Beruflich Dokumente

Kultur Dokumente

AneweBook Chemicalengineeringplantdesignproject, Howto

Hochgeladen von

Soufiane MarhraouiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

AneweBook Chemicalengineeringplantdesignproject, Howto

Hochgeladen von

Soufiane MarhraouiCopyright:

Verfügbare Formate

Reflections on how to excel in doing a chemical plant design project

Reflections on how to excel in doing a chemical plant design project

Contents

Why this short book? ........................................................................................................................ 4

Chapter One ...................................................................................................................................... 5

The literature survey ......................................................................................................................... 5

Chapter Two ..................................................................................................................................... 9

Process and Raw Material Selection .................................................................................................. 9

Chapter Three ................................................................................................................................. 12

Material and Energy Balances ......................................................................................................... 12

Chapter Four ................................................................................................................................... 17

Equipment Sizing and Selection ....................................................................................................... 17

Chapter Five .................................................................................................................................... 19

Detail Design of Equipment ............................................................................................................. 19

Chapter Six ...................................................................................................................................... 21

Financial and Economic Analyses .................................................................................................... 21

Chapter Seven ................................................................................................................................. 24

Site Selection and Plant Layout ....................................................................................................... 24

Chapter Eight .................................................................................................................................. 25

Environmental Impact Analysis ....................................................................................................... 25

Chapter Nine ................................................................................................................................... 26

Writing the References.................................................................................................................... 26

Chapter Ten .................................................................................................................................... 27

2

Reflections on how to excel in doing a chemical plant design project

Presentation and Defense ............................................................................................................... 27

Appendices ..................................................................................................................................... 29

Writing and grammar..................................................................................................................................................... 29

Format of Project ............................................................................................................................................................ 30

Writing the Abstract ....................................................................................................................................................... 31

Work plan and habit ....................................................................................................................................................... 32

Planning Experiments ..................................................................................................................................................... 33

Project ideas ................................................................................................................................................................... 33

Searching the internet .................................................................................................................................................... 35

Reflections on how to excel in doing a chemical plant design project

Why this short book?

The main reason behind writing this short book is to share some vital insights I have developed over

the four years as a final project advisor, evaluator and lecturer. It is not intended to repeat what

you have been taught but to reflect on them. During the last three years I have advised at least

three projects a year in total 9 projects not to mention 10 projects I have co-advised. Also I have

evaluated at least nine projects for last three year. I have advised students from top five students to

bottom five students.

Final year project grade plays a key role in someones professional life may be much more than the

theme of the project itself. Plant design projects are unique in this way as they require sound

understanding of major courses like mass and energy balance, mass transfer concepts, economic

analysis etc. Excellent project grade shows very good understanding of the subject matter

and even more her problem solving ability and research potential.

Over the years, unlike other departments, project grades of the chemical engineering department

(BDU) have changed. They are not like 90-95% 'A'. I have seen them evolve to more like regular

course grades. Therefore, projects needs much more understanding and smart effort. This

short book gives proven ideas in each section of the project. Note that application of them leads to

much more success.

Each chapter ends with useful books, software tools and web pages that can assist you in doing your

projects. This avoids running around looking for data. Furthermore, various insights into each

4

Reflections on how to excel in doing a chemical plant design project

section of plant desing are presented. Putting the insights into action is the vital step. Enjoy

reading the rest of the chapters which give you ideas from project ideas, writing the introduction to

presentation and defence.

Chapter One

The literature survey

The literature survey is best written if it is designed to contain the atleast the following

information; history and background, problem statement, methodology and objectives. More contents

are listed on the format of a project`` section.

History and background: It reviews previous literature on related topics of the main research idea.

Note that you should write only relevant information. Dont fall in the trap of stating every trivial

but non impotant texts just because you like them or want to increase your thesis volume.

For a plant design project, the best contents are short description or introduction, chemical

formula, chemical and physical properties, application and uses, source of raw materials and the

current and future demand and prices. (Market study)

Market study is the crucial part of the literature survey as it later determines the proper size of the

plant and the selling price of the product. It contains present demand and supply, priccing and

distribution and projected demand. The later could be made based on the past and current price

trends if figures are availble. Also, it can be estimated from expected future scenarios (e.g economic

5

Reflections on how to excel in doing a chemical plant design project

growth, growth or reduction of a sector etc). If figures are available, the average growth percent or

the expected growth rate could be used. The estimate should be conservative. Always present a table

showing the 3-5 years of annual production or import of the product.

Below is a list of recommendations where useful information for the literature survey can be found.

Useful references

1.

Central statistics agency, CSA publications, Money and economy biro library, Bahir-dar,

hospital road.

2.

CSA website, http://www.csa.gov.et/Census.htm

Or http://www.csa.gov.et/

3.

Encyclopedias and Handbooks

4.

Ethiopian foregn trade statistics, Ethiopian customs authority, Megenagna, close to the office

of Bole Sub City, http://www.erca.gov.et/

Problem statement: This section develops the main motivation for the study explaining real life

problems to be dealt with. It is also called the rationale. In stating the problem it is best to

specifically describe what the project intends to solve. For example, the possible real life

problems may be shortage or even absence of the product in the local market, or to reduce the

foreign import or to introduce a new and innovative product.

specifically mention these reasons.

The problem statement should

Reflections on how to excel in doing a chemical plant design project

The justifications of the project, reasons for studying the problem, should also be included in this

section. For instance, the fact that Brewery industries in Amhara region mainly import malt while it

was possible to produce the barely in highlands of the region could justify the malt production

project.

This part is best written if specific numbers are mentioned. For instance, if reduction in foreign

import is the main problem, the average import in 3-5 years and its implications should be

mentioned. This will transform the problem statement part to evidence based argument than

a mere general problem.

Objectives: This is the most crucial part of the project. It is the first seen by project evaluators hence

leading to many critical questions. If the student came up with an the project idea, the best step is

to have the preliminary objectives and discuss with the advisor to come up with the final clear

objectives. In writing the objective part the best format is to divide them into general

objective and specific objectives and write at least three objectives in each category.

The general objective is derived from the statement of the problem. It restates how this project

solves the problems and the overall uses thereof. For instance, for plant design project, the general

objectives could be to satisfy local demand, reduce foreign import and save foreign currency,

introducing new product that has market potential, create jobs and contribute to economy etc.

Please note that writing bulleted one line statements as objectives is the worest way to

describe them. So always write an elaborated objectives to make it clear to even the project evaluator

who has little knowledge about your objectives.

