Beruflich Dokumente

Kultur Dokumente

2889-Further Drilling Methods PDF

Hochgeladen von

syllavethyjimOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

2889-Further Drilling Methods PDF

Hochgeladen von

syllavethyjimCopyright:

Verfügbare Formate

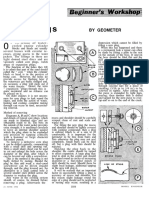

Further DRILLING METHODS

E N S U R E horizontal

accuracy

in hand drilling, some types

of hand and breast drills are

provided with small built-in spirit

levels. Thus, using such a machine

horizontally, keeping the bubble

central will maintain the line of

the hole horizontal, and looking

at the drill from above, it is easy

to see if reasonable squareness

obtains in the other direction,

For verifying the accuracy of the

built-in level (and it is always advisable

to test ones tools), another small level

is required. The accuracy of this is

first tested by placing it on a surface

to bring the bubble central, then

turning it through a half circle and

observing that the bubble is again

central. After which, the level can

be laid on a stiff true drill or piece

of rod held in the machine chuck,

when the bubbles of both levels

should lie centrally.

R O U ND

TOCK

4 OCTOBER

1956

If required, a machine without a

built-in level can be aligned in this

manner, placing the level on the drill

before commencing, then re-checking

when the hole has progressed a little

way but not so far as to prevent

correction if necessary. Yet another

method is to hold a small square to

the work and align the drill to the

blade.

On occasion it is necessary or

desirable for one hole or series of

holes to be vertically below another

as may happen in hanging doors or

gates in existing surrounds. Then a

plumb line dropped from the upper

hole(s) will provide the line on which

to position the lower.

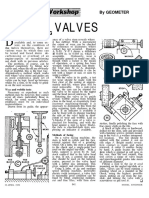

For the occasional angle drilling

job occurring in circumstances when

it is not convenient to employ gauges

described in the previous issue, adjustable types are useful equipment.

From any type of protractor, they

can be set on a nearby flat or straight

surface, then applied to the work.

For round or flat stock

The gauge at A can be made from

angle iron 1 in. on the flat, 2 1/2 in.

long for the base, with a blade about

3/32 in. thick, 3/4 in. wide, 2 1/2 in. long.

The pivot should be a screw with

a wing nut for holding the blade

when set.

An alternative type, B, for use on

either flat or round stock, may have

the same general dimensions; but

the angle iron should be slotted at

the corner to accept the blade centrally,

a small lug then being attached each

side to take the pivot screw and wing

nut. This gauge may be set with a

protractor on either round stock or a

flat surface, then employed as C.

If rivets are used for fixing the lugs,

the holes should be countersunk in

the underside of the angle iron; and

to hold the gauge on round stock,

there can be situated in the base

back from the blade an upstanding

screw on which to hook the ends of a

stout rubber band (from an old motor

tube) passed round the round stock.

Half-round holes produced by drilling may on occasion be necessary as

a feature of components, though at

times the principle can be employed

as a convenience or an alternative to

other methods.

An example of the necessity for half417

STRI p

DRILL

0

E

WASHER

0

F

round holes is the provision of locating

pegs for piston rings of small twostroke engines. On large pistons using

wide rings, locating pegs can be in

the grooves ; but on small pistons such

pegs would take up too much space.

Consequently,. a fitting half in the

grooves, half m the lands is desirable.

Drilling can be performed as D, with

a strip wedged in the groove. The

hole may then be tapped not quite

through, the strip removed, and a

peg (of brass) screwed tightly in,

snipped off and filed flush.

Another example of such drilling

can be seen in ash trays made from

flat discs-of brass or aluminium.

If they are made in pairs, each with

the centre turned out, they can be

clamped face to face for the drilling,

which should be followed by reaming

if possible. When opened, a neat

effect is revealed? E.

The principle is applicable to small

handwheels or knobs for models,

when a close-fitting washer is placed

over for the drilling, F. Given reasonable care, the result again can be

very neat.

