Beruflich Dokumente

Kultur Dokumente

Allowable Stress PDF

Hochgeladen von

sudokuOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Allowable Stress PDF

Hochgeladen von

sudokuCopyright:

Verfügbare Formate

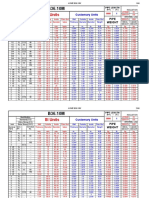

7/27/2016

AllowableStress

Show

Home>Results>ResultsEnvironment>ResultsMenu>LinearResultsMenu>BeamCodeChecking>Allowable

Stress

AllowableStress

X:Strongaxis

Y:Weakaxis

Z:Primaryaxis

Variable

Description

Rotationangleforprincipalaxesofanglesection

Crosssectionalarea

Af

Areaofcompressionflange.

As

Shearareafortubularmemberpipe

Asx

Xshearareaofprismaticmember

Asy

Yshearareaofprismaticmember

Widthofmember(bd)

b0

Distancefromneutralaxistoedgeofweb:

be

Effectivewidthofstructuraltubingmember

bf

Widthofflange.

Cb

Bendingcoefficientdependentuponmomentgradient(sectionF).

Cc

Columnslendernessratioseparatingelasticandinelasticbuckling(sectionE).

Cmx,

Cmx

Coefficientappliedtobendingtermininteractionequation(sectionH).

Depthofmember(db)

Modulusofelasticity

E0

Distanceoftheshearcenterfromcenterlineofwebforchannel:

E0=e0+tw/2

Fa

Maximumallowablecompressivestress

Fb

Maximumallowablebendingstress

Fbx

Maximumallowablestrongaxisbendingstress

Fby

Maximumallowableweakaxisbendingstress

Fex,Fey

Eulerstressforaprismaticmemberdividedbyfactorofsafety.

Ft

Maximumallowabletensilestress

Fy

Yieldstress

Maximumallowableshearstress

fa

Computedaxialstress(eithertensionorcompression,bothtakenaspositive)

fb

Computedbendingstress(takenasapositivequantity)

fbx

Computedstrongaxisbendingstress

fby

Computedweakaxisbendingstress

fx

ComputedshearstressinXdirection

fy

ComputedshearstressinYdirection

CleardistancebetweenflangesinIshapedmembers:

h=d2tf

http://download.autodesk.com/us/algor/userguides/mergedProjects/Results/results_environment/results/Nomenclature.htm

1/6

7/27/2016

AllowableStress

Ix,Iy

Momentsofinertiaaboutprincipalaxes

Iu,Iv

Momentsofinertiaaboutprincipalaxesofanglesectionmember

Effectivelengthfactorforprismaticmember

Distancebetweencrosssectionsbracedagainsttwistorlateraldisplacementofthecompressionflange.

Lb

Laterallyunsupportedlengthofthecompressionflange.

Lc

Maximumunbracedlengthofthecompressionflange.

LxLy

LinXandYdirections

M1,M2

Smallerandlargermomentatendofunbracedlength,respectively.

Axialforceload

Governingradiusofgyration

rT

Radiusofgyrationofasectioncomprisingthecompressionflangeplus1/3ofthecompressionwebarea,

takenaboutanaxisintheplaneoftheweb

rx,ry

Radiusofgyrationaboutprincipalaxes.

Thickness

tf

Thicknessofflange

U,V

Principalaxesofanglesectionmember

u,v

Distancesfromprincipalaxes

x,y

Offsetsofcentroidofanglesection

AllowableStresses:

Xisthestrongaxis,andYistheweakaxisforallIshapedandmembersandchannels.Teescanhaveeitheraxisastheir

strongaxis.

1.StrongAxisBendingStress

Membersloadedalongtheirweakaxis,Y(bentabouttheirstrongaxis,X).

ThismaximumallowablestrongaxisbendingstressisreferredtoasFbinthissection.

Twocategoriesareconsidered:

I.Ishapedmembers,teesandchannels

II.Pipesandstructuraltubing,includingsquareandrectangularductsandpipes

1.A.Memberswithcompactsections:

CategoryI.Ishapedmembers,teesandchannelsSectionF1.1

Includesteeswithcompactflanges.

TeesloadedalongthenXaxisarenotconsidered,inthiscodecheck.

Applicable to all Ishaped and members and channels, and tees with Ixx > Iyy. Tees with Ixx Iyy are not

consideredincodecheck.