Reflections on how to excel in doing a chemical plant design project

The specific objective should state what specific tasks are planned in the study. For

instance, the literature survey leads to identification of the state of the art in the production and

review of current researches related to the topic. These results are one specific objective.

Another specific objective could be derived from the mass balance, energy balance and sizing

chapters. This could be generalized as one specific objective i.e. to determine the exact size of the

plant that can balance supply and demand or at least reduce the shortage.

The market and demand study is another source of specific objectives. The outcome of this

study is to determine the demand of the product and the selling price that affect the financial success

of the plant. This could be generalized as one specific objective.

Financial and economic analysis gives a specific objective to determine the financial feasibility of the

process plant. The outcome of the environmental impact analysis section is summarized as one

specific objective.

Methodology

The methodolgy of

a project is details the principles, procedures or rules to be used. Plant design

procedures are usually clear. It starts with literature survey, market survey, design calculations,

may include laboratory experiments and ends with financial analysis and environmental impact

analysis. These processes should be elaborated in the project methodology section.

Reflections on how to excel in doing a chemical plant design project

Useful references

1.

Shafiur Rahman, 1995, Food properties handbook,1st ed, CRC press, Important for properties

of food and related items.

2.

Inroductory texts at FAO library http://www4.fao.org/faobib/

3.

Cheresources, Chemical engineerind resources , www.cheresources.com

4.

Perry et al, chemical engineers handbook, 8th ed, McGraw Hill, also available online

5.

400 project ideas discussion , https://sites.google.com/site/projectethio/

6.

Publication sites, get acess to them at , http://sites.google.com/site/ethiograd123/

Chapter Two

Process and Raw Material Selection

The state of the art and status of the research in the project idea is studied in the literature survey.

Competitive and possible production routes and raw materials are discussed in this chapter. This

section is written best when a well supported and balanced argument is presented in the selection

of process alternatives and raw materials.

The common mistake is to present more advantages for the process to be and discuss more

disadvantages of the other competitive ways. Most students reject alternative process entirely based

9

Reflections on how to excel in doing a chemical plant design project

on one or few reasons. The best way to compare alternative processes is to rate them on comparative

criteria. The main point to remember is that it is your ability to make reseonalble

arguments (as an engineer) that is being evaluated. It is not expected that you might make

wrong choices.

In some cases process selection could be obvious. The state of the art is the only process available. In

these cases, the alternative processes should be mentioned to comply with the plant design procedure.

These processes are predecessors of the current process and it is your jos to discrbibe how the process

evolved to it.

Raw material selection is done once the process is known in process selection. Some processes have

many alternative raw materials. Ethanol production and biodiesel are typical examples. From process

point of view, trans-esterification and estirification are possible pathways with the previous one

being the most common. If raw material sources are considered, numerous options could be sited. For

ethanol it could be cereals like corn or cheap alternatives like molases. In this case you can compare

the price per liter of the ethanol from the alternatives, potentital of raw material and price, process

technology and related utilities can be used to select the appropriate raw material. Therefore, each

alternative should be scrutinized to come up with convincing argument.

It is true that the selected process requires specific raw materials making it unnecessary or

challenging to try another. This step is only desired when it is possible to substitute one raw material

by another less cheap, more environmentally safe or available locally. But the basic requirement is

that it should give comparable process performance without substantial increase in process steps or

costs.

Common example is the methanol versus ethanol as a catalyst for bio diesel. It would seem

feasible to select ethanol because currently methanol is not widely availble. But this should be

10

Reflections on how to excel in doing a chemical plant design project

weighted with the cost of additional azeotropic distillation coloumn .

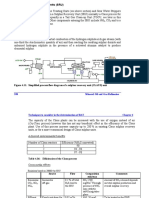

Finding flow sheets is challenging in most cases. The reference one below is the most common source

of flow sheet for common processes. Mostly it is not easy to find flowseets. Students should, however,

understand that once the process description is understood, flow sheets could be developed

from it.

The best way to prepare flow sheet is using CHEMCAD since actual unit diagrams are used

than simple boxes (prefered in the introduction section for briefe discription). Another disadvantage

with boxes is that they dont show auxiliary units leading to over simplifications. If you are

determiined to make a project sucessful, learning how to draw in CHEMCAD takes not more

than a day.

See reference 11 on flow sheet preparation and discription.

Useful references

1.

Shrives,1995, chemical process industries, McGraw Hill

2.

Encyclopedia of science and technology, 10th ed McGraw Hill

3.

Free resources at national academy of science, www.nasonline.org/ and issues

http://www.issues.org/

4.

Design thesis, collection of plant desing projects,

http://www.sbioinformatics.com/design_thesis/design-2520thesis.htm

5.

Cheresources plant design library http://www.cheresources.com/process_design.shtml

6.

Publication sites, get acess to them at , http://sites.google.com/site/ethiograd123/

11

Reflections on how to excel in doing a chemical plant design project

7.

Free publications of chresources, http://cheresources.tradepub.com/

8.

CHEMCAD, www.chemstations.com

9.

Or http://www.chemstations.com/Downloads/

10.

Guides on process and raw material selection, Klaus D. Timmerhaus Plant Design and

Economics for Chemical Engineers, Mcgraw Hill

11.

Stanely Waalas, Chemical process equipment selection and design, 2nd ed, Elsevier

Chapter Three

Material and Energy Balances

The market demand study and raw material availability studies give us the proper size of the

manufacturing plant. The size of the plant should balance the raw material availability and the

market demand. Based on this, the material and energy balances are done.

Using the information form demand study determine the capacity of the plant interms of total

annual production or total raw material requirement. This leads to the following ways of making

balances.

There are two approaches for performing material and energy balances; upstream and

downstream ways as known informally. In the upstream the balance is started from the last unit

in the process. Final product amount, quality, yield and equipement efficiency are mainly used to do

12

Reflections on how to excel in doing a chemical plant design project

the balance. In the downstream way, the initial raw material amount is determined to arrive at

desired production capacity. This could be possible if the overall yield of the process in tons of

product per tons of raw materials is known.

While writing material balance, the best format is to first present the overall or general material

balance and second the component balance. Show clearly the total flow rate and composition of the

known streams and represent the unkown stream with appropriate labels. At the end of each section

prepare summary tables with columns input, output and remark. In the remark write balanced, or

state the accumulated, generated or lost amount.

The common mistake students make is failing to mention the assumptions in the calculation and

yet worse not to show how the assumptions are justified. Therefore always mention the assumptions

at the beginning of the material and energy balance chapters with good justifications or references.

Balances for units with no change in mass like storage tanks are not done and it is acceptable.