Ei

MODEL ENGINEER

Das könnte Ihnen auch gefallen

- IMP Workshop ManualDokument336 SeitenIMP Workshop Manualsyllavethyjim67% (3)

- 2880-Supporting & Steadying PDFDokument1 Seite2880-Supporting & Steadying PDFsyllavethyjimNoch keine Bewertungen

- 2890-Nuts & Spanners PDFDokument1 Seite2890-Nuts & Spanners PDFsyllavethyjimNoch keine Bewertungen

- 2881-Radii Functions and Checking PDFDokument1 Seite2881-Radii Functions and Checking PDFsyllavethyjimNoch keine Bewertungen

- 2888-Oblique Drilling PDFDokument1 Seite2888-Oblique Drilling PDFsyllavethyjimNoch keine Bewertungen

- 2885-Dent & Bulge Removal PDFDokument1 Seite2885-Dent & Bulge Removal PDFsyllavethyjimNoch keine Bewertungen

- 2886-Stud Fitting & Removal PDFDokument1 Seite2886-Stud Fitting & Removal PDFsyllavethyjimNoch keine Bewertungen

- Contours 1: Hile It CannotDokument1 SeiteContours 1: Hile It CannotsyllavethyjimNoch keine Bewertungen

- 2876-Belt Fasteners PDFDokument1 Seite2876-Belt Fasteners PDFsyllavethyjimNoch keine Bewertungen

- 2887-Broken Drills & Taps PDFDokument1 Seite2887-Broken Drills & Taps PDFsyllavethyjimNoch keine Bewertungen

- 2884-Panel Beating PDFDokument1 Seite2884-Panel Beating PDFsyllavethyjim100% (1)

- 2871-Circular Clips #1 PDFDokument1 Seite2871-Circular Clips #1 PDFsyllavethyjimNoch keine Bewertungen

- 2879-Clamping & Holding PDFDokument1 Seite2879-Clamping & Holding PDFsyllavethyjimNoch keine Bewertungen

- 2883-Metal Working PDFDokument1 Seite2883-Metal Working PDFsyllavethyjimNoch keine Bewertungen

- 2872-Circular Clips #2 PDFDokument1 Seite2872-Circular Clips #2 PDFsyllavethyjimNoch keine Bewertungen

- 2870-Simple Screw Assembly PDFDokument1 Seite2870-Simple Screw Assembly PDFsyllavethyjimNoch keine Bewertungen

- 2873-Cotters & Wedges PDFDokument1 Seite2873-Cotters & Wedges PDFsyllavethyjimNoch keine Bewertungen

- 2878-Chains & Sprockets PDFDokument1 Seite2878-Chains & Sprockets PDFsyllavethyjimNoch keine Bewertungen

- 2866-Hardening & Tempering PDFDokument1 Seite2866-Hardening & Tempering PDFsyllavethyjimNoch keine Bewertungen

- 2875-Belt Drives PDFDokument1 Seite2875-Belt Drives PDFsyllavethyjimNoch keine Bewertungen

- Roller Chains and Sprockets GuideDokument1 SeiteRoller Chains and Sprockets GuidesyllavethyjimNoch keine Bewertungen

- 2863-Valve Seating Tools PDFDokument1 Seite2863-Valve Seating Tools PDFsyllavethyjimNoch keine Bewertungen

- 2869-Fitting & Joining Pipes PDFDokument1 Seite2869-Fitting & Joining Pipes PDFsyllavethyjimNoch keine Bewertungen

- 2874-Fitting Core Plugs PDFDokument1 Seite2874-Fitting Core Plugs PDFsyllavethyjimNoch keine Bewertungen

- 2868-Glands & Pipe Fittings PDFDokument1 Seite2868-Glands & Pipe Fittings PDFsyllavethyjimNoch keine Bewertungen

- 2867 Case HardeningDokument1 Seite2867 Case HardeningEr Sukhwinder SinghNoch keine Bewertungen

- 2861-Wheel & Shaft PullersDokument1 Seite2861-Wheel & Shaft PullersSandra Barnett CrossanNoch keine Bewertungen

- 2864-Poppet Valves & Seating PDFDokument1 Seite2864-Poppet Valves & Seating PDFsyllavethyjimNoch keine Bewertungen

- 2865-Testing & Facing Valves PDFDokument1 Seite2865-Testing & Facing Valves PDFsyllavethyjimNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Group13 Task1 FinalDokument22 SeitenGroup13 Task1 FinalAfnan MazNoch keine Bewertungen

- Cleartrip Flight Domestic E-TicketDokument3 SeitenCleartrip Flight Domestic E-TicketMkm ZafarNoch keine Bewertungen