Theallowablebendingstressis

Fb=0.66Fy

(F11)

withtheconstraintthatLbLc,whichisgivenbythesmallerof:

http://download.autodesk.com/us/algor/userguides/mergedProjects/Results/results_environment/results/Nomenclature.htm

2/6

7/27/2016

AllowableStress

(F12)

CategoryII.PipesandstructuraltubingSectionF3.1

Theallowablebendingstressis

Fb=0.66Fy

(F31)

subjecttothefollowingconditions:

Rectangularmemberscannothaveadepthgreaterthan6timesthewidth.

LbLc,whereLcisgivenby

(F32)

except,thatLcneednotbelessthan1200(b/Fy),M1isthesmallerandM2isthelargestbendingmomentsaboutthe

endsoftheunbracedlength,takenaboutthestrongaxis.

1.B.Memberswithnoncompactsections:

Must satisfy constraint, Lb Lc (F12) or (F32), including that rectangular members cannot have a depth

greaterthan6timesthewidth.

Includesteeswithnoncompactflanges.

TeesloadedalongtheXaxisarenotconsidered.

CategoryI.Ishapedmembers,teesandchannelsSectionF1.2

(F13)

CategoryII.PipesandstructuraltubingSectionF3.2

Fb=0.60Fy

(F33)

1.C.MemberswithcompactornoncompactsectionswithLb >Lc:

ThesectionisonlyapplicabletoCategoryI.Ishapedmembers,teesandchannels.

Ifmemberisintension,

Fb=0.60Fy

(F15)

Ifmemberisincompression,theallowablebendingstressisdeterminedasthelargervaluefromequations(F16)or

(F17)and(F18),withtheexceptions:

Onlyequation(F18)isusedforchannels.

Noneoftheseequationsapplytoteesincompression,thussuchteesarenotconsidered.

When

http://download.autodesk.com/us/algor/userguides/mergedProjects/Results/results_environment/results/Nomenclature.htm

3/6

7/27/2016

AllowableStress

(F16)

When

(F17)

ForanyvalueofL/rT :

(F18)

Cbisconservativelytakenasunity(1.0)inequations(F16),(F17)and(F18).

2.WeakAxisBendingStress

The section is only applicable to Category I. Ishaped members, tees, channels and solid bars (prismatic

members).

CategoryII.StructuraltubinginthiscategoryusesamevalueofFbfoundfortheirstrongaxisfortheirweakaxis.

A.Membersloadedalongtheirstrongaxis,X(bentabouttheirweakaxis,Y).

ThisweakallowablestrongaxisbendingstressisreferredtoasFby,yetinthissectionitislabeledasFb.

B.ApplicabletoallIshapedmembersallothersarenotconsidered.

2.A.Memberswithcompactsections:SectionF2.1

Fb=0.75Fy

(F21)

2.B.Memberswithnoncompactsections:SectionF2.2

(F23)

3.TensileStress

Ft=0.60Fy

SectionD1

http://download.autodesk.com/us/algor/userguides/mergedProjects/Results/results_environment/results/Nomenclature.htm

4/6

7/27/2016

AllowableStress

4.CompressiveStress

SectionE2

(E21)

whereKL/risthelargestofKLx/rxandKLy/ry,whichareequalforpipesandsquares,

and

(E22)

5.CombinedStress

ChapterH

5.A.Axialcompressionandbending:

Thefollowingrequirementsmustbesatisfiedformembersexperiencingbothaxialcompressionandbending:

(H11)

(H12)

Whenfa/Fa0.15,Equation(H13)isusedinlieuofEquations(H11)and(H12).

(H13)

Thecoefficients,alsoknownastheEulerstressdividedbysafetyfactor,FexandFeyaregivenbythefollowing:

http://download.autodesk.com/us/algor/userguides/mergedProjects/Results/results_environment/results/Nomenclature.htm

5/6

7/27/2016

AllowableStress

ThecoefficientsCmxandCmyhaveadefaultvalueof0.85.

5.B.Axialtensionandbending:

Thefollowingrequirementsmustbesatisfiedformembersexperiencingbothaxialtensionandbending:

(H21)

http://download.autodesk.com/us/algor/userguides/mergedProjects/Results/results_environment/results/Nomenclature.htm

6/6

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- 6-18-7 Flow Meters and Pressure InstrumentsDokument9 Seiten6-18-7 Flow Meters and Pressure InstrumentssudokuNoch keine Bewertungen

- 350 - Tray Installation Manual - EngDokument36 Seiten350 - Tray Installation Manual - EngRashid MadathilNoch keine Bewertungen

- Pressure Vessel Handbook Fourteenth Edition Eugene R MegyesyDokument1.014 SeitenPressure Vessel Handbook Fourteenth Edition Eugene R Megyesyluis sepulveda80% (10)