Electrical energy required for running units are not usually included in the balances. This is partly

because their rating in only known in the sizing and at the end it is included in calculation of utility

costs as fraction of total costs.

Choose the reference temperature to be the ambient conditions for energy balances. Always study the

detail process steps before calculating the total energy requirement. Spray driers, kilns, coolers and

combustion devices are included in this catagory and are always challenging. The common mistake is

considering only sensible heat changes. The above units combine sensible, latent heat and

superheating. Besides the processes are of simultaneous mass and heat transfer.

13

Reflections on how to excel in doing a chemical plant design project

If you are dealing with mixtures in energy balance stream the overall physical properites like density,

specific heat capacity and so on may be not found in tables. In this case they should be calculated

based on the methods discussed in coluson and Richardson, chemical engineering, Vol 6.

Balances of size reduction machines

Crushers, grinders and milling machines need mass balances in principle. Ususally the dust loss and

the recycled coarse fraction are ignored. This is not accurate and the best way to do this balance is to

consider the grinder alone then balances for dust recovery cyclones (high efficiency or high

throughput). If the control volume include the dust recovery system, it is possible to neglect the dust

loss lost but still there is some loss. Wet grinding aviods the need for dust recovery systems. Since

water is added during the crushing process the material balance should include this amount.

Energy balance for this units determines the energy required for crushing( Bonds Law). But this is

not relevant from energy balance point of view and is needed if it is designed in detail. This is

because the energy required is usually calculated indirectly as utility cost. For more details see

references 1 and 3.

Balances on filters

The filteration objective, whether the cake or the liquid is the final product, determines the type of

filteration to be used and operating pressure. Overall balance on filtes requires the calculation of the

accululated cake amount. This calculation inturn requires prehand determination of the filter area,

cake properties and operating pressures. Further complexity arises when the rate of filterate flow

should be detemined for subsequent balances. This means the filter design and operation should be

known prehand.

14

Reflections on how to excel in doing a chemical plant design project

The best way to approach this problem is first to seek for general guides on operations of filteration

units. See reference 11, which contains design guides such as cake properties of some common

materails and performance data of filters. availble.

Balances on spray diers

In spray diers hot air at given humidity and temerpature absorbs mosture from wet substabce and at

the same time the heat is transfered. Hence both mass balance and energy balance equations should

be used. The heat transfered raised the temperature of the dry air and the moisture. One typical

problem is the final humidity of the exit air. It should be assumed to calculate the outlet air mass flow

and solve the energy balance equations. Therefore some iteration is required to arrive at final values.

For more details see refernce 7.

Balances on kilns

Cement kilns balances are complex. The feed materials contain surface water and inherent water.

The surface water undergoes sensible heat change and latent heat change at lower temperature. The

inherent water in clay for instance, is evaporated in the kiln zone where temperature around 600C.

Sensible heat change of every feed material shoud be considered. Besides separate balances of the

primary and secondary kiln air should be done. Reaction energy of clinker formation reactions should

be calculated. This calculation requires the knowledge of heat of formation of the kiln reactions at

standard temperature and then at the kiln temperature. There is alos considerable kiln gasses

released as loss.

15

Reflections on how to excel in doing a chemical plant design project

Useful references

1.

Nicolas et al,2003, Hand book of chemical engineering calculations, McGraw Hill

2.

Reynolds et al, 2002, Handbook of chemical and environmental engineering calculations,

3.

Mc Cabe, Unit operation of chemical engineering, 3rd ed, Mc Graw Hill

4.

Fundamentals of chemical engineering text book

5.

Seader et al, 2nd ed, Separation process principles, Willey

6.

Chrome balance in leather processing

http://www.4shared.com/document/2CzAlvHr/Chrome_balance_in_Leather_Proc.htm

7.

Spray drier balances, G V Barbosa et al, 1997, Food engineering lab manual,

8.

Mass balances in leather processing

http://preresi.ineti.pt/documentacao/guias/doc_tec/Curtumes/UNIDO/MassBalance

inLeatherProcessing.pdf

9.

Online steam tables and unit converters www.cheresources.com

Online steam tables calculator, http://www.dofmaster.com/steam.html

16

Reflections on how to excel in doing a chemical plant design project

Chapter Four

Equipment Sizing and Selection

Once accurate results of the material and energy flow are determined, sizing determines the volume

of storage tanks. The common mistake I have seen over the years is to size reactors and

distillation columns as a storage tank. For these units the mass and heat transfer inside leads to

different mass and energy balance and hence size.

Input flow rate and residence time are used to calculate the volumes of units involving no reaction or

accumulation. For reactors, the appropriate rate equation should be used to determine the volume of

the reactor. Common mistake is usually to assume first order kinetics. Reaction engineering

laboratory equipment such as batch reactors should be used to determine the order of the reaction.

The equipment sizes should not be unusually large. This is partly because of the selected capacity for

design. In this case using two or more identical units avoids the need for one very large volume.

Length to width ratios are used to determine the dimensions once the volume is known. Refernce 1

below is a good guide for sizing units as it gives standard dimensions and proper rules. The

common mistakes is sizing is to simply calculate the size without feeling the numbers,

for instance, a CSTR with 15m diameter.

Selection is done to determine the type of equipment to be used, for example, reactor types or heat

exchanger types. Unless a new process is developed, there is not much need for rigorous

17

Reflections on how to excel in doing a chemical plant design project

equipment selection with a scope of plant design projects. In real cases, the different manufacturers

with different specialty for one unit may exist. Only in this case thorough analysis of competitive

suppliers should be done.

Design of Mixers

It requires the parameters like specific gravity , solid content and settling velocity (Stokes law) and

the nature of mixing (uniform of off bottom). The blend tim, superficial velocity, power requirement

should be determined besides the detail geometery and orientation of the tank, baffles and impeller.

See reference 1 for complete discussion.

Useful references

1.

Stanley M Walas, 1990, chemical process equipment selection and design, 3rd ed

2.

J M Coulsen and Richardson, chemical engineering vol 6, 6th ed

3.

Chemical engineering resources, design software library

http://www.cheresources.com/invision/files/

4.

Comprehensive guide on spray diers design, http://www.spraydrysys.com/spraydryers/spray-dryers.htm

5.

Kern, process heat transfer, chapters 10 onwards, furnace and kiln design

18

Reflections on how to excel in doing a chemical plant design project

Chapter Five

Detail Design of Equipment

This chapter is always included in plant design projects to test the students' capability in detail

design of equipment. Sizing provides only simple details like size, length, width or volume. This

section selects one major unit and deals in detail about it starting from thermodynamics to

theoretical explanation on opertaion, proper dimensions and to selecting the material of construction.

