Beruflich Dokumente

Kultur Dokumente

2843-Sharpening Drills & Tools

Hochgeladen von

syllavethyjim0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

16 Ansichten1 SeiteGeometer Tips

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenGeometer Tips

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

16 Ansichten1 Seite2843-Sharpening Drills & Tools

Hochgeladen von

syllavethyjimGeometer Tips

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

DING AND FORMING

GEOMETER gives further instructions to the

novice on shaping metals

UMEROUS BENDING AND form-

ing operations can be performed in the vice with a

hammer and simple mandrels and

formers. From round rod can be

made hooks, eyes, special staples,

chain links; flat sheet or strip serves

for light-section angles, channels,

boxes and endplates.

Small diameters and thin sections

can be worked cold but for manipulating large sections using mild steel,

a concentrated form of heating is

desirable-such as a welding torchwhich brings the metal to bright red

heat.

Heating prevents cracking in hard

steels and some types of iron are prone

to cracking if bent when cold. Cracking is also prevented in copper and

brass sheet by annealing; this is

performed by heating the material to

red and plunging it in water.

Some materials may tend to crack

when bent in one plane and not when

MODEL

ENGINEER

bent at right angles. Hard brass and

copper, common iron and duralumin

are most prone to cracking when

working. The first and second should

be annealed, the third worked at

bright red heat and the last avoided

except, for large-radii bends-or when

heat treatment is possible.

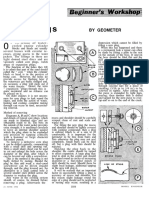

Forming an eye

From wire, an eye can be turned on

a piece of rod A using round-nosed

pliers, but diameters of about 1/8 in. or

over require the assistance of the

vice. A mandrel from a piece of

mild steel rod is then utilised; it is

gripped in the vice with the rod B.

It is convenient for the mandrel to

be provided with a flat one side,

filed for the vice jaw to grip; on the

opposite side there can be a shallow

groove at an angle to locate the rod

to be used for the eye. This groove

can be cut with a small round file.

At the second stage of the work C,

the end of the rod X is pulled against

the edge of the vice to form the neck;

the end Y is then carried round the

mandrel to form the eye, as at D .

Removed from the vice, the rod is

tapped down the mandrel, the surplus

cut off and the eye straightened by

squeezing in the vice.

E and F show the flat and the groove

on the mandrel, while these may not

be absolutely necessary, they do

prevent movement while working. If

produced cold, the eye will spring

open slightly when pressure is released

on the end of the rod Y. Consequently,

a mandrel somewhat smaller than the

finished inside diameter of the eye is

required.

At red heat, however,

close-fitting eyes can be produced

from mild steel rod.

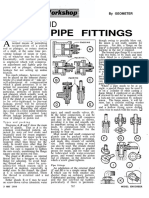

chain link and utilised as at J for the

third turn forming a tee handle.

Channels and flanges

Short angle lengths in strip metal

can be hammered over the vice jaws

but for long lengths the strip should

be held between two lengths of angle

iron K, gripped one end in the vice

and the other fixed with a clamp.

When an angle is formed, a channel

L can be produced over a suitable

section piece of bar.

For turning thin, ductile sheet

metal and strip, hardwood formers of

oak or beech should be made to the

inside dimensions required, as for the

metal box at M. A piece of bar should

be clamped on the opposite side of

the sheet metal, level with the block

where the corner is to be turnedLinks and tee handles

this prevents buckling as the metal is

Chain links and tee handles G can turned over.

Round flanged ends, as for small

be turned using simple holders. For

the first stage H , a hole can be drilled boilers, can be formed from copper

discs held between two suitable large

through a piece of bar to take the

rod, the end of the hole radiused if washers N and squeezed in a powerful

necessary. For the second stage, a vice. The discs should be annealed

split holder Z can be made by drilling beforehand; forming can be assisted

at the joint of two pieces of bar. part of the way through the operation

Cut to form jaws, they can be gripped by hammering over the smaller of

about the rod for the second turn of a the washers.

