 - 1991 - Estacas - Prova de Carga EstáticasilvaronaldorNoch keine Bewertungen

- Abnt 6925Dokument2 SeitenAbnt 6925Luciano FontesNoch keine Bewertungen

- NB 97 - Rosca Métrica ISO - TolerânciasDokument9 SeitenNB 97 - Rosca Métrica ISO - TolerânciasLuciano FontesNoch keine Bewertungen

- Eletronica Dgital 4 Cruzeiro Do SulDokument18 SeitenEletronica Dgital 4 Cruzeiro Do SulLuciano FontesNoch keine Bewertungen

- NBR 12118 - MB 3459 - Blocos Vazados de Concreto Simples para Alvenaria - Determinacao Da AbsorcaDokument3 SeitenNBR 12118 - MB 3459 - Blocos Vazados de Concreto Simples para Alvenaria - Determinacao Da AbsorcaMariana ArrudaNoch keine Bewertungen

- MAtéria Técnica Sobre Extintores de IncêndioDokument6 SeitenMAtéria Técnica Sobre Extintores de IncêndioLuciano FontesNoch keine Bewertungen

- NBR 10538 - 1988 - Interpretação Estatística de Dados - TestDokument26 SeitenNBR 10538 - 1988 - Interpretação Estatística de Dados - Testbrunojahn8873Noch keine Bewertungen

- ABNT NBR 6943 - Conexões de Ferro Fundido Maleável Com RoscaDokument78 SeitenABNT NBR 6943 - Conexões de Ferro Fundido Maleável Com RoscaLuciano Fontes100% (3)

- Guia Aço Acerlor MittalDokument132 SeitenGuia Aço Acerlor MittalPedro Henrique da RochaNoch keine Bewertungen

- Din 50962 PDFDokument11 SeitenDin 50962 PDFLuciano Fontes100% (1)

- Din 17671Dokument0 SeitenDin 17671Niculescu Marian50% (2)

- DIN 17223-Part PDFDokument12 SeitenDIN 17223-Part PDFBeatriz StockhausennNoch keine Bewertungen

- Din 50190-3 PDFDokument3 SeitenDin 50190-3 PDFLuciano FontesNoch keine Bewertungen

- Din 71428 PDFDokument2 SeitenDin 71428 PDFLuciano Fontes100% (1)

- Din 50190-2 PDFDokument4 SeitenDin 50190-2 PDFLuciano Fontes100% (1)

- Din 50190-1 PDFDokument4 SeitenDin 50190-1 PDFLuciano Fontes100% (1)