Distillation columns designs for instance included detail mass and heat transfer equations,

determining the parameters like number of trays, column dimensions, tray spacing and so on. But

this is not the whole story, also included mechanical design (pressure vessel desing) of the distillation

column besides checking for entrainement and weeping. Please donot forget the heat exchanger

design of the condenser.

The heat loss assumption is one of the most challenging and controversial. Normally, energy

balances are made assuming no heat loss. Even the assumption of 10 percent loss of the input energy

can lead to misleading figures based the energy amount considered. Assuming there is loss of energy

is more accurate that the no loss assumption and should be used if proper guides on the loss

available. Always use justified or referenced assumptions on detail design.

If you do detail design very well, I assure you that you have multiple best outcomes. First, you

get most of the mark by the advisor. Second, you get high marks by the document evaluator in the

19

Reflections on how to excel in doing a chemical plant design project

content criteria. Third, you will get high marks while presenting and defending it. Fourth, you will

have unforgettable knowledge. Invest quite a good time in this part it pays off high.

The best way to end this chapter is to summarize the results in scaled drawing showing every

detail dimension and key results. Challenging designs include boiler design, filtration unit design,

kiln design, furnace design, and cooler design and spray dryer design. The following materials

are highly useful.

Useful references

1.

Stanley Walaas, chemical equipment sizing and design

2.

Process equipement design handbook,

http://www.4shared.com/document/ObRSRAHN/Process_Equipment_Design_Handb.htm

3.

Coulsen and Richardson, chemical engineering vol 1, 2 and 6

4.

Kern, process heat transfer, chapters 10 onwards, furnace and kiln design

5.

Detail design of sulfuric acid absorber desing,

http://www.sbioinformatics.com/design_thesis/Sulphuric_acid/Sulfuric-2520Acid_Design2520of-2520Equipments.pdf

6.

Distillation column design,

www.sbioinformatics.com/design_thesis/Ethylene_Glycol/Ethyleneglycol_Design-2520of2520Equipments.pdf

7.

Ammonia absorber design, www.sbioinformatics.com/design_thesis/Soda_ash/Soda2520ash_Design-2520of-2520Equipments.pdf

20

Reflections on how to excel in doing a chemical plant design project

Chapter Six

Financial and Economic Analyses

Using the specifications obtained in the sizing and detail design chapters, approximate costs of

equipments are obtained. Using the results from the material and energy balance sections, annual

raw material and utility cost could be determined. The most common mistake students make in

this chapter is to use the fraction of capital investment cost as raw material cost and process and

utility cost. The purpose of material and energy balances is to determine the annual raw material and

utility cost directly.

Steam cost is the less known though it is used largely in the industry. It is the price of energy used

to generate steam per ton of steam produced. It is dependent on the efficiency of the equipment.

Comparable prices could be obtained from similar plants and equipments. It is essential tool in

calculating the utility cost.

The selling price is always the controversial part in most cases. It is usually made higher if the

plant is found unprofitable and this happens at the last hour. This problem arises from many sources;

larger plant capacity, errors in balances leading to oversized and costly units or errors in sizing.

Always try to know the selling price before hand to help you determine the plant capacity. If the

selling price is cheap, going for larger size improves the feasibility.

Payback time, ROR, IRO and NPV/W are main methods used in financial analysis. A common

mistake is failing not to use NPV/W. The main point one should remember is NPV/W is the best

21

Reflections on how to excel in doing a chemical plant design project

method for evaluation of projects and it should be large and positive. In payback analysis it is

assumed that the plant will give revenue similar to first year revenue through 20yrs life time making

it obviously a poor method.

The useful life of plants is usually taken as 20-25yrs. This is the financial life time not the actual life

time. It is to mean the cash flow after 20-25yrs discounted to present time is worth

insignificant. Actually plants last longer than 25 years. Depreciation is usually calculated using

straight line method which is a handy method.

The average values of fractions should be used to calculate various costs. For instance, the raw

material cost may be 10-20% of the total capital investment. In this case, the average 15% should be

used. Do not fall in to assuming that since fewer raw materials are used, 10% should be

used.

The other most common mistake is to use costs directly from the internet. This is wrong for many

reasons. Firstly, the price stated may be out dated, second hand price or wrong totally. Usually

truseted suppliers dont provide costs directly on the web page. You have to ask for quotations.

Refence 1 is unque in such a way that it is mainky designed for equipement costs. You can opt for

various dimensions of the equipement to get the cost and they are very recent costs. Reference 4 is

also a good resource but values available for most equipements are old and Marshall and Swift cost

index must be used to get current costs.

What is the plant is not profitable? There many questions after this. Is the plant known to be non

profitable? If yes, you are more justified. If no you have done the following mistakes and here are

some tips. Is the selling price so cheap? If yes try alternative justified prices since you have to

change only small pages of the paper. Or show the minimum price required for profitability. Have

22

Reflections on how to excel in doing a chemical plant design project

you made silly mistakes in cost estimation? Check back and change only few pages of the project.

Have you made mistakes in material and energy balance?( Which affects the sizing, costing and

profitability) This type of problem is hard to solve. Sometimes, provisions are made so that you will

submit the corrected version after the presentation date. Hence discuss with the advisor. Have you

designed a small scale capacity plant ? If yes then you have to confess this in the paper and state how

going for large scale improves profitabilty.

Useful references

1.

www.matche.com , Updated equipement prices

2.

Complete financial analysis in excel, at, http://sites.google.com/site/ethiograd123/moges

3.

Guides economic anamysis , Klaus D. Timmerhaus Plant Design and Economics for

Chemical Engineers, Mcgraw Hill

4.

Equipement costs and cost index, D E Garette, 1989, Chemical engineering economics,

Springer

23

Reflections on how to excel in doing a chemical plant design project

Chapter Seven

Site Selection and Plant Layout

Site selection determines the location where the plant could operate profitably. Almost 85% of the

projects studied so far located their plant around Addis Ababa in my estimations. It may be right,

but the common mistake is choosing Addis Ababa without showing at least another

competitive town.

The best arguments in sitel selection are done using the data of sites raw material potential along

with near ness to the potential market. Remember it may be obvious to located the plant arround

Addis Ababa. BUT you have to show how justified the are criterea such as availabilty of labor,

infrastructure, the demand and supply market (in numbers) even for the selected location.

Plant layouts show the top view of the equipement positioning, offices and other accessories in the

industry. This is the test of you industry experience, if you havent any i advise you to use help. The

best way to do this section is also to prepare physical model out of paper. I challange you to do this if

you would like to have nice very good presentation and much better marks.