- Technical-specs-Heat ExchangersDokument96 SeitenTechnical-specs-Heat ExchangerssudokuNoch keine Bewertungen

- KettleDokument185 SeitenKettlesudokuNoch keine Bewertungen

- ASTM A388 Standard Practice For Ultrasonic Examination of Heavy Steel ForgingsDokument8 SeitenASTM A388 Standard Practice For Ultrasonic Examination of Heavy Steel ForgingsGonzalo TelleríaNoch keine Bewertungen

- 3-11-10 Pressure Vessels Carbon SteelDokument34 Seiten3-11-10 Pressure Vessels Carbon Steelsudoku100% (2)

- Standard Specification: UOP Engineering Department Date Status SPNSR ApvdDokument5 SeitenStandard Specification: UOP Engineering Department Date Status SPNSR ApvdsudokuNoch keine Bewertungen

- 6-14-9 Control ValvesDokument14 Seiten6-14-9 Control ValvessudokuNoch keine Bewertungen

- Structural Analysis and Design of Process EquipmentDokument360 SeitenStructural Analysis and Design of Process EquipmentSurya Tej88% (8)

- 15250-194-EN04-SP-005-Rev 0 (Specification For Atmospheric Storage Tank)Dokument22 Seiten15250-194-EN04-SP-005-Rev 0 (Specification For Atmospheric Storage Tank)sudokuNoch keine Bewertungen

- Basics 2016Dokument81 SeitenBasics 2016andy131078Noch keine Bewertungen

- Nozzle flange pressure calculationDokument2 SeitenNozzle flange pressure calculationsudokuNoch keine Bewertungen

- Astm A578 - 07 PDFDokument5 SeitenAstm A578 - 07 PDFMuhammad Maulana100% (1)

- Hot Insulation Specification GuideDokument55 SeitenHot Insulation Specification Guideapply19842371Noch keine Bewertungen

- E010 - Hydrotest Gland RingDokument5 SeitenE010 - Hydrotest Gland RingsudokuNoch keine Bewertungen

- NI-0253 - J Pressure Vessel DesignDokument45 SeitenNI-0253 - J Pressure Vessel DesignsudokuNoch keine Bewertungen

- E-001 - Hydrotest Device (Loose Ring) - OutDokument13 SeitenE-001 - Hydrotest Device (Loose Ring) - OutsudokuNoch keine Bewertungen

- Handbook of Mechanical Engineering TermsDokument366 SeitenHandbook of Mechanical Engineering Termsjakejohns95% (44)

- Tema 9Dokument300 SeitenTema 9sudokuNoch keine Bewertungen

- Training Manual For PVelite Basic LevelDokument41 SeitenTraining Manual For PVelite Basic LevelsudokuNoch keine Bewertungen

- PipeDokument44 SeitenPipesudokuNoch keine Bewertungen

- 2917 HXGN LIVE 2917 DelaforceDokument58 Seiten2917 HXGN LIVE 2917 DelaforceVitor OlivettiNoch keine Bewertungen

- Standard Stud Heavy Hex Nut Specs Peste 4 InchDokument1 SeiteStandard Stud Heavy Hex Nut Specs Peste 4 InchsudokuNoch keine Bewertungen

- B564Dokument11 SeitenB564razvandanutNoch keine Bewertungen

- Allowable Stress PDFDokument6 SeitenAllowable Stress PDFsudokuNoch keine Bewertungen

- Rayleigh Method Versus Eigenvalue MethodDokument6 SeitenRayleigh Method Versus Eigenvalue MethodCY Lee0% (1)

- Astm A194m 15 PDFDokument13 SeitenAstm A194m 15 PDFsudokuNoch keine Bewertungen

- Declaration g4 g7Dokument1 SeiteDeclaration g4 g7sudokuNoch keine Bewertungen

- Buckling Stress Check For A Vertical VesselDokument11 SeitenBuckling Stress Check For A Vertical Vesselmechengg01Noch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- STN Cat Novelties Vol.i 2023Dokument89 SeitenSTN Cat Novelties Vol.i 2023ruba herbawiNoch keine Bewertungen

- Mobiltech (Textile Used in Transportation, Automotive & Aerospace)Dokument12 SeitenMobiltech (Textile Used in Transportation, Automotive & Aerospace)cario galleryNoch keine Bewertungen

- Modeling of SO2 Scrubbing in Spray TowersDokument16 SeitenModeling of SO2 Scrubbing in Spray Towersrebelde96100% (1)