El

826

1 DECEMBER 1955

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- IMP Workshop ManualDokument336 SeitenIMP Workshop Manualsyllavethyjim67% (3)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- 2884-Panel Beating PDFDokument1 Seite2884-Panel Beating PDFsyllavethyjim100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Astm A 743 PDFDokument8 SeitenAstm A 743 PDFWill MottaNoch keine Bewertungen

- Astm G 44 - 99 - RZQ0Dokument4 SeitenAstm G 44 - 99 - RZQ0Samuel EduardoNoch keine Bewertungen

- AWS CWI Part B-Book of Specs-Spanish 2017Dokument105 SeitenAWS CWI Part B-Book of Specs-Spanish 2017SYED FADZIL SYED MOHAMED100% (4)

- Seam DefectDokument4 SeitenSeam DefectPatrick Dominguez100% (2)

- API 610 Centrifugal Pumps For Petroleum Petrochemical and Natural Gas Industries 11th Ed 2010 APPENDIX HDokument8 SeitenAPI 610 Centrifugal Pumps For Petroleum Petrochemical and Natural Gas Industries 11th Ed 2010 APPENDIX HZlatko CvetkovskiNoch keine Bewertungen

- Specs 670-26 - C27Dokument13 SeitenSpecs 670-26 - C27Hery Mardiono Hery50% (2)

- HDPE Pipe Joining System PDFDokument22 SeitenHDPE Pipe Joining System PDFVasilica Barbarasa50% (2)

- En 10208-1Dokument49 SeitenEn 10208-1Semcabih100% (4)

- 2885-Dent & Bulge Removal PDFDokument1 Seite2885-Dent & Bulge Removal PDFsyllavethyjimNoch keine Bewertungen

- 2890-Nuts & Spanners PDFDokument1 Seite2890-Nuts & Spanners PDFsyllavethyjimNoch keine Bewertungen

- 2889-Further Drilling Methods PDFDokument1 Seite2889-Further Drilling Methods PDFsyllavethyjimNoch keine Bewertungen

- 2886-Stud Fitting & Removal PDFDokument1 Seite2886-Stud Fitting & Removal PDFsyllavethyjimNoch keine Bewertungen

- 2881-Radii Functions and Checking PDFDokument1 Seite2881-Radii Functions and Checking PDFsyllavethyjimNoch keine Bewertungen

- 2880-Supporting & Steadying PDFDokument1 Seite2880-Supporting & Steadying PDFsyllavethyjimNoch keine Bewertungen

- 2872-Circular Clips #2 PDFDokument1 Seite2872-Circular Clips #2 PDFsyllavethyjimNoch keine Bewertungen

- 2874-Fitting Core Plugs PDFDokument1 Seite2874-Fitting Core Plugs PDFsyllavethyjimNoch keine Bewertungen

- 2883-Metal Working PDFDokument1 Seite2883-Metal Working PDFsyllavethyjimNoch keine Bewertungen

- Contours 1: Hile It CannotDokument1 SeiteContours 1: Hile It CannotsyllavethyjimNoch keine Bewertungen

- 2888-Oblique Drilling PDFDokument1 Seite2888-Oblique Drilling PDFsyllavethyjimNoch keine Bewertungen

- 2879-Clamping & Holding PDFDokument1 Seite2879-Clamping & Holding PDFsyllavethyjimNoch keine Bewertungen

- 2887-Broken Drills & Taps PDFDokument1 Seite2887-Broken Drills & Taps PDFsyllavethyjimNoch keine Bewertungen

- 2878-Chains & Sprockets PDFDokument1 Seite2878-Chains & Sprockets PDFsyllavethyjimNoch keine Bewertungen

- 2876-Belt Fasteners PDFDokument1 Seite2876-Belt Fasteners PDFsyllavethyjimNoch keine Bewertungen

- 2875-Belt Drives PDFDokument1 Seite2875-Belt Drives PDFsyllavethyjimNoch keine Bewertungen

- 2873-Cotters & Wedges PDFDokument1 Seite2873-Cotters & Wedges PDFsyllavethyjimNoch keine Bewertungen

- 2868-Glands & Pipe Fittings PDFDokument1 Seite2868-Glands & Pipe Fittings PDFsyllavethyjimNoch keine Bewertungen

- 2877-Roller Chain & Sprockets PDFDokument1 Seite2877-Roller Chain & Sprockets PDFsyllavethyjimNoch keine Bewertungen

- 2871-Circular Clips #1 PDFDokument1 Seite2871-Circular Clips #1 PDFsyllavethyjimNoch keine Bewertungen

- 2870-Simple Screw Assembly PDFDokument1 Seite2870-Simple Screw Assembly PDFsyllavethyjimNoch keine Bewertungen

- 2865-Testing & Facing Valves PDFDokument1 Seite2865-Testing & Facing Valves PDFsyllavethyjimNoch keine Bewertungen

- 2863-Valve Seating Tools PDFDokument1 Seite2863-Valve Seating Tools PDFsyllavethyjimNoch keine Bewertungen

- 2869-Fitting & Joining Pipes PDFDokument1 Seite2869-Fitting & Joining Pipes PDFsyllavethyjimNoch keine Bewertungen

- 2867 Case HardeningDokument1 Seite2867 Case HardeningEr Sukhwinder SinghNoch keine Bewertungen