[1] Guides site selection, Klaus D. Timmerhaus Plant Design and Economics for Chemical

Engineers, Mcgraw Hill

24

Reflections on how to excel in doing a chemical plant design project

Chapter Eight

Environmental Impact Analysis

Environmental performance of the process is discussed in this section to prove that the process is safe

environmentally. Some advisors disagree on the naming. This is true environmental impact analysis

is a wide subject by itself. It is better renamed as environmental effects for the purpose of plant

design projects. Always express the detail environmental impacts of the product, raw

materials and waste streams both liquid and gaseous.

Make sure all the hazardous wastes are treated or recyled and even those released has negligible

impact. Use environmental protection agency (EPA) regulations and rules as a standard for the

evaluation of your project. EPA USA [1], hosts such information and the best way to end your

project is to use it well.

[1] http://www.epa.gov/lawsregs/topics/

25

Reflections on how to excel in doing a chemical plant design project

Chapter Nine

Writing the References

References state the sources of information implying credibility. Looking at the back of most of the

final year projects, one could notice that references are poorly mentioned. In a text of about 120

pages, the reference is not more than a page.

Another common mistake in referencing is not mentioning the sources inside the main text.

From my experience, this is done deliberately to hide plagiarism. Well turn on the light, we can see

you. You should always have time to read and reread the text and write it in your own words. It has

double advantages; avoiding the plagiarism and that the knowledge is yours.

The best ways to write your project is to mention the references inside the main text is one of the

two ways; giving references a number like, the yield of the process is 40%[1] and at the end write

[1] name of the reference in the proper format. The other way goes like this; the yield of the process is

40 %. (Name, year)

This is the format in writing the references; Authors, year, Title, publisher, city.

Always use the proper format for references. Mention the references in appropriate places in the text.

These are 100% the advice you need in writing the references.

Useful references

1.

Online bibliography maker, www.easybib.com

2.

Very good guide on how to write references, http://www.aresearchguide.com/12biblio.html

26

Reflections on how to excel in doing a chemical plant design project

Chapter Ten

Presentation and Defense

Chemical engineering department has a good name in having two presentations until the completion.

This gives a chance to shape the projects to much better outcome. Being aware of this fact is vital for

the students as 10-15% of its mark is decided on the progress presentation. The best advice is the

project should be done by reading very well so that you have understood it.

Dont copy paste related texts from everywhere. If this is not the case, you can defend your project.

This is 90% of the advice you need to score well in oral presentation. But it is not all. One

trick I have seen it work magic for me is to present to yourself at least once after you have

prepared the power point.

There are some helpful tools online you can download for free. The first is my screen recorder.

With a head phone and microphone, the software can make a video of your presentation with a voice.

You can replay this and listen to it so that correct you mistakes. The other magic trick is to

deliberately write sentences to say at the presentation and study them by heart. This is

nice because it can dramatically improve you score on the confident speaking and grammar. Because

of poor general English speaking ability, students find it hard to speak well constructed and

grammatically correct sentences. Deliberate writing of key sentences improves the grammar

and presentation. Important notice here is that do not write all you will say, that will make it clear

during the presentation that you are merely reading.

One silly mistake students make in power point presentation is to copy paste texts from project to

the power point. This will one make them loose mark in slide preparation, two, force them read it

adding to lose of mark in presentation skills. The key is to put key words that will remind you

what to say. Remember this is very useful if coupled with the idea of presenting for yourself before

27

Reflections on how to excel in doing a chemical plant design project

defense since you become very familiar with the key words.

Using key words in power point is useful for the literature survey, process description, and

environmental impact analysis. For presenting material and energy balances, here are few

ideas. Usually you can prepare series of boxes representing each unit and show balances there with

summary of calculations steps and results for each. This has advantages and disadvantages. The

clear presentation in this way gives you more marks but exposing some of the errors you have made

hence stealing you marks. Sometimes the latter makes you lose more marks.

Optionally also, summary of key material and energy balance results could be put on the process

flow sheet and the process description can be made with numbers from balance results. This makes it

less necessary to put so many boxes in the power point and focus the presentation to very important

parts like detail design. Another alternative is to show detail balance for selected major processes

like reaction or separation units and show summary of other in table. This can earn you points by

making the presentation focused and hence interesting.

One important advice is to prepare well and discuss the detail design part. This really earns you

more points as it makes the presentation very lively. But remember prepare well not to make

yourself vulnerable for many questions. You must be sure that you have done the detail design well.

Defense is answering questions raised by the judge and guests. The project evaluator raises the most

critical questions. Try your best to answer this question. This doesnt mean argue with him. Mostly

he/she has identified a weakness you havent seen. If this is obvious, accept it.

Dont argue one sided. Acknowledge the comment first and present your view. Arguing is preferred

if only you are so sure that you can answer it. Otherwise it is running against the persons ego

which will be defended at whatever cost. The best step whether you know the answer or not is

to first acknowledge the comment before defending it. You have already lost if you begin by

saying no!

28

Reflections on how to excel in doing a chemical plant design project

Appendices

Writing and grammar

Final projects must be well organized and written with very good grammar. Almost every student

struggles with grammar and composition. It is always easy to identify when paragraphs are copy

paste because uneven writing and grammar skill throughout.

The best solution is first to edit before the advisor reads it. Secondly, use several online grammar

editors and software tools. It is not up to the advisor to correct grammars for you.

These are tools you can use;

1.

Whitesmoke: www.shitesmoke.com this is one my favorite software. It gives suggestions on

grammar, spelling, style, vocabulary suggestions and enrichment. You can download for 9

days trials hence use it to edit the final text. It requires internet connection to do the tasks. It

integrates with word putting the corrections in the main text. No need for you to copy the

text or corrections. Just press F2 inside any text and press apply and then the software copies

the corrections in the main text.

2.

Style writer: www.stylewriter-usa.com this software is more focused on style of your writing.

It is very powerful tool. You can use this software for 10 runs only. Hence, you can run this

software more than enough for your progress and final report since the runs are counted

when you close the software. You need to copy paste the main text and the corrections.

3.

Grammar expert: www.wintertree-software.com/app/gramxp/index.html this is also

good software with 30 days trial. But it can work even after 30 days, only you have to wait

29

Reflections on how to excel in doing a chemical plant design project

10sec between each run. You need to copy paste the text and the corrections.

4.

Online grammar checker. www.spellchecker.net/grammar/ copy paste the main text and

click on check to use this online tool. It is handy if you use it daily checking small texts.