- IoT Globalstar Brochure PDFDokument16 SeitenIoT Globalstar Brochure PDFJosue OuattaraNoch keine Bewertungen

- Final Big BiteDokument10 SeitenFinal Big Biteapi-519944026Noch keine Bewertungen

- Tips To Improve Your Freestyle BreathingDokument6 SeitenTips To Improve Your Freestyle BreathingreacharunkNoch keine Bewertungen

- The Island of FeelingsDokument1 SeiteThe Island of FeelingsKimberley Sicat BautistaNoch keine Bewertungen

- LalaDokument6 SeitenLalaJulius BaguinangNoch keine Bewertungen

- Whirlpool Awo D 41100Dokument29 SeitenWhirlpool Awo D 41100Teodora OnciuNoch keine Bewertungen

- DUSH AND RUSH CAR DRIVINGDokument5 SeitenDUSH AND RUSH CAR DRIVINGUmer Asfandyar BalghariNoch keine Bewertungen

- Velo FaxDokument54 SeitenVelo FaxjuanNoch keine Bewertungen

- El Nido Resort Lagen Island InnovationDokument5 SeitenEl Nido Resort Lagen Island InnovationAlessandra Faye BoreroNoch keine Bewertungen

- What Is ISDN (Integrated Services Digital Network) ?: How It WorksDokument5 SeitenWhat Is ISDN (Integrated Services Digital Network) ?: How It Workssoqylio mcbarNoch keine Bewertungen

- StyleCAD V7 Marking ManualDokument162 SeitenStyleCAD V7 Marking ManualazadiNoch keine Bewertungen

- Week 11 - Script - Comparative AdjectivesDokument3 SeitenWeek 11 - Script - Comparative Adjectivesvaleria marmolejoNoch keine Bewertungen

- South Toms River Elementary Spring ConcertDokument4 SeitenSouth Toms River Elementary Spring ConcertChris BurbankNoch keine Bewertungen

- "Thought Bubble" - Anime Fanzine Issue 04 - December 2015Dokument30 Seiten"Thought Bubble" - Anime Fanzine Issue 04 - December 2015Thought Bubble100% (1)

- How To Start An Online StoreDokument6 SeitenHow To Start An Online StoreFikirte LegesseNoch keine Bewertungen

- Traveller Grammar Beginners KEYDokument6 SeitenTraveller Grammar Beginners KEYchuantilly100% (1)

- Eddie Higgins: Jazz Pianist and ComposerDokument4 SeitenEddie Higgins: Jazz Pianist and Composerjoao famaNoch keine Bewertungen

- Life Pre Int Unit 2 CompetitionsDokument12 SeitenLife Pre Int Unit 2 CompetitionsVioleta UrrutiaNoch keine Bewertungen

- Bill Statement: Previous Charges Amount (RM) Current Charges Amount (RM)Dokument11 SeitenBill Statement: Previous Charges Amount (RM) Current Charges Amount (RM)Vaishnavi ManoharanNoch keine Bewertungen

- PROPHECY: Book Club GuideDokument1 SeitePROPHECY: Book Club GuideEpicReadsNoch keine Bewertungen

- Escolta Street: Don Roman Santos BuildingDokument8 SeitenEscolta Street: Don Roman Santos BuildingHerilou SañezNoch keine Bewertungen

- Birdy Shelter Piano MusicDokument11 SeitenBirdy Shelter Piano MusicClare DawsonNoch keine Bewertungen

- Online Stocks User Guide IDokument22 SeitenOnline Stocks User Guide ITan Teck HweeNoch keine Bewertungen

- Mardi GrasDokument23 SeitenMardi Grasjayjay1122Noch keine Bewertungen

- Public Garden Automation ControlDokument3 SeitenPublic Garden Automation ControlSebastin Ashok100% (2)

- Monsoonsim Configuration: Ujian Akhir Semester Semester Genap Tahun Akademik 2021/2022Dokument5 SeitenMonsoonsim Configuration: Ujian Akhir Semester Semester Genap Tahun Akademik 2021/2022Cindy OktaviaNoch keine Bewertungen

- A Near-Optimal Strategy For A Heads-Up No-Limit TexasDokument8 SeitenA Near-Optimal Strategy For A Heads-Up No-Limit TexasMaria CordeliaNoch keine Bewertungen

- GM DietDokument10 SeitenGM DietexoticrumNoch keine Bewertungen