- 2014-6-2 PCED South Hill Coalition Proposed Elements MatrixDokument2 Seiten2014-6-2 PCED South Hill Coalition Proposed Elements MatrixSpokane City CouncilNoch keine Bewertungen

- Ea80 Series PDFDokument82 SeitenEa80 Series PDFAnca MunteanuNoch keine Bewertungen

- Wacker Neuson-Dpu - 25 KNDokument3 SeitenWacker Neuson-Dpu - 25 KNMilutin BožovićNoch keine Bewertungen

- Correlation Study and Regression Analysis of Water Quality Assessment of Nagpur City, IndiaDokument5 SeitenCorrelation Study and Regression Analysis of Water Quality Assessment of Nagpur City, IndiaShakeel AhmadNoch keine Bewertungen

- 2014 Solder Joint ReliabilityDokument18 Seiten2014 Solder Joint ReliabilitychoprahariNoch keine Bewertungen

- Lec 958975Dokument19 SeitenLec 958975Rajasekar PichaimuthuNoch keine Bewertungen

- Usn LM2500 Asme Paper GT2010-22811 61410 JalDokument7 SeitenUsn LM2500 Asme Paper GT2010-22811 61410 Jalferrerick0% (1)

- SDCK CD Ies 01 (Rev B)Dokument125 SeitenSDCK CD Ies 01 (Rev B)Narada HerathNoch keine Bewertungen

- 8 Ways To Achieve Efficient Combustion in Marine EnginesDokument10 Seiten8 Ways To Achieve Efficient Combustion in Marine EnginestomNoch keine Bewertungen

- 1855OME - Instruction Manual - Kinney Oil Mist EliminatorsDokument15 Seiten1855OME - Instruction Manual - Kinney Oil Mist EliminatorsahmedNoch keine Bewertungen

- Propeller DesignDokument74 SeitenPropeller DesignBambang Teguh Setiawan75% (4)

- Galvanize Galvanize Business Unit: Trust Us To GalvanizeDokument6 SeitenGalvanize Galvanize Business Unit: Trust Us To GalvanizeAdet WildanNoch keine Bewertungen

- Diffraction of Laser Beam Using Wire Mesh, Cross Wire and GratingDokument2 SeitenDiffraction of Laser Beam Using Wire Mesh, Cross Wire and GratingPriyesh PandeyNoch keine Bewertungen

- Adaptive ArchitectureDokument27 SeitenAdaptive ArchitectureSanjeev BumbNoch keine Bewertungen

- 2:4 Decoder: DECODER: A Slightly More Complex Decoder Would Be The N-To-2n Type Binary Decoders. These TypesDokument6 Seiten2:4 Decoder: DECODER: A Slightly More Complex Decoder Would Be The N-To-2n Type Binary Decoders. These TypesPavithraRamNoch keine Bewertungen

- Bilge Alarm Monitor OMD 11Dokument22 SeitenBilge Alarm Monitor OMD 11Lucian Iftemie100% (3)

- How rock layers are formedDokument3 SeitenHow rock layers are formedAlemar AllecerNoch keine Bewertungen

- List of Linkages2016Dokument74 SeitenList of Linkages2016engrwho0% (1)

- Luran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)Dokument3 SeitenLuran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)rosebifNoch keine Bewertungen

- Unit 6Dokument13 SeitenUnit 6VeronicaNoch keine Bewertungen

- Guess Questions of Aramco Written Examination For Hse Supervisor / Engineer / OfficerDokument31 SeitenGuess Questions of Aramco Written Examination For Hse Supervisor / Engineer / OfficerAlam Shamsher0% (1)

- 25kl SS Tank EstimateDokument1 Seite25kl SS Tank EstimateRaja ManiNoch keine Bewertungen

- Thinking ForthDokument311 SeitenThinking ForthCristianNoch keine Bewertungen

- Ornl 2465Dokument101 SeitenOrnl 2465jesusNoch keine Bewertungen

- Loading Equipment For Amsco Evolution™ Steam Sterilizers: ApplicationDokument4 SeitenLoading Equipment For Amsco Evolution™ Steam Sterilizers: ApplicationniNoch keine Bewertungen

- Conventional and Non-Conventional Energy Resources of India: Present and FutureDokument8 SeitenConventional and Non-Conventional Energy Resources of India: Present and FutureAnkit SharmaNoch keine Bewertungen

- SRSUNTOUR General Fork GlossaryDokument23 SeitenSRSUNTOUR General Fork GlossaryThomas JunkersfeldNoch keine Bewertungen