Format of Project

Plant design projects have the following format.

Chapter one: Literature survey

History and backgrounds

Short process description

Demand study

1.

Current and future prices

2.

Prices and distributions

Objectives

Methodology

Chapter two: Processes and raw material selection

Detailed process description

30

Reflections on how to excel in doing a chemical plant design project

Chapter three: Material and energy balance

Chapter four: Detail design of equipment

Chapter five: Financial analysis

Chapter six: Environmental analysis

Chapter seven: Site selection and plant layout

References

Writing the Abstract

The abstract summarizes what has been done in the study. The format of the thesis is IMRAD. The

letter I stand for introduction, M is for materials and methods and RAD is for results and

discussion. Therefore, writing the abstract should follow this format. The first part should

summarize the introduction and then the method is expressed. The result summarizes key results of

the study. The discussion part tells the interpretations of the result.

More on http://www.unc.edu/depts/wcweb/handouts/abstracts.html

31

Reflections on how to excel in doing a chemical plant design project

Work plan and habit

For successful completion of plant design project four months effort is required. The real question is

not time management, it is energy management. It is choosing what to focus on.

Time plan depends on the nature of the project. The usual plan is to give one month for literature

survey, process and raw material selection and process description. Give two and half months for

material and energy balance and sizing and detail design. The rest 15days is used for financial

analysis.

This is a tight schedule because it is interrupted by exams and time is lost in waiting for advisor

comments or making the corrections. No time is available to correct mistakes and rework the

financial analysis making students fall in to the trap of manipulating the financial part.

The best schedule in my view is to give a maximum of two weeks for everything before the

balances. While waiting for comments, start reading and collecting data for balances. Give one

month for the balances and have comments from advisor. While waiting for comments read a lot

about the detail design. Once you make the correction give about a month for detail design including

comments. Give only two weeks in the extreme case for financial analysis and have time for grammar

editing at the rest of the time. If experiments are planned, always the best projects do, plan the

night time for it. You have to work in balances and experiments at the same time.

The work habit in plant design projects that leads to best result is work every day. Here is one trick

for avoiding procrastination. Work only for ten minutes on the important task every day.

You will find it impossible to stop after the end of ten minutes.

Dont count on the internet as best source of data. It is intended for advertising most of the

time not as a genuine source of data. Realizing this saves you a lot of time otherwise wasted for

32

Reflections on how to excel in doing a chemical plant design project

nothing. At least ask for advice on the search and specific websites before Googling directly.

Planning Experiments

It is always best if projects include demonstration experiment. You can give the night time for

making experiments. But make sure that accuracy will not be harmed.

Here are some advices for making plans.

1.

Give enough time for collection relevant chemical and equipments to be used. Without these

dont start it.

2.

Know the procedures well first at least by making trial experiment to know sources of error.

3.

Consult with your advisor so that he is aware of the procedures and invite him to see

crucial step results, not the final result. This contributes a lot to openness of your work and

the trust of the advisor.

4.

Consult other lecturers you know has research experiences for valuable insights on setup

and execution of experiments.

Project ideas

Using internship experiences to come up with a project idea is the best way.

The next best step is to contact local institutes like Amhara investment office, Tiret, GTZ and

Minstry of mines and energy in Bahirdar or similar offices where ever near and Ethiopian science

33

Reflections on how to excel in doing a chemical plant design project

and technology commission for patents. The unique advantage of doing such a search is usually you

will find real life problems whose accomplishment presents very good opportunities.

The other ways is to use the publication and professional websites in related fields. The following

sites are useful.

1.

Ethiograd123, http://sites.google.com/site/ethiograd123/ project ideas in chemical and energy

engineering. Graduate and undergraduate project library and access to publications (most of

them accessed on Bahir-dar University server )

2.

Project ethio, https://sites.google.com/site/projectethio/ collection 400 project ideas in every

major sector in Ethiopia.

3.

This site is my favorite. www.cheresources.com is the best site in my view in the fields of

chemical engineering.

4.

Chemical engineering societies have numerous discussion topics, newsletters and journals

you can follow to get ideas. For instance, Ethiopian society of chemical engineers, ESCHE,

www.esche.org.et/

5.

American institute of chemical engineers, www.aiche.org/

Visit websites of excellent universities in the related field and see their research activities.

Usually, their research is top level, but reading I could spark ideas.

6.

The following sites, free patents online, www.freepatentsonline.com

science, www.nasonline.org/

national academy of

are useful. The later has interesting reports and reviews.

Follow publications and take time to read and understand them to come up with a project idea.

Knowing the hot topic at the time through reading a lot leads you to best project title. Also discuss

with instructors to get suggestions which can be developed to projects or share your ideas.

34

Reflections on how to excel in doing a chemical plant design project

Searching the internet

One of the major difficulties searching the internt for infomation about projects. The initial

assumption that there is everything on the internet is wrong. There is not everything about your

projects on the internet. However; this doesnt mean to underestimate the power of the internet. It

can help you a lot if you know how to search it.

Here is short guide for internet searching,

1. Use nouns as query keywords. Never use articles ("a," "the"), pronouns ("he," "it"),

conjunctions ("and," "or") or prepositions ("to," "from") in your queries

2. Use 6 to 8 keywords per query

3. Where possible, combine keywords into phrases by using quotation marks, as in "solar

system"

4. Spell carefully, and consider alternate spellings

5. Avoid redundant terms

6. Insert a plus or minus sign: Put a plus sign (+) in front of a word that must be found in the

search window. For example, city guides + New York will help you narrow the search for

city guides for New York only.

More http://www.virtualsalt.com/howlook.htm

35

Das könnte Ihnen auch gefallen

- A New Ebook - Chemical Engineering Plant Design Project, How ToDokument37 SeitenA New Ebook - Chemical Engineering Plant Design Project, How ToMoges Ashagrie100% (6)

- SampleDokument14 SeitenSampleNamratha NamrathaNoch keine Bewertungen

- Nasty Gal Case Paper Evaluation HD - High Distinction 80%+ For Student ReferenceDokument133 SeitenNasty Gal Case Paper Evaluation HD - High Distinction 80%+ For Student ReferenceJe Bobo100% (1)

- Report EditedDokument25 SeitenReport EditedSaswati TalukdarNoch keine Bewertungen

- Chemical Projects Scale Up: How to go from Laboratory to CommercialVon EverandChemical Projects Scale Up: How to go from Laboratory to CommercialNoch keine Bewertungen