- 2861-Wheel & Shaft PullersDokument1 Seite2861-Wheel & Shaft PullersSandra Barnett CrossanNoch keine Bewertungen

- 2866-Hardening & Tempering PDFDokument1 Seite2866-Hardening & Tempering PDFsyllavethyjimNoch keine Bewertungen

- 2864-Poppet Valves & Seating PDFDokument1 Seite2864-Poppet Valves & Seating PDFsyllavethyjimNoch keine Bewertungen

- Automated Controlled Shot Peening of Metallic Articles Prior To Nickel, Autocatalytic Nickel, or Chromium Plating, or As Final FinishDokument9 SeitenAutomated Controlled Shot Peening of Metallic Articles Prior To Nickel, Autocatalytic Nickel, or Chromium Plating, or As Final FinishDanZel DanNoch keine Bewertungen

- Process Optimisation For A Squeeze Cast Magnesium Alloy MetalDokument8 SeitenProcess Optimisation For A Squeeze Cast Magnesium Alloy MetalAugusto GoulartNoch keine Bewertungen

- PM BOQ Electrical EstimateDokument53 SeitenPM BOQ Electrical EstimateXozanNoch keine Bewertungen

- IscarDokument158 SeitenIscarDOBJAN100% (1)

- 2013 Mechanismofdebismuthizingwithcalciumandmagnesium PDFDokument5 Seiten2013 Mechanismofdebismuthizingwithcalciumandmagnesium PDFLayos Peru HdzNoch keine Bewertungen

- Determining Density Lab ReportDokument3 SeitenDetermining Density Lab ReportJohn JohnsonNoch keine Bewertungen

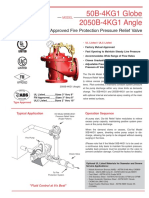

- 50B-4KG1 Globe 2050B-4KG1 Angle: Listed/Approved Fire Protection Pressure Relief ValveDokument2 Seiten50B-4KG1 Globe 2050B-4KG1 Angle: Listed/Approved Fire Protection Pressure Relief ValveNazrul IslamNoch keine Bewertungen

- FH Thermal Exp Piping Sys-Part1Dokument50 SeitenFH Thermal Exp Piping Sys-Part1mehdiNoch keine Bewertungen

- Welded JointsDokument15 SeitenWelded Jointsoki zNoch keine Bewertungen

- Esdep Lecture Note (Wg2)Dokument26 SeitenEsdep Lecture Note (Wg2)Rahul ShrivastavaNoch keine Bewertungen

- Heat Treatment PDFDokument1 SeiteHeat Treatment PDFkdalavadi3905Noch keine Bewertungen

- Japanese Iron and Steel Certified Reference Materials: I. Crms For Chemical Analysis I-1. Pure Iron SeriesDokument10 SeitenJapanese Iron and Steel Certified Reference Materials: I. Crms For Chemical Analysis I-1. Pure Iron SeriesrizaedlysamNoch keine Bewertungen

- VACTOR Nozzle CatalogDokument28 SeitenVACTOR Nozzle CatalogmvalleNoch keine Bewertungen

- Zinc On Stainless Steel Danger PDFDokument104 SeitenZinc On Stainless Steel Danger PDFLâm ThanhNoch keine Bewertungen

- PacificValvesCastSteelBoltedBonnetCatalogCV 421 PDFDokument28 SeitenPacificValvesCastSteelBoltedBonnetCatalogCV 421 PDFGoutham KSNoch keine Bewertungen

- Diacid Corrosion Water Based FluidsDokument18 SeitenDiacid Corrosion Water Based FluidsNgũ Viên Gia CácNoch keine Bewertungen

- Structural Repair Manual: S - Indicates Single Action RivetDokument6 SeitenStructural Repair Manual: S - Indicates Single Action RivetJose Miguel Atehortua Arenas100% (1)

- Chemical Composition and Mechanical Properties of Steel (Indian Standard)Dokument6 SeitenChemical Composition and Mechanical Properties of Steel (Indian Standard)Sreenubabu KandruNoch keine Bewertungen

- Metallic ChemistryDokument14 SeitenMetallic ChemistryEko Budi PrasetioNoch keine Bewertungen

- Farm Shop: Multiple ChoiceDokument2 SeitenFarm Shop: Multiple ChoiceAlfredo CondeNoch keine Bewertungen

- Acuflo Price List 2016Dokument35 SeitenAcuflo Price List 2016anilrawat1987Noch keine Bewertungen

- Chapter21 - Fundamental of MachiningDokument63 SeitenChapter21 - Fundamental of Machining叭叭叭2Noch keine Bewertungen