- Đi inDokument41 SeitenĐi inLê Đình HuânNoch keine Bewertungen

- Basic Thesis TitleDokument6 SeitenBasic Thesis Titlefjoxrygig100% (2)

- Zhengyi, Wang Yijie, Shen Qile of New OrientalDokument18 SeitenZhengyi, Wang Yijie, Shen Qile of New Oriental刘佳煊Noch keine Bewertungen

- Creating A Research Paper Word Chapter 2Dokument8 SeitenCreating A Research Paper Word Chapter 2wihefik1t0j3100% (1)

- Practical Improvement Planning For FactoriesDokument158 SeitenPractical Improvement Planning For FactoriesIrani MohsenNoch keine Bewertungen

- Dissertation g123411v1Dokument52 SeitenDissertation g123411v1Paridhi LapalikarNoch keine Bewertungen

- Project Dissertation LayoutDokument5 SeitenProject Dissertation LayoutWriteMyPaperCoUK100% (1)

- Engineering and Construction Dissertation Conclusions and RecommendationsDokument7 SeitenEngineering and Construction Dissertation Conclusions and Recommendationschip JamesNoch keine Bewertungen

- Example of A Literature Review TableDokument6 SeitenExample of A Literature Review Tableafdtnybjp100% (1)

- Customer Sentiment Analysis for Business InsightsDokument43 SeitenCustomer Sentiment Analysis for Business InsightsParidhi LapalikarNoch keine Bewertungen

- Aksum University College of Business and Economics Department of Logistics and Supply Chain ManagementDokument9 SeitenAksum University College of Business and Economics Department of Logistics and Supply Chain ManagementbezawitwubshetNoch keine Bewertungen

- Thesis Topics Operations ManagementDokument4 SeitenThesis Topics Operations Managementtiffanysandovalfairfield100% (2)

- How To Write Chapter 4 of Research PaperDokument6 SeitenHow To Write Chapter 4 of Research Paperclwdcbqlg100% (1)

- Proposal Guideliness 2024Dokument6 SeitenProposal Guideliness 2024ndirajeffaNoch keine Bewertungen

- Business Project Plan For A Startup Business 2Dokument73 SeitenBusiness Project Plan For A Startup Business 2alikahdNoch keine Bewertungen

- How to Scale-Up a Wet Granulation End Point ScientificallyVon EverandHow to Scale-Up a Wet Granulation End Point ScientificallyBewertung: 4 von 5 Sternen4/5 (1)

- Role of Capital Budgeting in Project ManagementDokument8 SeitenRole of Capital Budgeting in Project Managementmubarik awolNoch keine Bewertungen

- Project Work GuidelinesDokument10 SeitenProject Work Guidelinesee23258Noch keine Bewertungen

- Fundamental Analysis Research PaperDokument5 SeitenFundamental Analysis Research Paperhkdxiutlg100% (1)

- Summer Project Work GuidelinesDokument24 SeitenSummer Project Work GuidelinesSharmila SithanandhanNoch keine Bewertungen

- Example of Chapter 1 in Research Paper PDFDokument5 SeitenExample of Chapter 1 in Research Paper PDFafeedvnlb100% (1)

- Chapter 4 Thesis Sample PDFDokument4 SeitenChapter 4 Thesis Sample PDFjenwilliamsneworleans100% (2)

- Economics Research Paper Topics IndiaDokument6 SeitenEconomics Research Paper Topics Indiakifmgbikf100% (1)

- 1 Guidelines 3Dokument11 Seiten1 Guidelines 3MemoNoch keine Bewertungen

- Chapter 7 Writing A Feasibility Study (Business Plan 2)Dokument60 SeitenChapter 7 Writing A Feasibility Study (Business Plan 2)Colin KmNoch keine Bewertungen

- Project Guidelines MRPDokument14 SeitenProject Guidelines MRPAnik KararNoch keine Bewertungen

- Online Instructor's Manual: To AccompanyDokument6 SeitenOnline Instructor's Manual: To AccompanyMamdouh MohamedNoch keine Bewertungen

- Online Resources for Supply Chain Management TextbookDokument6 SeitenOnline Resources for Supply Chain Management TextbookRODRIGO FERNANDEZ ALVAREZ0% (2)

- Business Plan Dissertation ExampleDokument8 SeitenBusiness Plan Dissertation ExampleCanYouWriteMyPaperNorman100% (1)

- ASSESSMENT OF PRODUCT COSTING - Copy-1Dokument53 SeitenASSESSMENT OF PRODUCT COSTING - Copy-1Gadisa Gudina100% (2)

- Thesis Topics On Building ConstructionDokument4 SeitenThesis Topics On Building Constructionalyssaschultecolumbia100% (2)

- Research Paper Topics in EconometricsDokument6 SeitenResearch Paper Topics in Econometricsafeemfrve100% (1)

- What Is Literature Review in Final Year ProjectDokument4 SeitenWhat Is Literature Review in Final Year Projectafdtftloi100% (1)

- Managing New Product and Process Development: Text CasesVon EverandManaging New Product and Process Development: Text CasesBewertung: 3 von 5 Sternen3/5 (1)

- How To Write Feasibility Studies: What Is A Feasibility Study?Dokument5 SeitenHow To Write Feasibility Studies: What Is A Feasibility Study?Dynalie Bago - DingdingNoch keine Bewertungen

- Extended Project Dissertation IdeasDokument5 SeitenExtended Project Dissertation IdeasSomeToWriteMyPaperAnnArbor100% (1)

- Term Paper Final ProjectDokument7 SeitenTerm Paper Final Projectdajemevefaz2100% (1)

- Thesis Title IdeasDokument5 SeitenThesis Title Ideasmichellealexanderminneapolis100% (2)

- Chapter 3 Sample Research PaperDokument5 SeitenChapter 3 Sample Research Papercaq5kzrg100% (1)

- Business Case Methodology Template: Division of The State Chief Information OfficerDokument35 SeitenBusiness Case Methodology Template: Division of The State Chief Information OfficerVenkat Chowdary Yamparala100% (1)

- Research Paper On Industry AnalysisDokument4 SeitenResearch Paper On Industry Analysisogisxnbnd100% (1)

- Oil Literature ReviewDokument5 SeitenOil Literature Reviewea844bbv100% (1)

- MSC Dissertation Proposal StructureDokument4 SeitenMSC Dissertation Proposal StructureCustomPaperWritingServicesPittsburgh100% (1)

- Product ThesisDokument6 SeitenProduct ThesisPaperWriterCanada100% (2)

- Potential Economic Dissertation TopicsDokument8 SeitenPotential Economic Dissertation TopicsCustomNotePaperSingapore100% (1)

- Dissertation For II Year M .Com StudentsDokument12 SeitenDissertation For II Year M .Com Studentsnischal mathewNoch keine Bewertungen

- Bachelor Thesis Search EngineDokument8 SeitenBachelor Thesis Search Enginekvpyqegld100% (2)

- Literature Review On RentDokument4 SeitenLiterature Review On Rentea5vpya3100% (1)

- Extended Project Dissertation TitlesDokument4 SeitenExtended Project Dissertation TitlesPaperWritingServiceSuperiorpapersSpringfield100% (1)

- BHO2259 Assessment Guide SummaryDokument11 SeitenBHO2259 Assessment Guide SummaryGarima MishraNoch keine Bewertungen

- Dwnload Full Business and Its Environment 7th Edition Baron Solutions Manual PDFDokument12 SeitenDwnload Full Business and Its Environment 7th Edition Baron Solutions Manual PDFgaskampaliahuk1783100% (15)

- Research Papers On Production Engineering PDFDokument7 SeitenResearch Papers On Production Engineering PDFafedthktn100% (1)

- Essay Help ServiceDokument5 SeitenEssay Help Serviceafabifazv100% (2)

- Hydrocyclones For Particle Size SeparationDokument7 SeitenHydrocyclones For Particle Size SeparationJean DejardinNoch keine Bewertungen

- Filtering Hydrocyclone Performance AnalysisDokument10 SeitenFiltering Hydrocyclone Performance AnalysisBenjamin Cortés ENoch keine Bewertungen

- Water Managemen in MoroccoDokument2 SeitenWater Managemen in MoroccoSoufiane MarhraouiNoch keine Bewertungen

- Lobp Cis Fuels and Lubricants Conference 2013 1Dokument13 SeitenLobp Cis Fuels and Lubricants Conference 2013 1Soufiane MarhraouiNoch keine Bewertungen

- Reviews E.: Comxerc Al Organc Axalysis, Vol. in BoDokument2 SeitenReviews E.: Comxerc Al Organc Axalysis, Vol. in BoSoufiane MarhraouiNoch keine Bewertungen

- Aardolie Engasraffinaderijen 4.23.5.2sulphurrecoveryunitssruDokument9 SeitenAardolie Engasraffinaderijen 4.23.5.2sulphurrecoveryunitssruSoufiane MarhraouiNoch keine Bewertungen

- Aardolie Engasraffinaderijen 4.23.5.2sulphurrecoveryunitssruDokument9 SeitenAardolie Engasraffinaderijen 4.23.5.2sulphurrecoveryunitssruSoufiane MarhraouiNoch keine Bewertungen

- Loss Prevention in Chemical PlantsDokument51 SeitenLoss Prevention in Chemical PlantsAnonymous yfGM1rkpWT100% (3)

- DRUM PUMP 50 HZ CATALOGUE PDFDokument17 SeitenDRUM PUMP 50 HZ CATALOGUE PDFjpsingh75Noch keine Bewertungen

- Company Profile PT Guna Teguh AbadiDokument23 SeitenCompany Profile PT Guna Teguh AbadialfiansputraNoch keine Bewertungen

- Cost - Estimation Chem PlantDokument39 SeitenCost - Estimation Chem PlantriffNoch keine Bewertungen

- Flare Pilot DesignDokument17 SeitenFlare Pilot DesignJamesbond3215100% (4)

- FOAM TRAILER BrochureDokument3 SeitenFOAM TRAILER BrochureTommaso ZerneriNoch keine Bewertungen

- Fundamentals of Chemical EngineeringDokument164 SeitenFundamentals of Chemical EngineeringAsif Hameed100% (1)

- Ultra Safe EXPDokument7 SeitenUltra Safe EXPAnonymous dqbb02DUhNoch keine Bewertungen

- Comparison of Methods of Hazard DOW ICI MONDDokument6 SeitenComparison of Methods of Hazard DOW ICI MONDnertNoch keine Bewertungen

- Is.15656.2006 - Hazard Identification and Risk AssessmentDokument31 SeitenIs.15656.2006 - Hazard Identification and Risk Assessmentjitesh26100% (3)

- Chapter Two Design of The Operations/production Systems 2.1. Product-Service Design and DevelopmentDokument46 SeitenChapter Two Design of The Operations/production Systems 2.1. Product-Service Design and DevelopmentThomasGetyeNoch keine Bewertungen

- Sinopec Engineering PresentationDokument83 SeitenSinopec Engineering Presentationstavros7Noch keine Bewertungen

- Batch Organic Chemical Synthesis and Unit Operations (39Dokument16 SeitenBatch Organic Chemical Synthesis and Unit Operations (39Soledad Colmenarez50% (2)

- PS Valve ServiceDokument40 SeitenPS Valve ServiceamojodiNoch keine Bewertungen

- New Generation FastenersDokument20 SeitenNew Generation FastenerscirclelineNoch keine Bewertungen

- ABHR SeptOct - 58-71Dokument14 SeitenABHR SeptOct - 58-71ssuthaaNoch keine Bewertungen

- INDEX: Contents of The ReportDokument34 SeitenINDEX: Contents of The Reportrahul rayNoch keine Bewertungen

- Spe 81 - 002 - 2016Dokument6 SeitenSpe 81 - 002 - 2016Dharmendra Jadeja100% (1)

- GAS Safety: Information BulletinDokument5 SeitenGAS Safety: Information BulletinTeguh SetionoNoch keine Bewertungen

- The Bhopal DisasterDokument9 SeitenThe Bhopal Disaster123kunaveNoch keine Bewertungen

- AES Comp ProfileDokument29 SeitenAES Comp Profileparvesh_awasthyNoch keine Bewertungen

- AijazDokument3 SeitenAijazRobinReddyNoch keine Bewertungen

- Safety Question BankDokument13 SeitenSafety Question BankTABREJNoch keine Bewertungen

- Problem Pumps: A Thing of The Past: OperatingDokument9 SeitenProblem Pumps: A Thing of The Past: Operatingkpostulart100% (1)

- ResumeDokument10 SeitenResumePankhuri KeshriNoch keine Bewertungen

- 48 Shilling FDokument6 Seiten48 Shilling Fkumar_chemicalNoch keine Bewertungen

- Oim DbsaDokument38 SeitenOim DbsaHendi HendriansyahNoch keine Bewertungen

- Plant Cost EstimationDokument27 SeitenPlant Cost Estimationfildaagumps0% (1)

- Bopp & ReutherDokument44 SeitenBopp & Reutherviveros_caos100% (1)